In this tutorial, we're going to troubleshoot OBD-I Code 25, which points to a problem with the Idle Air Control (IAC) valve on the 1992–1995 3.9L V6 Dodge Ram Pickup.

The IAC valve plays a key role in maintaining a stable idle, and when it goes bad —or its wiring fails— the engine is gonna idle rough, stall, or refuse to stay running unless you keep your foot lightly on the gas pedal.

I'll walk you through step-by-step tests to check the IAC valve itself, its wiring, and the PCM circuits using a simple multimeter —no expensive diagnostic equipment required.

With each test, you'll get clear, actionable results to help you pinpoint the issue and fix it right the first time.

Contents of this tutorial:

- What Does The IAC Valve Do?

- Symptoms Of A Bad Idle Air Control (IAC) Valve.

- Most Common Causes Of A Diagnostic Trouble Code 25.

- IAC Valve Connector Pinout.

- TEST 1: Connector Wiggle Test.

- TEST 2: Checking For Shorted IAC Valve Wires.

- TEST 3: Checking The IAC Valve Wires For A Short To Ground.

- TEST 4: Checking IAC Valve Stepper Motor Resistance (From FI Computer Connector).

- What If The PCM Itself Is Bad?

- How To Repair Shorted IAC Wires (Real-World Fix).

- More 3.9L V6 Dodge Ram Pickup Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 3.9L V6 Dodge Ram 150 Pickup: 1989, 1990, 1991, 1992, 1993.

- 3.9L V6 Dodge Ram 250 Pickup: 1989, 1990, 1991, 1992, 1993.

- 3.9L V6 Dodge Ram 1500 Pickup: 1994, 1995.

- 3.9L V6 Dodge Ram 2500 Pickup: 1994, 1995.

1996-2001 IAC VALVE TESTS:

What Does The IAC Valve Do?

On the 1992-1995 3.9L V6 Dodge Ram Pickup, the idle air control (IAC) valve valve is located on the back of the throttle body assembly and is connected to the intake manifold air stream.

The IAC valve is responsible for managing and maintaining the engine's idle speed. It ensures that the engine continues running smoothly when the throttle plate is closed —like when you're sitting at a stoplight or coasting with your foot off the gas.

This component is a four-wire stepper motor assembly. Internally, it contains two small stepper motors —and each motor is controlled by a pair of wires connected directly to the PCM.

The PCM sends electrical pulses to these motors, which precisely move a pintle (a round needle-like valve) in or out of an air passage inside the throttle body.

As this pintle moves, it opens or closes the bypass air passage that routes air around the closed throttle plate.

By adjusting this bypass airflow in very small increments, the IAC valve allows the PCM to fine-tune the amount of air entering the engine during idle conditions, ensuring stable and responsive idle RPMs.

Let's look at two real-world examples of the IAC valve at work:

- Coming to a stop or releasing the gas pedal:

- As you let off the gas pedal, the throttle plate closes —but the engine still needs air to keep running.

- The PCM quickly responds by adjusting the IAC valve, allowing just the right amount of air to bypass the closed throttle plate.

- This prevents the engine from stalling and keeps idle RPM steady while you're coasting, braking, or waiting at a stop.

- When an electrical or mechanical load is applied:

- Turning on accessories like the A/C compressor, headlights, or power steering adds extra load to the engine.

- The PCM senses this and immediately commands the IAC valve to open slightly more, increasing airflow and raising the idle speed just enough to maintain smooth operation.

- Without this automatic adjustment, the engine might stumble or stall under the added strain.

In short, the IAC valve is a small but critical component that allows the PCM to adapt idle speed on the fly —whether the load is changing, the throttle is closing, or the engine is simply trying to stay alive at idle.

Symptoms Of A Bad Idle Air Control (IAC) Valve

The PCM constantly monitors the IAC valve's electrical system. If it detects something off —such as:

- Voltage levels or resistance values in the IAC valve circuit that fall outside the expected range —usually caused by shorted or open wiring between the IAC valve and the PCM connector.

- Idle speed readings that don't match the idle speed the PCM is commanding.

...it'll trigger Code 25: Idle Air Control (IAC) Circuits and illuminate the check engine light (CEL).

When there's an issue with the IAC system, you're likely to notice one or more of these common symptoms:

- Stalling or low idle: The engine may die unless you keep your foot lightly on the gas pedal.

- Idle speed is unusually high or unstable: You might see RPMs hovering around 1500, or fluctuating up and down erratically.

- Rough idle: The engine runs unevenly when sitting still, often with a noticeable vibration.

- Normal idle, but code is still present: Even if the engine seems to idle fine, the PCM might detect an electrical problem and store the fault code anyway.

Most Common Causes Of A Diagnostic Trouble Code 25

Below are some of the most frequent causes behind a Code 25 fault:

- Bad IAC valve: While it's built to last, it'll eventually wear out. The IAC valve contains a pair of stepper motor coils —if one burns out, the valve won't function properly.

- Pintle stuck due to carbon buildup: Over time, deposits can accumulate on the pintle, restricting its movement or preventing it from sealing correctly, which disrupts the PCM's ability to adjust idle airflow accurately.

- Bad IAC electrical connector: If the connector is damaged, the electrical connection to the valve becomes unreliable, interrupting the PCM's control of the IAC valve.

- Open or Grounded IAC wiring: A break in the wire (open-circuit) or contact with bare metal (short to Ground) is a common issue that blocks the PCM's signals from reaching the IAC valve.

- IAC wires shorted to battery power: Another frequent issue —if the IAC valve wires carrying power and Ground are damaged and touch (short together), unwanted voltage can enter the Ground circuit and disrupt the PCM's control of the valve.

- PCM malfunction: Rare but possible —an internal failure in the PCM's IAC control circuit can prevent it from sending movement commands to the valve entirely.

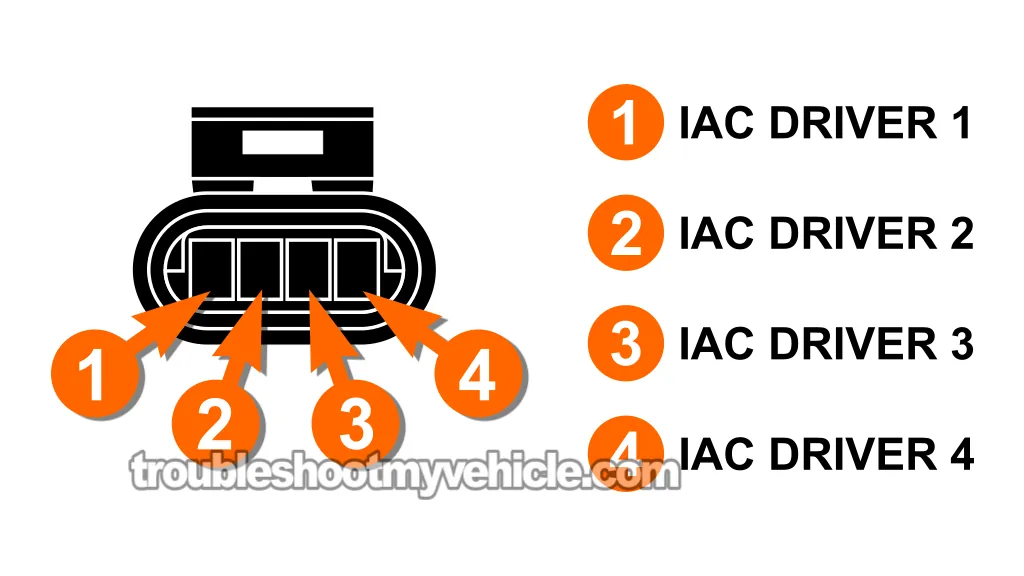

IAC Valve Connector Pinout

| 1996-2001 IAC Connector Pinout | ||

|---|---|---|

| Pin | Wire Color | Description |

| 1 | Grey with red stripe (GRY/RED) | IAC Driver 1 |

| 2 | Yellow with black stripe (YEL/BLK) | IAC Driver 2 |

| 3 | Brown with white stripe (BRN/WHT) | IAC Driver 3 |

| 4 | violet with black stripe (VIO/WHT) | IAC Driver 4 |

NOTE: The violet with white stripe (VIO/WHT) wire is also referred to as the purple with white stripe (PPL/WHT) wire.

TEST 1: Connector Wiggle Test

Over time, connectors and wires can develop hidden faults that only show up when the engine is vibrating or the wiring is moved around.

A quick and effective way to uncover these intermittent issues is by performing a wiggle test on the IAC valve connector and its wiring.

This test can help you catch loose terminals, broken wires, or internal shorts that might not be visible from the outside.

If moving the connector or harness causes a change in idle speed, you've found the root of the IAC valve problem.

IMPORTANT SAFETY NOTE: Since this procedure is done while the engine is running, be extremely careful. Keep your hands, tools, and clothing well away from spinning components —including the cooling fan, drive belts, and pulleys. Stay alert while working around a running engine.

Here's how to perform the wiggle test:

- 1

Start the engine and let it settle into an idle.

- 2

Gently move/wiggle the IAC connector and the wires leading into it.

Gently flex and shift the wires along their length, working your way back to where they merge with the main engine harness. - 3

Watch the idle speed as you wiggle the wiring.

If the RPM stays constant, the wiring and connector are fine. But if the engine stutters, drops in RPM, or stalls out —you've found a wiring or connector fault. - 4

Once you're done, shut off the engine.

Now, let's break down what the test results tell you:

CASE 1: Engine stumbles, surges, or shuts off when the connector or wires are moved. This confirms a bad connection or a loose wire inside the IAC 4-wire connector.

Replace the connector or if the fault lies within the wires, repair or replace the damaged section.

NOTE: If you're splicing in new wire, avoid crimp (butt) connectors —solder the splice instead. The heat and constant vibration in the engine bay will loosen crimped connectors over time, leading to hard-to-trace intermittent failures.

For more info on repairing the IAC valve wires, see: How To Repair Shorted IAC Wires (Real-World Fix).

CASE 2: Wiggling the connector and wiring has no effect —idle remains stable. That's the result we want. It means the connector and its wiring are likely in good shape.

The next step is to test the continuity of the wires. Head to: TEST 2: Checking For Shorted IAC Valve Wires.

CASE 3: The engine won't start, or stalls out immediately after starting. This could point to something more serious —like a completely failed IAC valve, damaged wiring, or even a malfunction inside the fuel injection computer.

To continue your IAC valve diagnostic, go to: TEST 2: Checking For Shorted IAC Valve Wires.

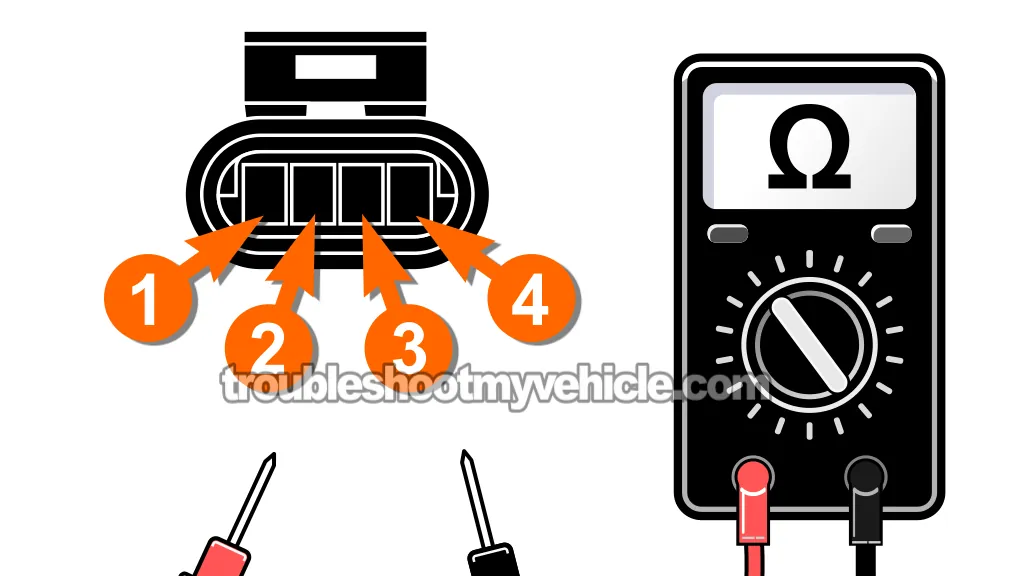

TEST 2: Checking For Shorted IAC Valve Wires

Each wire going to the IAC valve should be electrically isolated from the others —none of them should be shorted together.

In this test, we're going to check for any internal shorts between the wires by measuring resistance between each terminal at the IAC connector.

If any two terminals show continuity (low resistance), that's a problem —it usually means melted insulation or damaged wiring inside the engine wiring harness.

NOTE: Don't have a multimeter or need to upgrade yours? This is the one I use and recommend: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (at: amazon.com).

Follow these steps to carry out the test:

- 1

Turn the ignition OFF and disconnect the negative (–) battery cable from the battery terminal.

NOTE: This precaution helps protect your multimeter and prevents accidental shorts while testing. - 2

Unplug both the IAC valve connector and the FI computer's 60-pin connector.

- 3

Set your multimeter to Ohms mode.

- 4

Touch one probe of your multimeter to Terminal 1 on the IAC connector.

- 5

Use the other probe to check Terminals 2, 3, and 4 —one at a time.

- 6

No continuity should be detected —the multimeter should display infinite resistance between Terminal 1 and the rest.

- 7

Repeat the process for each of the other terminals.

Move the first lead to Terminal 2 and check against 3 and 4. Then do the same for Terminal 3. - 8

Have a helper wiggle the engine wiring harness.

While the probes are in place, your helper should gently flex and move the wiring harness near the IAC valve connector and along its path toward the PCM.

If the multimeter reading suddenly changes, you've found an intermittent short between wires.

If you get a low resistance reading —typically 5 Ohms or less— between any two terminals, it means those wires are shorted together.

Here's how to read your test results:

CASE 1: Multimeter shows infinite resistance (or OL) between all terminals. That's the correct test result. Each wire is electrically separate as it should be —no shorts detected.

You're clear to move on to the next test: TEST 3: Checking The IAC Valve Wires For A Short To Ground.

CASE 2: There's continuity between two or more terminals —5 Ohms or less. That confirms the wires are shorting together somewhere along the harness.

The most common cause? Damaged insulation inside the engine wiring harness. Here are some tips on how to fix it: How To Repair Shorted IAC Wires (Real-World Fix).

CASE 3: Readings shift as you move the wiring harness —or you see sporadic continuity (5 Ohms or less). This confirms a short circuit issue, or an internal wire break that's making intermittent contact.

Worn or cracked insulation on the wires is often to blame. Follow the repair suggestions outlined here: How To Repair Shorted IAC Wires (Real-World Fix).