P0505: Idle Control Malfunction is one of those trouble codes that can drive you nuts. You've probably already swapped out the idle air control (IAC) valve —but the darn code keeps coming back, and the engine's idle still isn't behaving.

The good news is that testing the IAC valve and its circuits (between the IAC valve and the PCM) isn't difficult.

I'll show you exactly how to test the wiring between the IAC connector and the PCM —step by step— so you can stop guessing and start pinpointing the real issue.

I've laid out all the tests in a clear and practical way, so you can narrow down the true cause behind that P0505 code —and finally get it resolved.

Contents of this tutorial:

- What Does The IAC Valve Do?

- Symptoms Of A Bad Idle Air Control (IAC) Valve.

- Most Common Causes Of A P0505 Diagnostic Trouble Code.

- IAC Valve Connector Pinout.

- TEST 1: Connector Wiggle Test.

- TEST 2: Checking For Shorted IAC Valve Wires.

- TEST 3: Checking The IAC Valve Wires For A Short To Ground.

- TEST 4: Check IAC Valve Stepper Motor Resistance (From PCM Connector).

- What If The PCM Itself Is Bad?

- How To Repair Shorted IAC Wires (Real-World Fix).

- More 3.9L V6 Dodge Ram Pickup Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 3.9L V6 Dodge Ram 1500 Pickup: 1996, 1997, 1998, 1999, 2000, 2001.

- 3.9L V6 Dodge Ram 2500 Pickup: 1996, 1997, 1998, 1999, 2000, 2001.

1992-1995 IAC VALVE TESTS:

What Does The IAC Valve Do?

In the 1996–2001 3.9L V6 Dodge Ram pickups, idle speed is managed by an idle air control (IAC) valve, which is bolted directly to the throttle body.

This 4-wire valve uses a pair of stepper motors to move a pintle in or out in small increments. Each movement adjusts how much air bypasses the closed throttle plate when the engine is idling.

By allowing just the right amount of air around the throttle plate, the IAC valve helps maintain a smooth idle —especially when your foot's off the gas and the throttle is fully closed.

The job of keeping idle speed steady falls on the Powertrain Control Module (PCM), which constantly monitors engine load and adjusts the IAC valve as needed to hold the target RPM. Here are two common examples:

- Extra load from accessories —like turning on the A/C or headlights— prompts the PCM to open the IAC valve more, increasing airflow and idle speed to keep the engine from shutting off.

- When slowing down or coming to a stop, the PCM adjusts the IAC valve to gently stabilize RPM, preventing the engine from stalling as speed drops.

Symptoms Of A Bad Idle Air Control (IAC) Valve

The PCM constantly keeps tabs on the IAC valve's electrical circuit. If it detects something off —like abnormal resistance, voltage out of range, an open or short-circuit, or even if the idle speed can't match the PCM's command —it will trigger a P0505 Idle Control Malfunction code and turn on the check engine light.

When the IAC system isn't working properly, you might notice one or more of the following symptoms:

- Stalling or extremely low idle: The engine won't stay running unless you keep pressing the gas pedal.

- Idle that's too high or erratic: RPMs might hover around 1500 or fluctuate unpredictably, going up and down without input.

- Rough or shaky idle: The engine may sound uneven or vibrate while idling —especially if a vacuum leak is making things worse.

- Normal idle but the code is still present: Sometimes the engine idles fine, but a problem in the IAC circuit still causes the code to set.

Most Common Causes Of A P0505 Diagnostic Trouble Code

To put it simply, the PCM relies on the IAC valve to manage how much air enters the engine at idle —which directly controls idle RPM.

Because it continuously tracks engine speed anytime the engine is running, any malfunction in this system —whether it's mechanical, electrical, or airflow-related —can lead the PCM to set a P0505 Idle System Malfunction trouble code.

Here are some of the most common causes of a P0505 code:

- Worn-out or stuck IAC valve: Although these valves are generally durable, they can fail over time. Problems might include a stuck pintle due to carbon buildup, internal motor coil failure (it has two), or physical wear that affects movement.

- Damaged IAC connector: If the plug or terminals are corroded, loose, or broken, it can disrupt electrical contact and interfere with valve operation.

- Open or shorted IAC wiring (to Ground): This is one of the more frequent issues. It means a wire going to the IAC valve is either broken or has rubbed against metal and Grounded out —cutting off or misrouting the signal between the PCM and the valve.

- Short to power within the IAC circuit: Also a common failure. This happens when one wire in the IAC harness touches another that carries voltage. When an IAC valve Ground wire gets hit with voltage from another circuit, the PCM can no longer regulate the valve correctly.

- PCM failure: Rare, but possible. If one of the internal driver circuits that controls the IAC motor burns out, the PCM won't be able to command valve movement at all.

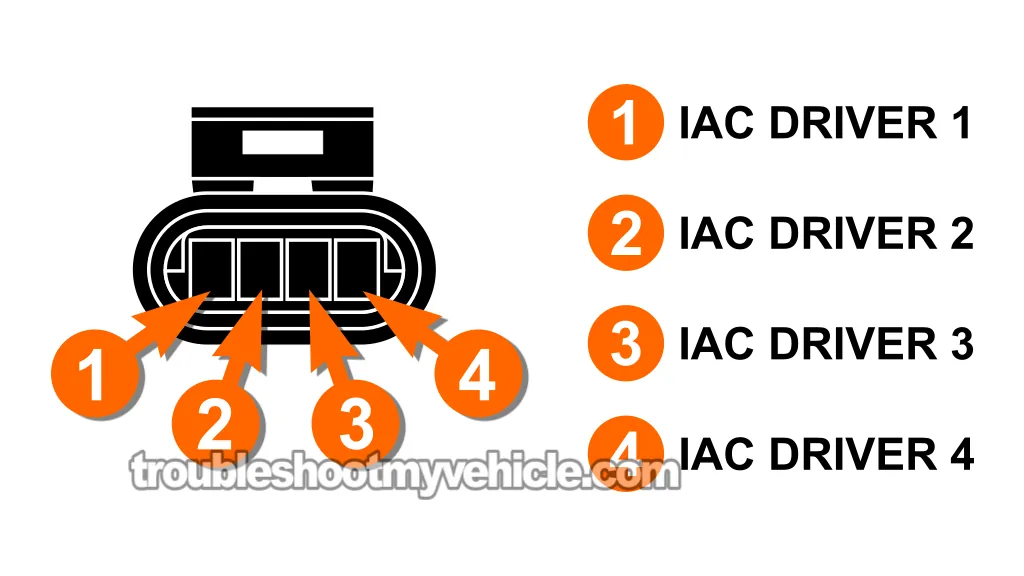

IAC Valve Connector Pinout

| 1996-2001 IAC Connector Pinout | ||

|---|---|---|

| Pin | Wire Color | Description |

| 1 | Grey with red stripe (GRY/RED) | IAC Driver 1 |

| 2 | Yellow with black stripe (YEL/BLK) | IAC Driver 2 |

| 3 | Brown with white stripe (BRN/WHT) | IAC Driver 3 |

| 4 | violet with black stripe (VIO/WHT) | IAC Driver 4 |

NOTE: The violet with white stripe (VIO/WHT) wire is also referred to as the purple with white stripe (PPL/WHT) wire.

TEST 1: Connector Wiggle Test

Over time, vibration, heat, and age can take a toll on the IAC valve's electrical connector and its wiring. Terminals may loosen, wires can break internally, or insulation can wear down and cause shorts —often without any visible damage.

These types of issues can lead to intermittent idle problems that are hard to catch through visual inspection alone.

One of the easiest ways to uncover hidden faults like this is with a simple wiggle test while the engine is running —a safe and effective way to see if wiring movement affects idle stability (which it shouldn't).

CAUTION: This test must be done with the engine running. Use extreme care. Keep your hands, tools, and clothing away from the fan, pulleys, and belts. Stay alert and take all safety precautions while working under the hood.

Alright, let's get going:

- 1

Start the engine and let it settle into an idle.

- 2

Carefully wiggle the IAC connector and the wires leading out of it.

Trace the wiring as far as it's visible, gently moving it along its length —especially near bends and where it enters the main harness. - 3

Watch the idle as you move the connector and wires.

The engine should maintain a steady idle. If the idle dips, surges, or the engine stumbles, there's a connection or wiring issue. - 4

Shut off the engine once testing is complete.

Let's break down what your results mean:

CASE 1: The engine stumbles, surges, or dies when you wiggle the connector or wires. This usually points to a loose pin, poor contact, or internal break in the wiring or connector.

Replacing the connector often solves the issue. If the problem is in the wiring itself, repair the damaged section.

When replacing wire, solder the new piece in place instead of using butt connectors. Heat and vibration under the hood can cause butt connectors to loosen and create future intermittent problems.

Even though the info in the following section walks through replacing an entire IAC circuit (from the PCM to the IAC valve), the techniques shown also apply to fixing a smaller section of wiring near the connector:

CASE 2: No change in idle when wiggling the connector and wiring. This is the correct and expected test result and tells you the wiring and connector are OK.

Next step: TEST 2: Checking For Shorted IAC Valve Wires.

CASE 3: The engine won't start, or starts then immediately stalls. This could indicate a completely failed IAC valve, a serious fault in the wiring, or a problem with the PCM itself.

Your next step is: TEST 2: Checking For Shorted IAC Valve Wires.

TEST 2: Checking For Shorted IAC Valve Wires

In this next step, we're going to check if any of the IAC valve wires are shorted to each other inside the harness.

The IAC system uses four separate circuits that run from the PCM directly to the valve. These wires should all be electrically isolated —there should be No continuity between any of them.

If you do find continuity between two or more IAC wires, it likely means there's a short somewhere in the engine wiring harness —often due to things like melted insulation or chafed sections.

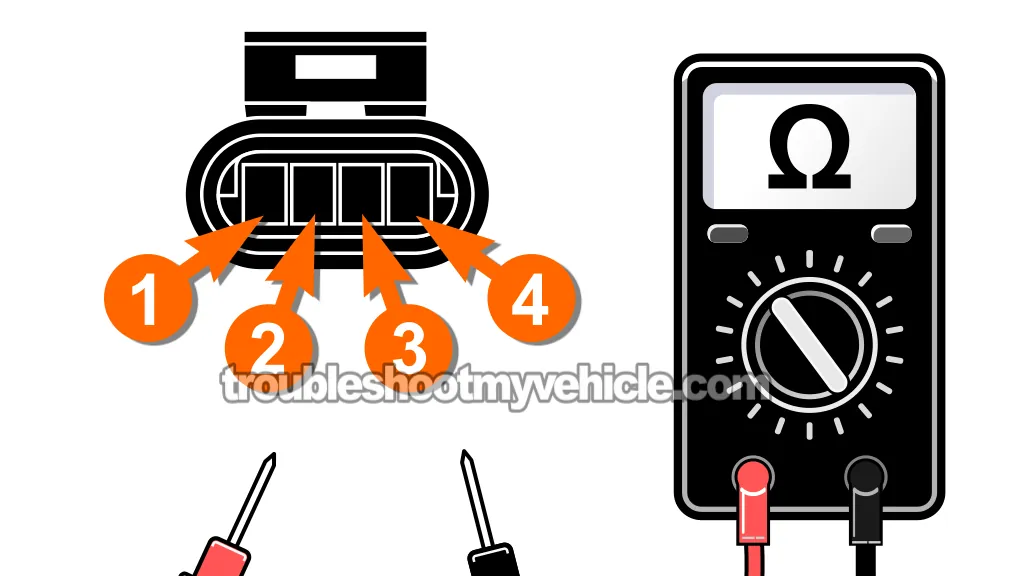

To perform this test, you'll need to disconnect the IAC valve connector as well as all three PCM connectors. Then, we'll use a multimeter to check each pin at the IAC connector for continuity with the others.

NOTE: Don't have a multimeter or need to upgrade yours? This is the one I use and recommend: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (at: amazon.com).

Let's get started:

- 1

Switch the ignition OFF and disconnect the battery negative (-) cable.

NOTE: This step helps protect both your multimeter and the vehicle's electronics from accidental shorts during testing. - 2

Unplug the IAC valve and all three PCM connectors.

- 3

Set your multimeter to Ohms mode.

NOTE: Don't use the Continuity setting (if your multimeter has one). - 4

Place one multimeter lead on Terminal 1 of the IAC connector.

- 5

Use the second lead to test Terminals 2, 3, and 4 one at a time.

- 6

You should see no continuity (infinite resistance) between Terminal 1 and any of the others.

- 7

Repeat the process with the remaining terminals.

Move your first lead to Terminal 2, and check for continuity to 3 and 4. Then repeat for Terminal 3.

The goal is to confirm that none of the terminals are shorted together internally.

If your multimeter shows a low resistance reading (typically under 5 Ohms) between any two terminals, that means those circuits are shorted together —and that's a problem that needs fixing.

Let's go over what your results mean:

CASE 1: Your multimeter shows infinite resistance between all four terminals. Perfect —this means the circuits are electrically isolated from one another, just like they're supposed to be.

Go ahead and move on to the next test: TEST 3: Checking The IAC Valve Wires For A Short To Ground.

CASE 2: Continuity exists between two or more terminals (resistance is low, typically under 5 Ohms). That indicates a short between the wires.

The most common cause is damaged insulation somewhere in the harness —especially where wires bend, rub, or have come in contact with an exhaust component.

You'll need to locate and repair the shorted section. Here's how: How To Repair Shorted IAC Wires (Real-World Fix).

CASE 3: Readings fluctuate or show momentary continuity as you move the wiring. This usually means there's an intermittent problem in the engine wiring harness —like a wire that's broken inside the insulation or two damaged wires that momentarily touch when the harness is bent or flexed.

You'll need to locate and repair the problem area in the harness. The following guide offers practical tips on how to fix this type of issue: How To Repair Shorted IAC Wires (Real-World Fix).