The crankshaft position (CKP) sensor can be considered the beating heart of the ignition system since it plays a crucial role in synchronizing the ignition timing with the engine's rotation, if it fails, the engine is not gonna start or stay running.

In this tutorial, I'll explain a simple method of testing it with a multimeter. With your test results, you'll quickly find out if its good or bad.

Contents of this tutorial:

- Important Tips And Suggestions.

- Symptoms Of A Bad CKP Sensor.

- Should I Test The CKP Sensor Or Just Replace It?

- Where To Buy The CKP Sensor And Save.

- How The CKP Sensor Works.

- TEST 1: Checking The CKP Signal With A Multimeter.

- TEST 2: Making Sure The CKP Sensor Is Getting 5 Volts.

- TEST 3: Making Sure The CKP Sensor Is Getting Ground.

- More Chevy Express/GMC Savana Articles And Tutorials.

ES ![]() You can find this tutorial in Spanish here: Cómo Probar El Sensor CKP (2008-2013 V8 Chevrolet Express, GMC Savana) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar El Sensor CKP (2008-2013 V8 Chevrolet Express, GMC Savana) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the Express/Savana 4.8L, 5.3L, and 6.0L V8 engines only:

- Chevrolet Express 1500, 2500, 3500: 2008, 2009, 2010, 2011, 2012, 2013.

- GMC Savana 1500, 2500, 3500: 2008, 2009, 2010, 2011, 2012, 2013.

ENGINE NO-START DIAGNOSTICS: Engine doesn't start? The following guide is a good troubleshooting resource:

- How To Diagnose An Engine Cranks But Does Not Start Problem (2003-2013 V8 Chevy Express, GMC Savana).

Important Tips And Suggestions

TIP 1: To perform the test, you'll need to manually turn the engine. The best point, to turn the engine with a 1/2 ratchet wrench and a socket, is the crank pulley.

You'll need to lift the vehicle to gain access to the crank pulley. Use jack stands to hold up the vehicle. DO NOT trust the jack. Think safety all of the time and take all necessary safety precautions (including using safety glasses).

TIP 2: Do not turn the engine with the starter motor, when doing the CKP sensor test. Using the starter motor will severely decrease the accuracy of your multimeter test results.

TIP 3: If your GM vehicle starts and runs, the CKP sensor is good and testing it will be pretty much point-less (since the test result will indicate it's functioning).

TIP 4: Since this is an on-car test of the CKP sensor, DO NOT remove the CKP sensor to test it. In the photo you'll notice it's out but this is just to make it easier to explain the test to you.

Symptoms Of A Bad CKP Sensor

The CKP sensor will fail in one of two ways: A complete failure or an intermittent failure. Here's the breakdown:

- Complete failure: When the CKP sensor experiences a complete failure, it ceases to function entirely. In this scenario, the sensor stops providing any information to the Powertrain Control Module (PCM) regarding the crankshaft's position or speed. As a result, the PCM is unable to determine the correct ignition timing and fuel injection parameters, leading to an engine that cranks but won't start.

- Intermittent failure: The CKP sensor may experience intermittent failures. In this case, the sensor may work correctly most of the time, but suddenly fails, causing the van's engine to shut down when you least expect it.

When the CKP sensor fails, you'll see one or all of the following symptoms:

- No Spark: No spark from all of the Coil-On-Plug (COP) ignition coils.

- No Fuel Injection: No fuel injector pulses from the fuel injector connectors as tested using a Noid Light.

- Trouble Codes: On that rare occasion the PCM stores a Diagnostic Trouble Code, you'll see one of these:

- P0335: No CKP Sensor Signal Detected.

- P0336: Inconsistent CKP Sensor Signal Detected.

- Check Engine Light (CEL): The PCM often detects the sensor malfunction, sets a CKP sensor trouble code and illuminates the CEL to alert you.

The thing to remember when testing the CKP sensor, is that if all eight ignition coils are sparking or the PCM is activating the fuel injector, the CKP sensor is OK and not the cause of your engine's no-start condition.

Should I Test The CKP Sensor Or Just Replace It?

In many cases, when faced with a CKP sensor diagnostic trouble code (DTC) and symptoms that suggest that the sensor is bad (for example: the engine cranks but does not start), most folks and even some auto repair shops generally choose to replace the sensor without testing it. There are two main reasons for this:

- The CKP Sensor Is Inexpensive: The CKP sensor is relatively inexpensive to purchase compared to other vehicle components. This lower cost makes it more appealing to simply replace the sensor rather than spending the time and effort to test it.

- Saving Time: Performing the CKP sensor tests can be time-consuming, especially if the problem is intermittent or difficult to replicate. For this reason, for many (including shops), replacing the CKP sensor outright may seem like the quickest solution.

Ultimately, the decision to replace the CKP sensor without testing it depends on factors such as cost, time constraints, and your level of diagnostic expertise. If you want to simply replace the CKP sensor, you can find my recommendations here: Where To Buy The CKP Sensor And Save.

If you test it, then this guide will help you test it using a multimeter (to measure the sensor's output signal) and find out if it's good or bad without having to replace it.

Where To Buy The CKP Sensor And Save

Check out the following links and comparison shop the original AC Delco (Delphi) crankshaft position sensor on your GM van:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

Not sure if the above crankshaft position sensor fits your particular GM vehicle? Don't worry, once you click on the links and arrive on the site, they'll make sure it fits! If it doesn't, they'll find you the right one.

How The CKP Sensor Works

The CKP sensor in 2008-2010 V8 Chevy Express and GMC Savana is a Hall-Effect three-wire sensor. This means it generates an ON/OFF DC voltage signal as the reluctor wheel on the crankshaft rotates.

This signal is then sent to the PCM, which uses it to activate ignition coils (COP coils), fuel injectors, and the fuel pump so the engine will start and stay running.

The signal the CKP sensor generates can be measured using various tools such as a multimeter, oscilloscope, or LED light.

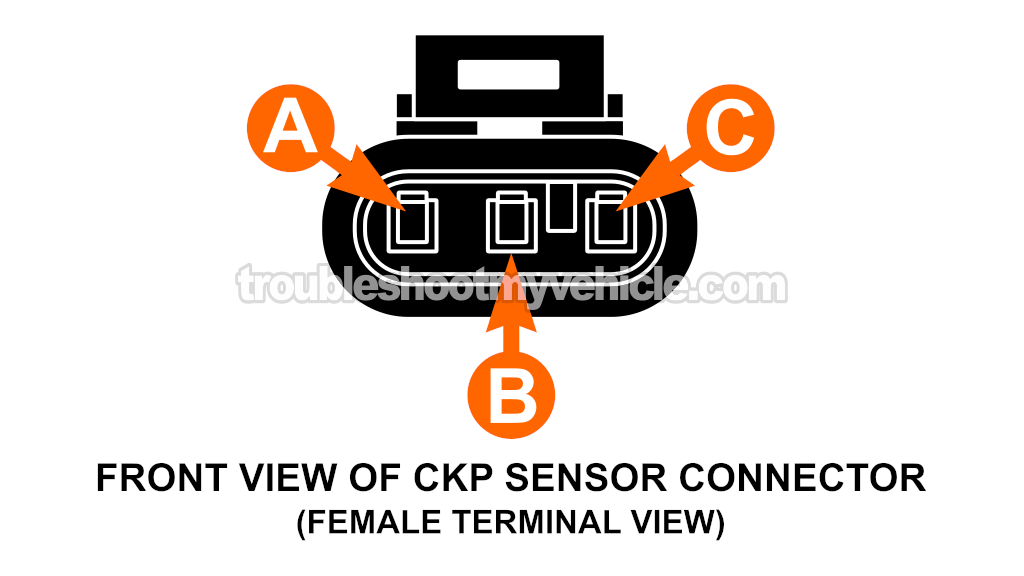

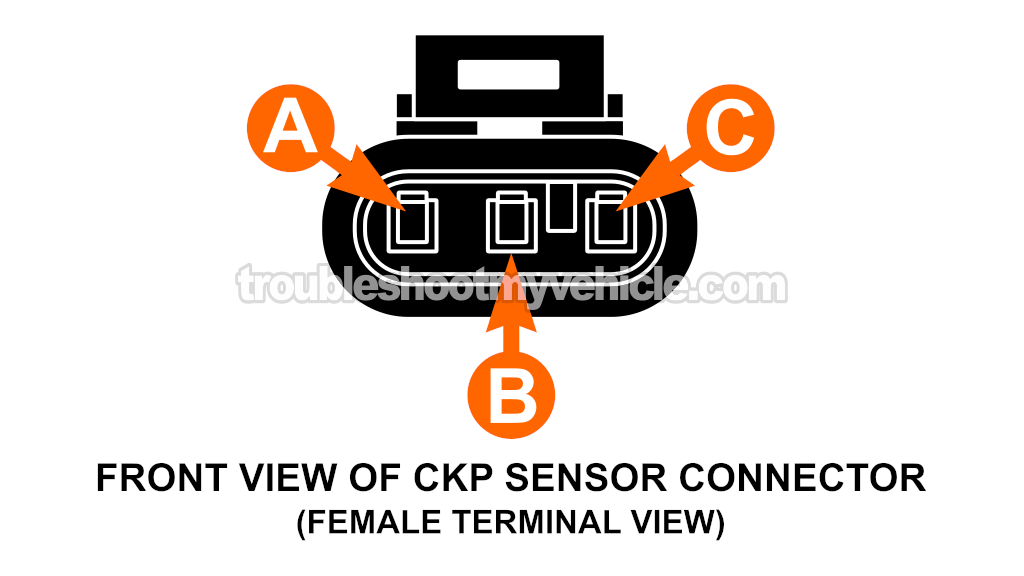

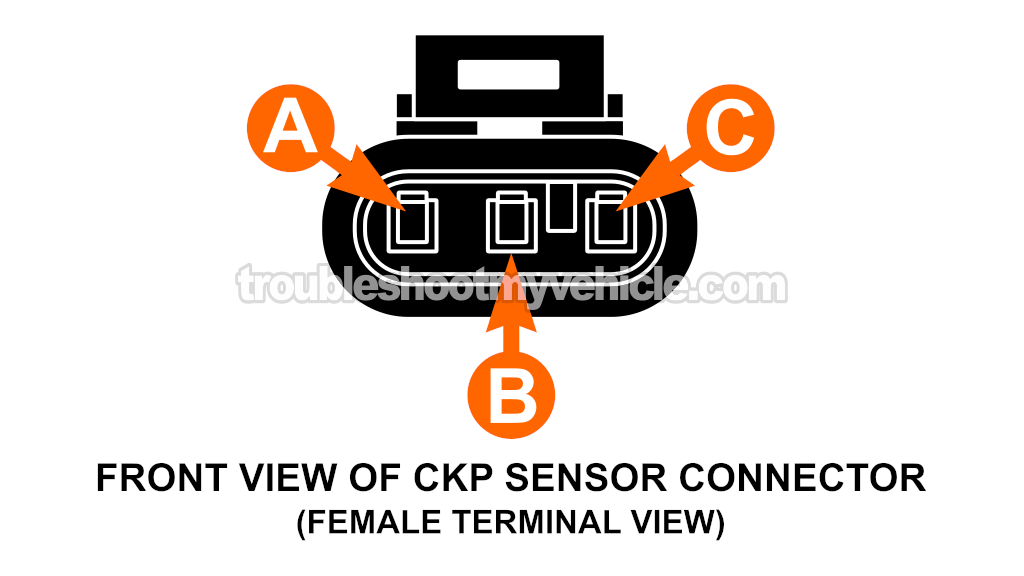

| CKP Sensor Circuits | ||

|---|---|---|

| Terminal | Wire | Description |

| A | WHT/BLK | CKP Sensor Signal |

| B | GRY/BLK | Sensor Ground |

| C | PPL/WHT | 5 Volts |

Wire color legend:

- BLK: Black

- GRY: Grey

- PPL: Purple

- WHT: White

The most important thing to know, is that if the CKP sensor goes bad, your 4.8L, 5.3L, 6.0L Express/Savana van will 'crank but not start'.

TEST 1: Checking The CKP Signal With A Multimeter

In case you're wondering, the CKP sensor is located on the passenger side of the engine, right beside the starter motor (or behind the starter motor, depending on your point of view).

To be able to test the CKP sensor you'll need to remove the starter motor. The starter motor can remain off of the engine for the remainder of the test.

NOTE: To get access to the CKP sensor to test it, you'll need to first remove the starter motor.

CAUTION: You'll need to raise the van and place it on jack stands to access the CKP sensor. Don't trust the jack alone to keep the van up in the air, use jack stands!

OK, let's get started:

- 1

Disable the fuel system. You can easily do this by removing the fuel pump relay that's located in the underhood fuse box.

IMPORTANT: This is an important safety precaution! Don't skip this step. - 2

Locate the CKP sensor and disconnect it from its connector.

- 3

Remove some of the plastic wire loom protector and/or the black electrical tape that shields the three wires of the CKP sensor.

Remove enough of this electrical tape insulation to gain comfortable access to the three wires it protects.

NOTE: Do not remove the CKP sensor from the engine block. - 4

Connect the black multimeter test lead to the negative (-) battery post.

- 5

Place the multimeter in Volts DC mode.

- 6

Disconnect the CKP sensor from its electrical connector.

- 7

Connect the red multimeter test lead to the CKP sensor signal wire. This should be the WHT/BLK wire of the connector.

You'll need to use a wire-piercing probe to connect the red multimeter test lead the CKP sensor signal wire.

To see what a what wire piercing probe tool looks like (and where to buy one), see here: Goupchn 4mm Banana to Banana Plug Test Leads Kit (Amazon affiliate link). - 8

Reconnect the CKP sensor to its electrical connector. The crankshaft position sensor must be connected to its electrical connector for this test to work.

- 9

When everything is set up, have a helper turn the crankshaft pulley by hand in a clock-wise direction using a ratchet and the appropriate size socket on the crankshaft pulley bolt.

IMPORTANT: Do not use the starter motor to crank the engine, since this will defeat the accuracy of this test. - 10

The multimeter should register an ON/OFF voltage of 5 and 0 Volts DC.

OFF will be 0 Volts and ON will be 5 Volts.

Alright, let's find out what your test result means:

CASE 1: The multimeter registered the ON/OFF DC voltage as the crankshaft pulley was hand-turned: This is the correct and expected result and tells you that the CKP sensor is working good. The CKP sensor is not the cause of your no-start condition.

CASE 2: The multimeter DID NOT register the ON/OFF voltage pulses as the crankshaft pulley was hand-turned: Recheck all of your connections. If still no ON/OFF 5 Volt pulses on the multimeter, it looks like the CKP sensor is bad.

The next step is to check that the crankshaft position sensor is getting power. Go to: TEST 2: Making Sure The CKP Sensor Is Getting 5 Volts.

TEST 2: Making Sure The CKP Sensor Is Getting 5 Volts

A reliable voltage supply is essential for the CKP sensor to deliver precise and consistent readings. This voltage supply is typically regulated to ensure it remains constant regardless of fluctuations in the vehicle's electrical system or operating conditions.

In the case of our CKP sensor, the regulated voltage supply is set to 5 Volts. The wire that delivers these 5 Volts to the CKP sensor is the purple with white stripe (PPL/WHT) wire.

The PPL/WHT wire is the one that connects to the female terminal of the connector labeled with the letter C in the illustration above.

We'll perform a simple multimeter voltage test to check for the presence of these 5 Volts in the PPL/WHT wire with the key on but engine off.

This is what you'll need to do:

- 1

Set your multimeter to Volts DC mode.

- 2

Connect the black multimeter test lead to the battery negative (-) post or a clean and unpainted metal spot on the engine.

- 3

With the red multimeter test lead, probe the female terminal identified with the letter C of the CKP sensor connector.

The PPL/WHT wire should connect to terminal C. - 4

When everything is set up, have your helper turn the key to the RUN position.

- 5

Your multimeter should register 4.5 to 5 Volts.

OK, let's interpret your test result:

CASE 1: The multimeter registered 4.5 to 5 Volts DC when the key was turned On. This is the correct test result and confirms the PCM is providing power to the CKP sensor.

There is still one more test to do, before we can condemn the CKP sensor as bad, and that is to test the Ground circuit. Go to: TEST 3: Making Sure The CKP Sensor Is Getting Ground.

CASE 2: The multimeter DID NOT register the indicated voltage when the key was turned On. Recheck your connections and try the test again.

If the multimeter still does not register 4.5 to 5 Volts, the issue causing the CKP sensor malfunction is a lack of power from the PCM. The most likely cause of these missing 5 Volts is an open-circuit issue in the wire between the CKP sensor connector and the PCM connector.

TEST 3: Making Sure The CKP Sensor Is Getting Ground

Like many sensors in automotive systems, the CKP sensor requires a complete electrical circuit to function properly. This circuit consists of a power supply (such as a 5-volt reference voltage you just confirmed in TEST 2) and a Ground connection.

The Ground connection serves as the return path for 5 Volts and is essential for completing the circuit and allowing the sensor to operate.

In the case of our CKP sensor, Ground is provided by the PCM and is called 'low reference' in most of the repair/service literature.

The wire that delivers this 'low reference' signal to the CKP sensor is the grey with black stripe (GRY/BLK) wire, which connects to the female terminal of the connector labeled with the letter B in the illustration above.

We'll perform a simple multimeter voltage test to check for the presence of Ground in the GRY/BLK wire with the key on but engine off.

IMPORTANT: Be careful not to short this sensor Ground wire to battery voltage, or you run the risk of damaging the PCM. The multimeter voltage test described in the test steps is a safe way to check for the presence of Ground in the circuit.

These are the test steps:

- 1

Set your multimeter to Volts DC mode.

- 2

Connect the red multimeter test lead to the battery positive (+) post.

- 3

With the black multimeter test lead, probe the female terminal identified with the letter B of the CKP sensor connector.

The GRY/BLK wire should connect to terminal B. - 4

When everything is set up, have your helper turn the key to the RUN position.

- 5

Your multimeter should register 10 to 12 Volts if Ground is present in the circuit.

Let's find out what your test results mean:

CASE 1: The multimeter registered 10 to 12 Volts DC when the key was turned On. Then the CKP sensor is getting a good Ground.

You can conclude that the CKP sensor is bad and in need of replacement if you have:

- Confirmed that the CKP sensor is not generating an ON/OFF voltage (TEST 1).

- Confirmed that the sensor is getting 4.5 to 5 Volts (TEST 2).

- Confirmed, in this section, that the sensor is getting Ground.

CASE 2: The multimeter DID NOT register the indicated voltage when the key was turned On. Recheck your connections and try the test again.

If the multimeter still does not register 10 to 12 Volts, the issue causing the CKP sensor malfunction is a lack of Ground from the PCM. The most likely cause of this missing Ground is an open-circuit issue in the wire between the CKP sensor connector and the PCM connector.

More Chevy Express/GMC Savana Articles And Tutorials

You can find a complete list of articles and diagnostic tutorials for the V8 Chevy Express and GMC Savana here:

Here's a sample of the tutorials you'll find in the index:

- How To Test For The Fuel Pump (2008-2013 V8 Chevy Express, GMC Savana).

- How To Test For A Blown Head Gasket (2003-2013 V8 Chevy Express, GMC Savana).

- How To Diagnose An Engine Cranks But Does Not Start Problem (2003-2007 V8 Chevy Express, GMC Savana).

- How Can I Tell If The Automatic Transmission Is Bad? (2003-2013 Chevrolet Express, GMC Savana).

If this info saved the day, buy me a beer!