With the help of this tutorial, you'll be able to check the spark plug wires, the distributor cap and rotor, and the ignition coil.

If any one of these ignition system components fail, you'll either have a cylinder misfire or an engine no-start problem.

I'm also gonna show you where you can find my step-by-step tutorial for testing both the camshaft position (CMP) sensor —also called the distributor pickup coil— and the crankshaft position (CKP) sensor.

Contents of this tutorial:

- Ignition System Test Basics.

- What Tools Do I Need To Test The Ignition System?

- Ignition Coil Circuit Descriptions.

- TEST 1: Testing The Spark Plug Wires For Spark.

- TEST 2: Testing For Spark At The Distributor Cap.

- TEST 3: Testing The Ignition Coil's High Tension Wire For Spark.

- TEST 4: Testing The Ignition Coil For Spark.

- TEST 5: Making Sure The Ignition Coil Is Getting 12 Volts.

- TEST 6: Testing The Ignition Coil's Activation Signal.

- Other Causes Of A Misfire.

- Where To Buy The Ignition Coil And Save.

- Where To Buy The Distributor Cap, Distributor Rotor, Spark Plug Wires And Save.

- More 3.9L V6 Dodge Ram Pickup Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 3.9L V6 Dodge Ram 150 Pickup: 1992, 1993.

- 3.9L V6 Dodge Ram 250 Pickup: 1992, 1993.

- 3.9L V6 Dodge Ram 1500 Pickup: 1994, 1995, 1996, 1997, 1998, 1999, 2000, 2001.

- 3.9L V6 Dodge Ram 2500 Pickup: 1994, 1995, 1996, 1997, 1998, 1999, 2000, 2001.

IGNITION SYSTEM WIRING DIAGRAM:

- Ignition System Wiring Diagram (1992-1993 3.9L V6 Dodge Ram Pickup).

- Ignition System Wiring Diagram (1994-1995 3.9L V6 Dodge Ram Pickup).

- Ignition System Wiring Diagram (1996-1997 3.9L V6 Dodge Ram Pickup).

- Ignition System Wiring Diagram (1998-2000 3.9L V6 Dodge Ram Pickup).

- Ignition System Wiring Diagram (2001 3.9L V6 Dodge Ram Pickup).

DISTRIBUTOR PICKUP COIL TESTS:

- How To Test The Camshaft Position Sensor (1992-1995 3.9L V6 Dodge Ram Pickup).

- How To Test The Camshaft Position Sensor (1996-1997 3.9L V6 Dodge Ram Pickup).

- How To Test The Camshaft Position Sensor (1998-2001 3.9L V6 Dodge Ram Pickup).

CKP SENSOR TESTS:

- How To Test The Crankshaft Position Sensor (1992-1997 3.9L V6 Dodge Ram Pickup).

- How To Test The Crankshaft Position Sensor (1998-2001 3.9L V6 Dodge Ram Pickup).

Ignition System Test Basics

The 3.9L V6 in 1992–2001 Dodge Ram pickup uses an old-school, distributor-style ignition setup. It's made up of a few key parts that all work together to get spark where it needs to go:

- Ignition coil: Generates and shoots out the high-voltage spark each cylinder needs to ignite the air/fuel mixture.

- Distributor: Sends that spark to the correct cylinder right when it's needed.

- Camshaft position (CMP) sensor: Tells the PCM which cylinder is approaching Top Dead Center (TDC) so it can keep ignition and fuel timing dialed in.

- Distributor cap and rotor: Work together to pass the spark along to the right cylinder in the right order.

- Crankshaft position (CKP) sensor: Monitors engine RPM and keeps the PCM in sync with the crankshaft's rotation.

- Spark plug wires (also known as high-tension wires): Carry the spark from the distributor to each spark plug.

So, what exactly goes down when you turn the key and fire up the pickup? Here's the rundown:

- CMP/CKP sensors kick in: These two sensors start sending cam and crank signals to the fuel injection computer (PCM).

- Ignition coil gets the green light: Once the PCM sees the CMP and CKP signals:

- It activates the ASD relay —which supplies voltage to the ignition coil and injectors.

- It enables the fuel pump relay.

- It triggers the ignition coil so it can start generating spark.

- It pulses the fuel injectors so they can spray fuel into the cylinders.

- Spark heads to the distributor: The ignition coil pushes the spark up a high-tension wire to the center of the distributor cap.

- Distributor rotor does its thing: Inside the cap, the spinning rotor picks up that spark and flings it to the right terminals under the cap.

- Spark fires the plugs: Finally, the spark travels through the plug wires and lights up each spark plug in turn.

I'm gonna show you, in this tutorial, how to test the ignition coil's high-tension wire, the spark plug wires, the distributor cap and rotor, and the ignition coil itself.

What Tools Do I Need To Test The Ignition System?

Before getting started with the ignition system tests on your V6 Dodge Ram pickup, you'll need a few basic tools. Good news —none of this stuff is pricey.

First up, grab yourself a spark tester. Here's the one I always reach for:

- HEI spark tester: This little guy is a must-have tool. It's hands-down the best way to check for spark and get results you can trust. I recommend this one (it's the one I use):

- OTC 6589 Electronic Ignition Spark Tester (at: amazon.com).

- 12-volt test light: We'll use this to check if the ignition coil's getting its activation signal. This is the one I keep in my toolbox:

- Lisle 28400 Heavy Duty 12 Volt Test Light (at: amazon.com).

- Jumper cables: Yep —just your everyday battery booster cables.

- Multimeter: If you don't have one or need to upgrade, here's the one I personally use and recommend:

- Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (at: amazon.com).

- Spark plug wire pliers: These are a must for pulling the wires without tearing off their metal terminals (the one that connects to the spark plug). If you don't already have a pair, check these out:

- OEMTOOLS 25542 Spark Plug Pliers. (at: amazon.com).

- And last but not least —a helper. Trust me, having someone turn the key (to crank the engine) while you test makes the ignition coil diagnostic easier.

Ignition Coil Circuit Descriptions

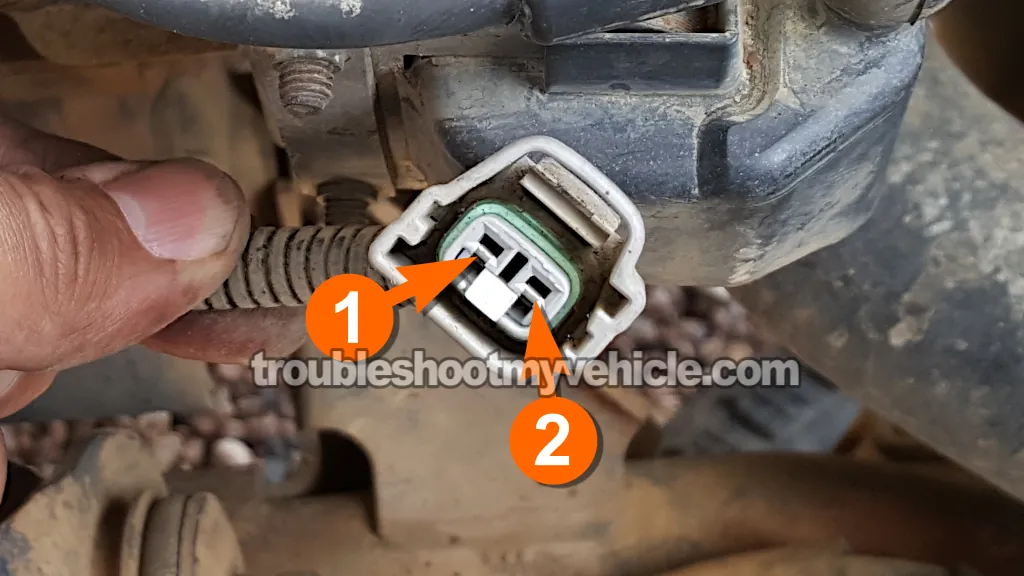

I'm covering a long stretch of 3.9L V6 Dodge Ram pickup model years —1992 through 2001. Depending on the year of your pickup, you'll come across one of two different ignition coil connectors.

The good news? Even though they don't look the same, both connectors use just two wires —and the ignition coil and system work the same way with either one.

If you check out the images of the ignition coil connectors above, here's what each terminal does:

- Terminal 1: This is the power feed. It delivers 10 to 12 Volts to the ignition coil, but only while the engine's cranking.

- Terminal 2: This one sends the ignition coil's activation signal from the fuel injection computer —also called the Powertrain Control Module (PCM).

TEST 1: Testing The Spark Plug Wires For Spark

We're gonna start by checking for spark —which is the most important part of the whole ignition system diagnostic process. It'll tell us right away if the engine's no-start or misfire issue is coming from the ignition system.

The other very important thing to keep in mind is that you should use a dedicated spark tester for your spark tests.

Any quality one will get the job done, but if you're buying one, I strongly recommend going with an HEI spark tester.

You can see what it looks like and buy one here: OTC 6589 Electronic Ignition Spark Tester (at: amazon.com).

Alright, the test instructions below assume you're testing all six spark plug wires and I highly recommend you do, whether it's just a misfire or an engine no-start issue you're troubleshooting.

CAUTION: You'll be working around a cranking the engine during these tests, so stay alert and take all necessary safety precautions.

Alright, here's how to kick things off:

- 1

Start by removing the spark plug wire from cylinder #1.

NOTE: Check image 2 of 2 if you're not sure which one that is. - 2

Hook up your HEI spark tester to that plug wire (see photo above).

- 3

Ground the spark tester using a jumper cable directly on the battery's negative (-) terminal.

- 4

Have your helper crank the engine while you eye-ball the spark tester.

NOTE: If you're dealing with a misfire, the engine might actually start —so be ready and stay safe. - 5

The spark tester should spark as the engine cranks.

- 6

Repeat this test for the other six spark plug wires.

Now let's break down what your results mean:

CASE 1: All of the spark plug wires sparked. That's the correct and expected test result.

This tells you the ignition coil, the distributor cap and rotor, the pickup coil inside the distributor, CKP sensor and the spark plug wires are all working like they should.

If you're chasing a misfire on your 1992–2001 V6 Dodge Ram pickup, the next thing to check is here: Other Causes Of A Misfire.

If it's a no-start you're troubleshooting, then a lack of spark isn't the issue —it's coming from somewhere else.

CASE 2: None of the plug wires are sparking. Your next step is to check if the ignition coil's high-tension wire is sending spark to the center of the distributor cap.

You can find that test right here: TEST 3: Testing The Ignition Coil's High Tension Wire For Spark.

CASE 3: Some wires have spark and others don't. That usually means you've got either bad plug wires or a failing distributor cap.

To confirm, we'll test directly at the distributor cap towers for the wires that aren't sparking. Here's where to go next: TEST 2: Testing For Spark At The Distributor Cap.

TEST 2: Testing For Spark At The Distributor Cap

If one or more spark plug wires didn't spark back in TEST 1, chances are high that:

- The towers on the distributor cap that connect to those wires are bad.

- The spark plug wire (or wires) that didn't spark are no good anymore.

We're gonna sort that out by checking for spark right at the distributor cap towers that feed those wires.

Here's how to run the test step by step:

- 1

Unplug the spark plug wire from the distributor cap tower —the one that didn't spark during TEST 1.

- 2

Place the spark tester directly to the cap tower, securing it to the metal terminal using a short piece of vacuum hose (the arrow in the photo points to the hose I used).

- 3

Use a jumper cable to Ground the spark tester directly to the battery's negative (-) terminal.

- 4

Have your helper crank the engine while you watch the HEI spark tester from a safe distance.

- 5

The spark tester should spark while the engine's turning over.

- 6

If any other wires failed TEST 1, repeat this process on each of their cap towers.

Let's go over what your results mean:

CASE 1: You saw spark. That's the result you want —it confirms the spark plug wire that was connected to that tower is the one that's bad. Time to replace it. Better yet, just replace the whole set.

Swapping them out should get rid of the misfire. And if the cap and rotor have been in there just as long, it's a good idea to replace those too while you're at it.

Why it matters: Spark plug wires wear down over time. As internal resistance builds up, they stop transmitting spark. That leads to misfires or even an engine no-start condition.

CASE 2: You didn't see spark. That points to a bad distributor cap —it's not sending spark through that tower like it's supposed to.

Installing a new distributor cap and rotor should solve the misfire. And again, if your wires and plugs are just as old, now's the time to replace them too.

Why? The metal contacts inside the cap towers (where the wires plug in) corrode with age. That corrosion increases resistance and, eventually, blocks spark from getting through —shutting down ignition to that cylinder.