Sooner or later, you're going to run into a problem that'll have you checking the continuity of a wire (circuit) between a component and the 104-pin PCM connector. That component could be a sensor, a solenoid, or a control module —with one or more circuits leading straight to the PCM.

The thing is, when you're testing the continuity of a circuit between the component connector and the PCM connector, you've got to use the right tool and the right method. If you don't, you risk damaging the PCM's terminals —and trust me, that's a headache you don't want.

So in this guide, I'm going to share some solid, experience-based tips on what to do (and what not to do) so you can safely test those circuits between the PCM connector and the component connector without damaging your Ford Windstar's PCM connector.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 3.8L V6 Ford Windstar: 1995, 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003.

What I Don't Do (And Why)

The Powertrain Control Module (PCM) on the 1996-2003 3.8L V6 Ford Windstar is an EEC-IV fuel injection computer equipped with a 104-pin connector.

It's located in the engine compartment and uses a weather-sealed connector designed to withstand heat, vibration, and —most importantly— moisture.

There are two very important things you need to know about these weather-sealed PCM connectors:

- Each wire passes through a small rubber seal as it enters the PCM connector before attaching to the metal terminal inside. These seals keep moisture from entering the connector, which in turn prevents the corrosion that moisture would cause on the metal terminals.

- The round female terminals inside the PCM connector are very small and can easily deform if the wrong probe is used to test from the front of the connector.

Whether you're back probing from the rear (where the wire enters the connector) or front probing from the face of the connector (where the metal terminals are), there are risks you need to watch out for:

- Back probing the connector: When you insert a back probe, it has to pierce through the rubber seal to contact the metal terminal. Once you remove it, that tiny hole in the seal can allow moisture to enter, eventually corroding the terminal and causing connection problems.

- Front probing the connector: If the probe is too thick, it can spread or deform the small metal terminal when inserted. This permanently weakens the connection and may lead to intermittent electrical or drivability issues down the road.

Either way, the wrong probing method can set the stage for hard-to-diagnose electrical problems later on —so it pays to use the right tools and the right method.

Here's what I avoid when probing the PCM connector:

-

I never use standard multimeter leads to probe the front of the female terminals.

The probes on regular test leads are too thick to probe the front of the female terminals. Since the metal terminal itself is recessed into the connector, the only way for the multimeter probe to make contact is by using force to get that metal-to-metal connection. This can easily damage or spread the terminal, causing loose or false connections that'll lead to performance issues down the road. And that's something you definitely want to avoid.

-

I don't back-probe the connector either.

Back-probing the PCM connector seems to be the standard practice, but as I've mentioned before, this method damages those small rubber seals the wires pass through. Once a probe pierces a seal, you've now created a path for moisture to enter the connector —and that's what starts corrosion on the terminals. Add engine heat and vibration, and you've got the perfect conditions for that damage to accelerate.

So what's the safe way?

Over the years, working as an automotive diagnostic technician, I've tested circuits between the PCM connector and the component connector more times than I can count —and I've learned a few things along the way. One of them is that testing the front of the terminal can be done, but it has to be done with precision automotive test probes.

The tips on these probes are much thinner than regular multimeter leads, so when I use them, I can test without risking damage or spreading the female terminals in the PCM connector.

Personally, I use a wire-piercing probe kit that lets me remove the needle probe from the housing and use it directly on the front of the PCM terminals:

- Goupchn 4mm Banana to Banana Plug Test Leads Kit (Amazon affiliate link).

Here are some other kits that'll also do the job:

- AUTOOL 68PCS Multimeter Test Leads Kit (Amazon affiliate link).

- LUTIFIX 68PCS Automotive Circuit Test Leads Kit (Amazon affiliate link).

The only downside to precision probes is the price —some of them aren't cheap. And the other thing is, you usually have to order them online and wait for delivery. But let me tell you, compared to the nightmare of damaging the PCM connector and having to replace the entire engine wiring harness because of it, you're way better off spending the money on those probes. In the end, they're worth every penny.

The Safe, Low-Cost Method I Use

I always recommend using precision probes with thin tips when testing the front of the PCM connector terminals. But if you don't have any on hand, there's still a safe way to get the job done. This simple method is one I've used for years to safely probe the front of the female terminals on the PCM connector.

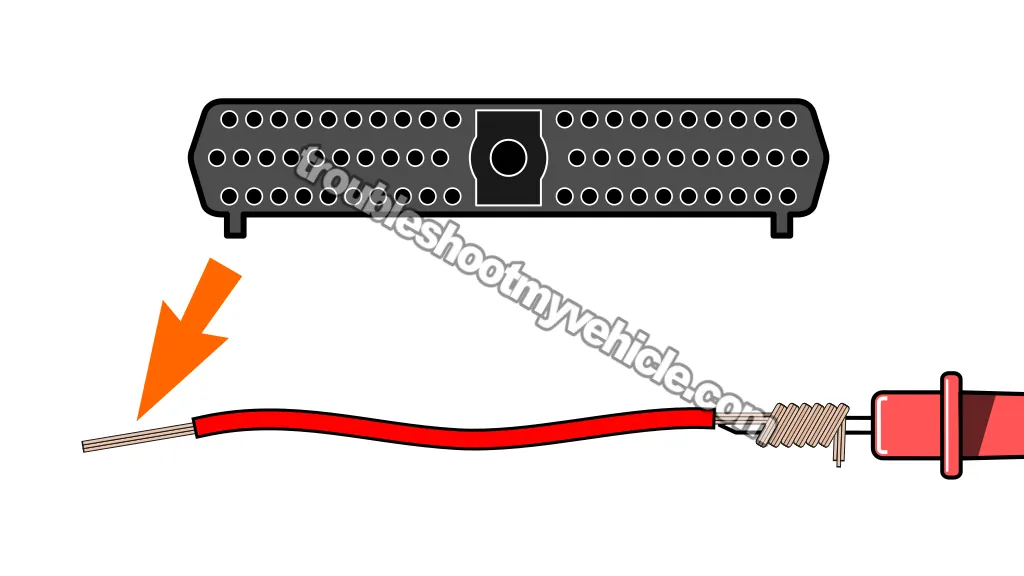

All right —in a nutshell, this method uses a short piece of wire as the probe. Strip the insulation from both ends. One end slips into the round female terminal of the connector, and the other end wraps around your multimeter test lead.

Now, here are the specifics of how to do it.

- Grab a small piece of scrap wire, about 3 to 4 inches long. I usually pull one from an old engine wiring harness, but any automotive-grade wire you've got lying around will do just fine.

- Strip about ½ to 1 inch of insulation off both ends of the wire.

- On one end, wrap the bare copper strands tightly around the metal tip of your multimeter lead. You want a good, solid connection here.

- Wrap a small strip of electrical tape around the test lead where the copper is wrapped.

- This keeps the connection tight and also insulates it, so the exposed wire doesn't accidentally touch metal and throw off your reading.

- On the other end, insert the bare copper into the PCM connector terminal (the same side the PCM plugs in —not the back).

- If the wire has too many strands to slide in cleanly, just trim a few off with wire cutters. You want it to go in with slight resistance, enough to make a good and solid contact.

This method gives you a clean, reliable connection to the PCM terminal with no risk of spreading or damaging it. When you're done testing, just pull the wire out and plug the connector back in like normal.

Always Disconnect The Battery Before Working On The PCM Connector

Anytime you need to disconnect or reconnect the PCM on your Ford Windstar, it's super important to disconnect the battery's negative (-) cable from the post first. Now, let me explain why this isn't just good practice —it's critical.

The PCM's internal circuits are extremely sensitive to voltage spikes and can be damaged in an instant if power is still present while you're plugging or unplugging the 104-pin connector. Even a tiny static charge spark could cause an internal failure. Believe you me, that's a nightmare you don't want to deal with.

So before you touch that PCM connector, pull the key out of the ignition and disconnect the battery's negative (-) cable.

Now, there are a few tests where, after you've disconnected the connector from the PCM, you'll need to reconnect the battery's negative cable —specifically when you're checking for power at certain PCM terminals. In those cases, it's totally fine for the PCM connector to stay unplugged from the PCM while your reconnect the battery (to supply voltage for those specific terminals during your test).

The key thing to remember is this: once you've finished checking for power, and you're ready to reconnect the PCM connector, always disconnect the battery's negative cable first before plugging it back in.

No matter what kind of test you're running, keep this rule in mind —the battery must always be disconnected from its negative (-) battery cable anytime you disconnect or reconnect the PCM connector.

More 3.8L V6 Ford Windstar Diagnostic Tutorials

You can find a complete list of diagnostics tutorials for the 3.8L V6 Windstar in this index:

Here's a small sample of the tutorials you'll find in the index:

- How To Test The TPS (1996-1999 3.8L V6 Ford Windstar).

- How To Test The MAF Sensor (1996-1998 3.8L V6 Ford Windstar).

- How To Test For A Blown Head Gasket (1995-2003 3.8L V6 Ford Windstar).

- How To Do And Interpret An Engine Compression Test (1995-2003 3.8L V6 Ford Windstar).

If this info saved the day, buy me a beer!