The igniter (ignition control module) is the ignition system component that activates the ignition coil on your 1996-1997 1.6L Toyota Corolla.

When the igniter fails, the ignition coil won't spark and the engine is not gonna start. The cool thing is that it can be easily tested to find out if it's good or bad.

In this tutorial, I'll walk you through my method of testing the igniter. By following my step-by-step instructions, you'll easily find out whether the igniter is functioning properly or not.

Contents of this tutorial:

- Symptoms Of A Bad Igniter.

- Igniter Circuit Descriptions.

- Basic Operation Theory Of The Igniter.

- Where To Buy The Igniter.

- TEST 1: Making Sure The Igniter Is Getting Power.

- TEST 2: Making Sure The Igniter Is Getting Ground.

- TEST 3: Testing The Igniter Control Signal.

- TEST 4: Testing The Ignition Coil Activation Signal.

- More 1.6L Toyota Corolla Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 1.6L (4A-FE) Toyota Corolla: 1996, 1997.

IMPORTANT: Before testing the igniter, check the ignition coil for spark first.

If even one spark plug wire is firing spark, the igniter is working properly and there's no need to test it. If you haven't already check for spark, do so first:

Ignition System Wiring Diagrams:

Distributor Pickup Coil And CKP Sensor Tests:

- How To Test The Distributor Pickup Coil (1996-1997 1.6L Toyota Corolla).

- How To Test The CKP Sensor (1996-1997 1.6L Toyota Corolla).

Engine No-Start Diagnostics:

Other Igniter Test Tutorials:

- How To Test The Igniter (1989-1992 1.6L Toyota Corolla).

- How To Test The Igniter (1993-1995 1.6L Toyota Corolla).

Symptoms Of A Bad Igniter

The igniter (or ignition control module) plays a big role in getting your engine started and keeping it running. It teams up with the fuel injection computer to:

- Activate the ignition coil so it sparks.

- Manage ignition timing by controlling when and how long the ignition coil sparks.

- Send spark event feedback to the fuel injection computer, letting it know the engine's cranking or running, which then powers up the fuel pump and injectors.

If the igniter goes bad, the ignition coil won't fire, meaning no spark reaches the spark plugs. On top of that, the fuel pump and injectors won't turn on, leaving the engine without spark and fuel —so it won't start.

Igniter Circuit Descriptions

The igniter is located on the driver-side strut tower, next to the diagnostic link connector (DLC). In the image viewer above, look at image 2 of 2 —the orange arrow points to the igniter's location.

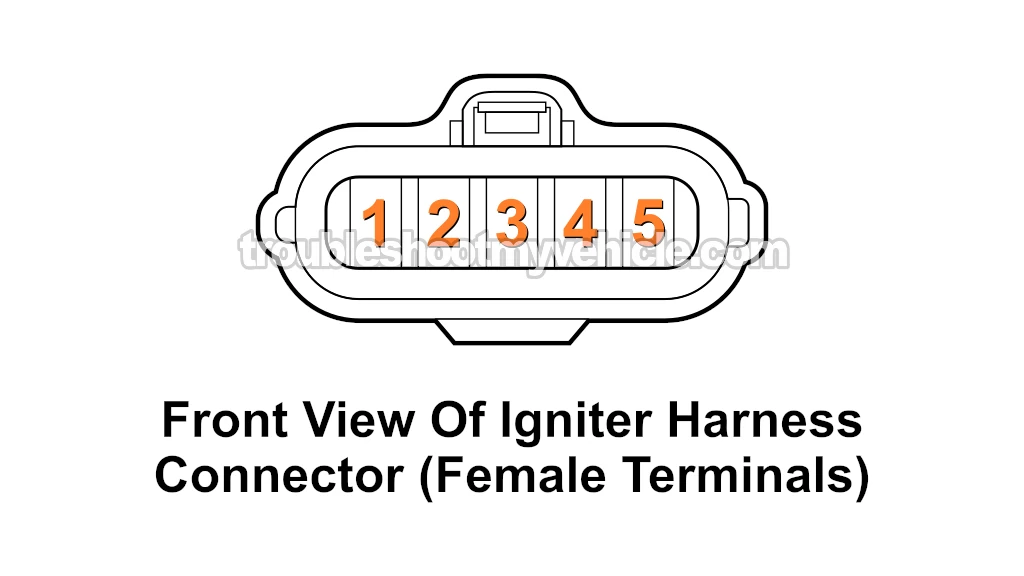

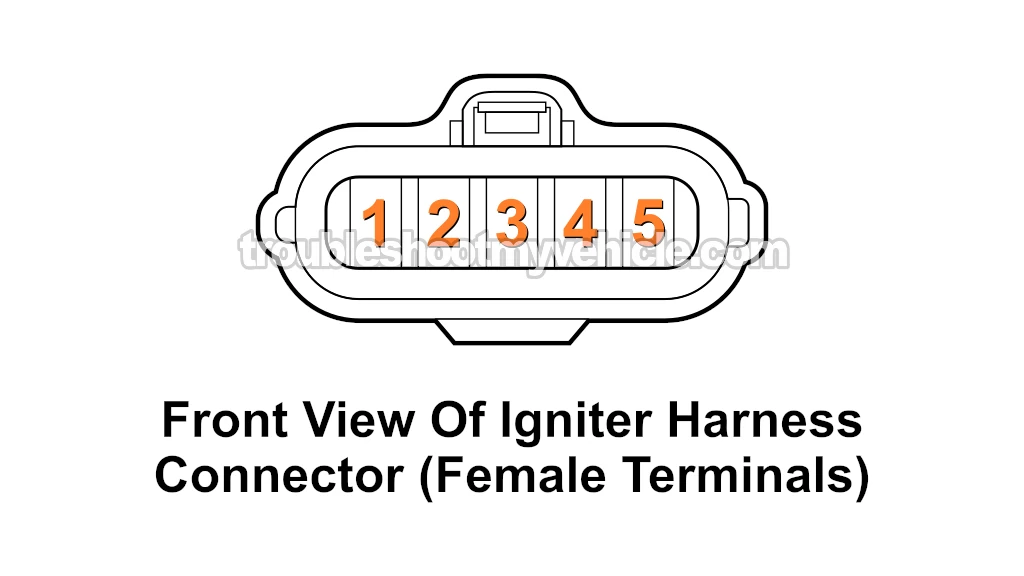

Your igniter (ignition control module) has five wires in its connector, and each one has a specific role. Here's a quick breakdown:

| Pin | Wire Color | Description |

|---|---|---|

| 1 | Blue with yellow stripe (BLU/YEL) | IGF → Ignition coil firing feedback |

| 2 | Yellow with green stripe (YEL/GRN) | IGT → Igniter control signal |

| 3 | Black (BLK) | +B → Battery power |

| 4 | Black (BLK) | IG- → Tachometer signal |

| 5 | Black (BLK) | +B2 → Ignition coil control signal |

NOTE: The igniter's harness connector has female metal terminals, so you'll need a back probe or a wire-piercing probe to check the signals in the wires.

Basic Operation Theory Of The Igniter

When you turn the key and crank your 1996-1997 1.6L (4A-FE) Toyota Corolla's engine, a lot happens behind the scenes to generate and distribute spark to all four cylinders.

In a nutshell, here's how the ignition system works:

- The ignition switch sends 10 to 12 Volts DC to the igniter.

- This power flows through the black (BLK) wire that connects to terminal 3 of the igniter's 5-wire connector. This circuit also powers the ignition coil.

- As the engine cranks:

- The distributor's pickup coil produces its G2 signal, which goes straight to the fuel injection computer.

- The crankshaft position (CKP) sensor produces its NE signal, which is also sent directly to the fuel injection computer.

- After receiving the NE and G2 signal, the ECM sends out an IGT (Ignition Timing) signal to the igniter.

- The igniter uses this IGT signal to trigger the ignition coil.

- The yellow with green stripe (YEL/GRN) wire carries the IGT signal to terminal 2 of the igniter.

- Once the igniter receives the IGT signal, it sends an activation +B2 signal to the ignition coil.

- The black (BLK) wire carries the +B2 signal from terminal 5 of the igniter to the ignition coil.

- This +B2 signal fires up the ignition coil to produce spark.

- Once the ignition coil fires, the igniter sends an IGF (Ignition Feedback) signal back to the fuel injection computer.

- The IGF signal confirms the ignition coil has done its job, allowing the fuel injection computer to activate the fuel pump and injectors.

Now that we've got the basics down, let's get to testing.

Where To Buy The Igniter

The following links will help you shop for the igniter made by Delphi (a well-known, but pricey automotive brand) and cheaper priced X-brand:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

NOTE: Not sure if the igniter fits your particular Corolla? Don't worry. Once you get to the site, they ask you the specifics of your vehicle. If it doesn't fit, they'll find you the right one.

TEST 1: Making Sure The Igniter Is Getting Power

IMPORTANT: If the ignition coil is sparking and sending that spark to all four cylinders, then the igniter's doing its job. If you haven't checked for spark yet, do that first before jumping to the testing the igniter:

Let's kick off our igniter test by checking if it's getting power (10 to 12 Volts DC).

This voltage reaches the igniter through the black (BLK) wire, which connects to the female terminal marked as number 3 (see photo above).

Once we confirm the igniter's getting power, we'll move on to TEST 2.

Let's begin:

- 1

Unplug the igniter from its 5-wire connector.

- 2

Attach the black multimeter lead to the battery's negative (-) terminal.

- 3

Have your helper switch the key to the ON position.

- 4

Set your multimeter to Volts DC mode.

- 5

Carefully probe female terminal number 3 on the 5-wire connector using the red multimeter lead.

NOTE: Double-check that terminal number 3 on the igniter's 5-wire connector lines up with the BLK wire. - 6

Your multimeter should show a reading of 10 to 12 Volts DC.

Here's what your test results mean:

CASE 1: Terminal 3 has 10 to 12 Volts. That's exactly what you want to see. Now, you gotta check if the igniter's getting Ground.

To check that the igniter is getting Ground, head over to: TEST 2: Making Sure The Igniter Is Getting Ground.

CASE 2: Terminal 3 doesn't have 10 to 12 Volts. That means the igniter isn't working 'cause it's not getting battery power.

Now, you need to figure out why the power's missing and fix it. Once it's back, the igniter should start working again.

TEST 2: Making Sure The Igniter Is Getting Ground

Once you've confirmed in TEST 1 that the igniter is getting power, the next step is to check if it's properly Grounded.

Unlike other engine management components that have a dedicated Ground wire, the igniter is Grounded directly through its metal case.

Since the igniter is bolted to the driver-side strut tower, and the battery's negative (-) cable is also connected to the chassis, this provides a direct Grounding path through the vehicle's metal body (chassis Ground).

To confirm the igniter is properly Grounded, we'll use a multimeter to check for continuity between the igniter's case and the battery's negative (-) post.

If the igniter is Grounded as it should be, the multimeter will show continuity between the case and the battery's negative (-) post.

Alright, let's get to it:

- 1

Unplug the igniter from its 5-wire electrical connector.

- 2

Disconnect the battery's positive (+) cable.

NOTE: Don't touch the negative (-) cable—leave it connected to the battery's negative (-) post. - 3

Switch your multimeter to Ohms (Ω) mode.

- 4

Touch one multimeter lead to the igniter's metal case.

- 5

Place the other lead on the center of the battery's negative (-) post.

- 6

The multimeter should show continuity.

If you get a low resistance reading (1 Ohm or less), the igniter's Grounded properly.

If there's no continuity (infinite resistance or OL on the screen), then the igniter isn't Grounded.

Here's what your test results mean:

CASE 1: The igniter has continuity to Ground. This is exactly what you want to see.

For our next test, we'll make sure the igniter's getting the IGT signal from the fuel injection computer. Head over to: TEST 3: Testing The Igniter Control Signal.

CASE 2: The igniter DOES NOT have continuity to Ground. This usually happens because of corrosion or bad contact between the igniter's case and its mounting surface.

Your next move is to check and clean the igniter's mounting points to get proper metal-to-metal contact. Once the case is Grounded right, the igniter should start working as it should.