If the igniter (ignition control module) on your 1989-1992 1.6L 4A-FE Toyota Corolla fails, the engine won't start. Thankfully, it can easily be tested to see if it's bad and causing the no-start problem.

In this tutorial, I'm gonna take you through a quick, step-by-step process to check if the igniter's working. The best part? You don't even need to remove it from the car.

Contents of this tutorial:

- Symptoms Of A Bad Igniter.

- Distributor Connector Circuit Descriptions.

- Basic Operation Theory Of The Igniter.

- TEST 1: Making Sure The Igniter Is Getting Power.

- TEST 2: Making Sure The Igniter Is Getting Ground.

- TEST 3: Testing The Igniter Control Signal.

- TEST 4: Testing The Ignition Coil Activation Signal.

- More 1.6L Toyota Corolla Tutorials.

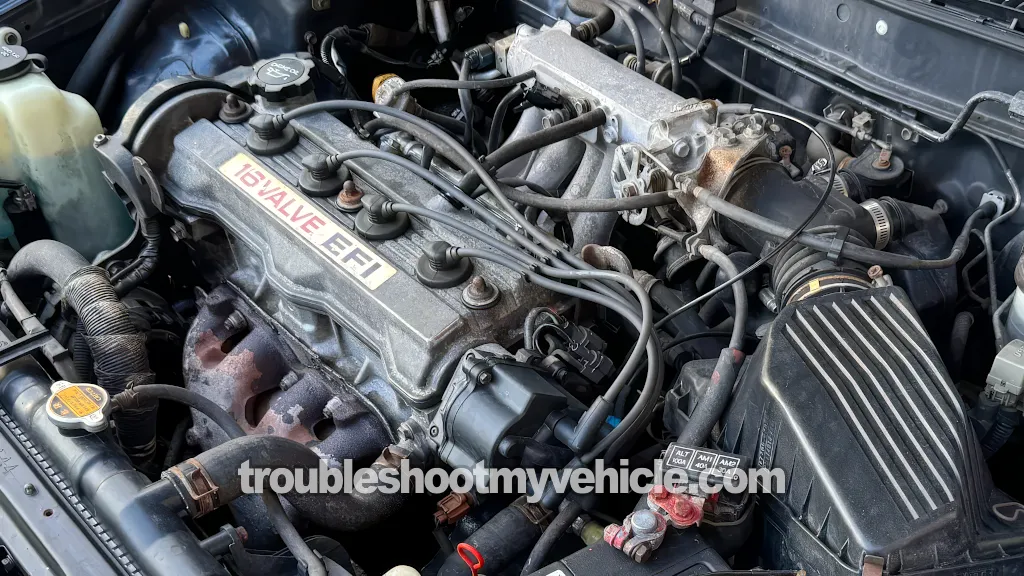

APPLIES TO: This tutorial applies to the following vehicles:

- 1.6L 4A-FE Toyota Corolla: 1989, 1990, 1991, 1992.

IMPORTANT: Before testing the igniter, check the ignition coil for spark first.

If you've got spark, that means the igniter's working fine, so you don't need to go any further with this guide. But if you haven't tested the ignition coil yet, make sure you do that first:

Ignition System Wiring Diagrams:

Distributor Pickup Coil Tests:

Engine No-Start Diagnostics:

Other Igniter Test Tutorials:

- How To Test The Igniter (1993-1995 1.6L Toyota Corolla).

- How To Test The Igniter (1996-1997 1.6L Toyota Corolla).

Symptoms Of A Bad Igniter

The igniter (ignition control module) is a crucial part of the ignition system that helps the engine start and stay running. It works alongside the fuel injection computer to:

- Fire the ignition coil by sending it an activation signals.

- Manage ignition timing by controlling when and how long the coil sparks.

- Let the fuel injection computer know the engine's cranking or running, so it can turn on the fuel pump and injectors.

If the igniter goes bad, the ignition coil won't fire, so no spark reaches the spark plugs. On top of that, the fuel pump and injectors won't turn on, meaning the engine won't start because it's got neither spark nor fuel.

Distributor Connector Circuit Descriptions

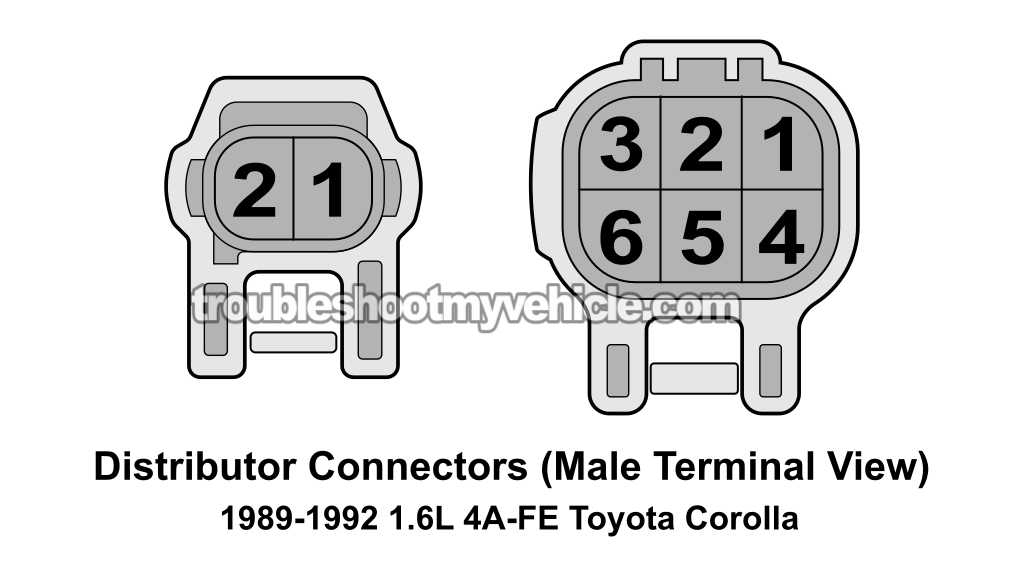

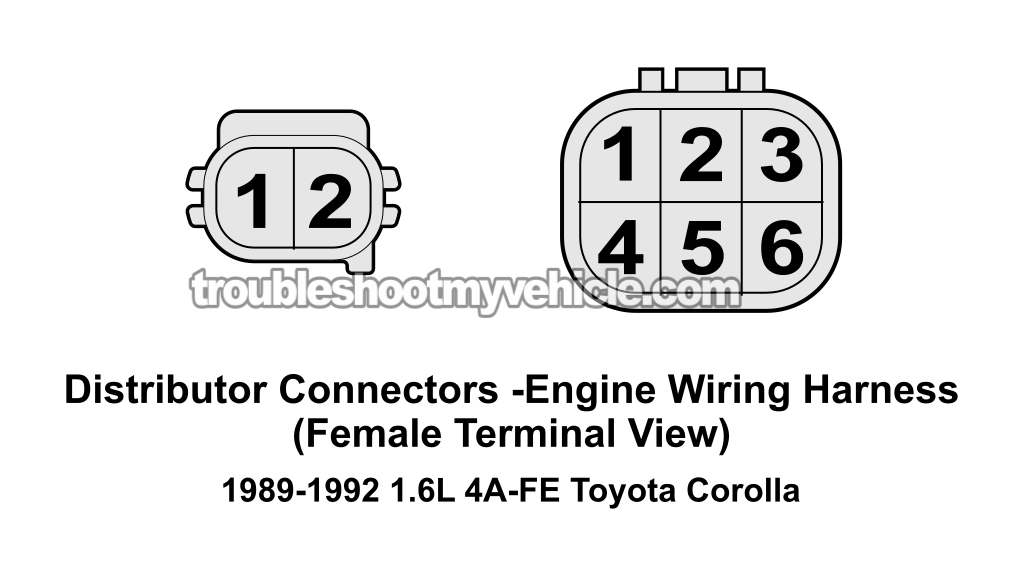

The igniter is located in the distributor (under the distributor cap). The distributor has 2 connectors. One is a 2-wire connector and the other is a 6-wire connector (with one empty slot).

Each of those wires has a specific job to do and here's a brief description of each:

2-Wire Connector:

| Pin | Wire Color | Description |

|---|---|---|

| 1 | Black with orange stripe (BLK/ORG) | B+ -Ignition 12 Volts |

| 2 | Black (BLK) | IG- -Tachometer Signal |

6-Wire Connector:

| Pin | Wire Color | Description |

|---|---|---|

| 1 | Black (BLK) | IGT -Ignition Timing Signal |

| 2 | Red (RED) or Black (BLK) | NE -Engine Speed Signal |

| 3 | -- | Not Used |

| 4 | Black with yellow stripe (BLK/YEL) | IGF -Ignition Feedback Signal |

| 5 | White (WHT) | G- -Sensor Ground For G1 and NE |

| 6 | Black (BLK) | G1 -Crankshaft Position Signal |

NOTE: The distributor harness connector has female terminals. The connector coming out of the distributor itself has male terminals.

Basic Operation Theory Of The Igniter

When you turn the key and crank your 1989-1992 1.6L Toyota Corolla's engine, a lot happens to get spark to all four cylinders, start the engine, and keep it running.

Here's how it works:

- The igniter gets 10 to 12 Volts DC from the ignition switch.

- This power is delivered by the black with orange stripe (BLK/ORG) wire of the distributor's 2-wire connector, which also powers the ignition coil.

- As the engine cranks, the pickup coil inside the distributor creates the G1 and NE signals and sends them straight to the fuel injection computer.

- Once the ECM gets the both signals, it sends an IGT (Ignition Timing) signal to the igniter.

- The IGT signal tells the igniter to fire the ignition coil.

- This signal is delivered by the black (BLK) wire, which connects to terminal number 1 of the distributor's 6-wire connector.

- After receiving the IGT signal, the igniter sends the +B2 activation signal to the ignition coil.

- The +B2 signal makes the ignition coil fire spark.

- Once the ignition coil fires, the igniter sends back an IGF (Ignition Feedback) signal to the fuel injection computer.

- The IGF confirms the ignition coil fired, letting the fuel injection computer turn on the fuel pump and injectors.

Now that you've got a clear picture, let's start testing.

TEST 1: Making Sure The Igniter Is Getting Power

IMPORTANT: If the ignition coil is firing and sending spark to all four cylinders, then the igniter's working fine. So if you haven't checked the ignition coil for spark yet, do that first before testing the igniter:

First, we're gonna check if the igniter's getting power (10 to 12 Volts DC) with a multimeter.

This voltage reaches the igniter through the black with orange stripe (BLK/ORG) wire, which connects to female terminal labeled number 1 of the distributor's 2-wire connector (check the illustration above).

Once we confirm the igniter's getting power, we'll move on to TEST 2.

Here's how to test it:

- 1

Disconnect the distributor's 2-wire electrical connector.

- 2

Connect the black multimeter test lead to the battery negative (-) terminal.

- 3

Have your helper turn the key to the ON position.

- 4

Place your multimeter in Volts DC mode.

- 5

Gently probe female terminal number 1 (of the 2-wire connector) with the red multimeter test lead.

NOTE: Verify that female terminal number 1 of the 2-wire connector corresponds to the BLK/ORG wire. - 6

Your multimeter should read 10 to 12 Volts DC.

Here's what your test results mean:

CASE 1: Terminal 1 has 10 to 12 Volts. That's exactly what you should see.

Next, you need to check if the igniter's getting Ground. To do that, move on to: TEST 2: Making Sure The Igniter Is Getting Ground.

CASE 2: Terminal 1 does NOT have 10 to 12 Volts. That means the igniter isn't working because it's not getting battery power.

Your next step is figuring out why that power is missing and fixing the issue. Once the battery power is restored, the igniter should work again.

TEST 2: Making Sure The Igniter Is Getting Ground

Once TEST 1 confirms the igniter is receiving power, the next step is to verify it has a proper Ground.

Unlike other components that use a dedicated Ground wire, the igniter grounds through its metal case.

Since it's bolted to the distributor with two screws —and the distributor is mounted to the cylinder head— this creates a direct connection to chassis Ground.

To check for Ground, we'll simply test for continuity between the igniter's case and the battery's negative (-) post.

If the igniter is properly grounded, the multimeter should confirm continuity.

Let's get started:

- 1

Disconnect the battery positive (+) cable from the battery positive (+) post.

NOTE: Leave the battery negative (-) cable connected to the battery negative (-) post. - 2

Remove the distributor cap.

- 3

Set your multimeter to Ohms (Ω) mode.

- 4

Place one multimeter test lead on the igniter's metal case.

- 5

Place the other multimeter test lead on the center of the battery negative (-) post.

- 6

The multimeter should read continuity.

If there's continuity (anything under 1 Ohm), the igniter is properly grounded.

If there's no continuity (infinite resistance or OL on the display), the igniter is not grounded.

Here's what your test results mean:

CASE 1: The igniter has continuity to Ground. This is the correct and expected test result.

Now, we need check if the igniter's getting the IGT signal from the fuel injection computer. Head over to: TEST 3: Testing The Igniter Control Signal.

CASE 2: The igniter DOES NOT have continuity to Ground. This usually happens when there's corrosion or a bad connection between the igniter's case and its mounting surface.

Next, inspect and clean the mounting points to make sure there's solid metal-to-metal contact. Once the case is properly grounded, the igniter should work like it should.