The fuel pump driver module (FPDM) on the 2000, 2001-2007 3.0L V6 Ford Taurus and Mercury Sable can be quite easily tested to find out if it's good or bad.

In this tutorial, I'm going to show you how to check it step by step to see if the FPDM module is behind an engine no-start problem. Specifically, if the FPDM module is behind a 0 PSI fuel pressure test result.

I'm going to walk you through the following tests:

- Power and Ground tests —You'll test VPWR (12V power input) and PWR GND (chassis Ground).

- Control signal tests —You'll verify the Fuel Pump Control (FPC) and Fuel Pump Monitor (FPM) signals.

- Fuel pump activation test —You'll confirm the FPDM module is actually commanding the fuel pump to run.

Contents of this tutorial:

- Fuel Pump Driver Module (FPDM) Location.

- Fuel Pump Driver Module Basic Checks.

- Tools Needed To Check The FPDM.

- TEST 1: Checking The FPDM PWR (12 Volts) Circuit.

- TEST 2: Checking The PWR GND (Power Ground) Circuit.

- TEST 3: Checking Fuel Pump Activation.

- TEST 4: Checking The Fuel Pump Control (FPC) Signal.

- TEST 5: Checking The Fuel Pump Monitor (FPM) signal.

- More Fuel Pump Troubleshooting Help.

- More 3.0L V6 Ford Taurus Diagnostic Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 3.0L V6 Ford Taurus: 2000, 2002, 2003, 2004, 2005, 2006, 2007.

- 3.0L V6 Mercury Sable: 2000, 2002, 2003, 2004, 2005.

MORE FUEL PUMP DIAGNOSTIC RESOURCES: You can find fuel pump circuit wiring diagrams, related fuel pump tests, and the inertia switch tests in this section:

Fuel Pump Driver Module (FPDM) Location

FPDM location —It sits in the trunk (sedan) or cargo area (wagon) on the passenger side, behind the right-hand luggage compartment lining, which must be removed to access the FPDM module.

Fuel Pump Driver Module Basic Checks

Before we begin our FPDM module tests, there are two important first steps we need to take:

STEP 1 → Scan for Codes (P1233–P1237):

The first order of business is to check for any fuel pump control circuit issue trouble codes with a scan tool (capable of reading Ford's enhanced codes). These are the diagnostic trouble codes (DTCs) we're looking for:

- P1233: Fuel Pump Driver Module Offline or Disabled (No communication from PCM).

- P1234: Fuel Pump Driver Module Offline or Disabled (identical to DTC 1233, but won't illuminate the check engine light).

- P1235: Fuel Pump Control Out Of Range (PCM can't regulate it properly).

- P1236: Fuel Pump Control Out Of Range (identical to DTC 1235, but won't illuminate the check engine light).

- P1237: Fuel Pump Secondary Circuit Fault (often internal to the FPDM).

- P1238: Fuel Pump Secondary Circuit Fault (identical to P1237, but won't illuminate the check engine light).

Finding any of these codes confirms the PCM can't communicate with the FPDM module or isn't receiving proper feedback from it and it's our green light to test the FPDM module itself.

NOTE: A P0191 code may point to the fuel rail pressure (FRP) sensor, but the real cause could be the FPDM not regulating pressure.

If no codes are present —the FPDM module or fuel pump may still be toast, so continue on to step 2.

STEP 2 → Check Fuel Pressure:

After checking for FPDM codes, we need verify fuel pressure with a mechanical fuel pressure test gauge.

The fuel pressure test (with a mechanical gauge) shouldn't be skipped because it ensures you know the fuel pump's true output, independent of what the FRP sensor reports on your scan tool's live data mode.

If you haven't checked fuel pressure, these tutorials will help you with the test:

- How To Test The Fuel Pump (2000 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test The Fuel Pump (2001-2002 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test The Fuel Pump (2003 3.0L V6 Ford Taurus, Mercury Sable).

IMPORTANT: Although this tutorial targets an engine no-start issue from a bad FPDM module or failed fuel pump, the step-by-step tests (especially the voltage drop test in TEST 2) can also uncover FPDM circuit-related performance issues.

Tools Needed To Check The FPDM

The one must-have tool you'll need is a multimeter that can read duty cycle % (not just Hertz).

Why a multimeter with duty cycle % capability? —Because the PCM's command to the FPDM (FPC signal) and the FPDM's feedback to the PCM are both duty cycle % signals.

To successfully diagnose the FPDM module, we need to compare these signals to the manual's spec to confirm FPDM operation.

If you already own such a multimeter, great; if not, this is the one I use and recommend and it doesn't cost an arm and a leg:

- Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (Amazon affiliate link).

You'll also need a few more things:

- Back-probe pins or wire-piercing probe.

- These T-pins are the ideal back probe for the FPDM tests: Straight Pins T-Pins Stainless Steel (Amazon affiliate link).

- Battery jump start cable: We'll use a jump start cable to extend the reach of the multimeter test lead to the battery negative (-) post in TEST 2.

TEST 1: Checking The FPDM PWR (12 Volts) Circuit

For our first FPDM module test, we're going to make sure that it's getting 10 to 12 Volts while cranking the engine.

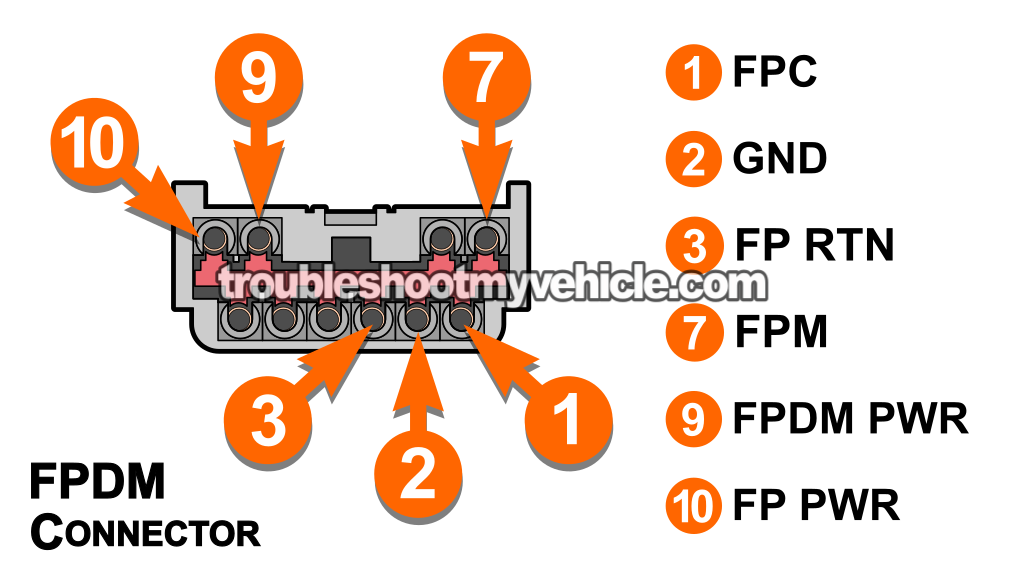

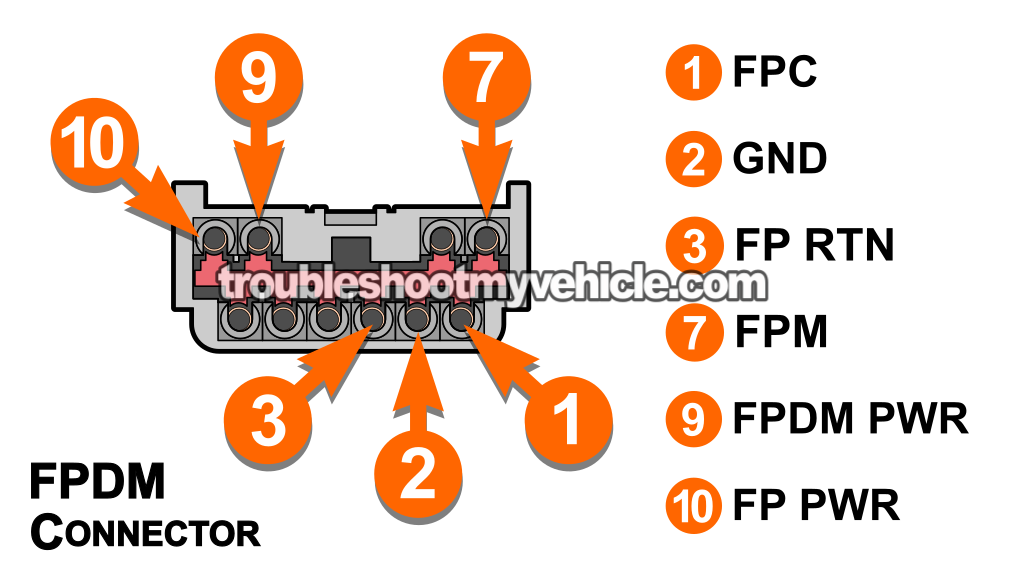

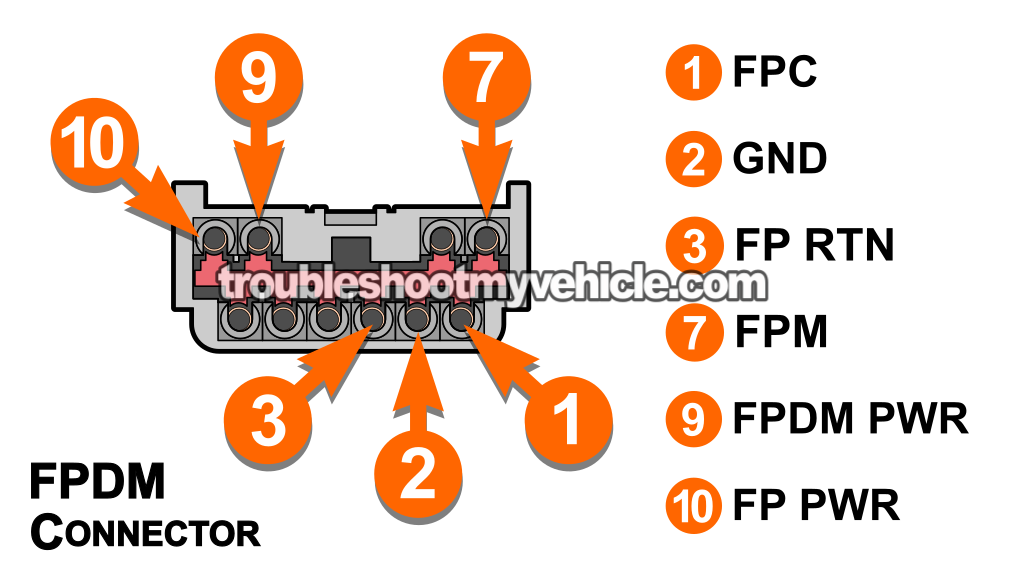

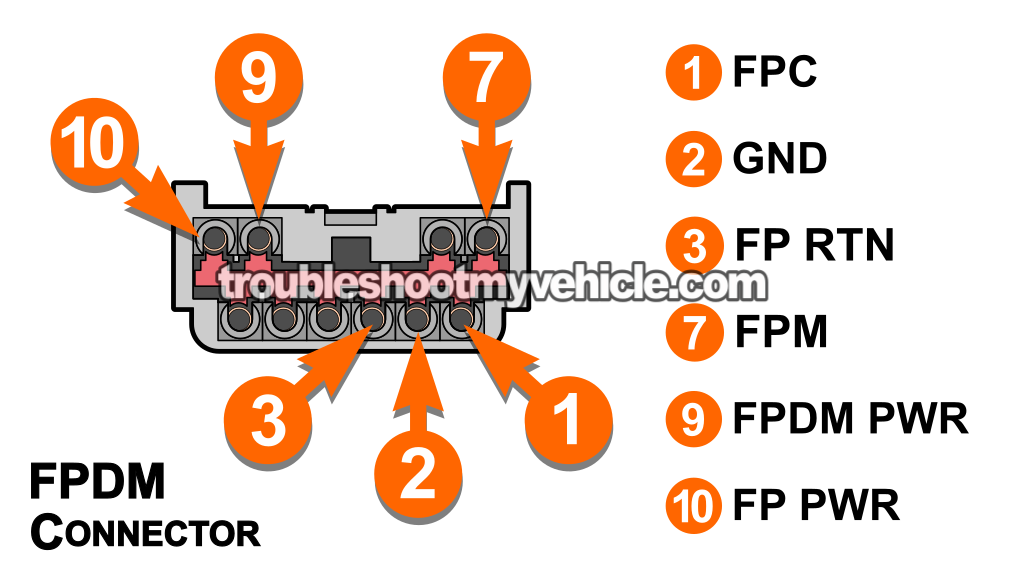

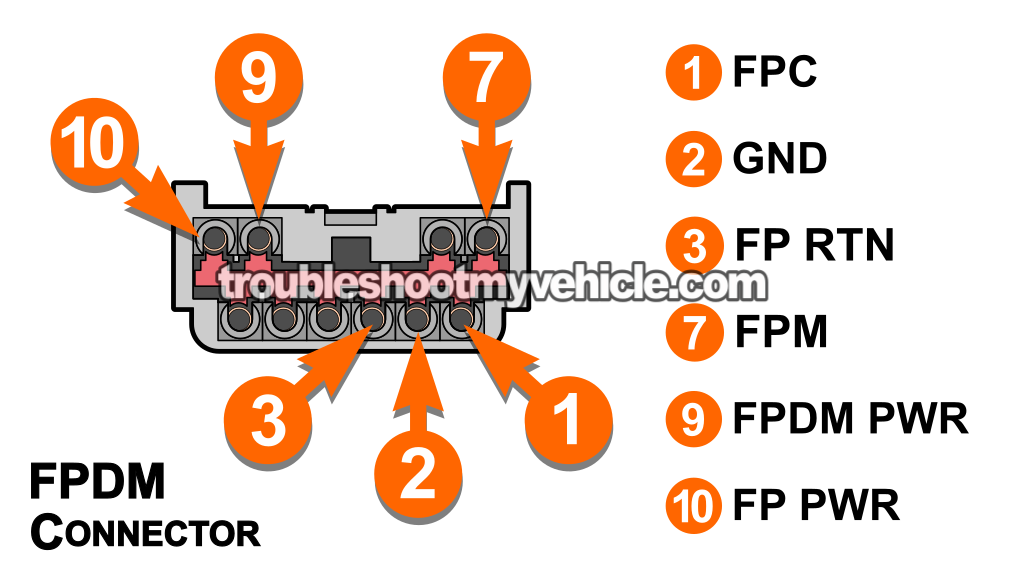

We'll check for the presence of this FPDM PWR voltage at female terminal 9 of the module's connector.

The wire that connects to terminal 9 is going to be the pink with black stripe (PNK/BLK wire of the module's connector.

NOTE: Take extra care when probing the front of the female terminals of the FPDM module connector with your multimeter test leads. If the terminal gets damaged, you'll have to replace the connector.

- 1

Disconnect the FPDM module from its connector.

- 2

Set your multimeter to Volts DC mode.

- 3

Connect the black multimeter test lead to a clean, rust-free, and paint-free metal spot on the chassis (solid Ground).

- 4

Gently probe female terminal 9 of the connector.

Confirm that the PNK/BLK wire actually connects to terminal 9. - 5

Have your help crank the engine while you observe the multimeter.

- 6

You should see close to battery voltage —between 10 and 12 Volts.

Let's interpret that test result:

CASE 1: 10-12 Volts are present at terminal 9. This confirms the inertia switch, fuel pump fuse, fuel pump relay and VPWR circuit are good, and power is reaching the FPDM module.

Our next step is checking the PWR GND circuit, for this test go to: TEST 2: Checking The PWR GND (Power Ground) Circuit.

CASE 2: No voltage is present at terminal 9. This means the FPDM module isn't getting powered, and without power, it's not gonna activate the fuel pump.

The most likely cause of this missing FPDM PWR voltage is due to a blown fuse, bad fuel pump relay, bad/tripped inertia switch, or wiring fault between the underhood fuse/relay box and FPDM module.

You're next steps are to:

- Check the fuel pump fuse.

- Check the fuel pump relay.

- Check the fuel pump inertia switch.

Once power is restored to the FPDM PWR circuit, the FPDM module should function and activate the fuel pump.

TEST 2: Checking The PWR GND (Power Ground) Circuit

The FPDM module relies on a solid chassis Ground through terminal 2 of its 6-wire connector (PWR GND circuit).

This PWR GND circuit's black (BLK) wire doesn't connect directly to the battery's negative (-) post. Instead, it Grounds to the chassis.

Over time, that connection point can develop corrosion. When it does, resistance builds up in the circuit, and that added resistance often causes strange FPDM problems that turn into diagnostic headaches.

More specifically, corrosion-induced resistance creates a voltage drop in the BLK wire, and that voltage drop can cause all sorts of issues —engine no-starts, low fuel pressure, or stalling.

To check the PWR GND circuit, we're not just gonna do a quick continuity test in Ohms mode. Instead, we'll run a proper voltage drop test under load, which is the only way to catch the problem while it's actually happening.

IMPORTANT: The FPDM must be connected to its connector to check the Ground wire's voltage drop.

Here's how to do it:

- 1

Reconnect the FPDM to its 6-wire connector.

- 2

Set your multimeter to Volts DC mode.

- 3

Connect the red multimeter lead to the BLK wire at the FPDM connector.

You can back-probe the connector or use a piercing probe on the wire itself. - 4

Connect the black multimeter lead directly to the battery negative (-) post.

IMPORTANT: This connection has to be done at the battery negative (-) post. I use a battery jump start cable to extend the reach of the multimeter test lead. - 5

Have a helper crank the engine.

NOTE: This circuit check has to be done while the engine's cranking, since that's when the FPDM module is active and current is actually flowing through the PWR GND circuit. - 6

Your multimeter should show a voltage reading as close as possible to 0 Volts DC.

Any voltage reading at 5 or more Volts is considered a big voltage drop problem.

Let's break down what the test result means:

CASE 1: Voltage drop is under 1V. This confirms the FPDM has a solid connection to chassis Ground.

With the PWR GND circuit confirmed to be OK, let's move on to: TEST 3: Checking Fuel Pump Activation.

CASE 2: Voltage drop is 5V or more. This indicates excessive resistance in the Ground path. This voltage drop can cause fuel delivery issues like no-starts, low pressure, or stalls.

The most likely cause of this is corrosion or loose Ground connections between the FPDM module and the chassis or between the chassis and the battery negative (-) post.

To fix this voltage drop, clean and tighten all Ground connection points, then retest to confirm voltage drop is below 1V. Once the voltage drop is eliminated, the FPDM module will function reliably.

TEST 3: Checking Fuel Pump Activation

In this test section, we're gonna confirm the FPDM module is actually powering the fuel pump while cranking the engine.

Before we start, keep in mind:

-

The FPDM module supplies the fuel pump with 12 Volts (Fuel Pump Power —FP PWR).

This FP PWR voltage is sent to the fuel pump through the white with red stripe (WHT/RED) wire.

-

The FPDM module also supplies the fuel pump with Ground (Fuel Pump Return —FP RTN).

The FP RTN Ground is provided to the fuel pump through the black with pink stripe (BLK/PNK) wire.

The FP RTN Ground that the FPDM module provides is a pulse-width modulated Ground, meaning it switches ON and OFF very rapidly. But during cranking, it should act almost like a solid Ground (close to 100% duty cycle).

To check for fuel pump activation, we'll tap into both the FP PWR and FP RTN wires (while keeping the FPDM module connected) and watch the voltage the multimeter displays while cranking the engine.

IMPORTANT: The FPDM must remain connected to its 6-wire connector to confirm the fuel pump's activation.

Here are the test steps:

- 1

Set your multimeter to Volts DC mode.

- 2

Back-probe the FPDM connector at the WHT/RED wire with the red multimeter test lead.

The WHT/RED is the FP PWR wire and it should connect to the back of terminal 10. - 3

Back-probe the FPDM connector at the BLK/PNK wire with the black multimeter test lead.

The BLK/PNK is the FP RTN wire and it should connect to the back of terminal 3. - 4

Have your helper crank the engine while you observe the multimeter reading.

- 5

You should see 9 to 12 Volts while the engine is cranking if the FPDM module is working correctly and activating the fuel pump.

Let's interpret your test results:

CASE 1: The multimeter registers 9 to 12 Volts. Great! This result confirms three important things:

- The PCM is sending the FPC signal.

- The FPDM module is powering the FP PWR circuit.

- The module is completing the FP RTN Ground circuit.

With this test result, you can conclude that the 0 PSI reading you got from your fuel pressure test is due to a bad fuel pump. Replace the fuel pump.

CASE 2: The multimeter registers 0 Volts. This means the FPDM module isn't activating the pump.

Recheck your connections and repeat the test. If you still see 0 Volts, your next step is to verify that the PCM is commanding the FPDM module to activate the pump by checking for the FPC signal. Go to: TEST 4: Checking The Fuel Pump Control (FPC) Signal.

TEST 4: Checking The Fuel Pump Control (FPC) Signal

Up to this point, you've verified:

- The FPDM module has power (TEST 1).

- The module has a good Ground (TEST 2).

- The module isn't turning on the pump (TEST 3).

Our next step is to see if the PCM is actually commanding the FPDM module to activate the fuel pump via the Fuel Pump Control (FPC) signal.

The FPC signal isn't a steady voltage. It's a pulse-width modulated (PWM) duty cycle % command. The PCM uses this duty cycle to tell the FPDM module how much fuel pressure it wants from the fuel pump.

Here's a quick breakdown of how the FPC duty cycle works:

- Low duty cycle (~5%) —PCM is requesting low fuel pressure.

- Mid duty cycle (close to 50%) —PCM is requesting moderate fuel pressure.

- High duty cycle (at 50%) —PCM is commanding maximum pump output at full speed and pressure.

The FPDM monitors the FPC signal and adjusts the fuel pump's output accordingly: higher duty cycle = more fuel pressure, lower duty cycle = less pressure.

To check for the presence of the FPC signal, you'll need a multimeter that can read duty cycle %. A multimeter that only reads frequency (Hz) won't cut it.

If you're looking for a reliable, budget-friendly duty cycle-capable multimeter, this is the one I use and recommend:

- Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (Amazon affiliate link).

IMPORTANT: The FPDM must stay plugged into its 6-wire connector during this test.

Here's how to do it:

- 1

Set your multimeter to duty cycle (%) mode.

- 2

Connect the black multimeter lead to a clean, rust-free Ground point.

- 3

Back-probe the FPDM module connector at the LT BLU/ORG wire with the red multimeter test lead.

The LT BLU/ORG wire is the FPC wire and it should connect to the back of terminal 1. - 4

Have your helper crank the engine while you monitor the multimeter.

- 5

You should see a duty cycle reading around 50% during cranking (if the engine isn't starting).

NOTE: Ford considers any duty cycle between 5% and 50% as normal with the engine running. During startup conditions the reading is usually around 50%.

Let's interpret your test result:

CASE 1: Multimeter reports a 40–50% duty cycle during cranking. This confirms the PCM is commanding the FPDM module to activate the fuel pump.

You can conclude the FPDM module is bad and needs to be replaced if all of the following are true:

- Fuel pump pressure is 0 PSI.

- The FPDM module is getting FPDM PWR power (TEST 1).

- The module has a good chassis Ground (TEST 2).

- The module isn't powering the fuel pump (TEST 3).

- The module is receiving a Fuel Pump Control (FPC) signal (this test section).

Before replacing the FPDM module, make sure you check the fuel pump's amperage draw. A failing pump with a high current draw will fry the new module.

CASE 2: Multimeter reports 0% duty cycle. This means the PCM isn't sending the FPC signal, which explains why the FPDM module won't activate the fuel pump.

The most likely cause of this missing FPC signal is an open in the FPC wire between the PCM and the FPDM module.

Your next step is to troubleshoot the issue and restore the FPC signal to the circuit.

TEST 5: Checking The Fuel Pump Monitor (FPM) signal

NOTE: This section covers an optional test that checks the FPM (Fuel Pump Monitor) signal to verify FPDM-to-PCM communication.

When the FPDM module is powered, Grounded, and properly commanded by the PCM, it sends a 50% duty cycle feedback signal back to the PCM.

This feedback signal, called the FPM signal, returns to the PCM through the dark green with yellow stripe (DK GRN/YEL) wire, which connects to terminal 7 of the FPDM module's 6-wire connector.

In a nutshell, the purpose of the FPM signal is to tell the PCM what the FPDM module is seeing on the fuel pump side, using one of three feedback signals:

- 25% duty cycle signal —FPDM module didn't receive a valid FPC signal from the PCM.

- 50% duty cycle signal —FPDM module is operating normally and communicating correctly (though the fuel pump itself could still be bad).

- 75% duty cycle signal —Indicates a fuel pump–side problem, such as an open-circuit, short, or excessive current draw.

The cool thing is that we can quickly confirm if a valid duty cycle (25%, 50%, or 75%) is present —and that's exactly what we'll do in this test section.

Alright, let's get to it:

- 1

Set your multimeter to duty cycle (%) mode.

- 2

Connect the black multimeter lead to a clean, rust-free Ground point.

- 3

Back-probe the FPDM module connector at the DK GRN/YEL wire with the red multimeter test lead.

The DK GRN/YEL wire is the FPM wire and it should connect to the back of terminal 7. - 4

Have your helper crank the engine while you monitor the multimeter.

- 5

You should see a duty cycle reading around 50% during cranking (assuming the engine isn't starting).

NOTE: You may see a reading of 25% or 75% instead —both are valid signals and indicate the FPDM is alive and communicating.

Let's interpret your test result:

CASE 1: The multimeter reports a 50% duty cycle. This indicates the FPDM module is receiving a valid command, sees no internal issues, and reports normal operation.

Here's how to interpret that if the engine isn't starting:

- 0 PSI fuel pressure with FPDM module confirmed working —Points to a failed fuel pump as the cause of the no-start.

- Normal fuel pressure but the engine doesn't start —The engine no-start problem isn't fuel-related and something else is causing it.

CASE 2: The multimeter reports a 25% or 75% duty cycle. This shows the FPDM module is active but signaling a fault back to the PCM.

- 25% duty cycle —Indicates the FPDM module isn't receiving the PCM's FPC command, is getting an invalid signal (outside the 5%-50% fuel pump ON range), or hasn't received the PCM's normal 70%-80% fuel pump OFF command.

- 75% duty cycle —Indicates a fault between the FPDM module and the fuel pump, such as a bad pump, a short, or an open in the pump's power or Ground wire.

CASE 3: The multimeter reports a 0% reading. This usually means the FPDM isn't powering up, most often due to a tripped inertia switch cutting power.

- If inertia switch is good —verify power is reaching the FPDM module, then check for a corroded or loose chassis Ground.

- If power and Ground are good —no feedback signal confirms an internally failed FPDM module that must be replaced.

More Fuel Pump Troubleshooting Help

FUEL PUMP PRESSURE TESTS:

- How To Test The Fuel Pump (2000 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test The Fuel Pump (2001-2002 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test The Fuel Pump (2003 3.0L V6 Ford Taurus, Mercury Sable).

FUEL PUMP AMPERAGE DRAW TESTS:

ENGINE NO-START DIAGNOSTICS:

More 3.0L V6 Ford Taurus Diagnostic Tutorials

You can find a complete list of 3.0L V6 Ford Taurus and Mercury Sable diagnostic tutorials in this index:

Here's a sample of the diagnostic tutorials you'll find in the index:

- How To Do And Interpret An Engine Compression Test (1990-2007 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test For A Blown Head Gasket (1990-2007 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test The MAF Sensor (1996-1999 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test The MAF Sensor (2000-2003 3.0L V6 Ford Taurus, Mercury Sable).

If this info saved the day, buy me a beer!