Testing camshaft position (CMP) sensor A isn't that difficult and it's something you can do with a multimeter (no scan tool needed).

In this tutorial, I'll explain how to check CMP Sensor A's output signal, and make sure it's getting both power and Ground. These three tests will let you know for sure whether CMP Sensor A —which monitors and helps control the Variable Timing Control (VTC) system— is in good shape or needs to be replaced.

Now, if you'd prefer to skip the diagnostic tests and go straight to swapping it out, no problem. I'll show you where you can buy a quality replacement from a known automotive brand I've trusted for years.

Contents of this tutorial:

- Symptoms Of A Bad CMP Sensor A (Intake Cam – VTC Control).

- Should I Replace CMP Sensor A Without Testing It?

- Where To Buy The CMP Sensor And Save.

- How the CMP Sensor A Works.

- TEST 1: Checking The CMP Signal With A Multimeter.

- TEST 2: Making Sure The CMP Sensor Is Getting 12 Volts.

- TEST 3: Making Sure The CMP Sensor Is Getting Ground.

- More 2.4L Honda Accord Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 2.4L Honda Accord: 2003, 2004, 2005, 2006, 2007.

CMP SENSOR WIRING DIAGRAM:

CMP SENSOR B TESTS:

CKP SENSOR TESTS:

Symptoms Of A Bad CMP Sensor A (Intake Cam – VTC Control)

The 2003–2007 2.4L Honda Accord uses two separate camshaft position sensors:

- Sensor A (intake camshaft side): Feeds the PCM cam position data so it can monitor and control the Variable Timing Control (VTC) system.

- Sensor B (exhaust camshaft side): Provides the cylinder identification signal that lets the PCM know exactly where cylinder #1 is in the combustion cycle.

When CMP Sensor A starts to fail or stops working altogether, the PCM can't accurately track the intake camshaft's position —and that throws the VTC system out of sync. Here's what you might notice:

- Loss of VTC performance: You may feel reduced power, especially under acceleration, because the intake cam timing isn't being adjusted properly.

- Sluggish throttle response: The engine feels flat or hesitant when you tip into the gas, since cam timing is stuck in one position.

- Bad gas mileage: Incorrect intake cam timing can cause the PCM to run less efficient spark and fuel timing strategies.

- Rough idle or unstable RPM: With the cam timing control disabled, the engine may idle unevenly.

- Check Engine Light with CMP A trouble codes: The most common codes for a failed or failing CMP Sensor A are:

- P0341: CMP Sensor A Range/Performance Problem.

- P0344: CMP Sensor A Intermittent Interruption.

- Occasional stalling or hard starting: While less common than with CMP Sensor B failures, an intake cam signal problem can still cause starting issues in certain conditions.

Should I Replace CMP Sensor A Without Testing It?

When a CMP Sensor A trouble code lights up the check engine light, the most common reaction is to replace the sensor right away without testing it. And there are plenty of reasons why:

- Some folks don't have the step-by-step testing info.

- Others don't have the tools.

- And some just don't have the time.

There's nothing wrong with replacing it outright. If swapping the sensor fixes the problem —great, life goes on. If it doesn't, well, now you know you need to dig deeper, and in that case, the cost of the sensor is simply part of the diagnostic process.

That said, here's the case for testing the CMP sensor before replacing it: quite a few issues besides an internal sensor failure can trigger a CMP Sensor A code —and one of the biggest culprits is a timing chain problem.

If the timing chain stretches or skips a tooth (or more) and this happens quite a bit on high mileage/older vehicles, the PCM will flag a CMP Sensor A trouble code, even though the sensor itself is fine.

This is why I encourage you to test the sensor before spending $30–$50 on a replacement that may not solve the problem. Testing the CMP sensor isn't difficult, and in this tutorial I'll walk you through the process step by step.

Now, if you've already decided to replace it without testing, no problem —below you'll find a link to CMP Sensor A from a reputable brand I've used for years and still trust today:

- Holstein 2CAM0355 CMP Sensor (Amazon affiliate link)

But if you'd prefer to confirm without a doubt that the sensor is at fault before replacing it, stick with me —I'll walk you through the exact test procedure, step by step.

Where To Buy The CMP Sensor And Save

If you're ready to replace the CMP Sensor A, here are two options from trusted automotive brands I've used time and time again —and still recommend without hesitation. They've earned my trust through years of real-world use (I try to avoid knockoffs):

Disclosure: As an Amazon Associate, I earn from qualifying purchases. Buying through these links helps support this site at no extra cost to you. Thanks for your support —it really means a lot!

How the CMP Sensor A Works

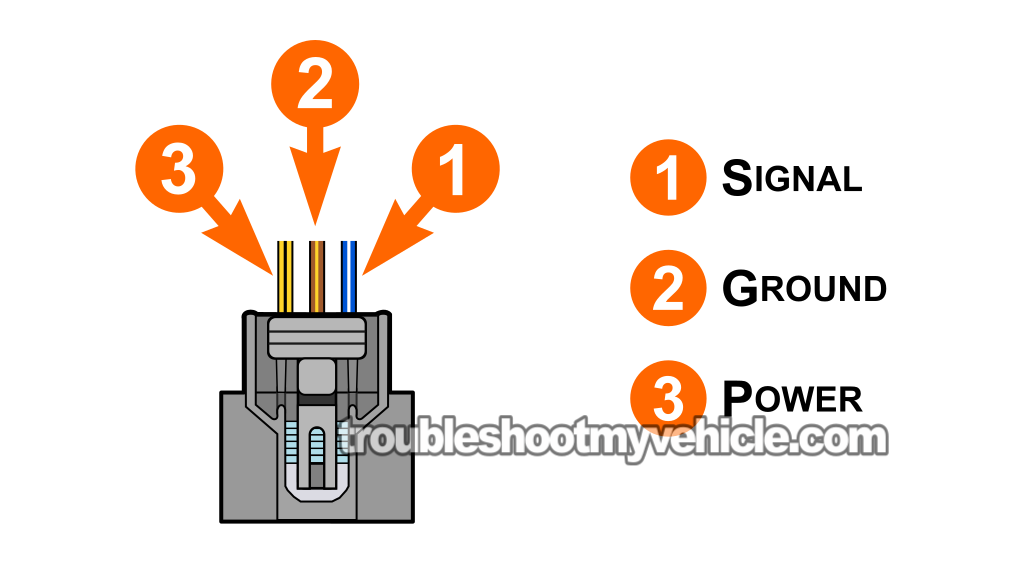

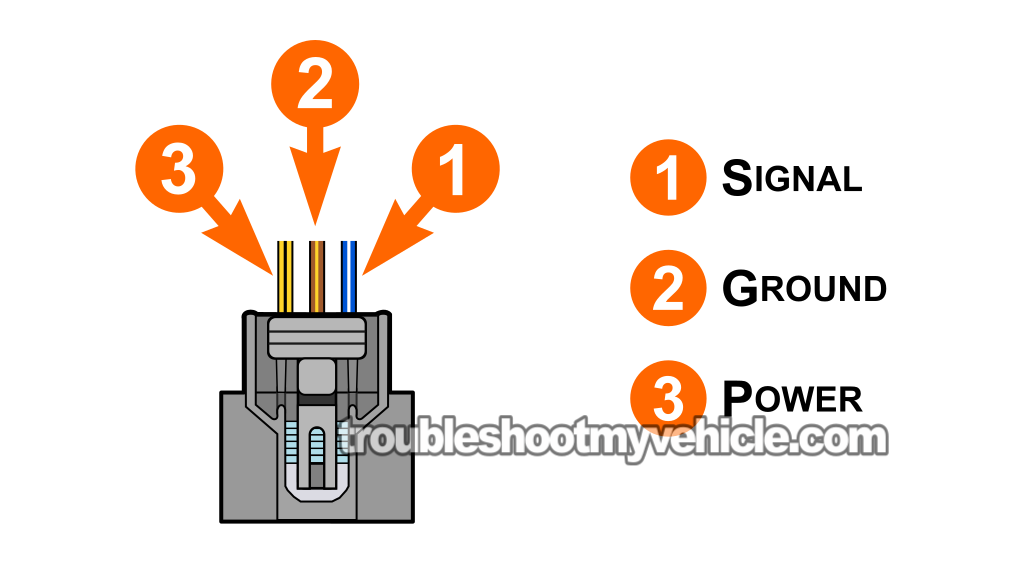

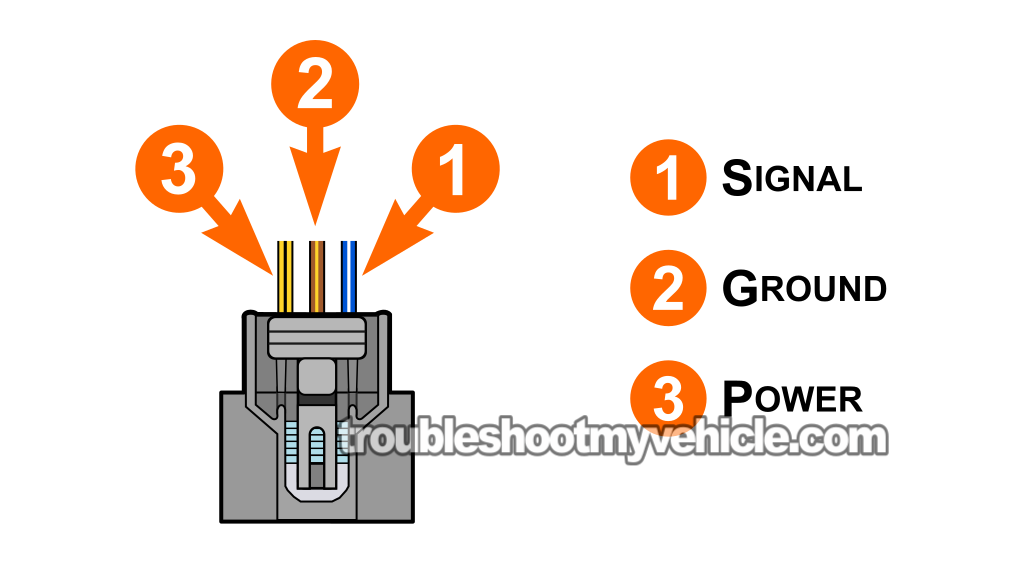

The camshaft position (CMP) sensor A on the 2003–2007 2.4L Accord is bolted into the rear of the cylinder head —the side that faces the EGR Valve and automatic transmission. It reads a four-tooth trigger wheel mounted on the intake camshaft and operates as a Hall-effect sensor.

Here's a breakdown of how it works —this will help you picture what's going on during the test:

- With the key in the RUN or START position, the sensor receives 10–12 Volts on the yellow with black stripe (YEL/BLK) wire and chassis Ground on the brown with yellow stripe (BRN/YEL) wire.

- As the intake camshaft rotates, each tooth on the trigger wheel passes under the sensor, causing the signal voltage (sent to the PCM through the blue with white stripe (BLU/WHT) wire) to switch between high (~5 Volts) and low (near 0 Volts).

- Each time a tooth passes, you get one ON/OFF pulse.

- Since the camshaft turns at half the crankshaft speed, two complete crankshaft revolutions equal one full camshaft revolution.

- For every full camshaft revolution, CMP Sensor A produces four ON/OFF pulses (4 pulses per 2 crankshaft revolutions).

NOTE: The key thing to remember while testing the CMP Sensor A is that, since the camshaft turns at half the speed of the crankshaft, you'll need to rotate the crankshaft pulley two complete turns to see all four ON/OFF pulses during your test. Turning it only one full crankshaft revolution will produce roughly two pulses.

TEST 1: Checking The CMP Signal With A Multimeter

The first step in diagnosing CMP Sensor A is to confirm that it's producing a proper ON/OFF voltage signal as the engine is rotated by hand.

This signal alternates between ON and OFF. Specifically:

- ON: The multimeter displays around 5 Volts DC.

- OFF: The reading drops to 0 Volts (anything close to 0.2 V is considered zero).

For accurate results, the engine must be turned over manually —using a 1/2-inch ratchet and the correct socket on the crankshaft pulley to rotate it yourself.

If you don't have a multimeter, or are thinking about upgrading, here's the model I personally use and recommend:

- Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (Amazon affiliate link).

LOCATION: CMP Sensor A is mounted at the front of the cylinder head on the intake camshaft side (timing chain side of the engine). It reads the camshaft's trigger wheel to help the PCM control the Variable Timing Control (VTC) system. Access typically requires removing the upper timing cover components in the sensor area.

IMPORTANT: Disconnect all ignition coil connectors before performing this test. This prevents the engine from starting while you're working.

CAUTION: To manually crank the engine, you'll need to raise the front of the vehicle to access the crankshaft pulley bolt. Always support the vehicle securely on jack stands —never rely solely on a jack.

NOTE: Keep the CMP sensor connected to its 3-wire harness during the test. The easiest and safest way to tap into the signal wire is with a wire-piercing probe. If you don't have one, here's the exact tool I recommend: Goupchn 4mm Banana to Banana Plug Test Leads Kit (Amazon affiliate link).

Alright, let's get going:

- 1

Raise the front of the vehicle and support it securely on jack stands.

With the car safely supported, remove any splash shields or covers needed to access the crankshaft pulley bolt. - 2

Disable the ignition system by disconnecting each ignition coil from its electrical connector.

This prevents the engine from accidentally starting while you perform the signal check. - 3

Connect the red lead of your multimeter to the blue with white stripe (BLU/WHT) wire at the CMP Sensor A connector.

The BLU/WHT wire is the signal wire that sends the intake camshaft position information to the PCM.

NOTE: The CMP sensor must remain connected to its 3-wire harness while testing. Use a wire-piercing probe (or back-probing method) to attach your multimeter to the BLU wire without unplugging the connector. - 4

Switch your multimeter to Volts DC mode.

- 5

Ground the black multimeter lead to the negative (-) battery post. A jumper cable works well for a secure Ground connection.

- 6

Turn the ignition key to ON (Position II) without starting the engine.

This will power the CMP sensor so you can capture its output signal when the engine is rotated by hand. - 7

Use a 1/2-inch ratchet and the proper socket to turn the crankshaft pulley clockwise by hand two full revolutions.

NOTE: Use a bright-colored marker to put a reference mark on the crankshaft pulley. This will make it easy to keep track of the revolutions as you turn it.

IMPORTANT: To see the ON/OFF signal with your multimeter, you've got to rotate the engine manually. You're not gonna see the voltage pulse if you use the starter motor. - 8

Watch for an ON/OFF voltage signal on the multimeter (if the sensor is functioning properly).

"ON" means the multimeter shows about 5 Volts DC, and "OFF" means it drops to 0 Volts (anything near 0.2 V counts as zero).

NOTE: You should see a total of four ON/OFF pulses during two full turns of the crankshaft pulley.

How to read your results:

CASE 1: You saw four ON/OFF 5-volt pattern while rotating the engine by hand two full revolutions. This indicates CMP Sensor A is generating a valid signal.

No additional testing is required —if the signal is present, the sensor is already receiving the power and Ground it needs.

CASE 2: No ON/OFF 5-volt signal appears while turning the engine manually. This often means the sensor has failed, but before replacing it, we need confirm that it's getting both battery power and a solid Ground.

By verifying the power and Ground circuits, you can avoid replacing a good sensor and identify if the real fault lies elsewhere. The next step is to confirm power: TEST 2: Making Sure The CMP Sensor A Is Getting 12 Volts.

TEST 2: Making Sure The CMP Sensor Is Getting 12 Volts

In TEST 1, we determined that CMP Sensor A isn't outputting the ON/OFF voltage signal the PCM uses to control the VTC system.

The next step is to make sure the sensor is actually being supplied with power. On your Honda Accord, that means checking that the yellow with black stripe (YEL/BLK) wire is delivering 10 to 12 Volts with the key turned to the ON or START position.

To check for the presence of this voltage, we'll do a simple and easy multimeter voltage test.

Alright, let's get this show on the road:

- 1

Disconnect the CMP Sensor A connector.

- 2

Set your multimeter to Volts DC.

- 3

Connect the black multimeter lead to the negative (-) terminal of the battery.

- 4

Have an assistant turn the ignition switch to ON —but do not start the engine.

- 5

Probe the terminal for the YEL/BLK wire with the red multimeter lead, making contact from the front of the connector.

- 6

Your multimeter should read between 10 and 12 Volts DC.

Interpreting your results:

CASE 1: The multimeter shows battery voltage on the YEL/BLK wire. This confirms that CMP Sensor A is getting the power it needs. The next step is to verify its Ground circuit: TEST 3: Making Sure CMP Sensor A Is Getting Ground.

CASE 2: No voltage on the YEL/BLK wire. In this case, the sensor itself isn't to blame —without power, it can't operate.

To get it working again, you'll need to find and fix the source of the missing voltage. For reference, here's the wiring diagram you'll need:

TEST 3: Making Sure The CMP Sensor Is Getting Ground

By this point, the first two tests have already confirmed two important things:

- CMP Sensor A is not producing the ON/OFF signal we expect (from TEST 1).

- The sensor is receiving battery voltage on the YEL/BLK wire (from TEST 2).

The last step is to make sure that the brown with yellow stripe (BRN/YEL) wire is providing a reliable chassis Ground.

This Ground should be present at all times. To verify it, we'll do a simple voltage check similar to the battery power test you performed in TEST 2.

Here's what we need to do:

- 1

Disconnect CMP Sensor A from its electrical connector.

- 2

Set your multimeter to Volts DC.

- 3

Connect the red multimeter lead to the positive (+) battery terminal.

- 4

Have a helper turn the ignition key to ON, without starting the engine.

- 5

Using the black multimeter lead, probe the terminal for the BRN/YEL wire from the front of the connector.

- 6

You should see a reading between 10 and 12 Volts DC.

How to interpret the results:

CASE 1: The BRN/YEL wire shows a solid Ground. This is exactly what you want to see.

If you have confirmed all of the following:

- No signal output from the sensor (TEST 1),

- Correct power on the YEL/BLK wire (TEST 2),

- And now a good Ground on the BRN/YEL wire (TEST 3),

…then you can be confident that CMP Sensor A is defective and should be replaced.

Here are two high-quality replacements I recommend —from brands I've trusted and used many times in professional repairs:

- Holstein 2CAM0355 CMP Sensor (Amazon affiliate link)

CASE 2: No Ground on the BRN/YEL wire. In this case, the CMP Sensor A itself isn't the cause —without a proper Ground, it simply can't function.

Tracking down and fixing the missing Ground is beyond the scope of this tutorial, but once restored, the sensor will work normally and the PCM will clear the trouble code. For help finding the fault, use the following wiring diagram:

More 2.4L Honda Accord Tutorials

You can find a complete list of tutorials for your 2.4L Honda Accord equipped car here:

Here's a small sample of the tutorials you'll find in the index:

- How To Test The TPS With A Multimeter (2003-2006 2.4L Honda Accord).

- How To Test The Fuel Injectors (2003-2007 2.4L Honda Accord).

- How To Test The Ignition Coils (2003-2006 2.4L Honda Accord).

- How To Test The MAP Sensor (2003-2007 2.4L Honda Accord).

If this info saved the day, buy me a beer!