Testing the alternator on the 1996-1998 Ford Windstar is a piece of cake —and the best part is, you don't need any expensive diagnostic equipment. A simple multimeter will do.

In this tutorial, I'm going to show you three specific tests you can run to figure out whether the alternator is toast and not charging the battery, or if the issue lies somewhere else.

All three tests are explained step by step so you can quickly and easily diagnose the alternator on your Windstar.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 3.8L V6 Ford Windstar: 1996, 1997, 1998.

1999-2003 ALTERNATOR TESTS:

Symptoms Of A Bad Alternator

Your Ford Windstar's alternator has one main job in life —to keep the battery charged so the engine will crank and start the next time you need it.

Besides charging the battery, the alternator also supplies electrical power to all of your vehicle's accessories while the engine is running —things like the headlights, A/C blower motor, radio, and power windows.

So when this bad boy fails, you'll usually see one or more of the following symptoms:

- Charge light: The battery indicator light will be glowing nice and bright on the instrument panel.

- Engine won't crank: The engine doesn't turn over. The only way to get it started is by jump-starting it with another vehicle.

- Battery fully discharged: The engine only cranks and starts after you've recharged the battery.

- Dim headlights: The front headlights shine with less than normal brightness when turned on.

TEST 1: Checking Battery Voltage With The Engine Running

Before you begin your alternator test, make sure your Windstar's battery is fully charged.

The reason is simple —you'll need to keep the engine running for about 5 to 10 minutes while performing the battery voltage test with the engine running. If the battery is weak or discharged and can't crank the engine, charge it completely first. Otherwise, you won't be able to get accurate test results.

As I mentioned at the beginning of this tutorial, the only tool you'll need is a multimeter. If you don't have one, or if you're looking to upgrade, this is the one I personally use and recommend. It's reliable, inexpensive, and perfect for this type of test: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (Amazon affiliate link).

Alright, let's kick things off:

- 1

Start the engine and let it idle.

NOTE: Be careful, since you'll be working around a running engine. - 2

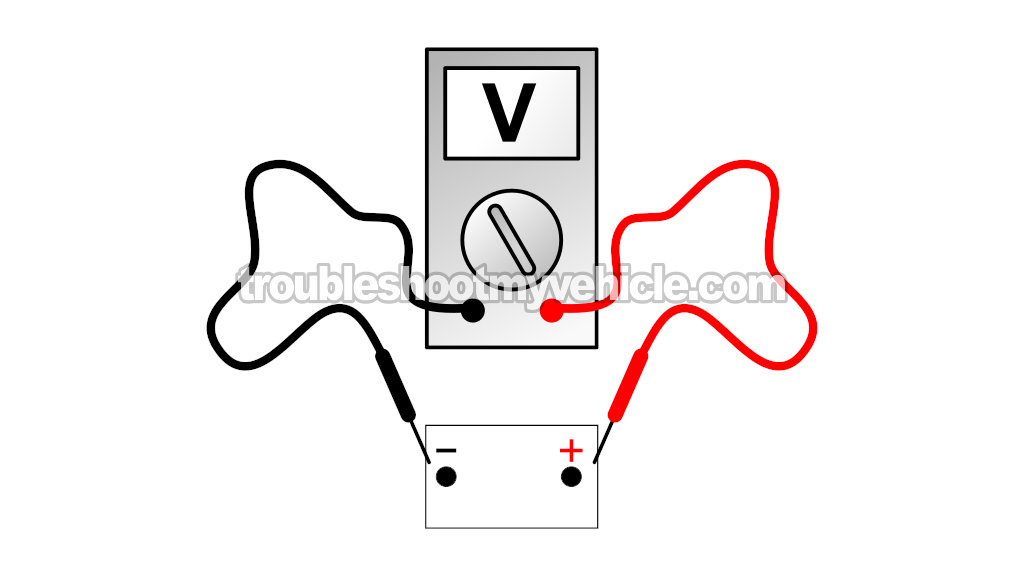

Place your multimeter in Volts DC mode.

- 3

Connect the red multimeter test lead to the battery positive (+) terminal.

- 4

Connect the black multimeter test lead to the battery negative (-) terminal.

- 5

Your multimeter should register 13.5 to 14.5 Volts DC.

If if doesn't, don't worry. Continue to the next step. - 6

Have an assistant turn ON everything and anything that uses electricity inside the vehicle like: headlights, windshield wipers, turn signals, a/c or heater blower on high, etc.

This will put an electrical load on the alternator to either confirm it's really working or it's fried. - 7

Your multimeter will register one of two things:

1.) The multimeter will register a nice and steady 13.5 to 14.5 Volts DC no matter what gets turned on.

2.) It will register 12.5 Volts DC and this voltage will decrease more and more as you turn on stuff inside your vehicle.

Let's see what your test result is telling us:

CASE 1: Battery voltage stayed steady between 13.5 and 14.5 Volts. Perfect —this tells you that the alternator is functioning correctly and charging the battery as it should.

If you still find a dead battery every time you try to start the engine, you can rule out the alternator as the problem since it's clearly doing its job. In that case, the issue is most likely caused by one of the following:

- A bad battery that no longer holds a charge and needs to be replaced.

- A parasitic load (electrical drain) that's discharging the battery overnight when the engine is off.

CASE 2: Battery voltage steadily drops to around 9 Volts as the engine runs. This confirms that the alternator isn't charging the battery.

In most cases, this means the alternator is bad and needs to be replaced. However, to be absolutely certain that it's toast, we'll perform two more easy checks. For the first of these, head over to: TEST 2: Testing The Continuity Of The Battery Circuit.

TEST 2: Testing The Continuity Of The Battery Circuit

The alternator's output is delivered to the battery through a large cable that attaches to the top of the alternator with a stud and nut.

Before this BAT+ cable reaches the battery, it passes through two inline fusible links —and there's always a chance that one or both of these fusible links could be blown.

In this test section, we're going to check the condition of this circuit by doing a simple continuity test with your multimeter set to Ohms mode.

If the BAT+ circuit shows continuity, then we can conclude that the inline fusible link is OK, and we'll move on to the next test.

Alright, here we go:

- 1

Disconnect the battery negative (-) cable from the battery.

NOTE: This is important, do not proceed beyond this point without first disconnecting the battery negative (-) cable. The battery positive cable must remain connected to the battery. - 2

Set your multimeter to Ohms mode.

- 3

Place the red multimeter test lead on the center of the stud to which the large wire is attached to with a nut.

The arrow in the photo above points to this BATT+ stud. - 4

With the black multimeter test lead, probe the center of the battery positive (+) post on the battery.

- 5

You'll see one of two results on your multimeter:

1.) No Continuity —If the inline fusible links protecting this circuit is blown, your multimeter will indicate a reading of OL (which means over limit).

2.) Continuity —If the inline fusible links are OK and not blown, your multimeter will register an Ohms reading of 0.5 Ohms or less.

OK, let's take a look at what your results mean:

CASE 1: The BAT+ circuit has continuity. This is the correct and expected test result. It confirms that both inline fusible links are OK and not blown.

For our last alternator test, we'll make sure the voltage regulator is getting its 12-Volt power supply. For this next step, head over to: TEST 3: Making Sure The Voltage Regulator Is Getting 12 Volts.

CASE 2: The BAT+ circuit does not have continuity. This tells you that one or both fusible links are blown. Even if the alternator were charging, that output would never reach the battery.

Your next step is to locate the fusible links, inspect them, and replace any that are blown with new ones of the same rating. Once the BAT+ circuit has continuity again, the alternator's charge will reach the battery, and the no-charge condition will be resolved.

NOTE: Still, it's a good idea to repeat the alternator tests afterward to confirm the repair fixed the issue.

TEST 3: Making Sure The Voltage Regulator Is Getting 12 Volts

The voltage regulator is the component that activates the alternator and gets it charging the battery. It's located inside the alternator assembly itself.

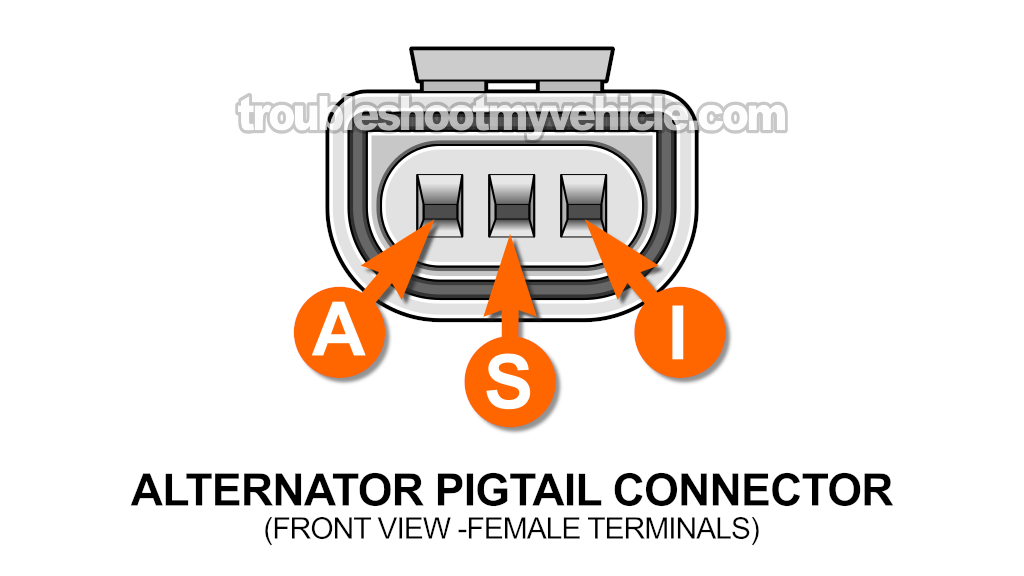

To do its job, the voltage regulator needs a steady 12-Volt power supply. These 12 Volts are delivered through the yellow (YEL) wire of the alternator's 3-wire connector (see the connector pinout illustration above to identify the connector and terminal layout).

This YEL wire connects to female terminal A and receives power through an inline fusible link.

To make sure the inline fusible link isn't blown and that terminal A is receiving 12 Volts, we're going to perform a simple multimeter voltage test at terminal A. This voltage is available at all times —it doesn't depend on the key position— so you should see power whether the key is OFF, RUN, or START.

Let's get started.

- 1

Reconnect the negative (-) battery cable to the battery's negative (-) post,.

- 2

Disconnect the 3-wire pigtail connector from the alternator.

This 3-wire connector connects to the alternator's voltage regulator. - 3

Set your multimeter to Volts DC mode.

- 4

Connect the black multimeter test lead to the battery negative (-) terminal.

IMPORTANT: The multimeter test lead must connect to a clean spot on the battery's negative (-) terminal. - 5

Connect the red multimeter test lead to the female terminal labeled with the letter A of the alternator's 3-wire pigtail connector (see the illustration above).

NOTE: Make sure that the terminal you're probing actually connects to the YEL/WHT wire. - 6

Your multimeter should register 10 to 12 Volts DC.

NOTE: Power is present at all times, no need to turn the key to the ON position.

Let's see what this result is telling us:

CASE 1: Terminal A has 10 to 12 Volts present. This is the correct and expected test result. It confirms that the voltage regulator is getting the power it needs to activate the alternator and start charging the battery.

You can now conclude that the alternator is bad and needs to be replaced only if the following have also been confirmed:

- TEST 1: Battery voltage steadily decreases as the engine runs and as you turn on accessories (headlights, blower motor, etc.).

- TEST 2: The BAT+ circuit has continuity.

- This test section: Terminal A has 10 to 12 Volts present.

CASE 2: Terminal A does not have battery voltage. Without this voltage, the alternator cannot charge the battery since the voltage regulator won't activate.

This test result confirms that the alternator itself is not the cause of the no-charge condition on your Ford Windstar.

Your next step is to locate the inline fusible link that connects to the YEL wire and check its condition. If it's blown, replace it with a fusible link of the same rating. Once terminal A has power again, the alternator should begin charging the battery normally.

More 3.8L V6 Ford Windstar Diagnostic Tutorials

I've written quite a few diagnostic tutorials for the 3.8L V6 Ford Windstar —and you can find them all in this index:

Here's a sample of the tutorials you'll find in the 3.8L V6 Ford Windstar index:

- How To Test The MAF Sensor (1996-1998 3.8L V6 Ford Windstar).

- How To Test The TPS (1996-1999 3.8L V6 Ford Windstar).

- How To Test For A Blown Head Gasket (1995-2003 3.8L V6 Ford Windstar).

- How To Do And Interpret An Engine Compression Test (1995-2003 3.8L V6 Ford Windstar).

If this info saved the day, buy me a beer!