PART 2: Checking The Fuel Injector Spray Pattern

Up to this point, you've checked the fuel injector's internal resistance and it's within specification, which tells you that it hasn't suffered an internal open or short-circuit problem.

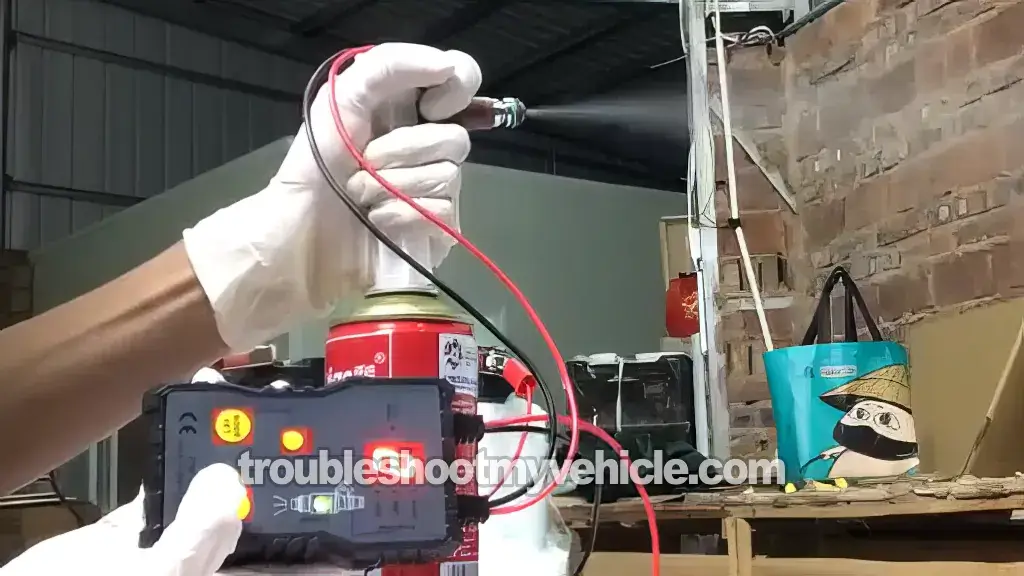

The next step is to remove the fuel injector. Then, using a specialized tool, connect the injector to its 12 Volt power module and to a spray can of brake cleaner with a special adapter. This setup will help you visually check if the fuel injector sprays fuel and atomizes it correctly.

The cool thing is that the power module allows you to activate the fuel injector in pulses (just like the fuel injection computer does), allowing the cleaner to flow through the fuel injector and out of its tip.

If the fuel injector isn't clogged, the brake cleaner fluid will get sprayed out and in a fine mist. If the fuel injector is clogged or faulty, it'll come out in a stream or squirt, or not at all.

This tool significantly simplifies the process of checking if the fuel injector can spray fuel correctly and it doesn't cost an arm and a leg. You can buy it here:

- QX Fuel Injector Tester & Adapter for Diagnosis and Cleaning of Injectors DIY Cleaning Tool Kit (at: amazon.com)

- EM276SET Fuel Injector Tester & Adapter DIY Cleaning Tool Kit Set (at: amazon.com)

IMPORTANT: Before installing the same or new fuel injector back on the fuel injector rail, take a look at: Important Tips For Installing A Fuel Injector.

CAUTION: Use safety glasses when performing the fuel injector cleaning procedure.

Alright, these are the test steps:

- 1

Remove the fuel injector.

- 2

Connect the fuel injector to the plastic adapter.

NOTE: I've found that securing the fuel injector to the adapter with a thick rubber band helps to make the whole process easier and less messier. - 3

Connect the fuel injector to the tool's power module.

NOTE: Follow the tool's safety and recommended set-up instructions. - 4

Connect the cleaning kit's power module to your van's battery.

- 5

Connect the fuel injector/adapter to a spray can of brake cleaner and press them onto the spray can.

- 6

Activate the power module.

- 7

The fuel injector should spray fuel in a fine mist and in a conical shape.

Let's interpret your test result:

CASE 1: The fuel injector did not spray at all. This tells you that the fuel injector is bad and needs to be replaced.

CASE 2: The fuel injector sprayed the brake cleaner in a fine mist and in a conical pattern. This tells you that the fuel injector is OK.

CASE 3: The fuel injector sprayed the brake cleaner in a squirt or a stream (not in a fine mist). This tells you that the fuel injector is dirty/clogged.

Continue cleaning the fuel injector until it starts to spray in a fine mist. If the cleaning it doesn't restore the injector's spray pattern to that of a fine mist, you'll need to replace it.

Important Tips For Installing A Fuel Injector

When installing a fuel injector (whether it's the same one or a new one) on the fuel injector rail, keep in mind the following important suggestions to ensure everything runs smoothly and safely.

- Always use new fuel injector O-rings: If you're reinstalling the same fuel injector (a new fuel injector will come with new O-rings), it should never be installed with its old O-rings. This is crucial for creating a tight seal and preventing fuel and vacuum leaks.

- Lubricate the new fuel injector O-rings: Before installing the new O-rings on the fuel injector, make sure to lubricate both with a bit of clean (new) engine oil (don't use any silicone based grease or lubricant).

Lubricating the O-rings makes it easier to slide the fuel injector into the injector rail and into the intake manifold injector port without damaging them. A damaged O-ring can cause fuel or intake manifold leaks, which is exactly what you want to avoid. - Replace damaged connector: If the fuel injector's connector is damaged in any way, replace it with a new one. It's not uncommon for the locking tab of the fuel injector to break; if it's broken, replace the connector.

Also, avoid using butt connectors to join the new connector's wires to the engine wiring harness. Instead, solder the wires for a permanent repair, as butt connectors are infamous for becoming loose and causing false contact issues.

Remember, the whole idea here is to prevent gasoline leakage and avoid the risk of a fire. So take your time and ensure everything is properly seated and secure.

Important Tips For Removing And Installing The Intake Manifold Plenum

When removing the intake manifold plenum to access the injectors underneath, there are a few important things to consider:

- Disconnect the battery from its negative (-) cable before removing the intake manifold plenum and leave it disconnected during the entire fuel injector testing procedure.

- Be careful that no foreign object, like a bolt, a nut, or any metal piece/part, falls into the open manifold port runners or you run the risk of engine damage if you start the vehicle.

- Once the plenum has been removed, place a clean rag or rags on the open intake runners. This will keep things from falling into them.

- As you're removing bolts, nuts and stuff from the intake plenum to remove it, place them in a container and away from the engine compartment.

- Never crank the engine with the plenum removed from the lower intake manifold.

If anything falls into the open intake ports (runners) without you knowing it, and you crank and start the engine, you're gonna be in a world of pain!

If this happens, the only way to remove the object is to remove the cylinder head. So, stay alert and be careful. Removing the plenum isn't an out of this world thing that nobody can or shouldn't do; you just have to be careful (heck, even just crossing the street has risks!).

When installing the intake manifold plenum, keep in mind the following important suggestions:

- Don't reuse the gaskets. It's critical that you use new gaskets.

- Don't cover them in any type of sealant (like RTV Silicone).

- Tighten the intake manifold in sequence and to the correct torque specification. You can find this info here:

More 4.2L Ford E150 And E250 Test Tutorials

If this tutorial was helpful, be sure and take a look at all of the 4.2L V6 E150 and E250 diagnostic tutorials and wiring diagrams in this index:

Here's a sample of the tutorials you'll find there:

- How To Test The Throttle Position Sensor (1997-2000 4.2L V6 Ford E150, E250).

- How To Test Engine Compression (1997-2003 4.2L V6 Ford E150, E250).

- How To Test The Fuel Pump (1997-2000 4.2L V6 Ford E150, E250).

- How To Test The CKP Sensor With A Multimeter (1997-2003 4.2L V6 Ford E150, E250).

If this info saved the day, buy me a beer!