TEST 3: Verifying The MAP Signal With A Multimeter

This test will require that you remove the MAP sensor from its spot on the intake manifold. And while it's still connected to its connector you'll manually apply vacuum to it.

The thing to remember is that as you're applying vacuum to the sensor, the sensor should start to vary its MAP signal voltage (middle wire).

The more vacuum you apply, the smaller the voltage the MAP sensor will create. Releasing the vacuum should get the MAP sensor to increase the voltage signal to the original voltage you saw before applying vacuum.

If your Honda's MAP sensor is bad, it'll no longer create a varying MAP signal voltage. In other words: no matter what the amount of vacuum applied to it, its output voltage will stay fixed at one single voltage value.

Alright, this is what you need to do:

- 1

Remove the MAP sensor from the top of the intake manifold.

NOTE: Reconnect the MAP sensor to its electrical connector, if you had to unplug it to remove it, since this test requires that the MAP sensor stay connected to its 3-wire electrical connector. - 2

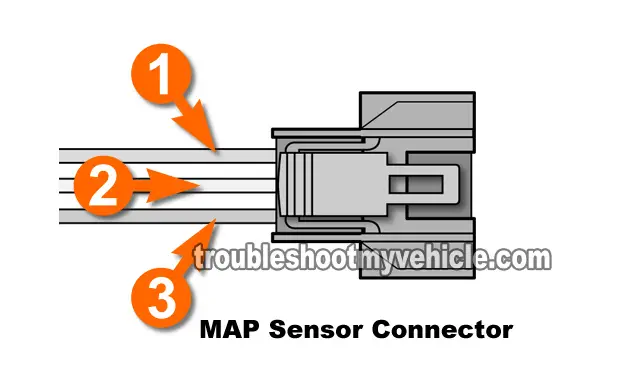

Connect your multimeter's red test lead to the wire labeled with the number 3 of the MAP sensor's connector (see illustration above).

You'll need to back-probe the MAP sensor connector or use a wire piercing probe to connect your multimeter to this circuit (to see what a wire piercing probe looks like, click here: Wire Piercing Probe). - 3

Ground the black multimeter test lead.

I suggest Grounding the black multimeter test lead directly on the battery negative (-) terminal. - 4

Turn the key on (but don't start the engine) and take a look at what voltage your multimeter is registering.

It should register around 2.9 Volts (± 1 V). If your multimeter is registering something different at this point, don't panic because right now you're just setting up the test. - 5

Attach a vacuum pump to the MAP sensor's vacuum inlet nipple using the appropriate size vacuum hose.

If you don't have a vacuum pump, you can use the ‘good ole' lungs’ and provide the necessary with your mouth. - 6

The voltage, your multimeter is registering, should decrease as you apply vacuum with your vacuum pump (or with your mouth).

- 7

The MAP sensor's voltage, as registered on your multimeter, should increase back to the original voltage value you saw in step 4 as you release the vacuum you applied with the vacuum pump (or your mouth).

Let's take a look at what your test results mean:

CASE 1: The MAP sensor's voltage decreased and increased as you applied and released vacuum. This confirms that the MAP sensor is good and operating normally.

This test result completely eliminates the MAP sensor on your Honda Civic as bad. If you're still having the MAP sensor trouble code come back, take a look at: MAP Sensor Is Good But Code Doesn't Go Away!.

CASE 2: The MAP sensor's voltage DID NOT decrease or increase as you applied and released vacuum. This confirms that the MAP sensor is bad and needs to be replaced if you have:

- Confirmed that the MAP sensor is getting 5 Volts (TEST 1).

- Confirmed that the MAP sensor is getting Ground (TEST 2).

- In this test section confirmed that the MAP sensor's signal voltage is stuck in one value as you apply/release vacuum to it.

If you need to buy the MAP sensor and would like to save some bucks, take a look at the section: Where To Buy The MAP Sensor And Save.

MAP Sensor Is Good But Code Doesn't Go Away!

If you have bench-tested the MAP sensor and the bench test tells you that the MAP sensor is good and not the cause of the MAP sensor trouble code, then there's something else fooling the PCM into thinking the MAP is bad when it's just reporting an actual true load condition.

Several things can prevent the engine from reaching an ideal load condition. Among them are:

- Vacuum leaks.

- An intake manifold gasket leak or a ruptured vacuum hose (especially a big one) that's leaking vacuum will have a direct impact on the MAP sensor readings.

- Excessively worn out engine.

- You'll need to do a compression test.

- What you're looking for is uneven wear and tear between the cylinders. This means that the compression each cylinder is producing varies more than 15%.

- This tutorial will help: How To Test Engine Compression (Honda 2.2L, 2.3L).

- Timing belt that's not synchronized correctly.

- If you've just replaced the timing belt (or had to remove it for any reason), double check your timing marks.

- MAP sensor isn't getting power and/or Ground.

- A short in the wiring between the MAP sensor and the PCM.

- You'll need to check the continuity of the 3 wires between the MAP sensor and the PCM using the appropriate wiring diagram.

- A bad PCM.

- This is very rare, but it does happen.

- A fuel system malfunction (that is also setting other trouble codes).

- If there are any other trouble codes, you'll need to diagnose and repair these first (since they may be indirectly causing the MAP sensor code).

- You've replaced the throttle body gasket and used silicone sealer on it and this sealer has plugged the MAP sensor's vacuum passage and/or orifice (I've seen this happen a lot!).

More 1.6L Civic Tutorials

You can find a complete list of tutorials in this index:

Here's a small sample of the 1.6L Honda Civic tutorials you'll find in the index:

- Testing Shift Control Solenoid Valves A and B (1996-2000 1.6L Honda Civic).

- How To Test The Alternator (1996-2000 1.6L Honda Civic).

- How To Test: Lock-up Control Solenoid Valves (1996-2000 1.6L Honda Civic).

- How To Test Trouble Code P0135 (1995-2000 Honda 1.6L).

- How To Test The Igniter, Ignition Coil Accord, Civic, CRV, and Odyssey (at:easyautodiagnostics.com).

If this info saved the day, buy me a beer!