If you're trying to figure out whether the crankshaft position (CKP) sensor on your 3.3L V6 minivan is bad, you don't need a scan tool or any fancy diagnostic gear.

In this tutorial, I'll show you how to test the CKP sensor -step-by-step— using just a simple multimeter.

And if you'd rather skip the test and go straight to replacing it, I'll point you to where you can grab a new one without breaking the bank.

Contents of this tutorial:

- Symptoms Of A Bad CKP Sensor.

- How The CKP Sensor Functions.

- Should I Just Replace The CKP Sensor Without Testing It?

- Where To Buy The CKP Sensor And Save.

- Crankshaft Position Sensor Connector Pinout.

- TEST 1: Testing The CKP Signal With A Multimeter.

- TEST 2: Making Sure The CKP Sensor Is Getting 5 Volts.

- TEST 3: Making Sure The CKP Sensor Is Getting Ground.

- Installing The CKP Sensor: Setting The Correct Air Gap.

- More 3.3L V6 Chrysler, Dodge, And Plymouth Minivan Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 3.3L V6 Chrysler Town & Country: 1990, 1991, 1992, 1993.

- 3.3L V6 Dodge Caravan: 1990, 1991, 1992, 1993.

- 3.3L V6 Dodge Grand Caravan: 1990, 1991, 1992, 1993.

- 3.3L V6 Plymouth Voyager: 1990, 1991, 1992, 1993.

- 3.3L V6 Plymouth Grand Voyager: 1990, 1991, 1992, 1993.

WIRING DIAGRAM:

IGNITION SYSTEM TESTS:

- How To Test The CMP Sensor (1990-1993 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

- How To Test The Coil Pack (1990-1998 Chrysler 3.3L, 3.8L) (at: easyautodiagnostics.com).

OTHER CKP SENSOR TEST TUTORIALS:

- How To Test The CKP Sensor (1994-1997 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

- How To Test The CKP Sensor (1998-2000 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

- How To Test The CKP Sensor (2001-2003 3.3L V6 Chrysler And Dodge Minivan).

- How To Test The CKP Sensor (2004-2007 3.3L V6 Chrysler And Dodge Minivan).

Symptoms Of A Bad CKP Sensor

A failing crankshaft position (CKP) sensor on your 3.3L V6 Chrysler, Dodge, or Plymouth minivan can light up the check engine light (CEL) and lead to driveability problems you can't ignore.

Below are the most common symptoms of a bad CKP sensor:

- Engine no-start: The starter turns the engine, but it won't actually start and run.

- Hard start: The engine struggles to start.

- Engine stalls randomly: It could shut off after starting or while driving.

- Rough idle: You may notice erratic idle behavior or light misfires.

- Weak acceleration: The engine feels bogged down or underpowered.

- Stored CKP sensor fault code: When the PCM doesn't see the crank signal, it'll usually set a CKP sensor diagnostic trouble code (DTC):

- Code 11: Missing Crank Reference Signal.

How The CKP Sensor Functions

This engine uses a Hall-Effect type crankshaft position (CKP) sensor, which is why it has a 3-wire connector.

These are the key things to know about the CKP sensor:

- The sensor is mounted on the transmission bellhousing, right where it butts up against the engine block —at the rear of the transmission.

- It relies on an 8-Volt supply and a Ground path from the PCM to function properly and produce a readable CKP signal.

- To be a bit more specific, as the crankshaft spins, the sensor sends out a digital square wave that toggles between 5 Volts and 0 Volts (0.3 to 0.5 Volts to be exact).

- The CKP sensor creates this signal by detecting the slots cut in the flywheel as they pass in front of its tip.

- Since the flywheel has a total of 12 slots cut into it, the sensor will produce 12 ON (5V) pulses and 12 OFF (0V) dips during one full turn of the crankshaft.

- This ON/OFF signal provides crankshaft position data to the PCM.

- The PCM uses this signal (along with the CMP signal) to fine-tune ignition timing and fuel delivery to get the engine to start and stay running.

Should I Just Replace The CKP Sensor Without Testing It?

Plenty of DIYers —and even the pros— often replace the crank sensor first without running any tests (when a CKP sensor code pops up or suspect it's bad). And in many cases, that does fix the problem.

Since the CKP sensor is affordable and fairly quick to replace, going that route can save time if you're in a hurry to get back on the road.

If that's the path you're taking, check out the links below to find low-cost replacement options —and make sure to read:

But if you'd rather not throw parts at the problem, this guide will walk you through how to test the sensor properly before you commit to replacing it.

Where To Buy The CKP Sensor And Save

The following links will help you comparison shop for the crankshaft position sensor:

CKP Spacer: Air Gap Spacer

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

NOTE: If you're installing a new sensor or removing and reinstalling the same one, see: Installing The CKP Sensor: Setting The Correct Air Gap.

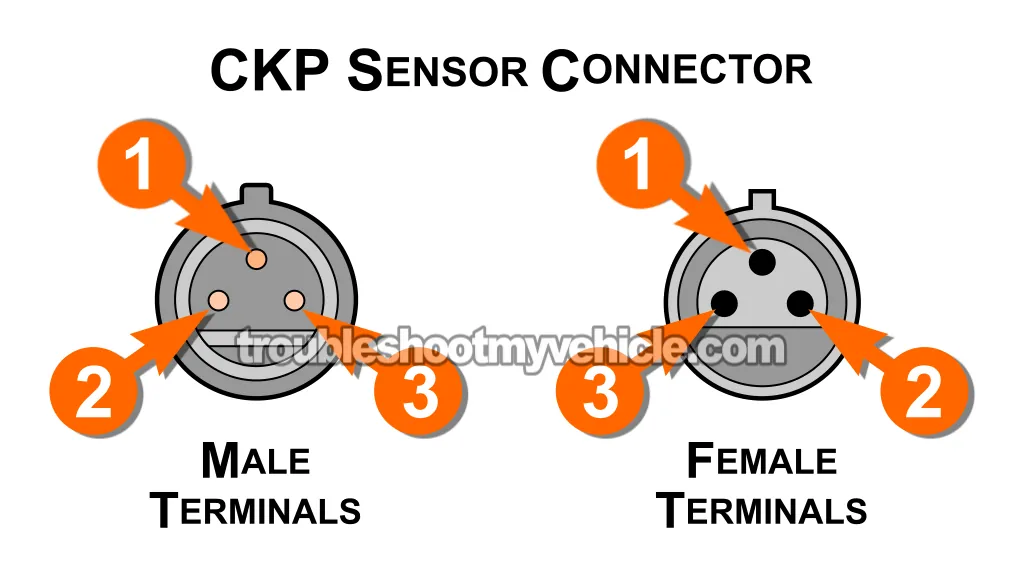

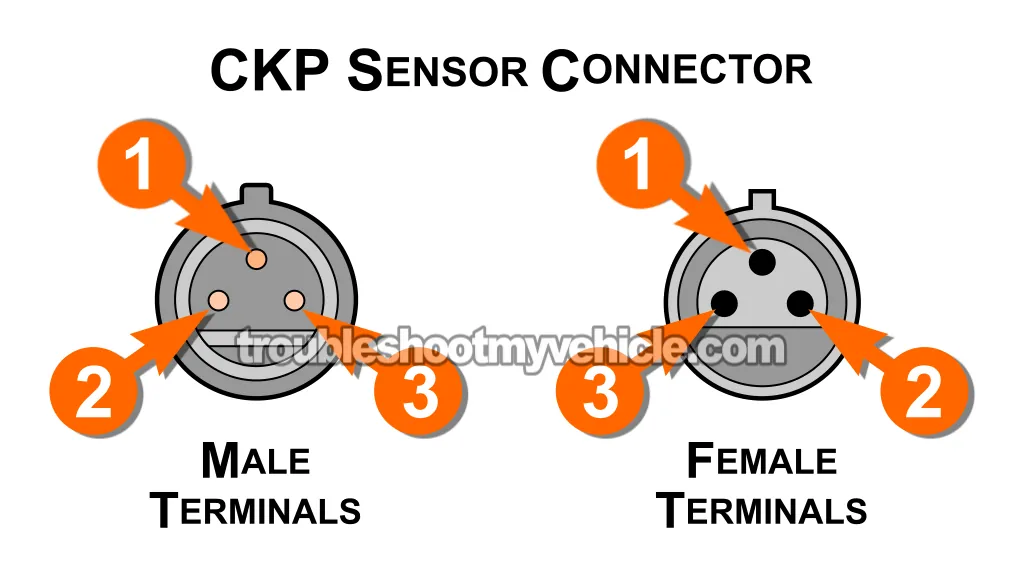

Crankshaft Position Sensor Connector Pinout

| CKP Sensor Circuits | ||

|---|---|---|

| Terminal | Wire | Description |

| 1 | Orange (ORG) | 8 Volts DC |

| 2 | black with light blue stripe (BLK/LT BLU) | Ground |

| 3 | Grey with black stripe (GRY/BLK) | CKP Sensor Signal |

TEST 1: Testing The CKP Signal With A Multimeter

We'll begin our crankshaft position sensor diagnosis with a simple signal output test —this test involves turning the engine by hand, not cranking it with the starter.

The main reason we don't use the starter motor is because it spins the engine too fast —your multimeter won't be able to catch the ON/OFF CKP signal at those high cranking speeds (you'd need an oscilloscope for that).

Here's what you're looking for:

- ON: Signal line shows 5 Volts.

- OFF: Signal drops to around 0 Volts.

If you don't have a multimeter or need to upgrade yours? This is the one I use and recommend: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (at: amazon.com).

NOTE: Don't use the starter motor —it spins the engine too fast for a multimeter to detect the signal change.

CAUTION: If you raise the minivan, to access crankshaft pulley bolt —use jack stands. Never trust a floor jack alone.

IMPORTANT: The sensor must stay connected to the pigtail connector of the engine wiring harness during testing. You'll need to back-probe the wire or use a wire-piercing tool —you can see an example of this tool (and where to buy it) here: Wire Piercing Probe.

Here's what we need to do:

- 1

Disconnect the ignition coil pack connector.

IMPORTANT: Do this first to prevent accidental engine startup during testing. - 2

Set your multimeter to DC Volts.

- 3

Ground the black lead on the battery's negative (-) terminal.

- 4

Back-probe the dark blue/gray wire at the CKP sensor, or pierce the wire with a wire piercing probe.

NOTE: The connector must remain plugged in during this test. - 5

Turn the key to ON (engine OFF).

- 6

Use a ratchet and socket to slowly rotate the crankshaft pulley clockwise.

IMPORTANT: Make sure to complete at least one full revolution of the crankshaft so the sensor passes by all the flywheel slots. - 7

Look for the voltage to toggle between 5 Volts and 0 Volts.

NOTE: You should see the voltage switch 12 times from 5V to 0V as the crankshaft makes one full rotation.

Here's what the results tell you:

CASE 1: You see the signal switching. Perfect —the sensor is functioning correctly.

This confirms the sensor is alive, receiving power and Ground, and sending the a CKP signal to the PCM. No further testing is needed unless another issue is present.

CASE 2: No voltage change. Recheck your connections and wire probe.

If the signal's still flat, your next step is to confirm the sensor's getting its 8 Volt power supply. Go to: TEST 2: Making Sure The CKP Sensor Is Getting 8 Volts.