The fuel pump on the 2003 3.0L V6 Ford Taurus and Mercury Sable can easily be tested and in this tutorial, I'll show you how.

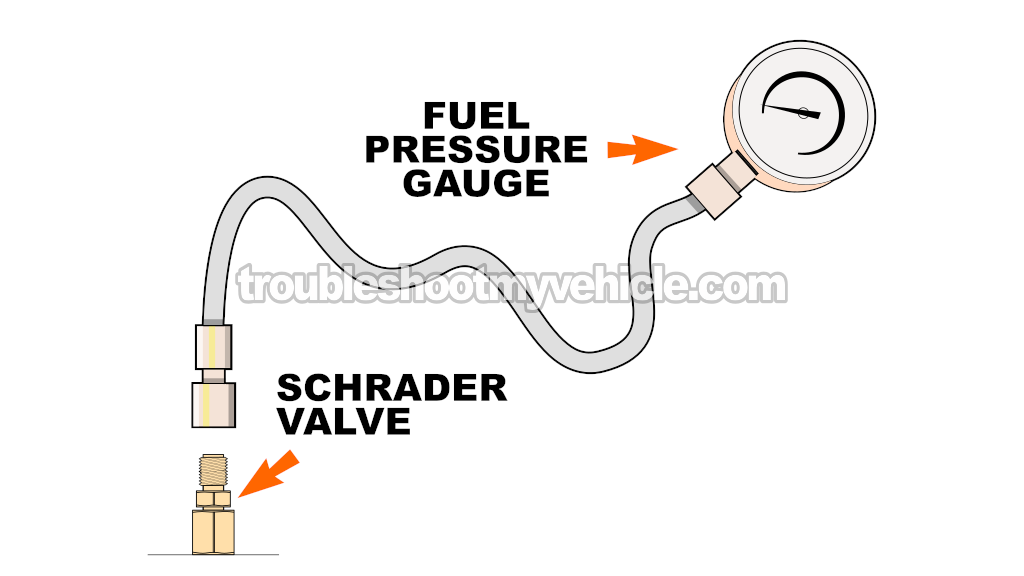

The early 2003 models have a Schrader valve (to connect a fuel pressure test gauge to) but the later 2003 models don't. Still, it's not that hard to check the fuel pressure on these later models without a fuel pressure test port.

For these non-Schrader valve models, I'll explain what adapter you need (to connect the gauge to the fuel injector rail), where to buy it, and the fuel pressure specification.

I'll also explain how to check an engine no-start issue caused by a lack of fuel with starting fluid.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 3.0L V6 (OHV) Ford Taurus: 2003.

- 3.0L V6 (OHV) Mercury Sable: 2003.

OTHER FUEL PRESSURE TESTS:

- How To Test The Fuel Pump (1990-1999 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test The Fuel Pump (2000 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test The Fuel Pump (2001-2002 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test The Fuel Pump (2004-2007 3.0L V6 Ford Taurus, Mercury Sable).

ENGINE NO-START DIAGNOSTICS:

Symptoms Of A Bad Fuel Pump

I've found over the years that a fuel pump usually fails in one of two ways:

- Complete failure: When this happens, the fuel pump stops working altogether and no fuel reaches the injectors.

- Failing fuel pump: In this scenario, the pump still manages to send some fuel to the engine, and the engine may start, but it's not enough to keep it running optimally.

Since the fuel pump's job is to supply the fuel the engine needs to start and run, when it fails, you're going to see one or more of the following problems:

- Engine cranks but won't start.

- Lean air/fuel mixture trouble codes.

- Rough idle.

- Engine starts after extended cranking.

- Lack of power when accelerating the vehicle down the road.

- Back-fires thru' the intake manifold when accelerating the car down the road.

One thing to keep in mind is that the 2003 Ford Taurus and Mercury Sable come equipped with a fuel pump driver module (FPDM). This component is in charge of activating the fuel pump, and when it fails, it can mimic several of the symptoms I listed above.

Still, the very first step in diagnosing either the fuel pump or the FPDM module is to physically check fuel pressure with a fuel pressure test gauge. I'll show you how to do that in this tutorial.

Where To Buy A Fuel Pressure Test Gauge

If your 2003 Ford Taurus or Mercury Sable doesn't have a Schrader valve on the fuel injector rail, you'll need a Ford Spring Lock Coupling Adapter to connect the fuel gauge.

You can buy a fuel pressure test kit that includes this adapter online, and the ones I'm recommending below, not only come with it but are also reliable and, also just as important, won't cost you an arm and a leg:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

Fuel Pressure Specifications

The fuel pressure specifications with the key on engine off (KOEO) and key on engine running (KOER) are:

| Year | KOEO | KOER |

|---|---|---|

| 1990-1993 | 35-40 PSI | 30-45 PSI |

| 1994-1995 | 40-43 PSI | 35-38 PSI |

| 1996-1998 | 35-40 PSI | 30-45 PSI |

| 1999-2000 | 37-43 PSI | 26-45 PSI |

TEST 1: Checking Fuel Pressure With A Fuel Pressure Gauge

Alright, as I mentioned before, we need a Ford Spring Lock Coupling Adapter to connect the fuel pressure test gauge to the fuel system. The spot where we're going to place this adapter is where the fuel line connects to the fuel injector rail. If you look at the photo above, the arrow points to this exact spot.

Now, to disconnect the fuel line from the fuel injector rail, you'll need a quick disconnect tool. If you don't have one, take a look at the ones I use and don't hesitate to recommend:

- Lisle 39400 Angled Disconnect Tool (Amazon affiliate link).

- AUPREX Disconnect Removal Tool (Amazon affiliate link).

Once the fuel pressure test gauge is connected between the fuel line and the fuel injector rail, we'll check the fuel pressure.

Now, according to the repair manual, the way to check fuel pump pressure (after installing the fuel pressure test gauge) is by activating the fuel pump with a bi-directional scan tool. And if you've got one —great, use it. If you don't, no worries. I'll show you how it can be done without one.

FUEL PUMP INERTIA SWITCH: Before you start, there's one more thing you need to check —make sure the fuel pump inertia switch hasn't been tripped. If it has, the fuel pump driver module won't get power, which means it won't activate the fuel pump.

Alright, here are the test steps:

- 1

Release the fuel pressure in the fuel line.

See this section for the procedure: Fuel Pressure Release Procedure. - 2

Disconnect the fuel supply line at the fuel injector rail.

- 3

Install the fuel pressure test adapter to the fuel injector rail's fuel supply inlet.

This is the same port where you just disconnected the fuel line.

NOTE: Be sure to follow your test kit's instructions to avoid any issues during setup. - 4

Connect the fuel supply line to the adapter.

- 5

Connect your fuel pressure gauge to the adapter.

- 6

Have your helper cycle the key ON and OFF several times —but don't crank the engine.

This will prime the system. Watch closely for leaks.

If no leaks, you're good to go.

If you see fuel leaking, stop and fix the leak before continuing.

KOEO Test (No Scan Tool): Engine doesn't start

- 7

Have your helper crank the engine, then release the key.

NOTE: After cranking, the key should stay in the RUN position. If your helper turns it all the way to OFF, the test won't work —you'll need to do it again. - 8

The fuel pressure gauge should show the fuel pressure within spec.

KOER Test (No Scan Tool): Engine starts and stays running

- 7

Have your helper start the engine and let it idle.

- 8

The fuel pressure gauge should show the fuel pressure within spec.

KOEO Test (No Scan Tool): Engine starts, but you need KOEO results

- 7

Disconnect the ignition coil pack from its 4-wire electrical connector.

- 8

Have your helper crank the engine, then release the key.

NOTE: After cranking, the key should stay in the RUN position. If your helper turns it all the way to OFF, the test won't work —you'll need to do it again. - 9

The fuel pressure gauge should show the fuel pressure within spec.

KOEO Test (With Scan Tool):

- 7

Connect your bidirectional scan tool to the OBD II diagnostic connector.

- 8

Turn the key to its RUN position but don't start the engine.

NOTE: The fuel pump activation (with the bidirectional scan tool) is done with the engine OFF. - 9

Enter component tests and activate the fuel pump.

NOTE: Consult your scan tool's user manual for exact steps on how to access the fuel pump activation feature —the process can vary depending on the brand and model. - 10

The fuel pressure gauge should show the fuel pressure within spec.

Let's take a look at what your results mean:

CASE 1: Gauge reads 0 PSI. This confirms that no fuel is reaching the fuel injectors, which explains why the engine isn't starting.

Since this is a fuel pump driver module (FPDM) equipped vehicle, we can't condemn the fuel pump as bad just yet. Our next step is to check the FPDM module and make sure that it's actually powering up the fuel pump. I've written a step-by-step tutorial that will help you troubleshoot the FPDM module:

CASE 2: The fuel pressure below spec. Low fuel pressure will definitely cause engine performance problems on your Ford Taurus or Mercury Sable.

If no fuel pump driver module (FPDM) or fuel rail pressure (FRP) sensor codes are present, then you're looking at a failing fuel pump that needs to be replaced.

Now, if you do have FPDM or FRP sensor codes, then you'll need to diagnose those codes first before condemning the fuel pump as bad.

CASE 3: Fuel pressure gauge within spec. This test result confirms that the fuel pump and the fuel pump driver module (FPDM) are operating correctly.

If the engine in your Ford Taurus or Mercury Sable won't start, you can rule out the fuel pump and the FPDM module as the cause (the issue lies elsewhere).

TEST 2: Using Starting Fluid To Confirm Lack Of Fuel

The starting fluid test has been my go-to diagnostic test when troubleshooting an engine no-start. Mainly because it's a very simple test to perform, and you don't need any tools —except, of course, for a can of starting fluid.

The key to successfully performing a starting fluid test is to first make sure all six cylinders are getting spark. That means we've got to test for spark at each spark plug wire with a spark tester.

This spark test is critical for getting an accurate result from the starting fluid test. So if you haven't checked for spark yet, please do that before you begin.

Alright, we can expect one of two things from the starting fluid test:

- The engine runs for a few seconds until the starting fluid is consumed —confirming a fuel delivery issue is behind the no-start condition.

- The engine still doesn't start when cranked, which tells us a fuel delivery issue isn't the cause of the no-start problem.

IMPORTANT: This is a very fast and easy test but you do have to take one very important safety precaution and this is to reconnect the air intake duct after spraying starting fluid down the throttle bore (although you don't have to fasten it). This will prevent any backfire, that might occur, from scaring the heck out of you when cranking the engine.

This is what you have to do:

- 1

Remove the intake air duct from the throttle body. You don't have to completely remove it, since you'll have to reconnect it in one of the next steps.

- 2

Open the throttle plate and spray starting fluid down the bore.

As a safety precaution reconnect the air duct after you have sprayed a good squirt of starting fluid (but you don't have to tighten the air duct's hose clamp). - 3

Crank the engine once the air duct is back on and you're clear of the engine compartment.

- 4

You'll get one of two results with this test:

1.) The engine will start momentarily and after a few seconds will die or.

2.) The engine will only crank but not start at all.

OK, let's find out what your results mean:

CASE 1: Engine runs briefly on starting fluid. This confirms a fuel delivery issue is preventing the engine from starting.

Since your vehicle is a fuel pump driver module (FPDM) equipped vehicle, this fuel delivery issue could be caused by either a bad fuel pump or a bad FPDM module.

If I were in your shoes, my next step would be to check fuel pressure with a gauge to begin my FPDM module diagnostic.

CASE 2: Engine doesn't start at all with starting fluid. This test result rules out a fuel delivery problem as a cause of your Ford Taurus or Mercury Sable's no start. But, this conclusion is only true if all six cylinders are getting spark.

More 3.0L V6 Ford Taurus Diagnostic Tutorials

You can find a complete list of 3.0L V6 Ford Taurus and Mercury Sable diagnostic tutorials in this index:

Here's a sample of the diagnostic tutorials you'll find in the index:

- How To Do And Interpret An Engine Compression Test (1990-2007 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test For A Blown Head Gasket (1990-2007 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test The MAF Sensor (1996-1999 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test The MAF Sensor (2000-2003 3.0L V6 Ford Taurus, Mercury Sable).

If this info saved the day, buy me a beer!