A compression test can give you valuable insight into your Toyota Camry engine's health. It's a key diagnostic step to figure out if low compression in one or more cylinders is causing issues like misfires or check engine light trouble codes.

This test can also help determine if a no-start issue is related to a broken timing belt or internal engine damage, giving you a clearer picture of where the problem lies.

In this guide, I'll explain how to perform the compression test step by step and, most importantly, how to interpret the results so you can troubleshoot your engine effectively.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 2.0L Toyota Camry: 1990, 1991, 1992, 1993, 1994, 1995, 1996, 1997, 1998, 1999, 2000, 2001.

Important Tips And Suggestions

TIP 1: Warm up the engine slightly. If your Camry's engine starts and runs, let it idle for about 15 minutes to warm up —just don't let it get to full operating temperature. A slightly warmed-up engine helps produce more accurate compression readings without being too hot to handle safely.

TIP 2: Prioritize safety. Always take safety precautions when working near an engine that's cranking. Use common sense, stay alert, and ensure you're thinking about safety at all times.

TIP 3: Be careful with the spark plugs. The cylinder head in your Camry's 2.0L engine is made of aluminum. To avoid damaging the spark plug threads, never remove the spark plugs while the engine is hot (normal operating temperature). Always wait for the engine to cool to a safe, warm level before starting this step.

Symptoms Of Low Or No Cylinder Compression

Engine compression problems usually show up in two main ways:

- The engine runs but has a rough idle or misfire.

- The engine cranks but won't start.

Let's break these down:

1. Rough idle or misfire from low compression

Low compression in one or two cylinders can make your 2.0L Toyota Camry idle roughly or misfire, causing noticeable vibrations or shaking.

Interestingly, this issue often improves or disappears when you rev up the engine or drive at higher speeds.

2. Engine cranks but fails to start

When two or more cylinders have no compression, the engine may crank but won't start. If all four cylinders lose compression, you'll likely notice these symptoms:

- Faster cranking: The engine turns over much quicker than usual, signaling a major internal issue.

- Spark is present: You'll find all cylinders are sparking properly, ruling out problems with the ignition system.

- Fuel is reaching the engine: The injectors are delivering fuel. You can check for this by:

- Using a Noid light to confirm the injector pulse.

- Inspecting the spark plugs —wet, fuel-soaked plugs indicate fuel is being injected.

Common causes of zero compression across all cylinders:

- Blown head gasket: This can cause compression loss between cylinders.

- Broken timing belt: A snapped belt stops the camshaft from turning, halting compression.

- Thrown connecting rod: Severe internal damage that disrupts engine operation entirely.

Which Compression Tester Should I Buy?

There are lot of engine compression testers to choose from and many places to buy them. I'm gonna' make some recommendations to you:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

TEST 1: Dry Compression Test

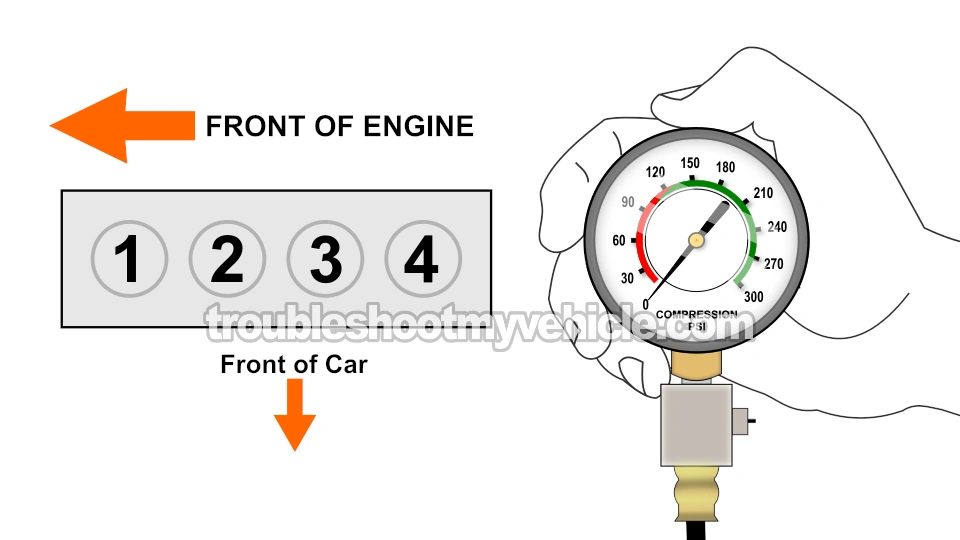

The first we're gonna do is a dry compression test. This test will let us know the compression of each cylinder. Once we have all four values, we can interpret the test results.

CAUTION: Be careful and be alert at all times since you'll be working around a cranking engine.

NOTE: If your Toyota's engine is hot, wait for it to cool down before removing 4 spark plugs. Removing the spark plugs from a hot engine can damage the spark plug threads in the cylinder head.

Alright, these are the test steps:

- 1

Disable the ignition system by disconnecting the ignition distributor from its electrical connector. This will prevent the ignition coil from sparking during the test.

- 2

Remove the spark plugs from a slightly warmed up engine (if it starts and runs). Remember, the engine can not be hot!

When removing the spark plugs, be careful not to drop any of them on the floor, or you run the risk of having the spark plugs porcelain insulator crack and then you'll have a misfire on your hands.

If the engine does not start, don't worry about it being warmed up. - 3

Thread the engine compression gauge into the spark plug hole for the number 1 engine cylinder. Hand tighten the compression gauge only! Do not use any type of tool to get it tight.

- 4

Have your helper crank the engine till the needle on the compression gauge stops climbing.

- 5

Now, record on paper the value at which the needle stopped and the number of the engine cylinder on a piece of paper. Release the pressure on the gauge and repeat this step one more time.

- 6

Repeat this test step on the remaining 3 cylinders.

Let's take a look at what your test results mean:

CASE 1: You go 0 PSI compression on all 4 cylinders. This is not good and tells you that one of the following conditions exists:

- Timing belt problem.

- Blown head gasket.

- Blown engine.

Any compression value below 100 PSI (even if it does not 0 PSI) means internal mechanical engine trouble.

CASE 2: Some, but not all, of the cylinders had a low compression value. Up to a certain point this is normal -especially if the engine has a lot of miles.

What is NOT normal is if the values vary too much. With a bit of math we can find out if the lowest compression values are normal or not. Go to: Interpreting Your Compression Test Results.

The rule of thumb is that the lowest compression value cannot vary more than 15% from the highest value you recorded. Any cylinder with a compression value lower than 15% of the highest will misfire.

Interpreting Your Compression Test Results

Over time, wear and tear can cause variations in compression between the cylinders of your Toyota's engine.

- Minor differences: Small variations in compression values are normal and typically don't affect engine performance.

- Significant differences: Larger variations can lead to issues like a rough idle or misfire.

To figure out if a lower compression value is problematic, compare it to the highest value recorded. If the difference is greater than 15%, it could be the root cause of your engine's rough performance.

Two ways to calculate the 15% difference:

- Manual Calculation: Use pen and paper to determine if a cylinder's compression value is more than 15% lower than the highest recorded value.

- Low Compression Calculator: Simplify the process with my low compression calculator, which you can access here: Online Low Engine Compression Calculator (at: easyautodiagnostics.com).

If you want to manually calculate the 15% difference, here's what you'll need to do:

- STEP 1: Multiply the highest compression value by 0.15 (this is the decimal value of 15%).

- STEP 2: Round the result to the nearest one (for example: 25.6 would become 26).

- STEP 3: Subtract the result (the number that was rounded) from the highest compression value.

- ANSWER: The result of this subtraction is the lowest possible compression value any cylinder can have.

Now, let me give you a more specific example: Let's say that I got the following compression readings:

| Cylinder | Pressure |

|---|---|

| #1 | 165 PSI |

| #2 | 95 PSI |

| #3 | 155 PSI |

| #4 | 175 PSI |

My next step is to do the following calculation:

- STEP 1: 175 x 0.15 = 26.25.

- STEP 2: 26.25 = 26 (rounded to nearest one).

- STEP 3: 175 - 26 = 149.

- ANSWER: 149 PSI. Any cylinder with this compression (or lower) value will misfire.

Since cylinder #2 is only producing 95 PSI, I can now conclude that it's 'dead' and causing a misfire.

To find out if the lowest compression value you got from your engine compression test is within a good range, you'll need to do the same calculation. Of course, you'll need to use the highest compression value you got and not the one in the example.

Once you've found the 'dead' cylinder, the next step is to find out what's causing the low compression value. For this step, go to: TEST 2: Wet Compression Test.

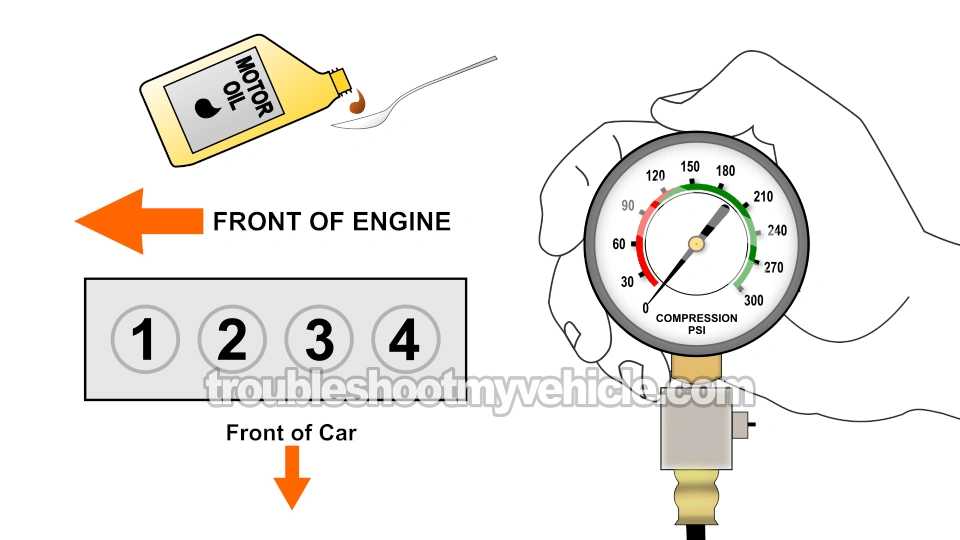

TEST 2: Wet Compression Test

If your compression test (TEST 1) revealed a cylinder with a value more than 15% lower than the highest recorded value, the next step is to determine whether the issue stems from severe wear or damage to the piston rings or cylinder head valves.

To do this, we'll do a 'wet' compression test by adding a small amount of engine oil to the affected cylinder and then retest the cylinder's compression.

We'll see one of two things:

- Compression value increases: If the compression improves with oil, the issue is likely due to worn piston rings.

- Compression value stays the same: If there's no change, the problem is likely with the cylinder head valves.

These are the test steps:

- 1

Add a tablespoon (or two) of engine oil in the cylinder you need to retest.

I suggest using a small and long funnel so that the oil will reach the inside of the cylinder. - 2

Once you've added the oil, install the compression gauge, and as before just hand tighten it.

- 3

Have your helper crank the engine till the needle stops climbing on the compression gauge.

- 4

You'll see one of two results:

A.) The needle will climb higher than the previous compression number you recorded for this specific cylinder.

B.) The needle will not move at all or stay at the same number you recorded earlier.

What ever value your compression tester reads, write it down again. - 5

If you have another cylinder that needs to be tested, then repeat steps 1 thru' 4 on it now.

Let's take a look at what test results mean:

CASE 1: The compression value went up after adding motor oil and retesting. This tells you that the low compression problem is due to worn piston compression rings.

Here's why: The motor oil you just added helped the piston rings to create a tighter seal. With the piston rings now sealing the compression inside the cylinder, the compression value on your compression tester went up. This type of test result only happens when the problem is due to worn piston rings.

CASE 2: The compression value DID NOT go up after adding oil and retesting (in other words, it stayed the same). This result tells you that the low compression value registered in this cylinder (in the dry test) is due to worn/damaged cylinder head valves.

More 2.0L Toyota Camry Tutorials

You can find a complete list of 2.0L Toyota Camry tutorials and wiring diagrams in this index:

Here's a sample of the tutorials you'll find there:

- TPS Idle Switch Multimeter Test w/ Automatic Transaxle (1987-1991 2.0L Toyota Camry).

- How To Test The TPS w/ Automatic Transaxle (1987-1991 2.0L Toyota Camry).

- How To Test For A Blown Head Gasket (1987-1991 2.0L Toyota Camry).

- How To Test The Engine Compression (1987-1991 2.0L Toyota Camry).

- How To Test The MAF Sensor (1987-1991 2.0L Toyota Camry).

If this info saved the day, buy me a beer!