When your 2.4L Honda Accord sets a P0420: Catalyst System Efficiency Below Threshold code, the PCM is telling you that the catalytic converter is no longer doing its job of cleaning up the exhaust gases passing through it.

In the vast majority of cases (I'd say in about 99 times out of 100) the fix will be to replace the converter. Still, it's important to do a couple of quick checks first to make sure the converter is truly toast.

In this guide, I'll take you through those checks step by step, one of them uses nothing more than a basic scan tool that can display live data. You can perform every step right in your driveway or garage without any special shop equipment.

Contents of this tutorial:

- Symptoms Of A Bad Catalytic Converter.

- What Causes Catalytic Converters To Go Bad?

- Catalytic Converter Diagnostic Checklist.

- TEST 1: Checking For A Broken Catalytic Converter.

- TEST 2: Checking Catalytic Converter Performance With O2 Sensor Data.

- What "Rich" And "Lean" Mean.

- What "Closed Loop" Means And Why It's Important.

- More 2.4L Honda Accord Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 2.4L Honda Accord: 2003, 2004, 2005, 2006, 2007.

REAR OXYGEN SENSOR DIAGNOSTIC TESTS: The following tutorial explains how to test the rear oxygen sensor step-by-step:

- Rear Oxygen Sensor Performance Tests (2003-2007 2.4L Honda Accord).

- P0137 Diagnostic Tests -Rear O2 Sensor (2003-2007 2.4L Honda Accord).

- P0138 Diagnostic Tests -Rear O2 Sensor (2003-2007 2.4L Honda Accord).

- P0141 Diagnostic -Rear O2 Sensor Heater Tests (2003-2007 2.4L Honda Accord).

Symptoms Of A Bad Catalytic Converter

On your 2003–2007 2.4L Honda Accord, the catalytic converter usually fails in one of two ways:

- Its internal substrate breaks apart into pieces.

- Its ability to scrub exhaust gases drops below the PCM's set efficiency threshold.

Depending on which of these failures occurs, the symptoms can range from barely noticeable to hard-to-ignore performance problems.

Either way, a failing converter will hurt performance and fuel economy. Here are the most common signs to watch for:

- Check Engine Light on with a stored P0420 code: You'll see the check engine light lit up on your instrument cluster when the catalytic converter starts to fail or has failed completely.

- Noticeable loss of power (especially when accelerating or climbing a hill): The engine will feel sluggish and unresponsive, and it may struggle to maintain speed on steep grades or when you try to pass another vehicle.

- Reduced fuel economy: You'll find yourself filling up more often because the engine has to work harder, burning more fuel than usual to overcome the restricted exhaust flow or inefficient emissions cleanup.

- Rattling sound from underneath the vehicle: If the converter's internal ceramic core breaks apart, you'll hear a metallic rattle from under the car, especially when starting the engine or revving it.

- Rotten-egg or sulfur smell from the exhaust: A failing catalytic converter can produce a strong, unpleasant odor that smells like sulfur or rotten eggs coming from the tailpipe.

- Converter overheating (in severe cases, glowing red hot): A clogged or overloaded converter can overheat to the point where it glows red during or after driving (something you might notice during a nighttime visual check).

What Causes Catalytic Converters To Go Bad?

A catalytic converter can fail on its own after many years of service, but in my opinion that's becoming more rare. In most cases, some issue upstream in the engine or exhaust system damages it much sooner.

Here are the most common problems that accelerate the demise of the catalytic converter on your Accord:

- Engine misfires: When an engine misfires, raw unburned fuel enters the exhaust stream. This fuel ignites inside the converter, causing extreme heat that can damage the ceramic substrate of the catalyst (filtering) element.

- Engine burning oil or coolant: Oil leaking past valve seals or piston rings —or coolant entering through a blown head gasket— contaminates the converter catalyst element's surface with deposits that prevent it from doing its job.

- Fuel-rich conditions from leaking injectors: A stuck-open or leaking fuel injector dumps excess fuel into the exhaust. This leads to overheating, substrate damage, and eventual loss of catalytic efficiency.

- Fuel-rich conditions from faulty sensors: A malfunctioning oxygen sensor, MAP sensor, or MAF sensor can cause the PCM to command an overly rich air/fuel mixture. Over time, this overheats and damages the converter internally.

- Stuck-open thermostat: If the thermostat sticks open, the engine runs cooler than normal. The PCM compensates with a richer mixture, which increases converter temperature and shortens its life.

- Physical damage to converter housing/core: Because the catalytic converter is mounted underneath the vehicle, it's vulnerable to impacts from road debris or bottoming out in potholes. A single hard hit can crack or shatter the ceramic core inside —instantly killing the converter.

The most important thing to keep in mind is to always fix the root cause of the catalytic converter failure (if there is one) before installing the new one —otherwise, the replacement will fail prematurely and the P0420 code will light up the check engine light again.

Catalytic Converter Diagnostic Checklist

Over the years, I've diagnosed more P0420 trouble codes than I can count (on all types of vehicles). One thing experience has taught me is this: when a P0420 turns on the check engine light, the converter is almost always failing or already failed.

Even so, I run through a checklist of common issues that could be killing it. This step is important, and I want to share it with you so you don't end up replacing the converter only to have the new one fail because the root cause wasn't fixed first.

Here's what I check right away whenever a P0420 shows up:

- STEP 1: Look for other diagnostic trouble codes (DTCs): Check for any codes that point to a sensor problem that could make the PCM run the engine rich. Cylinder misfire codes are a big red flag. If a sensor has failed and is causing the PCM to inject too much fuel, that extra fuel will overheat and damage the converter.

- STEP 2: Inspect the spark plugs: Make sure the electrodes haven't worn down to nubs. Worn plugs can cause misfires or incomplete combustion, which sends unburned fuel into the converter and can destroy it.

- STEP 3: Check for a recent blown head gasket issue: A head gasket failure that allows coolant to burn in the cylinders and flow out through the exhaust is one of the biggest catalytic converter killers out there, since it reduces the converter's ability to clean the exhaust passing through it. So, has the head gasket failed and been replaced in the last few weeks?

- STEP 4: Look for signs of oil burning: An engine that's consuming oil will coat the converter's filtering element with carbon and ash, killing its ability to clean the exhaust flowing through it.

- STEP 5: Check for a broken catalytic converter: Sometimes the catalytic converter's ceramic core will break apart inside the housing. When that happens, the loose pieces can rattle around, shift position, and even block exhaust flow. To check for this, see: TEST 1: Checking For A Broken Catalytic Converter.

- STEP 6: Check catalytic converter performance: One of the ways I've found to evaluate a bad converter is by checking the voltage output of the downstream (rear) oxygen sensors. I'll show you how step-by-step in this section: TEST 2: Checking Catalytic Converter Performance With O2 Sensor Data.

- STEP 7: Erase the P0420 DTC and road test: If the engine isn't burning oil, the head gasket hasn't been replaced recently, the plugs are in good shape, and there are no other codes (like MAP sensor codes, TPS codes, or misfire codes), erase the P0420 and drive the vehicle for a few days. If the P0420 comes back, the converter is toast.

TEST 1: Checking For A Broken Catalytic Converter

One of the most common ways a catalytic converter fails is when the ceramic substrate inside cracks or breaks apart. When the internal core is damaged, the loose pieces often rattle around inside the converter body. This is most noticeable when starting the engine or pressing the accelerator to rev the engine.

For this first inspection, we'll lightly tap on the catalytic converter with a rubber mallet, or with the palm of your hand if you don't have one, and listen for any internal rattling.

IMPORTANT: Perform this check only when the engine and exhaust system are completely cold. Exhaust components can stay hot for quite a while after the engine is shut off.

SAFETY WARNING: You'll need to raise the vehicle to access the catalytic converter. Always use jack stands on a solid, level surface, and never get under a vehicle supported only by a jack.

Here's the procedure:

- 1

Safely raise the vehicle and support it with jack stands.

NOTE: Make sure the engine is cold before starting. Use wheel chocks and jack stands for added safety. - 2

Lightly tap the catalytic converter's outer shell with your palm or a rubber mallet.

Avoid hitting it hard, the goal is to gently move the internal parts just enough to detect if anything is loose. - 3

Listen carefully for rattling or clunking sounds.

Tap in a few different spots to make sure the entire converter is checked.

How to interpret your results:

CASE 1: Rattling is heard coming from inside the converter. This indicates the ceramic core inside has cracked or broken into pieces.

When this happens, those loose fragments can shift around and partially block the exhaust flow. This can lead to reduced power, sluggish acceleration, or even engine stalling.

CASE 2: No rattling detected. This suggests the converter's internal structure is still intact.

To continue diagnosing the P0420 code, go to: TEST 2: Checking Catalytic Converter Performance With O2 Sensor Data.

TEST 2: Checking Catalytic Converter Performance With O2 Sensor Data

In this test, we're going to determine if the catalytic converter is still reducing emissions effectively by checking the rear oxygen sensor (after the converter).

As you probably already know, the rear (downstream) oxygen sensor is mounted after the catalytic converter and allows the PCM to measure the oxygen content in the exhaust once it has passed through the converter.

In a properly functioning system, the rear O2 sensor will slowly cycle between rich (about 0.9V) and lean (about 0.1V).

But if the catalytic converter is toast, the rear O2 sensor will often stay locked in a rich state above 0.5 Volts instead of cycling between rich and lean.

If you're unfamiliar with terms such as "rich", "lean", or "closed loop", these sections explain them in detail:

The cool thing is you can see the rear O2 sensor's output with a scan tool that has live data functionality, and that's exactly how we'll test it in this section. If you don't have a scan tool (or are looking for one), here's my recommendation:

- ZM301 OBD2 Scanner Diagnostic Tool (at: amazon.com) (Amazon affiliate link).

IMPORTANT: Make sure the engine has reached normal operating temperature and is in closed loop mode before you begin. You'll need a scan tool with live data capability to watch the sensor's voltage output in real time.

NOTE: The terms "rear" and "downstream" oxygen sensor refer to the same sensor, which is installed after the catalytic converter. The terms "front" and "upstream" oxygen sensor also refer to the same sensor, which is mounted before the converter (mentioned here only for context).

Alright, let's get going:

- 1

Start the engine and let it warm up completely.

Use your scan tool to confirm that the PCM is in closed loop mode before moving forward. - 2

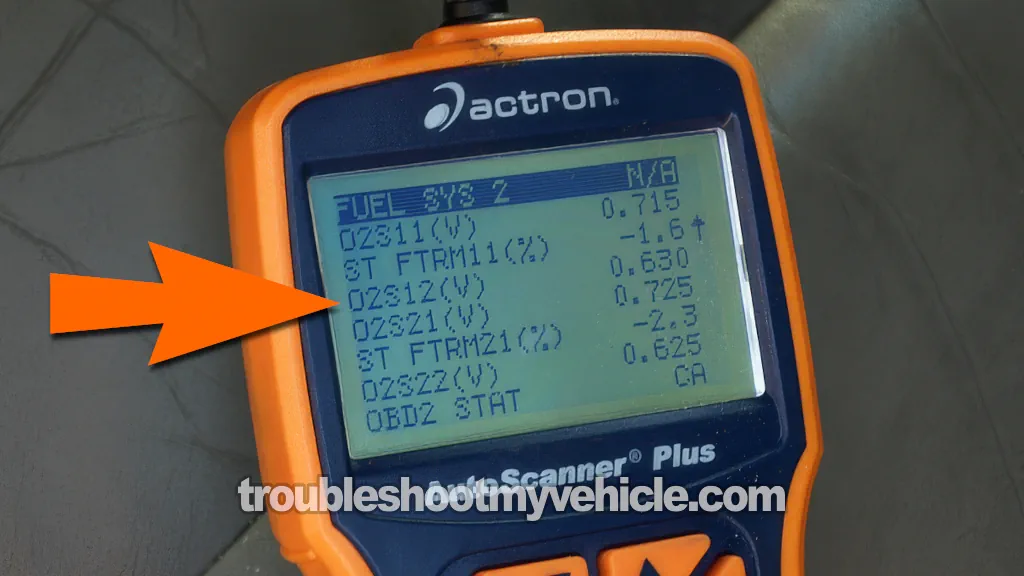

Connect your scan tool and open the live data display.

- 3

Locate the parameter ID (PID) for the downstream oxygen sensor.

On most scan tools, the downstream sensor (after the converter) will be labeled O2S12. - 4

Observe O2S12 voltage readings.

Let the engine idle while you watch the sensor for one to two minutes.

A healthy catalytic converter will cause the O2S12 sensor's output voltage to cycle very slow below and above 0.5 Volts. If the converter has failed, O2S12 will often remain locked above 0.5 Volts with little movement.

Here's how to read your test results:

CASE 1: The downstream sensor voltage shows a continuous rich condition (staying at or above 0.5 Volts with little to no change). This usually means the catalytic converter is no longer functioning efficiently and that exhaust gases are passing through without being cleaned.

If there are no other diagnostic trouble codes (DTCs) present and the spark plugs are in good condition, you can conclude the catalytic converter is fried and needs to be replaced.

NOTE: If you suspect the rear oxygen sensor itself might be faulty (even if no specific O2 sensor DTC is present), you can check its performance. I'll show you how in this tutorial: Rear Oxygen Sensor Performance Tests (2003-2007 2.4L Honda Accord).

CASE 2: The downstream sensor voltage changes more slowly, with smaller swings than 0.5 Volts, and is not stuck high. This suggests the converter is working as intended at this present time.

If there are no other diagnostic trouble codes (DTCs) present and the spark plugs are in good condition, go ahead and clear the P0420 code and drive the vehicle a few days. If the P0420 comes back, you can conclude the catalytic converter is fried and needs to be replaced.

What "Rich" And "Lean" Mean

When diagnosing catalytic converter or oxygen sensor problems, you'll often hear the terms "rich" and "lean".

In general, these terms describe the air/fuel ratio —the balance of air and gasoline the engine needs to run at its best. Specifically:

- Rich: The air/fuel mixture has more fuel and less air.

- Lean: The air/fuel mixture has more air and less fuel.

The technical name for this balance is the stoichiometric ratio, which is 14 parts of air to 1 part of fuel for ideal combustion.

Now, when we're talking about the rear O2 sensor, we're not looking at the mixture going in —we're looking at what's left over after combustion and after the exhaust gases have passed through the catalytic converter. In other words, we're measuring how much oxygen or unburned fuel remains in the exhaust stream at that point.

Here's how the rear O2 sensor interprets those conditions:

- Rich: The exhaust still carries excessive amounts of unburned fuel (hydrocarbons) even after passing through the catalytic converter. This tells us the converter wasn't able to scrub all of the hydrocarbons from the exhaust. Up to a certain point, this is normal —but when the rear sensor consistently reports high voltage, it indicates the converter is no longer oxidizing those hydrocarbons effectively. The rear O2 sensor will respond with a high voltage signal, usually around 0.8 to 0.9 Volts.

- Lean: The exhaust leaving the converter contains more oxygen than fuel residue (some unburned fuel is always present, since no engine burns perfectly). This indicates the converter was able to oxidize most of the hydrocarbons in the exhaust stream. The rear O2 sensor voltage will drop low, typically in the 0.1 to 0.2 Volt range.

What "Closed Loop" Means And Why It's Important

When the engine is first started (like after it has sat overnight or for a few hours and cooled down completely) the PCM operates in what is known as open loop mode.

In open loop, the PCM does not rely on live feedback from the oxygen sensors. Instead, it uses preset fuel values until the O2 sensors and engine warm up enough for accurate sensor readings. In other words, it's running on a fixed program until conditions are ready for real-time adjustments.

Once the O2 sensors have activated (which happens quickly thanks to the heating elements built into them) and the engine reaches a certain operating temperature, the PCM switches to closed loop mode.

Once in closed loop, the PCM begins adjusting the fuel mixture instantly and in real time, using feedback from the O2 sensors along with data from other engine management sensors. This results in better performance, lower emissions, and improved fuel economy.

If you're testing catalytic converter performance or downstream oxygen sensor function, it's essential that the engine is in closed loop mode. Without it, the data you see will not represent real driving conditions.

Most scan tools will indicate when this switch occurs. Look in the live data for something like "Fuel System Status: Closed Loop". That's your sign that it's safe to start testing.

Attempting to measure sensor performance while the PCM is still in open loop will give misleading results, so always allow the engine to warm up fully before beginning any tests.

More 2.4L Honda Accord Tutorials

You can find a complete list of tutorials for your 2.4L Honda Accord equipped car here:

Here's a small sample of the tutorials you'll find in the index:

- How To Test The TPS With A Multimeter (2003-2006 2.4L Honda Accord).

- How To Test The Fuel Injectors (2003-2007 2.4L Honda Accord).

- How To Test The Ignition Coils (2003-2006 2.4L Honda Accord).

- How To Test The MAP Sensor (2003-2007 2.4L Honda Accord).

If this info saved the day, buy me a beer!