When a crankshaft position sensor trouble code lights up the check engine light, it usually points to a failed CKP sensor.

At that point, you have two options: test it, or replace it without testing.

Either approach works —but if you want to test the sensor, this tutorial will walk you through the process step-by-step so you can know for sure if it's good or bad.

If you'd rather skip the testing and go straight to replacement, that's fine too. I'll also show you where to get a quality sensor from a trusted automotive brand I've used for years and confidently recommend.

Contents of this tutorial:

- Symptoms Of A Bad CKP Sensor.

- Should I Just Replace The CKP Sensor Without Testing It?

- Where To Buy The Crank Sensor And Save.

- TEST 1: Checking The CKP Signal With A Multimeter.

- TEST 2: Making Sure The CKP Sensor Is Getting 12 Volts.

- TEST 3: Making Sure The CKP Sensor Is Getting Ground.

- More 2.4L Honda Accord Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 2.4L Honda Accord: 2003, 2004, 2005, 2006, 2007.

CKP SENSOR WIRING DIAGRAM:

CMP SENSOR A AND B TESTS:

- How To Test The Camshaft Position Sensor B (2003-2007 2.4L Honda Accord).

- How To Test The Camshaft Position Sensor A (2003-2007 2.4L Honda Accord).

Symptoms Of A Bad CKP Sensor

On the 2.4L Accord, one of the clearest signs of a bad crankshaft position (CKP) sensor is a cranks but won't start situation.

The engine control module (ECM) is programmed to detect a failed CKP sensor and will usually trigger one of these diagnostic trouble codes:

- P0335: CKP Sensor No Signal Detected.

- P0336: CKP Sensor Signal Range/Performance Problem.

- P0339: CKP Sensor Intermittent Signal Loss.

When the CKP sensor hasn't completely died, it can fail off and on, and these intermittent failures can cause a range of issues, such as:

- Starts, then stalls immediately: May catch for a second or two, then die.

- Intermittent no-start condition: Sensor works sometimes, fails other times.

- Stalling while driving: Engine may cut out abruptly. You can usually restart it, but sometimes restarting is a challenge until the engine cools down.

Intermittent failures of the CKP sensor can be tricky to trace back to the sensor. Most of the time the CKP sensor works fine, and when it does fail, it might "come back to life" before you get a chance to test it.

If your Accord is stalling at random, you'll need to catch it in the act of not starting to confirm a CKP sensor fault. If it starts and stays running, the sensor is producing a signal and can't be tested accurately at that moment.

ENGINE NO-START DIAGNOSTICS: If you're diagnosing an engine no-start problem, this guide is a good resource:

Should I Just Replace The CKP Sensor Without Testing It?

If a CKP sensor code like P0320, P0335, or P0339 is:

- Lighting up the check engine light,

- The engine either won't start or has a clear driveability problem,

- And there are no other trouble codes present...

...then most folks (including plenty of repair shops) will skip the testing and go straight to swapping in a new crankshaft position sensor.

In many cases, that's the go-to diagnostic strategy. And there are three big reasons why:

- It's inexpensive: The CKP sensor isn't a high-dollar ignition system part, so replacing it right away feels like a low-risk move.

- It's not that difficult to replace: Although it's not the easiest part to replace on your Accord's engine, it's still not that big of a job. With the right tools and a little patience, most folks can swap it out in under an hour.

- It's a bit of a challenge to test in place: On paper, checking it with a multimeter is simple. In reality, its location makes connecting your multimeter test lead to the CKP signal wire a bit of a pain.

For some folks, the cost of the sensor is just part of the diagnostic process. Swap it out and if it fixes the problem, great —job done. If it doesn't, well, now it's time to dig deeper.

There's nothing wrong with that approach. If you're leaning that way, here are two CKP sensors I recommend from automotive brands I trust and that I've used many times in the field:

- Hitachi CPS0221 Engine Crankshaft Position Sensor (Amazon affiliate link)

- Delphi SS10931 New Crankshaft Sensor (Amazon affiliate link).

But if you're like me and you want to know for sure the CKP sensor is bad before replacing it, the next section of this tutorial will walk you through the exact test.

Where To Buy The Crank Sensor And Save

When it comes time to replace the CKP sensor, I'm picky about what goes into the vehicles I work on. I only recommend sensors from reputable automotive brands I've used in the field myself —no cheap knockoffs, no untested parts. Below are two quality options available on Amazon from brands I trust, so you can be confident you're installing a sensor that'll last.

Disclosure: As an Amazon Associate, I earn from qualifying purchases. Buying through these links helps support this site at no extra cost to you. Thanks for your support —it really means a lot!

TEST 1: Checking The CKP Signal With A Multimeter

The very first thing we'll do to figure out if the CKP sensor is bad is check whether it's producing an ON/OFF voltage signal when you turn the engine over by hand.

This signal is an ON/OFF voltage signal. Specifically:

- ON: When the multimeter displays 5 Volts DC.

- OFF: When it displays 0 Volts (0.2 Volts equals 0 Volts).

I want to stress that the accuracy of this CKP sensor signal test depends on turning the engine by hand. Which means using a 1/2-inch ratchet and the right socket to rotate the crankshaft pulley yourself.

If you don't have a multimeter, or need to upgrade yours, this is the one I recommend:

- Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (Amazon affiliate link).

LOCATION: The crankshaft position (CKP) sensor is mounted behind the crankshaft pulley, on the side of the timing cover that faces the firewall. It's inserted into a machined hole in the lower section of the timing chain cover.

IMPORTANT: Before you start this test you must disconnect all of the ignition coils from their harness connectors. This safety precaution will keep the car from starting.

CAUTION: To access the CKP sensor on the 2003–2007 2.4L Honda Accord, the front of the vehicle must be lifted. Never rely on the jack alone! Always support the vehicle securely with jack stands before working underneath it. Also, wear safety glasses to protect your eyes while you're under the vehicle.

NOTE: The CKP sensor must remain connected to its 3-wire connector during this test. This means the only way to tap into the signal wire is by using a wire-piercing probe on the connector. If you don't have one, here's the tool I recommend: Goupchn 4mm Banana to Banana Plug Test Leads Kit (Amazon affiliate link).

Here are the test steps:

- 1

Raise your vehicle and place it on jack stands (to gain access to the CKP sensor).

Once on jack stands, remove the driver-side water splash shield. - 2

Disable the ignition system by disconnecting each individual ignition coil from its harness connector.

By disabling the ignition coils, you'll keep the vehicle from accidentally starting as you perform the CKP sensor test. - 3

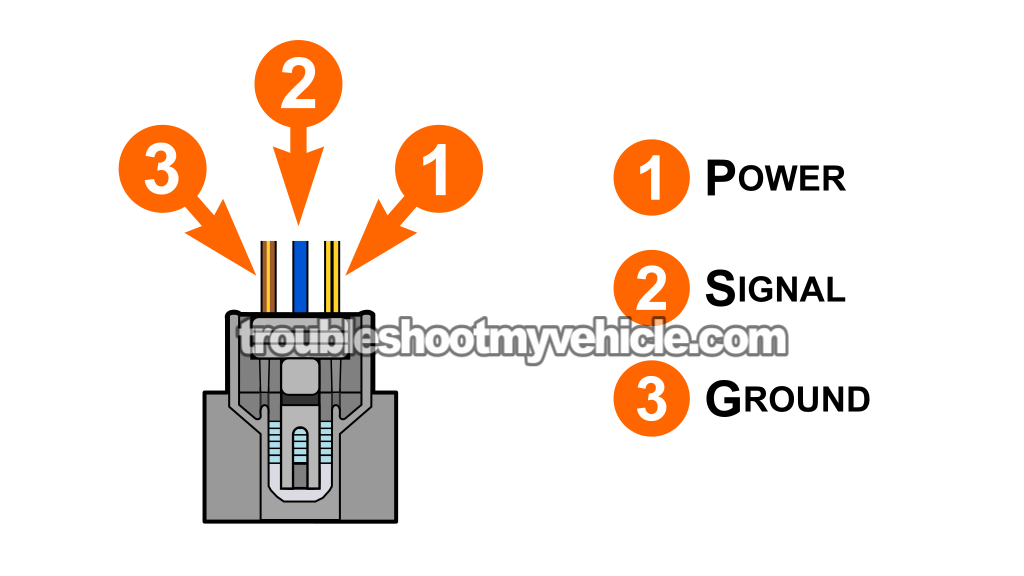

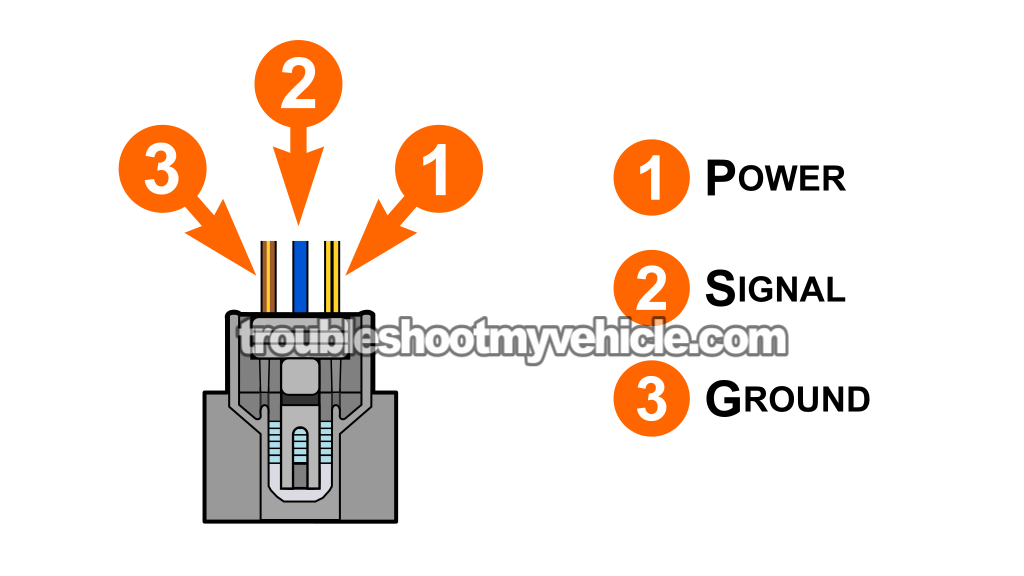

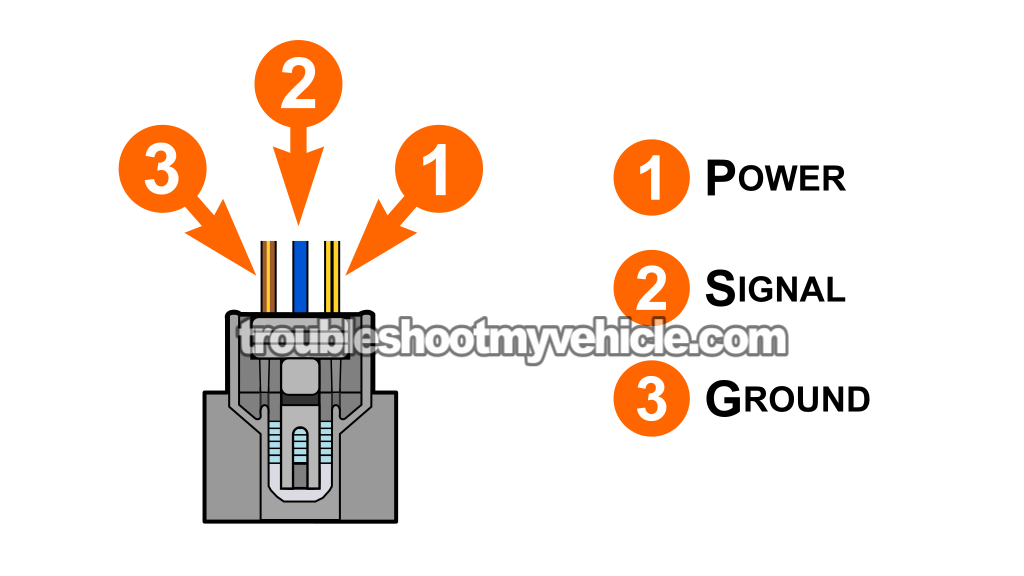

Connect the red multimeter test lead to the blue (BLU) wire on the connector.

The BLU wire is the one that transmits the signal (created by the crank sensor) to your Honda's PCM.

NOTE: The CKP sensor must remain connected to its 3-wire connector during the CKP signal test. You'll need to use a wire-piercing probe (or a back probe) to connect your multimeter's red test lead to the BLU wire of the CKP sensor connector. - 4

Place your multimeter in Volts DC mode.

- 5

Ground the black test lead directly to the negative (-) battery terminal. I usually use a jump-start cable for this.

- 6

Turn the key to the ON position (Position II) but don't crank the engine.

This will power up the CKP sensor with the voltage and Ground we need to test it in action. - 7

Using a 1/2-inch ratchet and socket, turn the crank pulley clockwise by hand.

IMPORTANT: For the accuracy of this test, the crankshaft pulley must be turned by hand. Using the starter motor to turn the engine will not give you the results indicated in this tutorial. - 8

Your multimeter will register an ON/OFF voltage signal (if the sensor is OK).

"ON" is when the multimeter displays 5 Volts DC, and "OFF" is when it displays 0 Volts (0.2 Volts equals 0 Volts).

Here's how to make sense of your test results:

CASE 1: The multimeter showed an ON/OFF 5-volt signal as you turned the engine by hand with the ratchet. This is exactly what you want to see and it means the CKP sensor is doing its job and producing the signal.

At this point, no additional testing is necessary. The other two tests in this tutorial check that the CKP sensor is receiving both power and Ground. Since you've confirmed it's generating a signal, that also tells you it's already getting the power and Ground it needs.

CASE 2: The multimeter DID NOT show an ON/OFF 5-volt signal as you turned the engine by hand. In most cases, this points to a bad CKP sensor that needs replacement. Still, it's best to verify that the sensor is also receiving power and Ground before calling it done.

By checking for both power and Ground, you can be 100% sure the CKP sensor has actually failed or discover that something else is causing the problem. Let's check for power first: TEST 2: Making Sure The CKP Sensor Is Getting 12 Volts.

TEST 2: Making Sure The CKP Sensor Is Getting 12 Volts

Up to this point, the test result you got in TEST 1 is letting you know that the CKP sensor isn't creating an ON/OFF signal that the PCM needs to get the engine started.

So our next step is to make sure that the CKP sensor is getting power and this power is in the form of battery voltage (10 to 12 Volts DC) when you turn the key to the ON or START position.

The wire that delivers these 10 to 12 Volts to the CKP sensor is the yellow with black stripe (YEL/BLK) wire of the CKP sensor's 3-wire connector.

To check for power in this circuit, we're going to do a simple multimeter voltage test.

OK, these are the test steps:

- 1

Disconnect the CKP sensor from its connector.

- 2

Place your multimeter in Volts DC mode.

- 3

Connect the black multimeter test lead to the battery negative (-) terminal.

- 4

Have your helper turn the key to the ON position, but don't crank or start the engine.

- 5

With the red multimeter test lead, probe the front of the terminal that connects to the YEL/BLK wire.

- 6

Your multimeter should read between 10 to 12 Volts DC.

Let's take a look at what your test results mean:

CASE 1: Battery power IS present in the YEL/BLK wire. This is the correct test result, and it tells you that the CKP sensor is getting the power it needs to function.

Our next test is to make sure that it's getting Ground. For this test, go to: TEST 3: Making Sure The CKP Sensor Is Getting Ground.

CASE 2: Battery power IS NOT present in the YEL/BLK wire. This test result rules out the CKP sensor itself as the cause of the problem, since without power it can't function.

Although it's beyond the scope of this tutorial to determine why battery power is missing, finding and fixing the source of that problem will resolve both the CKP sensor issue and the trouble code your Honda Accord is showing.

TEST 3: Making Sure The CKP Sensor Is Getting Ground

So far, your test results have confirmed two important things.

- The CKP sensor isn't creating a signal (TEST 1).

- The CKP sensor is getting power from the YEL/BLK wire (TEST 2).

Now for our last test, we're going to make sure that the brown with yellow stripe (BRN/YEL) wire is delivering Ground.

This Ground is a chassis Ground and is available to the CKP sensor at all times. To check for it, we're going to do a multimeter voltage test, just like we did to check for battery power in in TEST 2.

OK, let's begin:

- 1

Disconnect the CKP sensor from its connector.

- 2

Place your multimeter in Volts DC mode.

- 3

Connect the red multimeter test lead to the battery positive (+) terminal.

- 4

Have your helper turn the key to the ON position, but don't crank or start the engine.

- 5

With the black multimeter test lead, probe the front of the terminal that connects to the BRN/YEL wire.

- 6

Your multimeter should read between 10 to 12 Volts DC.

Let's take a look at what your test results mean:

CASE 1: Ground is present in the BRN/YEL wire. This is the correct and expected test result.

If you've confirmed that:

- The CKP sensor isn't creating an ON/OFF signal (TEST 1),

- It's getting power (TEST 2),

- And in this test section, it's getting a good chassis Ground,

...then you can confidently conclude the CKP sensor is bad and needs to be replaced.

Below are two solid options available on Amazon from well-known automotive brands I've used in the field for many years, brands I know will get the job done right:

- Hitachi CPS0221 Engine Crankshaft Position Sensor (Amazon affiliate link)

- Delphi SS10931 New Crankshaft Sensor (Amazon affiliate link).

CASE 2: Ground IS NOT present in the BRN/YEL wire. This test result rules out the CKP sensor itself as the culprit, since without Ground it can't function.

Although it's beyond the scope of this tutorial to track down why chassis Ground is missing, finding and fixing the source of that problem will resolve both the CKP sensor issue and the trouble code your Honda Accord is showing.

More 2.4L Honda Accord Tutorials

You can find a complete list of tutorials for your 2.4L Honda Accord equipped car here:

Here's a small sample of the tutorials you'll find in the index:

- How To Test The TPS With A Multimeter (2003-2006 2.4L Honda Accord).

- How To Test The Fuel Injectors (2003-2007 2.4L Honda Accord).

- How To Test The Ignition Coils (2003-2006 2.4L Honda Accord).

- How To Test The MAP Sensor (2003-2007 2.4L Honda Accord).

If this info saved the day, buy me a beer!