TEST 8: Making Sure The Ignition Coil Pack Is Getting Its Activation Signals

Up to this point, you've confirmed that:

- None of the spark plug wires are sparking (TEST 1).

- The ignition coil pack is getting 10 to 12 Volts DC (TEST 5).

In this test section, we'll check that the ignition coil pack is getting its activation signals. These are:

- Activation signal for cylinders #1 and #4.

- Activation signal for cylinders #2 and #3.

To check for these activation signals, we'll use an LED Light. If you don't have one, you can find out more about it and where to buy one here: The LED Light Test Tool And How To Make One (at: easyautodiagnostics.com).

These are the test steps:

- 1

Disconnect the ignition coil pack from its connector.

- 2

Connect the red lead of the LED light to the battery positive (+) terminal with a long jumper cable.

NOTE: You can also insert the end of the red LED wire into middle female terminal of the connector (which will have 10 to 12 Volts with the engine cranking). Just be careful that the wire doesn't damage the female terminal, or you'll have to get a new connector. - 3

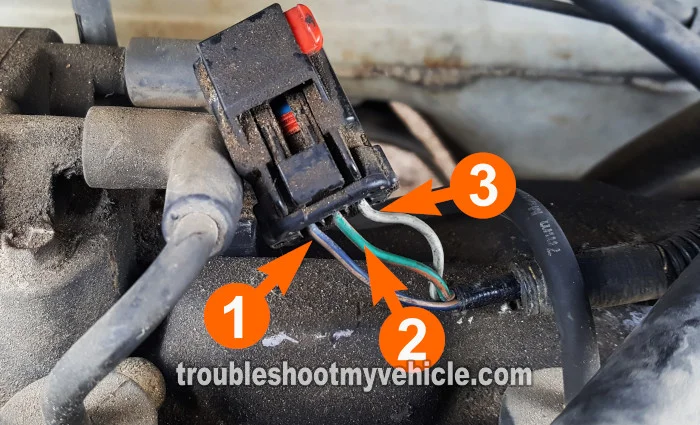

With an appropriate tool, connect the black lead of the LED light to the wire identified with the number 3 in the photo above.

This is the circuit that feeds the activation signal to the ignition coil (within the coil pack) that feeds spark to cylinders 1 and 4 simultaneously.

NOTE: You can also insert the end of the black LED wire into the female terminal of the wire. Just be careful that the wire doesn't damage the female terminal, or you'll have to get a new connector. - 4

Have your helper crank the engine while you observe the LED light.

- 5

If the activation signal is present, the LED light will flash ON and OFF the whole time the engine was cranking.

- 6

Remove the black lead from the terminal that connects to the wire labeled with the number 3.

- 7

Repeat step 2 on the female terminal that connects to the wire labeled with the number 1 in the photo above.

- 8

Have your helper crank the engine while you observe the LED light.

- 9

If the activation signal is present, the LED light will flash ON and OFF the whole time the engine was cranking.

Let's take a look at what your test results mean:

CASE 1: The LED light flashed ON and OFF the whole time the engine was cranking (in both terminals). This is the correct test result and it confirms that the fuel injection computer (PCM) is providing the activation signals and the circuits are OK.

This result confirms that the ignition coil pack is bad and needs to be replaced only if you have:

- Confirmed that all four spark plug wires do not spark (TEST 1).

- Confirmed that all four ignition coil pack towers do not spark.

- Confirmed that both of the ignition coil pack's activation signals are present (this test section).

CASE 2: The LED light DID NOT flash ON and OFF the whole time the engine was cranking (in both terminals). Without these activation signals, the ignition coil pack will not fire off spark to any of the cylinders.

The most likely cause of these missing signal is a bad camshaft position (CMP) or crankshaft position (CKP) sensor. Your next step is to test the CMP sensor first and if it's OK, then the CKP sensor:

- How To Test The CMP Sensor -P0340 (1996-2000 2.4L Dodge And Plymouth Minivan).

- How To Test The CMP Sensor -P0340 (2001-2002 2.4L Chrysler And Dodge Minivan).

- How To Test The CMP Sensor -P0340 (2003-2007 2.4L Chrysler And Dodge Minivan).

- Testing The Crankshaft Position Sensor -P0320 (1996-2002 2.4L Caravan, Grand Caravan, Voyager, Grand Voyager).

- How To Test The CKP Sensor -P0320, P0335, P0339 (2003-2007 2.4L Chrysler And Dodge Minivan).

Other Possible Misfire Causes

So you've done all of the tests in this tutorial and the ignition system checks out OK, but your minivan is still misfiring. Well, here are a couple of suggestions that might help:

- Inspect the inside of the spark plug wire boots and remove the spark plugs to visually check their ceramic insulators for carbon tracks

- The photo above points (the orange arrows) to what carbon tracks look like.

- Replace the components as affected with carbon tracks.

- The following case study on carbon tracks may come in handy: Carbon Tracks Are A Common Cause Of Ignition Misfires (at: easyautodiagnostics.com).

- Inspect the inside of all of the spark plug tubes. It's possible that the valve cover spark plug tube seals are leaking engine oil into the spark plug tubes.

- If engine oil is filling up the tubes, you'll need to replace the valve cover gasket along with the spark plug tube seals, the spark plugs, and the spark plug wires.

- Engine compression test.

- This is one of the easiest, yet most overlooked test to find the cause of a misfire condition.

- You'll need an engine compression tester of course.

- The engine compression value recorded on the compression gauge (between cylinders) should not vary more 15%.

- You can find a step-by-step compression test tutorial here: How To Test The Engine Compression (1996-2007 2.4L Caravan, Grand Caravan, Voyager, Grand Voyager).

- Fuel injector test.

- There are several methods to test them which are beyond the scope of this article but the fastest way to test them is by checking the resistance (Ohms) value of each one with a multimeter and comparing the Ohms values to each other.

- Any resistance that's not within the average of the others indicates the fuel injector is fried. If the Ohms readings are nearly identical to each other, you can rule them out as the cause of the misfire.

- Or you can buy a specific fuel injector tester (on line) that activates the fuel injector by a predetermined pulse width in conjunction with a fuel pressure gauge that will show you the fuel pressure drop this tester will cause.

If this info saved the day, buy me a beer!