The distributor pickup coil generates two crucial signals that the fuel injection system needs to activate the ignition coil, the fuel injectors and fuel pump.

Sooner or later, the distributor pickup coil will fail, and when it does, the engine is not gonna start.

In this tutorial, I'll show you how to test the pickup coil to find out if it's bad and causing a no-start issue. All of the test steps are explained in plain English and in a step-by-step way.

Contents of this tutorial:

- What Does The Distributor Pickup Coil Do?

- Symptoms Of A Bad Pickup Coil.

- Distributor Connector Circuit Descriptions.

- Where To Buy The Distributor Pickup Coil.

- TEST 1: Checking The Pickup Coil's Resistance With A Multimeter.

- TEST 2: Testing The Pickup Coil's Output With A Multimeter.

- More 1.6L Toyota Corolla Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 1.6L (4A-FE) Toyota Corolla: 1989, 1990, 1991, 1992.

Ignition System Tests:

- How To Test The Ignition Coil (1989-1992 1.6L Toyota Corolla).

- How To Test The Igniter (1989-1992 1.6L Toyota Corolla).

Ignition System Wiring Diagram:

- Ignition System Wiring Diagram (1989 1.6L Toyota Corolla).

- Ignition System Wiring Diagram (1990-1992 1.6L Toyota Corolla).

Engine No-Start Diagnostics:

What Does The Distributor Pickup Coil Do?

Here are some key details about the pickup coil that will help us diagnose it in the tests to follow:

- Dual Sensor Assembly: The distributor pickup coil is actually two sensors in one assembly. It produces two distinct AC voltage signals:

- The G1 signal: This signal serves as the actual crankshaft position (CKP) signal.

- The NE signal: This signal is an RPM reference signal.

- Magnetic Sensor: The pickup coil consists of two magnetic sensors and two reluctor wheels (toothed wheels attached to the distributor shaft).

- Signal Creation: As the engine cranks (or runs), the reluctor wheels spin with the distributor shaft, and their teeth pass by the magnetic sensors, generating two AC voltage signals —G1 and NE.

- The G1 signal provides the fuel injection computer with the crankshaft position (CKP) reference.

- The NE signal is used as an RPM signal, giving the computer crucial engine speed data.

- Ignition Spark and Timing Control: The fuel injection computer uses these AC signals to determine when to trigger the ignition coil via the igniter (ignition control module).

- The ignition coil then produces a high-voltage spark, which is sent to the correct spark plug via the distributor cap and rotor.

Symptoms Of A Bad Pickup Coil

A faulty pickup coil can lead to serious engine performance issues, including difficulty starting or sudden stalling. The two most common signs of failure are:

- Engine fails to start:

- The igniter does not receive its IGT activation signal.

- The igniter does not activate the ignition coil.

- The fuel injection computer does not enable the fuel injectors.

- The fuel injection computer does not enable the fuel pump.

- Rough running and unexpected stalling:

- The engine may misfire, run inconsistently, or shut off without warning while driving.

- Ignition system trouble codes:

- Code 12: G and NE Signal Problem.

- Code 13: NE Signal Circuit Problem.

Distributor Connector Circuit Descriptions

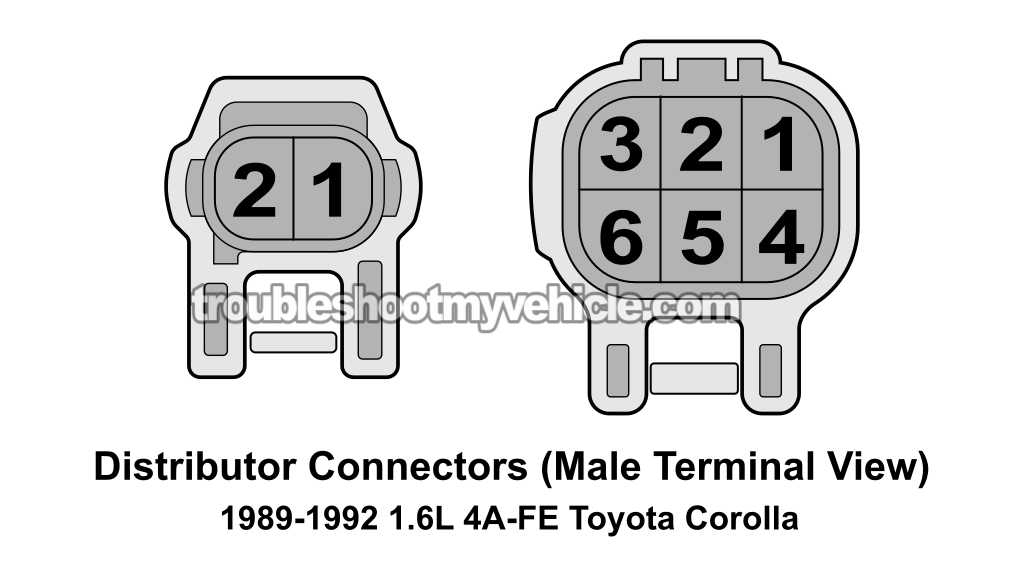

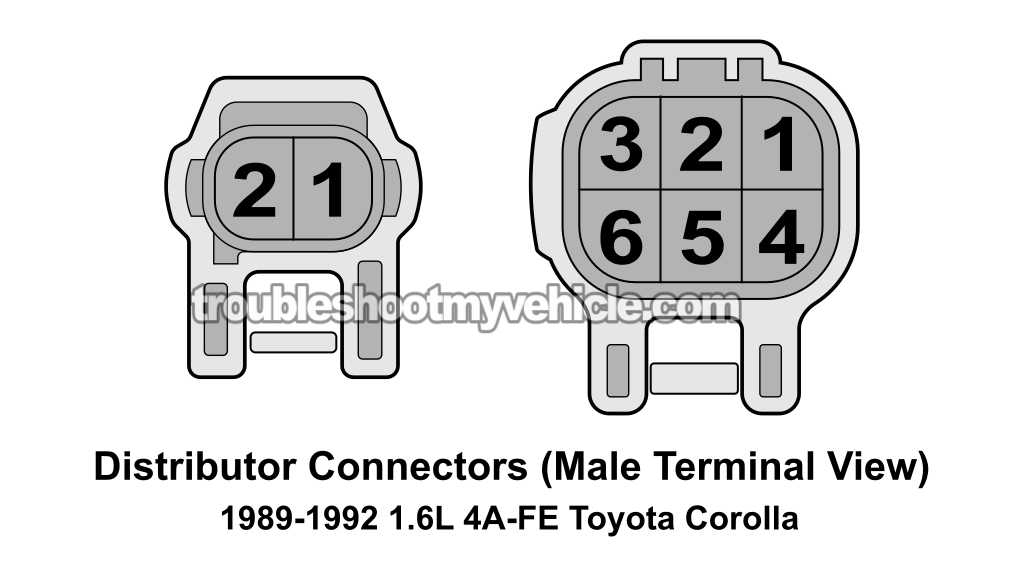

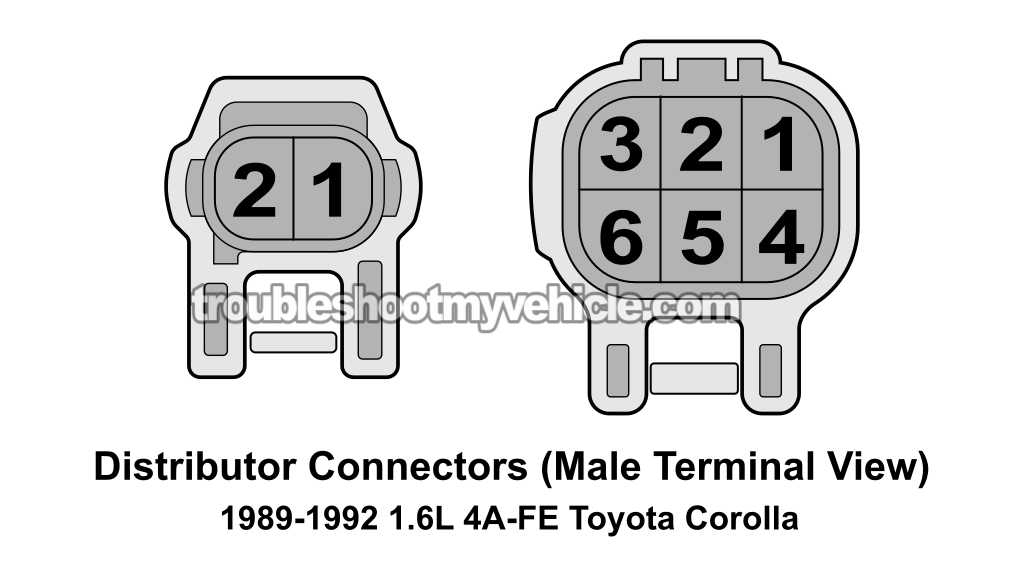

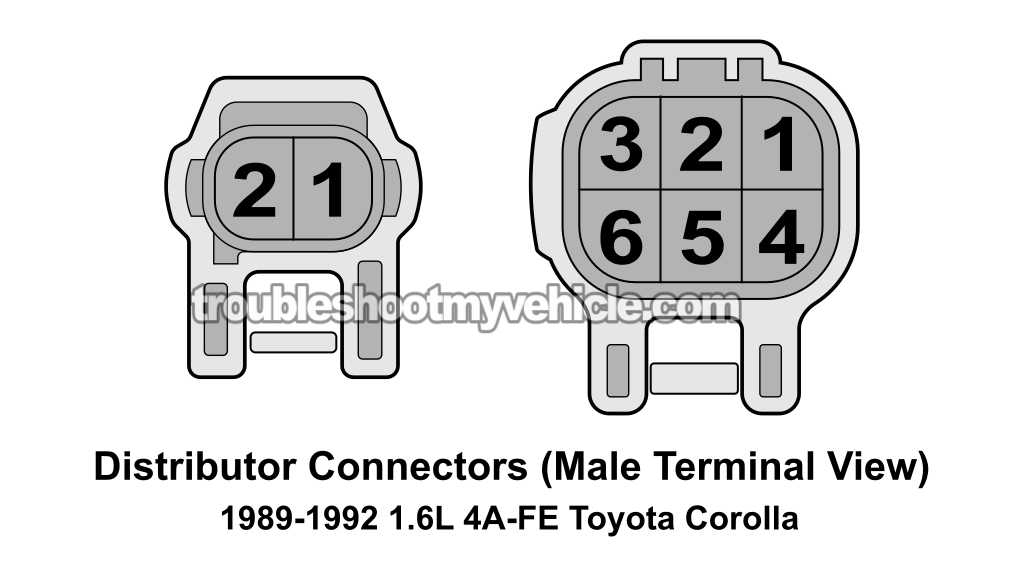

The distributor on your 1.6L Toyota Corolla has two connectors. One connector is a 2-wire connector and the other is a 6-wire connector (although this 6-wire connector only has 5 wires coming out of it).

NOTE: In the tables below, the color of the wires correspond to the engine wiring harness connectors, and not the connectors coming out of the distributor itself.

Here are the circuit descriptions of both connectors:

2-Wire Connector:

| Pin | Wire Color | Description |

|---|---|---|

| 1 | Black with orange stripe (BLK/ORG) | B+ → Ignition 12 Volts |

| 2 | Black (BLK) | IG- → Tachometer Signal |

6-Wire Connector:

| Pin | Wire Color | Description |

|---|---|---|

| 1 | Black (BLK) | IGT → Ignition Timing Signal |

| 2 | Red (RED) or Black (BLK) | NE → Engine Speed Signal |

| 3 | -- | Not Used |

| 4 | Black with yellow stripe (BLK/YEL) | IGF → Ignition Feedback Signal |

| 5 | White (WHT) | G- → Sensor Ground For G1 and NE |

| 6 | Black (BLK) | G1 → Crankshaft Position Signal |

NOTE: The distributor harness connector has female terminals. The connector coming out of the distributor itself has male terminals.

Where To Buy The Distributor Pickup Coil

The pickup coil isn't sold separately from the distributor, so if your test results indicate it's bad, you'll need to buy the entire distributor.

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

NOTE: Not sure if the distributor or spark plug wires fit your particular Corolla? Don't worry. Once you get to the site, they'll ask you for the specifics of your vehicle. If they don't fit, they'll find you the right ones.

TEST 1: Checking The Pickup Coil's Resistance With A Multimeter

When one of the two sensors in the distributor pickup coil assembly fails, it's usually due to an internal short circuit or an open circuit.

We can easily test the NE and G1 sensors for these issues using a multimeter set to Ohms (Ω) mode and that's what we'll do in this section.

If the NE and G1 circuits are functioning correctly (i.e., no internal shorts or open circuits), the multimeter should display the following resistance values:

- G1 Sensor: 130 and 210 Ohms (with the engine cold).

- NE Sensor: 130 and 210 Ohms (with the engine cold).

NOTE: This resistance tests are done on the distributor's 6-wire connector. This is connector that belongs to the distributor itself and has male spade terminals.

Let's get started:

- 1

Disconnect the distributor's 6-wire connector from its engine wiring harness connector.

- 2

Set your multimeter to Ohms mode.

- 3

Measure the resistance across the terminals 2 and 5 of the pickup coil connector.

Terminals 2 and 5 correspond to the NE sensor - 4

The multimeter should read 130-210 Ohms.

- 5

Measure the resistance across the terminals 6 and 5 of the pickup coil connector.

Terminals 6 and 5 correspond to the G1 sensor - 6

The multimeter should read 130-210 Ohms.

Let's interpret your test result:

CASE 1: The NE and G1 sensor resistance is within specification. This test result confirms that the pickup coil is functioning correctly.

Although not necessary, you can further confirm the pickup coil is good by performing TEST 2. Go to: TEST 2: Testing The Pickup Coil's Output With A Multimeter.

CASE 2: The NE and G1 sensor resistance IS NOT within specification. This test result confirms that the pickup coil is bad and needs replacement.

Since the distributor pickup coil assembly isn't sold individually, you'll need to replace the entire distributor.

Although not necessary, you can further confirm the pickup coil is bad by performing TEST 2. Go to: TEST 2: Testing The Pickup Coil's Output With A Multimeter.

TEST 2: Testing The Pickup Coil's Output With A Multimeter

When the engine is cranking, the G1 and NE sensors in the pickup coil assembly generate an AC voltage. We can easily test them using a multimeter set to Volts AC mode.

- If the G1 and NE sensors are functioning correctly, your multimeter should show an AC voltage reading between 0.4 and 1.2 Volts AC while the engine is cranking.

- If either sensor is faulty, the multimeter will display 0 Volts AC during cranking.

NOTE: The AC voltage output depends on the engine's cranking speed, which in turn relies on a fully charged battery. To get the most accurate test result, make sure the battery is fully charged before performing this test. If the battery is low, charge it fully first.

OK, let's get started:

- 1

Disconnect the 6-wire distributor connector from its engine wiring harness connector.

- 2

Set your multimeter to Volts AC mode.

- 3

Using your multimeter test leads, probe male spade terminals 2 and 5 of the 6-wire distributor connector.

Terminals 2 and 5 correspond to the NE sensor.

NOTE: You're probing the male spade terminals of the distributor's connector itself, not the female terminals of the engine wiring harness connector. - 4

Have a helper crank the engine while you observe the multimeter.

CAUTION: Be careful and stay alert as the engine is cranking. - 5

The multimeter should display an AC voltage oscillating between 0.4 and 1.2 Volts AC for the NE sensor.

- 6

Probe male spade terminals 6 and 5 of the 6-wire distributor connector.

Terminals 6 and 5 correspond to the G1 sensor.

NOTE: You're probing the male spade terminals of the distributor's connector itself, not the female terminals of the engine wiring harness connector. - 7

Have a helper crank the engine while you observe the multimeter.

CAUTION: Be careful and stay alert as the engine is cranking. - 8

The multimeter should display an AC voltage oscillating between 0.4 and 1.2 Volts AC for the sensor G1.

Now, let's interpret your test results:

CASE 1: The multimeter reported the indicated AC voltage for both sensors. This confirms that the G1 and NE sensors in the pickup coil assembly are functioning correctly.

CASE 2: The multimeter reported 0 AC voltage for one or both sensors. This indicates that the pickup coil assembly is faulty and needs replacement.

More 1.6L Toyota Corolla Tutorials

You can find a complete list of 1.6L Toyota Corolla tutorials and wiring diagrams in this index:

Here's a sample of the tutorials you'll find there:

- How To Test The Throttle Position Sensor (1989-1997 1.6L Toyota Corolla).

- How To Test Engine Compression (1989-1997 1.6L Toyota Corolla).

- How To Test The Fuel Injectors (1993-1997 1.6L Toyota Corolla).

- How To Do A Cylinder Balance Test (1989-1997 1.6L Toyota Corolla).

If this info saved the day, buy me a beer!