A bad crankshaft position (CKP) sensor can cause the engine to not start or stall out randomly. It’s also a common cause behind trouble codes like P0320, P0335, and P0339. The good news is that it isn't a difficult component to test on the car.

In this tutorial, I'll show you how to test the CKP sensor step by step —no guesswork, just solid results with a basic multimeter.

And if you're already planning on replacing the sensor without testing it, no worries —I'll show you where to get a good deal on one.

Contents of this tutorial:

- Symptoms Of A Bad CKP Sensor.

- How The CKP Sensor Functions.

- Should I Just Replace The CKP Sensor Without Testing It?

- Where To Buy The CKP Sensor And Save.

- Crankshaft Position Sensor Connector Pinout.

- TEST 1: Testing The CKP Signal With A Multimeter.

- TEST 2: Making Sure The CKP Sensor Is Getting 5 Volts.

- TEST 3: Making Sure The CKP Sensor Is Getting Ground.

- More 2.4L Chrysler, Dodge, And Plymouth Minivan Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 2.4L Chrysler Voyager: 2003.

- 2.4L Dodge Caravan: 2003, 2004, 2005, 2006, 2007.

WIRING DIAGRAMS:

IGNITION SYSTEM TESTS:

- How To Test The CMP Sensor -P0340 (2003-2007 2.4L Chrysler And Dodge Minivan).

- How To Test The Ignition Coil (1996-2007 2.4L Caravan, Grand Caravan, Voyager, Grand Voyager).

OTHER CKP SENSOR TEST TUTORIALS:

ENGINE NO-START DIAGNOSTICS:

Symptoms Of A Bad CKP Sensor

The crankshaft position sensor (CKP) works closely with the camshaft sensor (CMP) to help the PCM manage ignition timing and fuel injection. If the CKP sensor starts to fail, the PCM loses track of the crankshaft's position —and that throws everything off.

When this sensor goes bad on your 2.4L Caravan or Voyager, here are the most common symptoms you'll run into:

- Cranks but won't start: The starter turns the engine over, but it never actually fires up.

- Long crank times: It takes noticeably longer for the engine to start when you turn the key.

- Sudden stalling: The engine might shut off out of nowhere, whether you're idling or cruising down the road.

- Rough idle: You might feel the engine shaking, surging, or misfiring at a stop.

- Sluggish performance: The engine may feel flat, like it's struggling to respond when you hit the gas.

- Check engine light with CKP-related trouble codes: If the PCM loses the crank signal or detects a problem, it may store one of the following DTCs:

- P0320: No Crank Reference Signal At PCM.

- P0335: Crankshaft Position Sensor Circuit.

- P0339: Crankshaft Position Sensor Intermittent.

How The CKP Sensor Functions

The CKP sensor on your 2.4L Chrysler or Dodge minivan is a 3-wire Hall-effect type sensor. It needs a steady 5-volt power supply and a solid Ground —both of which are provided directly by the PCM (no external fuses or relays in the mix).

Here's a quick breakdown of how it operates:

- The sensor only starts sending a signal when the engine is turning —either while cranking or running.

- It detects movement by monitoring slots in the flywheel as they pass by its tip.

- There are 12 slots total (arranged in 3 sets of 4), and as the flywheel spins, the sensor produces a series of voltage pulses: 12 ON signals (around 5 Volts) and 12 OFF dips (0 Volts) for every full crankshaft revolution.

- This ON/OFF switching is how the PCM keeps track of crankshaft position and rotation speed in real time.

- The CKP sensor works together with the camshaft position sensor (CMP) to help the PCM manage ignition timing and fuel injection precisely.

When the PCM stops receiving a signal from the CKP sensor —for whatever reason— it responds by setting one or more of the following trouble codes: P0320, P0335, or P0339.

Location: The sensor is located on the side of the engine facing the firewall. Near where the oil pan meets the engine block

Should I Just Replace The CKP Sensor Without Testing It?

To be honest, a lot of people skip straight to replacing the crankshaft position sensor the moment a CKP-related trouble code shows up. No diagnostics, no testing —just swap it out and move on.

And truthfully? That approach works more often than not. You throw in a new sensor, clear the code, and the van fires right up like nothing ever happened.

There's logic behind that move, especially considering two things:

- The sensor isn't expensive, and changing it out won't take all day.

- The location isn't exactly convenient —it's buried near the bellhousing and not easy to get your test leads on without a fight. A lot of folks would rather skip the hassle and just install a new one.

If that's your plan, check the link below for a solid replacement option that won't drain your wallet.

But if you're the type who likes to be sure before spending money on parts, no worries —this guide will walk you through exactly how to test the sensor step by step so you can confirm it's the problem before replacing it.

Where To Buy The CKP Sensor And Save

The following links will help you comparison shop for the crankshaft position sensor:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

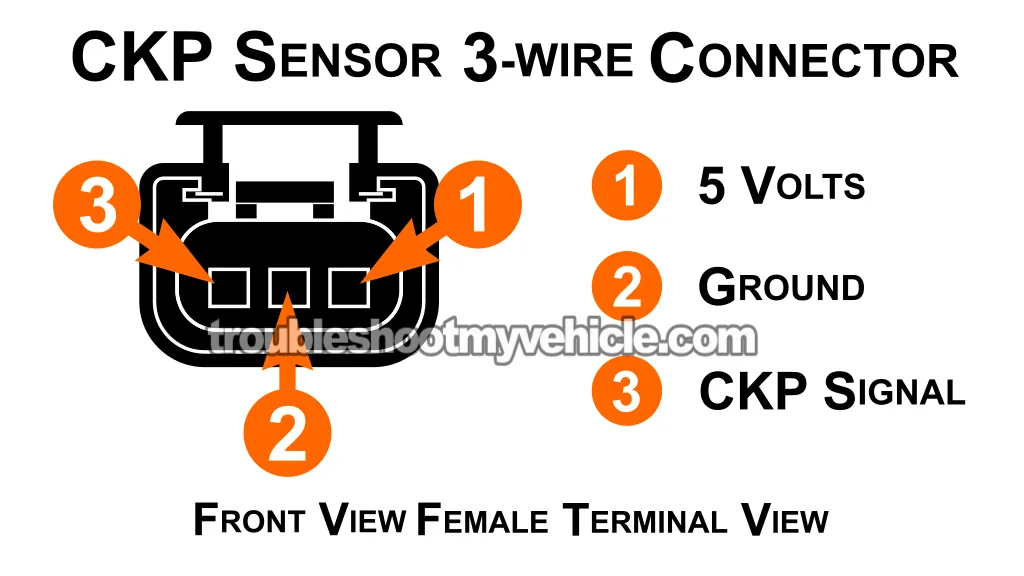

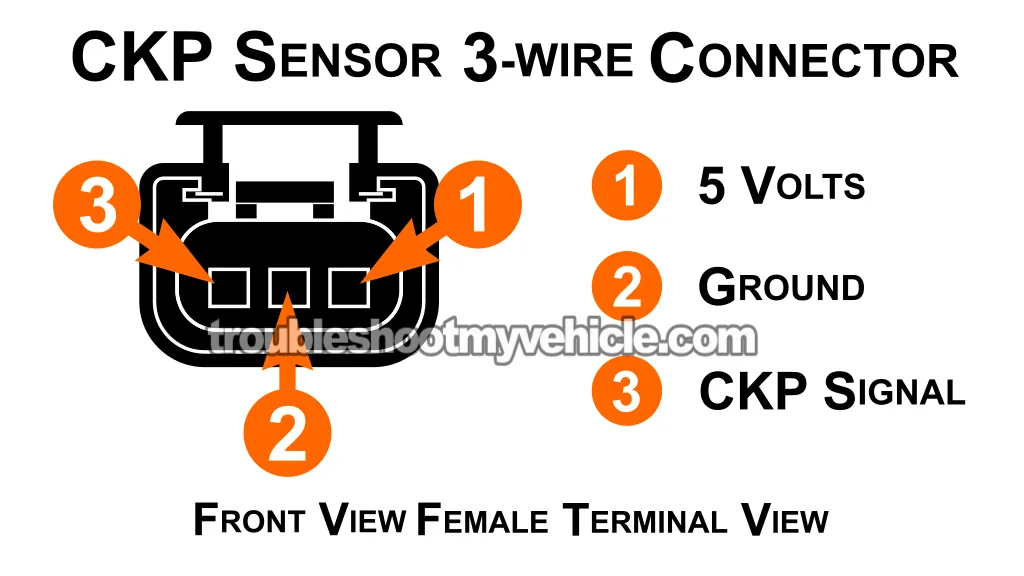

Crankshaft Position Sensor Connector Pinout

| 2004-2007 CKP Sensor Circuits | ||

|---|---|---|

| Terminal | Wire | Description |

| 1 | Pink with yellow stripe (PNK/YEL) | 5 Volts DC |

| 2 | Dark blue with dark green stripe (DK BLU/DK GRN) | Ground |

| 3 | Brown with light blue stripe (BRN/LT BLU) | CKP Sensor Signal |

TEST 1: Checking The CKP Signal With A Multimeter

We're going to kick things off by verifying whether the crankshaft position sensor is producing its expected ON/OFF signal —and we'll be doing it by manually turning the engine by hand, not using the starter.

This is what you're looking for on your multimeter display:

- ON: Voltage spikes up to 5 Volts.

- OFF: Drops back near 0 Volts.

The wire we'll be tapping into is the brown with light blue stripe (BRN/LT BLU) —this is the signal wire that feeds crankshaft position info straight to the PCM.

Don't have a multimeter, or thinking about upgrading? Here's the one I personally use and recommend: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (via Amazon).

NOTE: Don't use the starter for this test —it spins the engine too fast for the multimeter to catch the switching signal. Use a ratchet and socket on the crank pulley to turn the engine slowly by hand.

CAUTION: If you need to raise the vehicle to access the crankshaft pulley bolt, make sure to use jack stands. Never rely solely on the jack for safety.

IMPORTANT: Leave the CKP sensor plugged into its connector. You'll be back-probing the signal wire, or using a wire-piercing probe to access the voltage without disconnecting anything. If you need a good tool for this, here's one I recommend: Wire Piercing Probe.

Follow these steps to test for a CKP signal:

- 1

Disconnect the ignition coil pack.

NOTE: This keeps the engine from accidentally starting while you're rotating it manually. - 2

Set your multimeter to DC Volts mode.

- 3

Connect the black lead to the battery's negative (-) terminal.

- 4

Back-probe or pierce the BRN/LT BLU signal wire with your red lead.

NOTE: Keep the sensor plugged in while testing —this is critical. - 5

Turn the ignition key to the ON position (engine off).

- 6

Using a ratchet, slowly rotate the crankshaft pulley by hand.

NOTE: Don't use the starter here —you'll miss the signal.

TIP: Make sure you turn the crankshaft at least one full revolution to catch all 12 flywheel slots passing by the sensor. - 7

Watch your multimeter for ON/OFF voltage changes.

Anything in the 0.3–0.5V range counts as an "OFF" reading.

NOTE: As the crank completes one full turn, you should see the voltage toggle 12 times between 5V and 0V.

Now let's look at what your test results mean:

CASE 1: You see a clean ON/OFF voltage pattern. That's exactly what we're looking for —the CKP sensor is working and delivering a proper signal to the PCM.

This also confirms that the sensor is getting both its power and Ground —no further testing is needed here.

CASE 2: No signal, just flat voltage. Double-check your probe setup, connections, and make sure the crank is actually turning. If it still reads flat, move on to TEST 2: Checking For Power At The Sensor.