When the PCM on your 2003-2007 2.4L Honda Accord sets a P0138 diagnostic trouble code (DTC), it's letting you know the rear O2 sensor's output voltage signal is stuck at 0.75 Volts or higher.

That's a very important piece of info, one that's gonna help us troubleshoot the sensor as good or bad once we start testing its output voltage (and see if it really is stuck at such an extreme rich condition or not).

In this tutorial, I'll show you how to troubleshoot a P0138 DTC using a generic scan tool with live data capability (no fancy or expensive diagnostic equipment needed), and I'll walk you through it step by step.

NOTE: The rear O2 sensor goes by a few different names —downstream O2 sensor, post-catalytic converter O2 sensor, oxygen sensor bank 1 sensor 2 (O2S12) —but they all refer to the same sensor.

Contents of this tutorial:

- What Does A P0138 DTC Mean?

- Symptoms Of A P0138 DTC.

- Should I Just Replace The Sensor Without Testing It?

- Where To Buy The Oxygen Sensor And Save.

- TEST 1: Checking Rear O2 Sensor Voltage.

- TEST 2: Manually Inducing A Lean Condition.

- TEST 3: Checking For A Short To Power In The Rear O2 Sensor Wiring.

- More 2.4L Honda Accord Test Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 2.4L Honda Accord: 2003, 2004, 2005, 2006, 2007.

02 SENSOR CIRCUIT WIRING DIAGRAM:

REAR O2 SENSOR DIAGNOSTICS:

- Rear Oxygen Sensor Performance Tests (2003-2007 2.4L Honda Accord).

- P0141 Diagnostic -Rear O2 Sensor Heater Tests (2003-2007 2.4L Honda Accord).

- P0137 Diagnostic Tests -Rear O2 Sensor (2003-2007 2.4L Honda Accord).

- P0420 Diagnostic -Catalytic Converter Tests (2003-2007 2.4L Honda Accord).

What Does A P0138 DTC Mean?

A P0138: O2 Sensor Circuit High Voltage (Bank 1, Sensor 2) tells us the PCM is seeing the rear oxygen sensor's signal stuck rich —locked at 0.75 Volts or higher for longer than it should be.

To understand why this matters (and why it's a big clue in diagnosing the sensor), let's review what should happen under normal conditions:

- The rear O2 sensor's voltage is supposed to move slowly back and forth between about 0.1 and 0.9 Volts.

- Its main role is to keep an eye on the catalytic converter and report its efficiency back to the PCM.

Here are a few other key points to keep in mind:

- No gasoline engine burns fuel with 100% efficiency —there will always be some unburned fuel (hydrocarbons) in the exhaust stream.

- The PCM, using input from the front O2 sensor (air/fuel ratio sensor), constantly adjusts fuel delivery to keep the mixture balanced. But these corrections are never perfect —sometimes it adds a little too much fuel, other times it trims a little too much out.

- The catalytic converter burns off a large portion of those leftover hydrocarbons when extra fuel slips through, but it can't remove every last trace.

- As a result, the rear O2 sensor doesn't stay locked high or low. Instead, it reflects these ongoing fluctuations by slowly swinging between lean (around 0.1 V) and rich (around 0.9 V).

So when the PCM expects the rear O2 sensor to show those normal lean/rich swings but instead sees it flat-lined high (0.75 V or more), it sets a P0138 DTC. The common causes are a failing O2 sensor, wiring damage, or —in rare cases— a problem inside the PCM itself.

Symptoms Of A P0138 DTC

Most of the time, a P0138 will simply turn on the check engine light (CEL) without causing any obvious change in how your 2.4L Honda Accord drives.

Where it becomes a real headache is at inspection time. If your area requires a safety or emissions test, that lit up check engine light (CEL) on the dash (along with the stored P0138 in the PCM's memory) will cause your Accord to fail the inspection until the problem is repaired.

Should I Just Replace The Sensor Without Testing It?

For lots of folks, the go-to move for a P0138 trouble code is to swap the rear O2 sensor and see what happens. And to tell you the truth —about 8 times out of 10, it fixes the problem.

The reasons this "diagnostic" strategy is so appealing are:

- You can replace the rear O2 sensor in under 30 minutes (not that difficult).

- The rear O2 sensor doesn't cost an arm and a leg.

- Most folks don't have a scan tool with live data capability (which rules out checking the sensor's voltage output).

Now, if swapping out the rear O2 sensor doesn't clear up the P0138 code, they're not gonna sweat it —that's just part of the troubleshooting process for them. The upside is they did the job themselves, so the only money they spent was the cost of the sensor, but no shop labor or diagnostic charges.

Here's my take on this approach: you'll have a better shot at success if:

- The P0138 is the only code in the PCM's memory. If there are any others, they need to be resolved first before chasing this one.

- You've looked over the rear O2 sensor wiring where it runs from the sensor up into the body (this is super important). Make sure the rear O2 sensor's 4 wires are not melted against the exhaust or the catalytic converter or damaged in any way.

So, if you'd rather skip the testing and just install a new rear O2 sensor, that's perfectly fine. I've listed my two go-to recommendations below. Both are from brands I've relied on for years and never hesitate to recommend:

- Walker Products 350-34122 Oxygen Sensor (Amazon affiliate link).

- Denso 234-4797 Oxygen Sensor (Amazon affiliate link).

That said, I still recommend testing the rear O2 sensor before replacing it. The check is quick, simple, and all you need is a basic scan tool with live data. It's absolutely something you can do yourself.

And if you're like me, you want proof the sensor is truly bad before spending the money. That's what this tutorial is for —I'll guide you step by step through the tests.

Where To Buy The Oxygen Sensor And Save

If it's time to replace the rear O2 sensor, here are my two go-to recommendations. These come from brands I've trusted for years, and I can confidently suggest them to you without hesitation:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

TEST 1: Checking Rear O2 Sensor Voltage

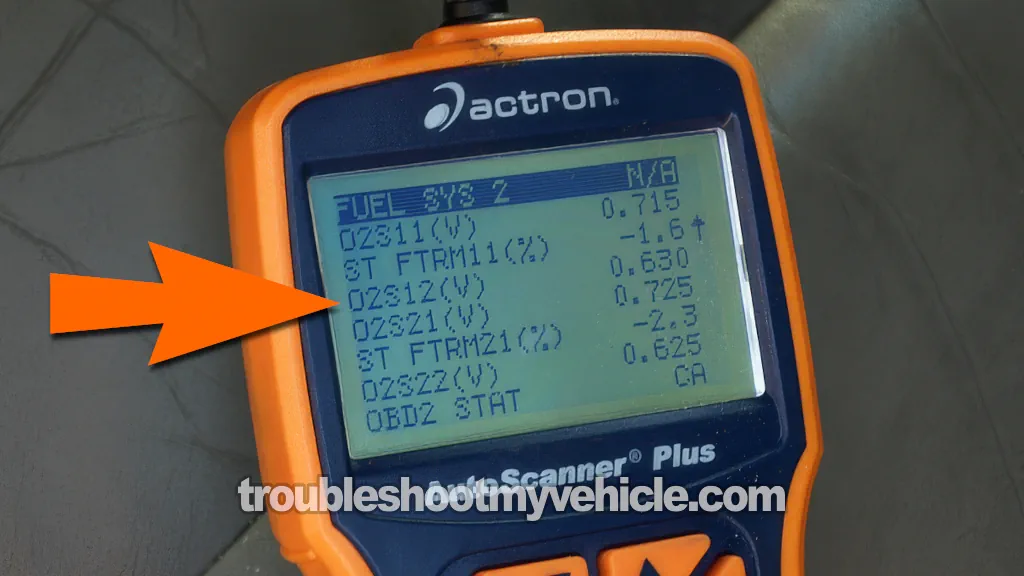

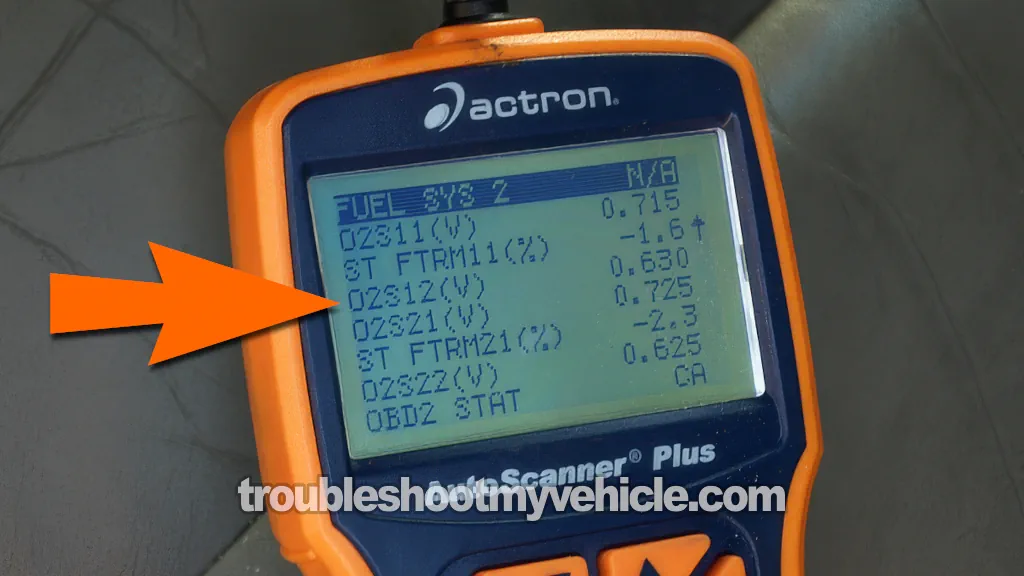

The first order of business is to see what the rear O2 sensor is actually outputting, and we can easily do this with a scan tool that has live data capability.

Just in case you're wondering what "live data" is on a generic scan tool, "live data" just means you can see the sensor signals and engine information updating in real time while the engine is running.

If the rear O2 sensor signal is really stuck at or above 0.75 Volts (which is what the P0138 DTC is accusing the rear O2 sensor of doing), we'll see it right there in the scan tool's live data section.

If you don't have a scan tool with live data capability, this is the one I recommend:

- ZM301 OBD2 Scanner Diagnostic Tool (Amazon affiliate link).

Alright, this is what we need to do:

- 1

Hook up your scan tool and open the live data menu.

- 2

Find the PID labeled O2S12 —this is the rear oxygen sensor (Bank 1, Sensor 2).

NOTE: Depending on the scan tool, this PID may be labeled differently. Check your scan tool's user manual to see how it appears on your particular model. - 3

Start the engine and hold the RPM steady at around 2,000 (transmission in Park) until the radiator fan cycles on.

- 4

Once the radiator fan comes on, let the engine settle back to idle.

- 5

Watch the O2S12 voltage at idle: Is it pegged high at 0.75 Volts or more, or does it slowly move back and forth between 0.1 and 0.9 Volts?

- 6

Snap the throttle a few times up to about 3,000 RPM, then let it return to idle.

- 7

Check the O2S12 voltage again at idle: Is it still stuck high (0.75 V or more), or is it showing the normal slow swings between lean and rich?

Here's how to read your results:

CASE 1: O2S12 voltage remains stuck between 0.75 to 1 Volts (both at idle and after snapping the throttle). This confirms the rear O2 sensor is stuck producing a high-voltage condition, which confirms the P0138 DTC.

Your next move is to force a lean condition while the engine is running and see if the rear O2 sensor reacts. For that procedure, go to: TEST 2: Manually Inducing A Lean Condition.

CASE 2: O2S12 voltage remains stuck at 9 Volts or more (both at idle and after snapping the throttle). This tells you the O2 sensor is signal wires are shorted to power and confirms the P0138 DTC lighting up the check engine.

Your next step is to go to: TEST 3: Checking For A Short To Power In The Rear O2 Sensor Wiring.

CASE 3: O2S12 voltage swings slowly between 0.1 and 0.9 Volts (at idle and after snapping the throttle). The rear O2 sensor is behaving normally at this time.

If that's the case, the fault may be intermittent —and those can be the toughest to nail down. Clear the code and take the vehicle for a road test. If the P0138 resets (it may take a drive cycle or two), repeat this test to confirm.

TEST 2: Manually Inducing A Lean Condition

In this test section, we're gonna create a lean air/fuel mixture (to see if the rear O2 sensor reacts) by slightly cracking open the brake booster vacuum hose while the engine is running.

The rubber vacuum hose that supplies vacuum to the brake booster is large enough in diameter that, even when opened just a little, it will immediately lean out the air/fuel mixture the PCM is commanding to keep the engine running.

Here's how the rear O2 sensor should behave:

- Working sensor: The rear O2 should react almost instantly, dropping its voltage close to 0.1 Volts as soon as the vacuum leak is introduced.

- Failing sensor: If there's no change in voltage, or the reaction is sluggish, then the rear O2 sensor isn't functioning correctly and needs to be replaced to resolve the P0138 DTC.

PREP STEP: Before starting the engine, loosen and remove the rubber brake booster hose from the metal vacuum pipe on the intake manifold (not at the brake booster itself). This way, you won't have to fight with it once the engine is running.

Here's what we need to do:

- 1

Hook up your scan tool and open the live data section. Find the parameter for the rear oxygen sensor —it's usually listed as O2S12 (Bank 1 Sensor 2).

- 2

Start the engine and let it reach full operating temperature.

- 3

With the engine idling, momentarily crack open the brake booster vacuum hose at the intake manifold.

This will create an instant vacuum leak and force a lean condition.

NOTE: If the engine stalls, you've opened the vacuum hose too much. Restart the engine and repeat the test but open the vacuum hose less. - 4

Watch the rear O2 sensor signal on your scan tool as you open and then reseat the hose.

- 5

A good rear O2 sensor will drop immediately toward 0.1 Volts as soon as the vacuum leak is introduced.

- 6

When the test is done, shut the engine off and re-secure the brake booster hose to the intake manifold vacuum inlet port.

Here's what those test results mean:

CASE 1: O2S12 voltage dropped immediately to around 0.1 Volts when the vacuum hose was cracked open. This is the correct test result and tells us the sensor is functioning and capable of detecting a lean condition at this moment.

Since it responded correctly and TEST 1 confirms it was stuck producing an output voltage 0.75 Volts or more, the rear O2 sensor is reporting a continuous rich condition. This could be caused by a number of issues.

Your next step is to see what is behind the PCM's inability to fine-tune the air/fuel mixture and causing it to inject too much fuel.

CASE 2: O2S12 voltage did not respond —it stayed stuck high during the lean condition test. The rear O2 sensor is not doing its job and needs to be replaced.

When you're ready to replace the rear O2 sensor, below are my two recommendations. They're from trusted brands I've used for years and don't hesitate to recommend:

- Walker Products 350-34122 Oxygen Sensor (Amazon affiliate link).

- Denso 234-4797 Oxygen Sensor (Amazon affiliate link).

TEST 3: Checking For A Short To Power In The Rear O2 Sensor Wiring

If your scan tool is showing the rear O2 sensor stuck at 9 Volts or more, then something is definitely wrong. The O2 sensor itself only produces a signal that ranges between 0.1 and 1 Volt —it should never hit 9 Volts or higher.

When you see that kind of reading, it usually means the O2 sensor signal wire has shorted to the black with red stripe (BLK/RED) wire, which carries 10 to 12 Volts DC to the rear O2 sensor's heater element.

The most common reasons these wires short together (causing the PCM to see 9 Volts or more on the O2 sensor's signal output) are the rear O2 sensor wires melting against the exhaust pipe or chafing through on a sharp body edge where the sensor's wiring passes into the cabin near the passenger seat area.

In this test, we're gonna check all 4 rear O2 sensor wires for damage and verify if any of other 3 rear O2 sensor wires are indeed shorted to the BLK/RED heater 12V power feed wire.

Here's what we need to do:

- 1

Raise and support the vehicle on jack stands.

NOTE: Do not rely on the jack alone —use jack stands as an essential safety precaution before going underneath the vehicle. - 2

Locate the rear O2 sensor and its wiring. The sensor is located on the exhaust pipe where it exits the catalytic converter and has a 4-wire harness coming out of it.

- 3

Visually inspect the four wires coming out of the sensor.

Trace each wire carefully, making sure none are melted against the exhaust pipe, chafed on sharp edges, or have damaged or missing insulation. - 4

Check the O2 sensor connector.

Make sure the connector itself is not cracked, burnt, or showing signs of corrosion or loose terminals. - 5

Inspect the rear O2 sensor wiring inside the vehicle.

Follow the wiring as it passes from underneath into the cabin (near the passenger side seat area). Look for any signs of rubbing, pinching, or insulation damage at the pass-through point.

Now, let's interpret your results:

CASE 1: You found obvious wiring damage. This means the O2 sensor signal wire has most likely shorted to the BLK/RED power wire.

If the damage is in the vehicle's wiring harness, repair the affected section. If it's in the wires coming directly out of the rear O2 sensor, replace the sensor.

After the repair, recheck the scan tool PID —it should no longer show the rear O2 sensor stuck at 9 Volts or more.

CASE 2: The wiring and connector look good. This tells you the signal wire is not visibly shorted to power.

If the scan tool PID (for the rear O2 sensor) is still reporting 9 Volts or more, then the short to power is likely in another section of the harness between the rear O2 sensor connector and the PCM connector.

Although it's beyond the scope of this tutorial to troubleshoot this specific problem further, your next step is to check continuity of the rear O2 sensor wires between the O2 sensor connector and the PCM. The following wiring diagram will help you track it down:

More 2.4L Honda Accord Test Tutorials

You can find a complete list of 2.4L Honda Accord wiring diagrams and diagnostic tutorials in this index:

Here's a sample of the tutorials you'll find there:

- How To Test Misfire Trouble Codes (2003-2006 2.4L Honda Accord).

- How To Test The Engine Compression (2003-2006 2.4L Honda Accord).

- How To Test The Fuel Injectors (2003-2006 2.4L Honda Accord).

- How To Test The Fuel Pump (2003-2007 2.4L Honda Accord).

If this info saved the day, buy me a beer!