Checking the performance of the rear (downstream) oxygen sensor on your 2.4L Honda Accord is a lot easier than most people think.

With nothing more than a generic scan tool that has live data capability, you can quickly see if the sensor is alive and doing its job.

In this tutorial, I'll walk you step by step through the process I use to test the downstream O2 sensor —from watching its normal operation at idle to stress-testing it with lean and rich conditions.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 2.4L Honda Accord: 2003, 2004, 2005, 2006, 2007.

P0420 DIAGNOSTICS: If your scan tool has pulled a P0420 trouble code and you need to go a step further by testing the catalytic converter itself, I've put together a dedicated tutorial that'll walk you through the process step by step:

REAR O2 SENSOR DIAGNOSTICS:

- P0137 Diagnostic Tests -Rear O2 Sensor (2003-2007 2.4L Honda Accord).

- P0138 Diagnostic Tests -Rear O2 Sensor (2003-2007 2.4L Honda Accord).

- P0141 Diagnostic -Rear O2 Sensor Heater Tests (2003-2007 2.4L Honda Accord).

REAR O2 SENSOR CIRCUIT WIRING DIAGRAM:

Symptoms Of A Bad Oxygen Sensor

A failing rear oxygen sensor usually doesn't cause the kind of obvious drivability problems that make the car undrivable. Still, when it starts to go bad, you'll see a few telltale signs pop up:

- Check Engine Light with an O2 sensor diagnostic trouble code (DTC): The most common clue is the CEL turning on with one of two types of trouble code —either a sensor performance issue or a heater element malfunction.

- O2 sensor performance trouble codes:

- P0137: Secondary Heated Oxygen Sensor Circuit Low Voltage.

- P0138: Secondary Heated Oxygen Sensor Circuit High Voltage.

- P0139: Secondary Heated Oxygen Sensor Slow Response.

- O2 sensor heater element trouble code:

- P0141: Secondary Heated Oxygen Sensor Heater Circuit Malfunction.

- Bad gas mileage: Even though the rear O2 sensor isn't used by the PCM to calculate fuel injection directly, a faulty signal can throw off long-term fuel trim strategies and catalyst monitoring. In the long run, this can lead to unnecessary enrichment and reduced fuel economy.

- Reduced engine performance (sometimes): Not in every case, but a failing sensor can cause symptoms like hesitation, uneven idle, or sluggish acceleration —especially if the sensor is "stuck" rich or lean and confusing the PCM's emissions control logic.

What Does The Rear O2 Sensor Do?

The rear oxygen sensor (also called the secondary O2 sensor or Bank 1 Sensor 2) is mounted in the exhaust stream after the catalytic converter. Its main purpose is not to control fuel injection —that job belongs to the upstream air/fuel ratio (A/F) sensor— but instead to monitor the health and efficiency of the catalytic converter.

- Location: Bolted into the exhaust pipe downstream of the catalytic converter. It measures the oxygen content of the exhaust gas after the converter has done its job.

- Main purpose:

- Monitor how well the catalytic converter is reducing harmful emissions (HC, CO, and NOx).

- Provide feedback so the PCM can run catalyst efficiency checks (the logic that sets a P0420 code when efficiency drops below threshold).

- Act as a "reference" signal that the PCM can compare against the upstream A/F sensor.

- How it works (signal generation):

- It uses a zirconia element that generates its own voltage when exposed to hot exhaust gases.

- Voltage output depends on oxygen content:

- Lean exhaust (more oxygen): Sensor voltage drops low, usually around 0.1–0.2 Volts.

- Rich exhaust (less oxygen): Sensor voltage rises high, usually around 0.8–0.9 Volts.

- This voltage is read directly by the PCM as an indicator of rich vs. Lean conditions in the post-cat exhaust.

- Normal behavior with a good catalytic converter:

- The upstream A/F sensor signal will fluctuate rapidly as the PCM constantly adjusts fuel trim.

- The downstream O2 sensor signal should change much more slowly and show smaller voltage swings because the converter is storing and releasing oxygen.

- Think of it this way: the rear sensor should look "lazy" compared to the upstream sensor —and that's exactly what you want to see.

- PCM strategy: If the PCM sees the rear sensor mimicking the front sensor too closely (same rapid rich/lean switching), it knows the catalytic converter isn't doing its job and sets a P0420 trouble code.

CATALYTIC CONVERTER TESTS: If you're dealing with a P0420 Catalyst Efficiency Below Threshold code and you want/need to test the catalytic converter itself. I've written a separate tutorial that explains exactly how to do this on the 2003-2007 2.4L Honda Accord:

TEST 1: Checking The Performance Of The Rear Oxygen Sensor

In this first test, we're going to evaluate the rear oxygen sensor's basic performance while the engine is idling. The goal here is to confirm that the sensor is generating a voltage signal and that it isn't "stuck" reporting a constant lean or constant rich condition.

Keep in mind that the rear O2 sensor's job is to monitor catalytic converter efficiency. Its signal reflects how well the converter is scrubbing the exhaust of leftover fuel from the combustion process. Because of this, the sensor's voltage should swing slowly between rich (about 0.9 V) and lean (about 0.1 V).

By watching this signal on your scan tool, you can quickly determine whether the sensor is alive and producing valid information. This test establishes a baseline —from here, we'll move on to stress-testing the sensor further with a manually induced lean condition if needed.

IMPORTANT: Make sure the engine has reached normal operating temperature and is in closed loop mode before you begin. You'll need a scan tool with live data capability to watch the sensor's voltage output in real time.

If you don't have a scan tool, or are looking for one, here's my recommendation: ZM301 OBD2 Scanner Diagnostic Tool (Amazon affiliate link).

NOTE: The terms "O2 sensor 2", "rear" and "downstream" oxygen sensor also refer to the same sensor, which is installed after the catalytic converter.

Here's what we need to do:

- 1

Start the engine and let it reach normal operating temperature. The PCM must be in closed loop mode before sensor data can be evaluated.

- 2

Connect your scan tool to the vehicle's diagnostic connector and power it up.

- 3

Navigate to the live data stream on your scan tool.

- 4

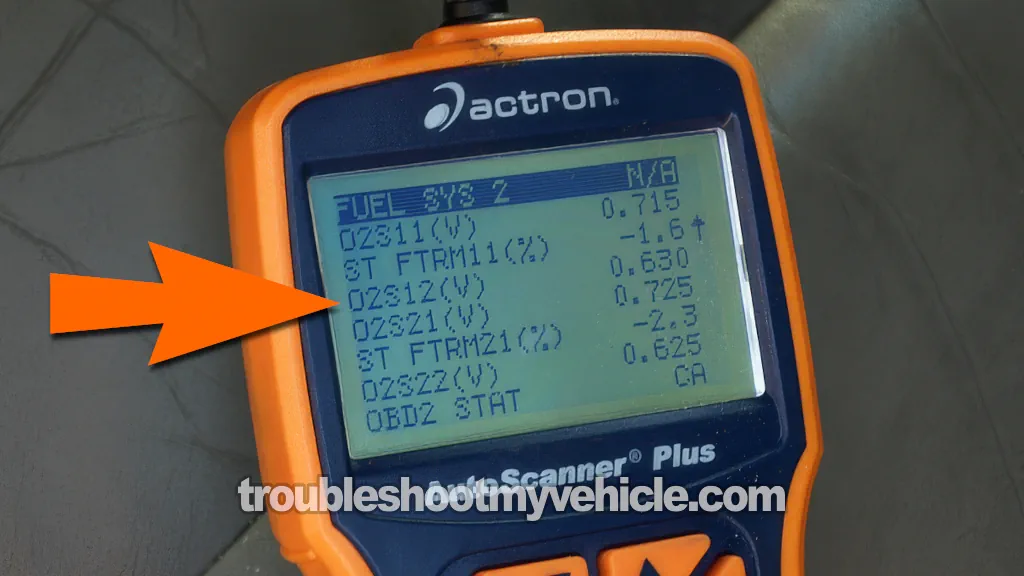

Look for the parameter ID (PID) that corresponds to the rear oxygen sensor.

On most scan tools this will be labeled as O2S12 (Bank 1, Sensor 2). - 5

Observe the rear oxygen sensor voltage while the engine is idling.

- 6

A properly functioning sensor will behave as follows:

a.) The voltage should not be stuck lean (very low output, around 0.1–0.2 Volts).

b.) The voltage should not be stuck rich (very high output, around 0.8–0.9 Volts).

c.) Instead, the voltage should move slowly between rich and lean, showing gradual swings in the 0.1–0.9 Volt range.

Let's find out what it all means:

CASE 1: The rear O2 sensor voltage is stuck rich (around 0.8–0.9 V) or stuck lean (around 0.1–0.2 V) continually. This means the sensor is not showing the expected slow swings between rich and lean.

In this situation, you'll need to confirm whether the sensor is truly bad or if another issue is at play. Continue to: TEST 2: Manually Inducing A Lean Air/Fuel Mixture.

CASE 2: The rear O2 sensor voltage swings slowly from lean to rich. This is the normal behavior of a functioning downstream O2 sensor.

Even though the sensor appears to be working correctly, you can still perform TEST 3 to see how quickly the sensor reacts when you create a manually induced lean condition. This test helps you evaluate its response speed and overall performance.

TEST 2: Manually Inducing A Lean Air/Fuel Mixture

In this next test, we're going to stress the rear oxygen sensor by forcing the engine into a lean condition.

The goal is to see if the sensor can detect the sudden increase in oxygen in the exhaust and drop its voltage output accordingly.

To do this, we'll briefly crack open a large vacuum hose —preferably the brake booster hose— to let in unmetered air.

Here's what we can expect:

- Good sensor: A properly functioning rear O2 sensor should react instantly, dropping below 0.5 Volts as soon as the hose is opened.

- Bad sensor: If the sensor doesn't respond or responds slowly, then we know it isn't doing its job and it will need to be replaced.

This is what you need to do:

- 1

Locate the brake booster vacuum hose. This is the large-diameter hose that connects the brake booster to the intake manifold. It's the best choice for this test because a small hose won't flow enough air to create a reliable lean condition.

- 2

With the engine off, loosen and disconnect the brake booster hose.

The idea is to make it easy to crack open once the engine is running.

Once you've disconnected it, reconnect it before moving on to the next step. - 3

Connect your scan tool and access the live data stream.

- 4

Start the engine and let it warm up to normal operating temperature. Make sure the PCM is in closed loop before continuing.

- 5

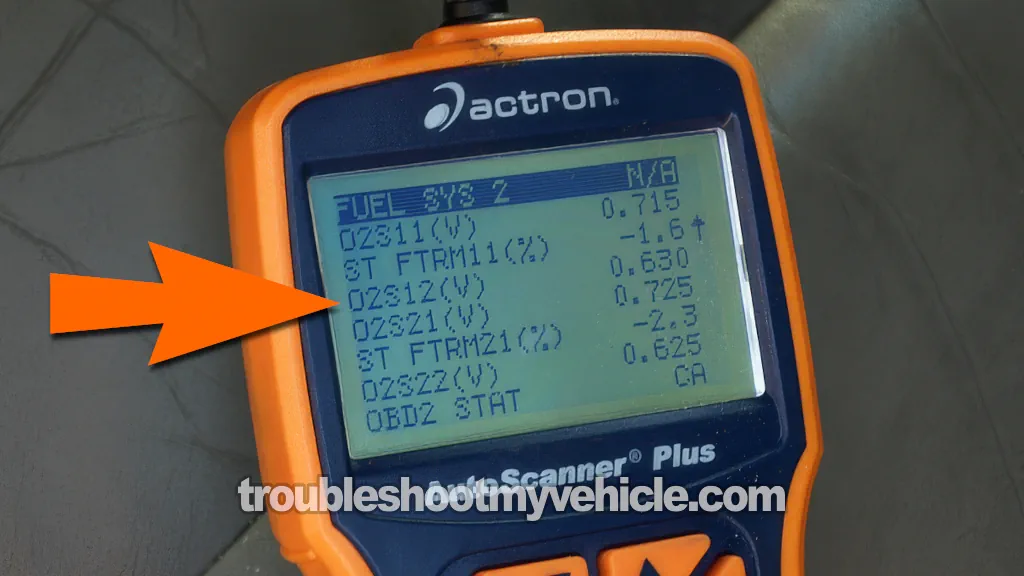

Locate the PID (parameter ID) for the rear oxygen sensor.

On most scan tools, this will be labeled O2S12 (Bank 1, Sensor 2). - 6

Let the engine idle for 2 to 3 minutes. This gives the rear O2 sensor time to get hot enough to produce an accurate signal.

- 7

Carefully crack open the brake booster vacuum hose. Allow just enough unmetered air to enter so the engine leans out, but not so much that it stalls.

- 8

Watch the rear O2 sensor voltage on the scan tool.

If the sensor is working correctly, its output should drop quickly to 0.5 Volts or less as soon as the hose is opened. This confirms that it's reacting properly to the induced lean air/fuel mixture. - 9

When finished, close the vacuum hose securely to eliminate the air leak, and then shut off the engine.

Here's how to interpret your test results:

CASE 1: The rear O2 sensor reacted immediately to the lean condition we created. This tells us that the sensor is working correctly so far.

The next step is to check whether it can also react to a manually induced rich condition, which we'll do in: TEST 3: Manually Inducing A Rich Air/Fuel Mixture.

CASE 2: The rear O2 sensor reacted slowly or did not react at all to the lean condition we created. This tells us the sensor is failing, since it should react immediately to the induced lean condition. In either situation, the sensor is malfunctioning and needs to be replaced.

If you're ready to replace it, I've placed links below to rear O2 sensors from well-known automotive brands that I've personally used and trusted for many years.

- Walker Products 350-34122 Oxygen Sensor (Amazon affiliate link).

- Denso 234-4797 Oxygen-Sensor (Amazon affiliate link).

TEST 3: Manually Inducing A Rich Air/Fuel Mixture

In this test, we're going to force the engine into a rich condition to see if the rear oxygen sensor reacts properly.

We're gonna create this rich condition by disconnecting the air duct at the throttle body and spraying starting fluid into it (the throttle body). Before you do this, make sure to check if your Accord is equipped with a MAF sensor.

If your Accord does have a mass airflow (MAF) sensor, we can't spray fuel directly into the throttle body —that would bypass the MAF, and we don't want that.

Instead, on MAF-equipped Accords, we'll introduce the starting fluid through the top air filter box cover (after loosening it). This way, the MAF still measures the airflow and isn't bypassed.

If your Accord doesn't have a MAF sensor, then you can disconnect the air duct directly at the throttle body and spray the starting fluid there.

Here's what to expect:

- Good sensor: A properly functioning rear O2 sensor should react instantly, spiking to 0.9 Volts or higher as soon as the starting fluid hits the engine.

- Bad sensor: If the sensor doesn't respond or reacts sluggishly, then it isn't doing its job and needs to be replaced.

Let's put this into action:

- 1

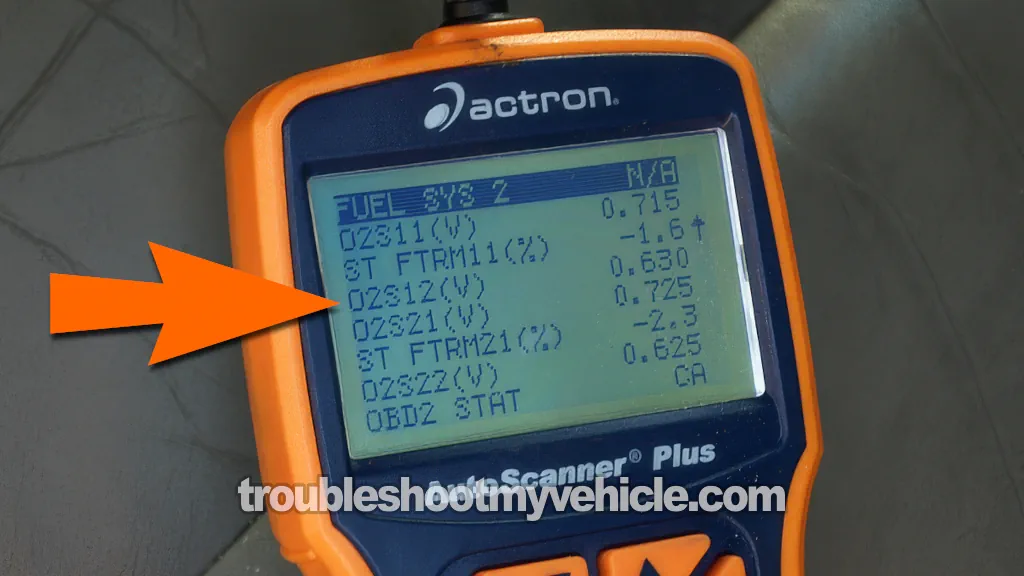

Connect your scan tool and go to the live data stream. Locate the PID for the rear oxygen sensor (usually labeled O2S12, Bank 1 Sensor 2).

- 2

Start the engine and let it warm up to normal operating temperature. The PCM must be in closed loop mode before continuing.

- 3

Let the engine idle for at least 2–3 minutes so the rear O2 sensor is fully up to operating temperature.

- 4

Spray a short burst of starting fluid into the throttle body (non-MAF sensor) or open air filter box (with MAF sensor) while watching the scan tool data.

Do not overspray —just a quick, controlled burst is enough to create a rich condition.

NOTE: If the engine stalls, you've sprayed too much. Restart the engine, let it idle for 1 to 2 minutes, and repeat this test step. - 5

Observe the rear O2 sensor voltage on the scan tool.

- 6

The rear O2 sensor voltage output should rise immediately above 0.8 Volts as soon as the starting fluid is drawn into the engine.

- 7

When finished, close the air filter box securely and shut off the engine.

Here's how to interpret your test results:

CASE 1: The rear O2 sensor reacted IMMEDIATELY to the rich condition we created. This is the correct and expected test result and confirms that the sensor can react quickly.

You can conclude the sensor is good, you should have:

- Seen the rear O2 voltage swing slowly between lean and rich in TEST 1.

- Verified that it reacted immediately to the lean condition in TEST 2.

- Observed it react to the rich condition in this test.

If all three are true, then the rear O2 sensor is working as it should.

CASE 2: The rear O2 sensor reacted slowly or did not react at all to the rich condition we created. This tells us the sensor is failing, since it should react immediately to the rich condition induced with the starting fluid. In either situation, the sensor is malfunctioning and needs to be replaced.

If you're ready to replace it, I've placed links below to rear O2 sensors from well-known automotive brands that I've personally used and trusted for many years.

- Walker Products 350-34122 Oxygen Sensor (Amazon affiliate link).

- Denso 234-4797 Oxygen-Sensor (Amazon affiliate link).

More 2.4L Honda Accord Tutorials

You can find a complete list of tutorials for your 2.4L Honda Accord equipped car here:

Here's a small sample of the tutorials you'll find in the index:

- How To Test The TPS With A Multimeter (2003-2006 2.4L Honda Accord).

- How To Test The Fuel Injectors (2003-2007 2.4L Honda Accord).

- How To Test The Ignition Coils (2003-2006 2.4L Honda Accord).

- How To Test The MAP Sensor (2003-2007 2.4L Honda Accord).

If this info saved the day, buy me a beer!