TEST 3: Engine Compression Test

Sometimes, an engine overheating issue can cause the head gasket to burn at a spot right between two side-by-side cylinders (as shown in the image at the beginning of this tutorial).

In my experience, even when this happens, the engine can still start and run. However, because those two adjacent cylinders don't produce any compression and are 'dead', the engine runs with a misfire.

The only way to check for this specific type of failure is to perform an engine compression test, and that's what we'll do in this test section.

NOTE: You can find the engine compression test and how to interpret its results explained in more detail here: How To Test Engine Compression (1997-2003 4.2L V6 Ford E150, E250).

OK, these are the test steps:

- 1

Disconnect the ignition coils from their electrical connectors. This is will disable the ignition system and is an important safety precaution.

- 2

Disconnect all spark plug wires (from their spark plugs).

- 3

Remove all of the spark plugs.

- 4

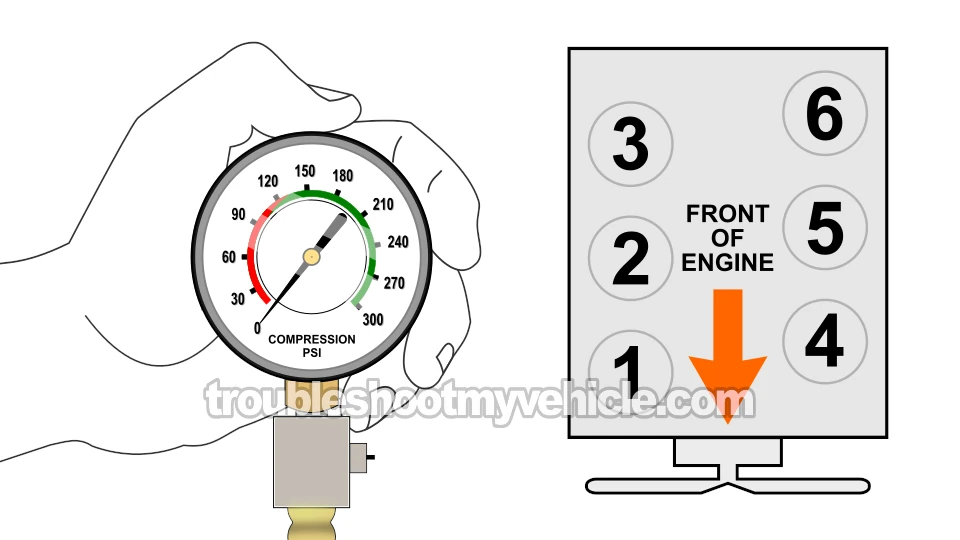

Thread in the compression tester by hand, on the first spark plug hole you're gonna' start with.

Do not use any tools to tighten the compression tester. Hand tightening the compression tester is more than enough to get the proper results. - 5

Have a helper crank the engine as you observe the compression tester.

- 6

When the gauge's needle stops climbing, have your assistant stop cranking the engine.

- 7

Write down the reading and what cylinder it belongs to on a piece of paper (you can use the illustration above to help you identify the cylinder).

- 8

Remove the compression tester and repeat the above steps in the remaining cylinders.

Let's examine what your results mean:

CASE 1: All cylinder compression readings where normal. This is the correct test result and it confirms that the head gasket isn't burned at a spot between two side-by-side cylinders.

If you still suspect a blown head gasket, go to: TEST 4: Using A Chemical Block Tester (Combustion Leak Tester).

CASE 2: Two side by side cylinders had 0 PSI compression. This test result confirms that the head gasket is burned at the point between those two cylinders. Replace the head gasket.

TEST 4: Using A Chemical Block Tester (Combustion Leak Tester)

In some cases, a head gasket fails without showing the issues the previous three tests check for. When this happens, the engine starts but then overheats within minutes for no clear reason, even though all cooling system components (like the water pump, fan clutch, and thermostat) are fine.

In these situations, the only way to confirm that the engine is overheating due to a blown head gasket is by performing a block test with a chemical combustion leak detector.

This is how the combustion leak detector test (block test) works:

- The combustion leak detector tester is filled with a blue liquid chemical (see photo above).

- The radiator cap is removed (you may have to drain some of the coolant in the radiator since this tool needs to ‘gulp’ some of the air inside the radiator).

- The engine is started.

- The tester is then placed on the open radiator neck.

- The rubber bellow is then squeezed to suck in the air up through the two fluid-filled chambers. As the air bubbles up through the fluid, it will cause a chemical reaction.

- If the blue chemical turns yellow (for gasoline engines), then combustion gases are entering the radiator. This in turn confirms a blown head gasket, a cracked block, or a cracked cylinder head issue.

- If the blue chemical doesn't change color, then you can conclude that you don't have a blown head gasket, a cracked block, or cracked cylinder head issue.

You can shop for a block tester here:

Should I Replace Both Head Gaskets?

Most, if not all auto repair shops will refuse to just replace one head gasket. Why? Because it's the only way they can guarantee the job, not to mention it's the right way to do it.

If you're thinking about doing the head gasket repair job yourself, you should also replace them both. Here's why:

Both Head Gaskets Stressed: The most common cause of a blown head gasket is engine overheating, which affects both sides of the engine equally. The stress, wear, and damage caused by the overheating issue that led to one head gasket failing have also affected the other one. Its failure isn’t far behind.

Replacing both gaskets ensures each side of the engine is equally prepared to handle the normal loads and stresses the engine typically subjects them to. Otherwise, the head gasket that didn't get replaced will fail soon after the repair.

Labor/Time Involved: Removing one cylinder head requires quite a bit of labor and time. Most of the components that need to be removed to access one cylinder head also expose the other cylinder head (for removal).

Since the engine is already partly disassembled, and removing the other cylinder head doesn't require much additional effort, it makes sense to replace the other head gasket that could fail soon, thus preventing another costly and time-consuming repair down the line.

To summarize this section, replacing both head gaskets at the same time is a smart move that'll save you time, money, and headaches in the long run, ensuring the 'job doesn't come back' on your Ford E150 or E250.

More 4.2L Ford E150 And E250 Test Tutorials

If this tutorial was helpful, be sure and take a look at all of the 4.2L V6 E150 and E250 diagnostic tutorials in this index:

Here's a sample of the tutorials you'll find there:

- How To Test The Throttle Position Sensor (1997-2000 4.2L V6 Ford E150, E250).

- How To Test Engine Compression (1997-2003 4.2L V6 Ford E150, E250).

- How To Test The Fuel Pump (1997-2000 4.2L V6 Ford E150, E250).

- How To Test The CKP Sensor With A Multimeter (1997-2003 4.2L V6 Ford E150, E250).

If this info saved the day, buy me a beer!