The alternator on your 1999–2003 3.8L V6 Ford Windstar is a PCM-controlled alternator. In other words, it's the Powertrain Control Module (PCM) that tells the alternator when to start charging the battery and how much current to produce for the electrical loads you turn ON —like the headlights, A/C blower, or rear defogger.

Even though this alternator is computer-controlled, it's actually one of the easiest charging systems to understand and diagnose, and it doesn't require any expensive diagnostic equipment to do it.

In this tutorial, I'm going to explain the basic operating theory behind this system —specifically how the PCM communicates with the alternator through the GEN-COM and GEN-MON duty-cycle signals.

I'll also include links to the step-by-step testing guides to diagnose a bad alternator and the GEN-COM and GEN-MON signal tests.

Contents of this tutorial:

- Voltage Regulator And PCM Communication Basics.

- GEN-COM (Command): How The PCM Controls Alternator Output.

- GEN-MON (Feedback): How The PCM Knows What's Really Happening.

- BATT-SENSE (Voltage Reference): How The PCM Keeps Its Finger On The Battery's Pulse.

- More 3.8L V6 Ford Windstar Diagnostic Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 3.8L V6 Ford Windstar: 1999, 2000, 2001, 2002, 2003.

BAD ALTERNATOR TEST AND SIGNAL DIAGNOSTIC TESTS:

- How To Test The Alternator (1999-2003 3.8L V6 Ford Windstar).

- Alternator PCM Control Signal Tests –GEN-COM, GEN-MON (1999–2003 3.8L V6 Ford Windstar).

Voltage Regulator And PCM Communication Basics

In a nutshell, the alternator's internal voltage regulator is in constant communication with your Ford Windstar's Powertrain Control Module (PCM).

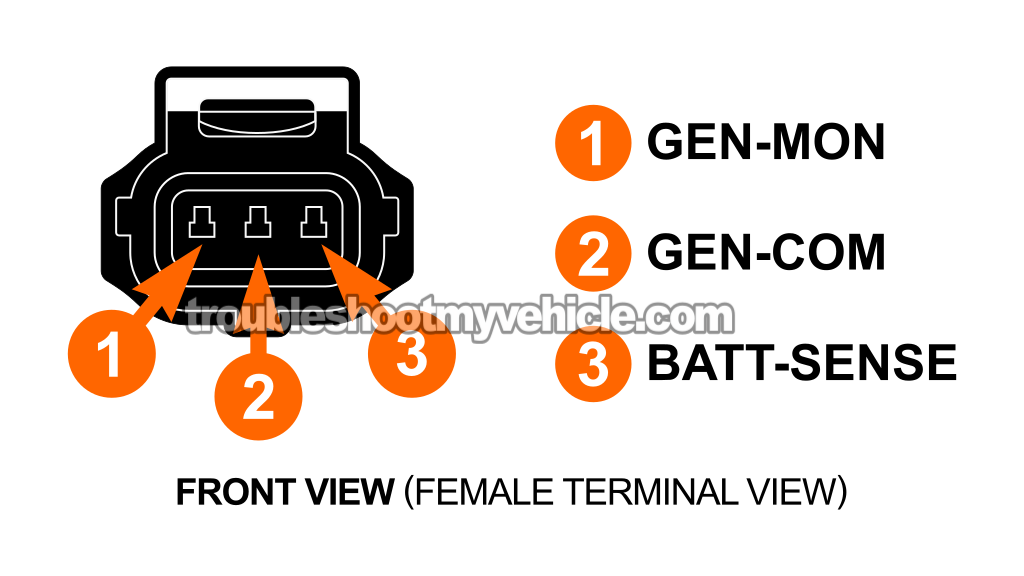

To be a bit more specific, the PCM takes an active role in the alternator's output —it commands how hard the alternator should work and monitors how hard it's actually working. That two-way conversation happens over two wires (circuits) of the alternator's 3-wire connector:

- GEN-COM: PCM ➜ Regulator (the command line).

- GEN-MON: Regulator/Alternator ➜ PCM (the feedback line).

There's also a BATT-SENSE feed (wire) for system voltage awareness, but the magic is in those two PWM lines.

GEN-COM (Command): How The PCM Controls Alternator Output

The GEN-COM circuit —the RED/PNK wire— carries the command signal from the PCM to the voltage regulator (which is located inside the alternator).

This is a duty-cycled signal —meaning the PCM switches the circuit's Ground ON and OFF rapidly to control alternator output.

It operates between 0% and 99% duty cycle, which means the PCM can vary how long it keeps this circuit Grounded during each pulse cycle.

In a perfectly functioning alternator and charging system, you'll see:

- The alternator's voltage regulator outputs 12 Volts (battery voltage) on the RED/PNK wire.

- At 0% duty cycle, the PCM isn't commanding the alternator to charge —so the RED/PNK wire stays at 12 Volts.

- At medium duty cycles (around 40–60%), the PCM is telling the alternator to maintain normal output —you'll see the voltage pulled down to a value around 8.7 to 5.8 Volts on the wire.

- At high duty cycles (80–99%), the PCM is commanding the alternator to produce maximum output —you'll see a voltage value around 2.9 to 0.3 Volts on the wire.

The key things to remember are:

- The higher the duty cycle, the lower the voltage reading on your multimeter, since the PCM is wanting more output from the alternator and thus Grounding the circuit more often.

- The lower the duty cycle, the higher the voltage reading on your multimeter, since the PCM is wanting less output from the alternator and Grounding the circuit less often.

- And most importantly, this signal is dynamic —you'll never see a fixed, steady voltage. It's constantly moving as the PCM and voltage regulator talk back and forth to keep the system in balance.

How To Test The GEN-COM Signal:

The absolute best way to check the GEN-COM signal is with a multimeter that has duty cycle capability since it can show you exactly how much time (out of each pulse cycle) the PCM is Grounding the RED/PNK wire —giving you a precise percentage value, such as 45% or 75%.

But even if you don't have a multimeter with duty cycle (%) capability, you can still check the GEN-COM signal accurately using Volts DC mode.

Since the voltage regulator keeps the GEN-COM line at 12 Volts and the PCM Grounds it to control alternator output, the average voltage on the line directly reflects that duty cycle.

So, by watching the voltage drop toward 3 or 1 Volt under load, you can tell the PCM is commanding more alternator output —just like reading a higher duty cycle.

GEN-MON (Feedback): How The PCM Knows What's Really Happening

The GEN-MON circuit —the violet (VIO) wire— carries the feedback signal from the alternator's voltage regulator back to the PCM.

Just like the GEN-COM signal, this is a duty-cycled circuit —but this time, it's the voltage regulator (not the PCM) that pulls the line to Ground.

It tells the PCM how hard the alternator is working —in other words, how much load is being placed on it.

It operates between 6% and 98% duty cycle, which means the regulator can vary how long it keeps this circuit Grounded during each pulse cycle to report alternator load and field current.

Here's a more detailed breakdown (in a good alternator and fault-free charging system):

- The PCM supplies 12 Volts (battery voltage) on the VIO wire.

- At 6% duty cycle (very light load), the alternator is hardly working —the line stays high most of the time, so you'll see around 11.3 Volts on your multimeter.

- At medium duty cycles (40–60%), the alternator is doing moderate work —the regulator Grounds the VIO wire about half the time, and you'll see roughly 7 to 5 Volts.

- At high duty cycles (80–98%), the alternator is under heavy load —the wire spends most of its time Grounded, and you'll see a reading between 3 and 0.2 Volts.

The key things to remember are:

- The higher the duty cycle, the lower the voltage reading on your multimeter, because the regulator is pulling the circuit (VIO wire) to Ground more often to report a heavier load.

- The lower the duty cycle, the higher the voltage reading, because the alternator isn't working hard and the wire stays near battery voltage most of the time.

How To Test The GEN-MON Signal:

The most accurate way to test the GEN-MON signal is with a multimeter that has duty cycle capability, since it can show you the exact percentage of time the regulator is Grounding the circuit —for example, 25%, 50%, or 90%.

That gives you a precise look at how much load the alternator is reporting to the PCM.

However, you can still verify this signal perfectly well using a standard multimeter set to Volts DC.

Because the PCM supplies 12 Volts and the voltage regulator pulls the line to Ground as load increases, the average voltage you see on your multimeter directly reflects the duty cycle.

So, if the alternator is under heavy load and your meter shows the VIO wire voltage dropping toward 1 Volt, you know the regulator is signaling high alternator output to the PCM —just as it would if you were reading a 90–98% duty cycle.

BATT-SENSE (Voltage Reference): How The PCM Keeps Its Finger On The Battery's Pulse

The BATT-SENSE circuit —the orange with light blue stripe (ORG/LT BLU) wire of the alternator's 3-wire connector— provides the voltage reference the PCM and voltage regulator use to monitor actual battery voltage.

Unlike the GEN-COM and GEN-MON circuits, the BATT-SENSE wire isn't pulse-width-modulated. It simply carries a steady DC voltage that mirrors battery voltage at all times. This allows both the PCM and the voltage regulator to "see" what the system voltage really is.

Here's how it works in practice:

- The BATT-SENSE female terminal (of the alternator's 3-wire connector) connects directly to the battery's positive side:

- 1999-2000 Windstar: To an inline fusible link.

- 2001-2003 Windstar: To Fuse 13 (10A) located in the Battery Junction Box.

- Battery voltage should be present on this wire at all times —usually between 12.4 V and 14.5 V, depending on charging state.

- The voltage regulator uses this signal to compare desired vs actual voltage and to decide how much field current to apply.

- At the same time, the PCM monitors the same voltage level to verify the system is charging correctly and to adjust the GEN-COM command signal if needed.

In short, the BATT-SENSE circuit gives both the PCM and the voltage regulator a real-time snapshot of battery voltage, allowing the control system to maintain stable charging under all operating conditions.

How To Check The BATT-SENSE Circuit:

With the key ON or engine running, you should read battery voltage (within about 0.5 V of what you see directly at the battery posts).

If the reading is significantly lower or missing, inspect inline fusible link (1999-2000) or fuse 13 of the Battery Junction Box (2001-2003) and the wiring between the fusible link/fuse box and the alternator connector.

A blown inline fusible link or fuse or corroded connection will prevent the alternator and PCM from seeing true battery voltage —and the alternator will either undercharge or fail to charge entirely.

More 3.8L V6 Ford Windstar Diagnostic Tutorials

I've written quite a few diagnostic tutorials for the 3.8L V6 Ford Windstar —and you can find them all in this index:

Here's a sample of the tutorials you'll find in the 3.8L V6 Ford Windstar index:

- How To Test The MAF Sensor (1996-1998 3.8L V6 Ford Windstar).

- How To Test The TPS (1996-1999 3.8L V6 Ford Windstar).

- How To Test For A Blown Head Gasket (1995-2003 3.8L V6 Ford Windstar).

- How To Do And Interpret An Engine Compression Test (1995-2003 3.8L V6 Ford Windstar).

If this info saved the day, buy me a beer!