When diagnosing wiring or sensor issues on your 3.9L V6 Dodge Ram pickup, it's often necessary to probe the PCM connector directly.

But if you're not careful, you can easily damage a terminal or compromise the weather seal —leading to hard-to-find electrical problems down the line.

In this guide, I'll show you the safe and reliable method I've used for years to test PCM circuits without risking costly damage.

Whether you're a seasoned tech or tackling this at home, this approach will help you get accurate readings while protecting the integrity of the PCM connector.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 3.9L V6 Dodge Ram 150 Pickup: 1989, 1990, 1991, 1992, 1993.

- 3.9L V6 Dodge Ram 250 Pickup: 1989, 1990, 1991, 1992, 1993.

- 3.9L V6 Dodge Ram 1500 Pickup: 1994, 1995, 1996, 1997, 1998, 1999, 2000, 2001.

- 3.9L V6 Dodge Ram 2500 Pickup: 1994, 1995, 1996, 1997, 1998, 1999, 2000, 2001.

What I Don't Do (And Why)

When it's time to check a PCM pin —like during a continuity test— I always use ultra-thin probes built for the job.

The safest option is to use a dedicated terminal testing probe, like the ones in the following links:

- AUTOOL 68PCS Multimeter Test Leads Kit (at: amazon.com).

- LUTIFIX 68PCS Automotive Circuit Test Leads Kit (at: amazon.com).

Trying to use standard test probes on PCM connectors is like using a butter knife for brain surgery —not a great idea. Those terminals are tiny, and most test leads are just too fat to fit safely.

Force them in, and you risk bending or damaging the connector —which can lead to loose connections, strange performance problems, or even a dead circuit.

Unfortunately, these skinny test probes aren't usually sold in local stores and can be pricey, which makes them tough to justify for a lot of folks.

Why I Don't Back-Probe PCM Connectors:

Even though back-probing is a tried-and-true technique, I steer clear of it when dealing with PCMs located in the engine compartment.

The rear of these connectors are built with weatherproof seals around the wires, as they enter the connector, to block out dirt and moisture.

Sliding a probe in from the back can pierce or stretch the rubber seal around the wire, which creates an open path for water and grime to sneak in.

That small puncture might not cause problems right away, but down the road it can trigger terminal corrosion, voltage drop, and complete circuit failure —especially in a harsh engine bay where heat, moisture, and vibration are always at play. For me, it's just not worth risking long-term damage.

The Safe, Low-Cost Method I Use

This is the simple, safe, and DIY-tested method I've used for years to probe a PCM connector without damaging the pins or weather seal (when you don't have the thin probes):

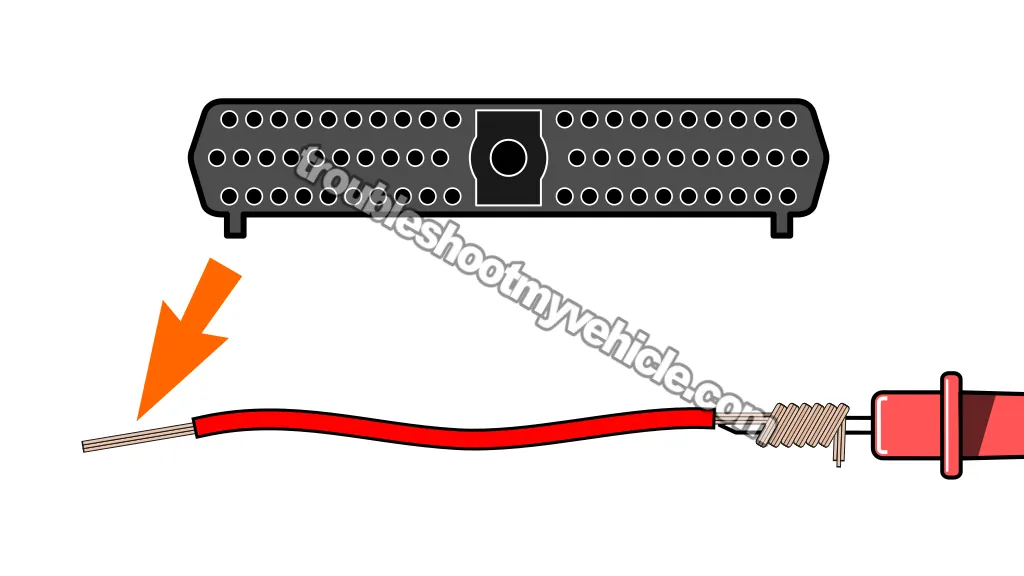

- Grab a short piece of scrap wire, around 3 to 4 inches long. I usually pull mine from an old engine harness, but any automotive-grade wire will do.

- Strip off about ½ to 1 inch of insulation from both ends of the wire.

- Take one end and tightly twist the bare copper around the metal tip of your multimeter lead. This creates a reliable connection point.

- Secure that connection with a bit of electrical tape around the lead where the wire is wrapped.

- The tape keeps it stable and insulates the connection so it doesn't accidentally touch anything metal and throw off your test results.

- Now take the other end and gently insert the bare copper into the PCM terminal from the front side —the same side the PCM plugs into.

- If the strands are too thick to slide in easily, trim a few off with cutters. You want a firm fit, not a tight one that forces the terminal open.

- Make sure it fits snugly —not loose, but also not crammed in. You're aiming for secure contact without stressing the terminal.

This trick gives you a clean connection to the PCM pin without risking any damage. Once your testing is done, just pull the wire out and reconnect everything like normal.

Remember, never force thick probes into any PCM terminal. Using this method takes a little extra care, but it'll help you avoid expensive problems later on.

Always Disconnect The Battery Before Disconnecting A PCM Connector

Before you disconnect, reconnect, or test anything at the PCM connector, the first thing you must do is disconnect the negative (–) battery cable.

This step isn't optional —it's critical. The PCM is full of delicate internal electronics that can be ruined in an instant if power is still present. A small spark, a static charge, or even brief contact while power is live can fry the circuit board inside.

So, remove the key from the ignition, give it a minute, then disconnect the battery's negative terminal before doing anything else at the PCM.

After you're done with your tests or repairs, go ahead and reconnect the battery as your last step.

More 3.9L V6 Dodge Ram Pickup Tutorials

I've written several more tutorials for the V6 Dodge Ram pickups that may be of interest to you that you can find in this index:

Here's a sample of the tutorials you'll find in the index:

- Does My Automatic Transmission Needs An Overhaul? (1996-2001 3.9L V6 Dodge Ram Pickup).

- How To Test The Ignition Coil (1992-2001 3.9L V6 Dodge Ram Pickup).

- How To Test The Fuel Pump (1992-2001 3.9L V6 Dodge Ram Pickup).

- How To Test For A Blown Head Gasket (1989-2001 3.9L V6 Dodge Ram Pickup).

If this info saved the day, buy me a beer!