TEST 3: Checking The IAC Valve Wires For A Short To Ground

This test checks for a short to Ground in any of the IAC valve circuits. Just like in TEST 2, each of the four wires at the IAC connector should be completely isolated —not just from each other, but also from Ground.

A short to Ground usually happens when the wire's insulation wears away —whether from heat, vibration, or rubbing against something— and the exposed copper wire touches the engine block or another metal surface that's Grounded.

If any of the IAC wires are shorted to Ground, the PCM won't be able to control the valve properly, and you'll end up with a P0505 Idle Control Malfunction code.

NOTE: Make sure the battery's negative (-) cable is disconnected from the battery post before you begin. This prevents any interference during testing and helps avoid false readings.

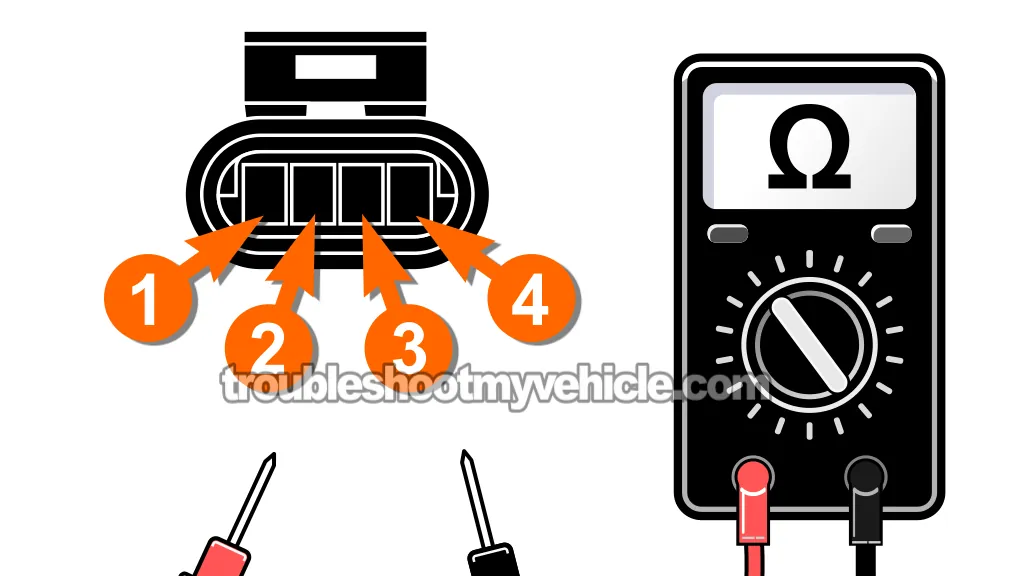

Follow these steps to test for a short to Ground in the IAC valve wiring:

- 1

Disconnect the battery's negative (-) cable from the battery post.

You'll use the loose terminal end of the cable as your Ground reference during the test. - 2

Unplug the IAC valve connector and all three PCM connectors.

NOTE: This isolates the wiring from both the PCM and the valve, ensuring you're testing only the harness. - 3

Set your multimeter to Ohms mode.

NOTE: Don't use the Continuity setting of the multimeter (if it has one). - 4

Touch one multimeter probe to Terminal 1 of the IAC connector, and the other probe to the disconnected battery negative cable.

- 5

Check the reading on the multimeter.

- 6

You should see infinite resistance (open-circuit).

If your meter shows low resistance (typically 5 Ohms or less), that wire is shorted to Ground and needs attention. - 7

Repeat the test for Terminals 2, 3, and 4, always comparing each one against your Ground reference.

- 8

Have a helper gently wiggle the engine wiring harness (between the IAC connector and PCM connectors) while you keep an eye on the multimeter.

Focus on moving sections near sharp bends and areas where the harness touches brackets or engine components. - 9

Watch for sudden drops in resistance during the wiggle test.

If the meter suddenly shows low resistance (5 Ohms or less or any significant change), the wire is shorting to Ground when flexed —confirming an intermittent fault hidden inside the engine wiring harness.

Now, let's break down what your results mean:

CASE 1: All terminals show infinite resistance to Ground. Great —this confirms that none of the IAC wires are shorted to Ground, and the circuits (wires) are in good shape.

Continue to the next step: TEST 4: Check IAC Valve Stepper Motor Resistance (From PCM Connector).

CASE 2: One or more terminals show continuity (low resistance —5 Ohms or less) to Ground. This means a wire is shorted to the vehicle's body (chassis) or engine somewhere along the harness.

Carefully inspect the wiring along its route —especially near brackets, sharp edges, and hot components. Once you find the damaged section, repair or replace it as needed. For help on this, see: How To Repair Shorted IAC Wires (Real-World Fix).

TEST 4: Check IAC Valve Stepper Motor Resistance (From PCM Connector)

At this stage, you've already ruled out wiring issues —including:

- Hidden wire damage inside the engine wiring harness (TEST 1).

- Shorts between the IAC valve's four wires (TEST 2).

- And shorts to Ground (TEST 3).

Now it's time to check the IAC valve itself —specifically, the two internal stepper motors that control the pintle inside the throttle body housing.

Each motor is controlled by its own pair of wires, which connect directly to the PCM. In this test, we'll measure the resistance across each wire pair at the PCM connector.

The typical resistance for each stepper motor is around 35 Ohms, although many good IAC valves test between 8–10 Ohms. While there's no official factory spec published, those ranges are generally considered normal.

The key is to look for similar resistance readings between the two motors. If one side reads significantly different —or shows infinite resistance (open-circuit) or near zero (short)— that motor is bad, and the IAC valve should be replaced.

CAUTION: When testing at the PCM connector, make sure you use a probe that fits properly into the round female terminals. Standard multimeter leads are usually too thick and can permanently damage or deform the PCM terminals if forced in.

To avoid this, use a fine-tip back probe or a proper terminal test probe designed for automotive connectors. Be extremely careful —damaging the PCM connector could lead to poor electrical contact, erratic drivability issues, or complete failure of the circuit.

OK, here are the test steps:

- 1

Confirm the battery's negative cable is still disconnected.

- 2

Plug the IAC valve back into its 4-wire connector.

- 3

Set your multimeter to the Ohms (Ω) setting to measure resistance.

- 4

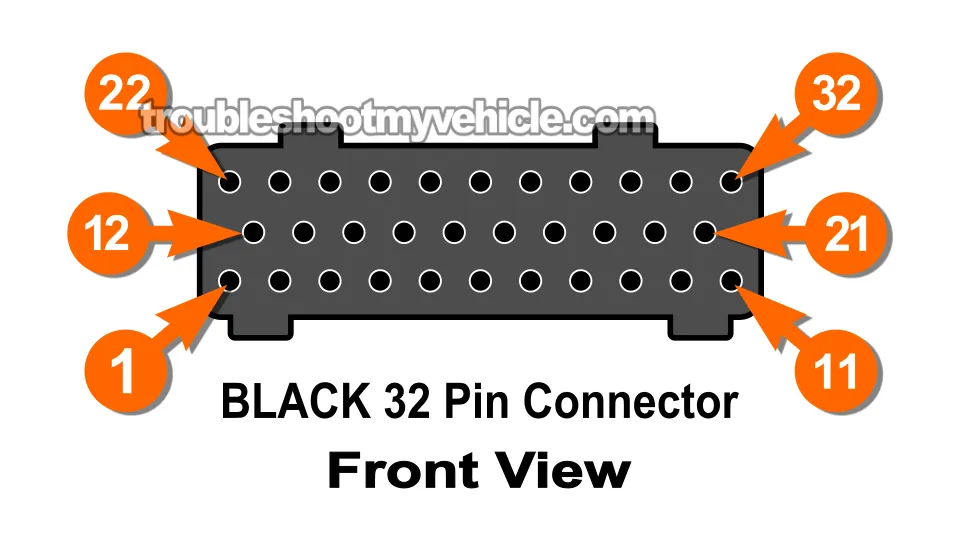

Testing Stepper Motor 1:

Place your meter leads on PCM black connector terminals 19 and 20.

A good reading should be approximately 35 Ohms, though some valves may read as low as 8–10 Ohms. - 5

Testing Stepper Motor 2:

Now check resistance between PCM black connector terminals 10 and 11.

Expect a similar reading —again, either around 35 Ohms or possibly 8–10 Ohms.

If you get a result of infinite resistance (open-circuit) or close to zero (short), that motor coil has failed and the IAC valve needs to be replaced.

Let's break down what your readings mean:

CASE 1: Both motor circuits read around 35 Ohms (or between 8–10 Ohms). That's the result we need to see.

This means the valve's internal windings are intact. If idle issues continue, the problem may be carbon buildup inside the valve or a pintle that's sticking. It's also a good idea to check for vacuum leaks.

There's also a very slim chance the PCM is at fault. For more on that, see: What If The PCM Itself Is Bad?

CASE 2: One or both readings show infinite resistance (open circuit). This means one of the stepper motor windings is broken.

The IAC valve will need to be replaced if you have confirmed:

- The wiggle test showed no issues (TEST 1).

- No shorts exist between any of the IAC valve's four wires (TEST 2).

- None of the wires are shorted to Ground (TEST 3).

CASE 3: One or both readings show extremely low resistance (near 0 Ohms). This suggests an internal short in one of the stepper motor coils —but only if:

- The wiggle test passed without issues (TEST 1).

- No shorts were found between any of the IAC valve's four wires (TEST 2).

- No shorts to Ground were found (TEST 3).

... then —and only then— can you confidently replace the IAC valve, since it's no longer functioning properly.

What If The PCM Itself Is Bad?

Although rare, a failed PCM —specifically the internal driver circuits that control the IAC valve— can be the root cause of a P0505 Idle Control Malfunction code.

That said, these types of PCM failures are very uncommon, and unfortunately, there's no direct way to test the IAC control circuits inside the PCM using a multimeter or scan tool.

The IAC driver circuits are solid-state components sealed within the PCM. When one of them fails, it stops sending the proper signals to the IAC valve, which can lead to rough idle, stalling, high RPMs —and, of course, a persistent P0505 code.

But here's the key point: You should only suspect the PCM after you've eliminated all other possibilities.

That means confirming all of the following:

- The IAC valve has tested good —proper resistance, no open or shorted coils.

- No shorts to Ground or between IAC circuits in the wiring harness.

- All connectors are clean, tight, and free of corrosion or damaged pins.

- No intake manifold gasket leaks.

- No vacuum leaks around the throttle body area.

- The throttle plate moves freely and isn't binding or damaged.

- The idle stop screw hasn't been adjusted or tampered with.

Only after you've ruled out every other cause —wiring, IAC valve, vacuum leaks, and mechanical issues— should you consider the PCM a suspect.

And even then, the only reliable way to confirm a faulty PCM is by swapping in a known-good unit and observing whether the issue disappears. If it does, you've found your answer.

Just remember —PCM failure is the exception, not the rule. Most P0505 issues are caused by wiring faults, vacuum leaks, or a failing IAC valve. Always start there before pointing the finger at the computer.

NOTE: If you're installing a used PCM, it'll need to be flashed with your vehicle's VIN number to load the correct programming.

There's a common workaround, though: if you install a used PCM from a pickup that matches the exact same year, engine size, and transmission type, the engine will usually start and run.

This can help you confirm if the PCM is the problem —if the P0505 code stays gone and idle returns to normal, the old PCM is bad. But even then, you'll still need to get the replacement PCM flashed for proper long-term use.

How To Repair Shorted IAC Wires (Real-World Fix)

Once you've confirmed that two IAC wires are shorted together —and the damaged section is buried somewhere inside the engine harness, out of sight —there's no need to tear the whole harness apart trying to trace the wires end to end. That's usually not how it's done in real-world diagnostics or repair work.

One long-term solution is to bypass the damaged section by splicing in a new length of wire.

Here's how the repair is typically performed:

- Cut the faulty wire(s) at least 3 to 4 inches away from the IAC valve connector to ensure you're past the damaged area.

- Do the same on the PCM side —leave yourself enough clean wire to work with.

- Use replacement wire that matches the same gauge and insulation type as the original. Strip the ends and solder the new wire in place.

- Avoid using butt connectors. They might work temporarily, but vibration, heat, and road shocks will cause them to loosen over time —leading to hard-to-find intermittent issues later on.

- Once soldered, seal the connection with heat-shrink tubing and/or wrap it tightly with high-quality electrical tape to keep moisture and corrosion out.

Replacing the entire engine wiring harness would be the ideal solution —and in some cases, it's the only fix— but it's expensive and usually overkill for a problem limited to just the IAC valve circuits.

A much more practical and reliable solution is to splice in a new wire to replace the damaged section. When done correctly, this kind of repair is solid, long-lasting, and just as effective as replacing the whole harness.

More 3.9L V6 Dodge Ram Pickup Tutorials

I've written several more tutorials for the V6 Dodge Ram pickups that may be of interest to you that you can find in this index:

Here's a sample of the tutorials you'll find in the index:

- How To Test The Fuel Injectors (1992-1999 3.9L V6 Dodge Ram Pickup).

- How To Test The Intake Air Temp (IAT) Sensor (1998-2001 3.9L V6 Dodge Ram Pickup).

- How To Test The Fuel Pump (1992-2001 3.9L V6 Dodge Ram Pickup).

- How To Test For A Blown Head Gasket (1989-2001 3.9L V6 Dodge Ram Pickup).

If this info saved the day, buy me a beer!