TEST 3: Engine Compression Test

If you're 3.0L Toyota Camry starts and runs, you can skip this test and go to: TEST 4: Using A Chemical Block Tester (Combustion Leak Tester).

In some cases, you may need to perform a compression test to confirm a head gasket failure. This is especially true if the gasket fails between two side-by-side cylinders.

When this happens, compression from one cylinder escapes into the other, leaving both cylinders with zero PSI compression.

The engine might still start, but it'll only be running on four cylinders and it's gonna run terribly if at all. The only way to confirm this type of failure is by doing an engine compression test.

NOTE: The engine compression test is explained in detail in this tutorial: How To Test Engine Compression (1992-2006 3.0L V6 Toyota Camry).

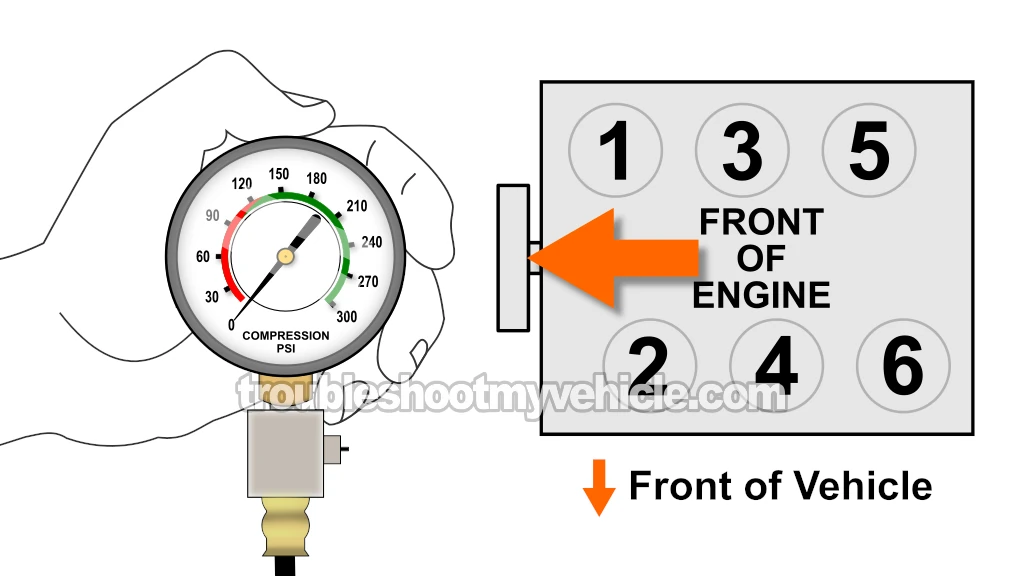

These are the test steps:

- 1

Remove the upper intake manifold plenum.

- 2

Disable the fuel system and the ignition system.

- 3

Remove the spark plugs and install the compression tester (hand tight only) on the first cylinder you're gonna' test.

- 4

Have a helper crank the engine while you observe the compression tester.

- 5

When the needle stops moving, have your helper stop cranking the engine.

- 6

Write down the compression readings.

- 7

Repeat on the next 3 cylinders.

Let's take a look at what your test results mean:

CASE 1: You got 2 side by side (adjacent) cylinders with 0 PSI. This confirms beyond a shadow of a doubt that you do have a blown head gasket on your hands.

CASE 2: All cylinders had sufficient compression. This is the correct and expected test result.

If you still suspect that your vehicle has a blown head gasket, go to: TEST 4: Using A Chemical Block Tester (Combustion Leak Tester).

TEST 4: Using A Chemical Block Tester (Combustion Leak Tester)

The go-to method in most auto repair shops for diagnosing and confirming a head gasket issue is a combustion leak detector, also known as a block tester.

Using a block tester is one of the easiest and most reliable ways to determine if a head gasket has failed.

This is how this test works:

- A blue liquid chemical, which is blue in color, is placed in the tester (see photo above).

- The engine is started.

- The tester assembly is then placed on the open radiator neck (you may have to drain some of the coolant in the radiator since this tool needs to ‘gulp’ some of the air inside the radiator).

- The rubber bellow is then squeezed to suck in the air up through the two fluid-filled chambers. As the air bubbles up through the fluid, it will cause a chemical reaction.

- If the blue chemical turns yellow (for gasoline engines), combustion gases are entering the radiator. This result confirms a head gasket failure, a cracked block, or a cracked cylinder head issue.

- If the blue chemical doesn't change color, you can conclude that you don't have a head gasket failure, a cracked block, or a cracked cylinder head issue.

You can shop for a block tester here:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

Frequently Asked Questions

1.) How can I tell if the cylinder head is cracked?

The cylinder head must be removed and visually inspected. If the crack is large enough, it'll be easily visible.

However, some cracks may not be obvious during a visual inspection. This is why it’s crucial to have a machine shop pressure test the cylinder head to confirm whether or not it’s cracked.

2.) Do I need to replace both head gaskets?

If only one head gasket has failed, technically, you can replace just the faulty one.

However, replacing both head gaskets is the way to go (most shops won't accept the job if only one is being replaced) because the other head gasket may already have significant wear or damage that’s not immediately apparent. Replacing both at the same time can save you from doing the job twice if the other gasket fails shortly after.

Additionally, the age and mileage of the engine play a role. If the engine has high mileage or has been overheated, both head gaskets are more likely to be compromised.

3.) Do I need to resurface the cylinder heads?

YES, you should always resurface both cylinder heads before reinstalling them. Overheating can warp the cylinder heads, and failing to resurface them can lead to improper sealing with the new head gasket, causing another failure.

If you or the machine shop check the cylinder heads with a straight-edge and confirm that there’s no warpage, then resurfacing may not be necessary. However, this is the exception rather than the rule, especially if the engine has overheated.

More 3.0L Toyota Camry Tutorials

You can find a complete list of 3.0L Toyota Camry tutorials in this index:

Here's a sample of the tutorials you'll find there:

- How To Test Engine Compression (1992-2006 3.0L V6 Toyota Camry).

- How To Test For A Blown Head Gasket (1992-2006 3.0L V6 Toyota Camry).

- How To Test The TPS (1997-2001 3.0L V6 Toyota Camry).

- How To Test The MAF Sensor (1997-2001 3.0L V6 Toyota Camry).

If this info saved the day, buy me a beer!