TEST 2: Inducing A Rich Condition

OK, after confirming that you do have a bonafide Lean condition, you can start doing some specific tests to find out where this Lean condition exists, if it exists.

Now to find out if the Lean condition is being caused by a real vacuum leak or by the oxygen sensor, the next step is to check the performance of the oxygen sensor or sensors. This can be very easily done and I'll go into some detail about it.

The best way to check the oxygen sensors (the pre-catalytic converter oxygen sensors) is to create a Rich condition while observing your scan tool (in Live Data mode) to see if the oxygen sensor numbers go up to 800 millivolts (0.800) to 1 Volt.

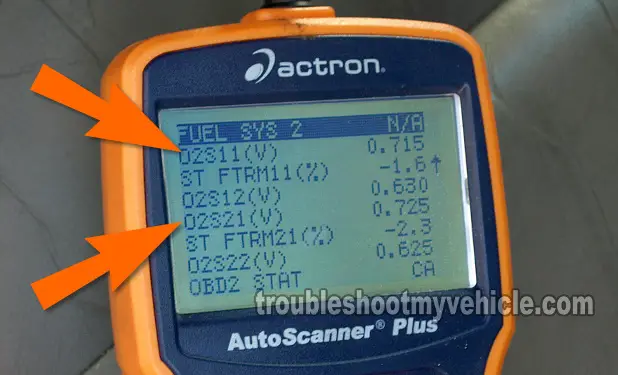

On your scan tool's display, you're going to be looking at the O2S11 and the O2S21 oxygen sensor values. By the way O2S11 means Oxygen Sensor Bank 1 Sensor 1 and O2S21 means Oxygen Sensor Bank 2 Sensor 1 and both of these are pre-cat sensors.

Creating the Rich condition can be accomplished by spraying a little bit of carburetor cleaner into the intake manifold via a small vacuum hose with the engine running.

I want to emphasize spraying carb cleaner spray into a small vacuum hose. You can not disconnect the intake air duct hose (while the engine is running) from the throttle body to spray carb cleaner into the throttle while the engine is running.

Here are the step-by-step instructions:

- 1

With your scan tool still connected to the diagnostic link connector and the engine running, scroll down to the oxygen sensor PIDs.

These PIDs will be labeled O2S11 and O2S21. - 2

Make sure the coolant temperature, as recorded on your scan tool, is still above 190° F (88° C).

- 3

While you observe the oxygen sensor values, have a helper spray a little bit of carburetor cleaner into the intake manifold via a small vacuum hose with the engine running.

- 4

If the oxygen sensor are working normally, as soon as the carburetor spray hits the inside of the intake manifold (via the vacuum hose), your scan tool should read 0.900 Volts for both O2S11 and O2S21.

You can repeat step 3 several times, if you need to make sure of your test result.

Alright, let's interpret your results.

Let's take a look at what your test results mean:

CASE 1: The O2S11 and O2S11 voltage values increased to 0.8 mV to 1 V when you sprayed carburetor spray. This is the correct test result and lets you know that the O2 sensors are functioning correctly.

You can also conclude that the O2 sensors are not the cause of the P0171, P0174 Lean codes. The next step is to check for vacuum leaks.

CASE 2: The O2S11 or O2S11 voltage value DID NOT increase to 0.8 mV to 1 V when you sprayed carburetor spray. This test result tells you the O2 sensor is bad and needs to be replaced. This is the one causing the diagnostic trouble code.

As soon as you replace the bad O2 sensor, you can see if it solved the DTC by checking the Fuel Trims again. If the problem was solved, they will be oscillating between a positive and negative number constantly.

Other Important Tests

Now, if the above oxygen (O2) sensor test confirms that they are OK, the next thing is to check the engine for vacuum leaks since vacuum leaks are usually the biggest causes of the P0171 and/or P0174 diagnostic trouble code(s).

Suggested Test 1: With the engine cold, visually and physically check all vacuum hoses. The most common vacuum leak problem is the PCV tube's elbow, where it connects to either the PCV valve or the intake manifold.

Suggested Test 2: Checking the intake manifold and plenum gaskets for leaks with carburetor spray.

For safety's sake, this type of test has to be begun with the engine completely cold. Once you've started the engine, you'll need to spray around the intake manifold's gaskets, plenum gasket, and around the Spider's fuel injector's connector to check for leaks. If the carb spray hits a spot that's leaking, you'll immediately hear a difference in the engine RPMs.

What will happen is that the RPMs will increase or decrease and this will pinpoint the source of the vacuum leak (before undertaking this test, see: Checking For Vacuum Leaks With Carb Spray).

Not only will the RPMs increase or decrease, but if the engine is warmed up enough, if you look at the O2S11 and O2S21 voltage numbers on your scan tool, they will max out a 0.8 to 1 Volts every time the leaking spot on the intake gasket sucks in the carburetor spray (remember, you can't let the engine get hot and continue to spray the intake manifold to cylinder head areas with carb spray).

If after visually and physically checking for vacuum leaks and none are found, the next step is to check fuel pressure.

Low Fuel Pressure Causing A Lean Condition

A fuel pump usually 'kicks the bucket' from one moment to the next and without any warning but every now and then, you'll have it die a very slow death. When this happens, it doesn't send enough fuel to the fuel injectors to keep the fuel injection computer happy.

When this happens, the PCM (Powertrain Control Module = Fuel Injection Computer) will think there's a major vacuum leak and this will set the DTCs P0171 and P0174.

The other very big giveaway, that the fuel pump is going out (on the 4.3L, 5.0L, and 5.7L Vortec engines) is that you've got to use Starting fluid to start the engine. Once it starts, it stays running.

The only way to test this is by doing a fuel pressure test with a fuel pressure gauge and then compare the values to the repair manual's specifications.

Checking For Vacuum Leaks With Carb Spray

Spraying the intake manifold gasket with carb spray is one of the most effective ways to find a vacuum leak, but it does have its risks. To minimize any possible risk of a back-fire and/or fire, this test should only be done when you have made sure the PCV tube's rubber elbow (at the intake manifold or at the PCV valve itself) is not torn or that it does not have dry-rot. Also, the engine should not be at its normal operating temperature.

Most Common Causes Of P0171, P0174 DTCs

CAUSE 1: PCV tube's rubber elbow (where it connects to the intake manifold) is torn open and causing a major vacuum leak.

CAUSE 2: Intake manifold gaskets or plenum gaskets are leaking vacuum. GM, in all its infinite wisdom, uses plastic and rubber gaskets for the intake manifold and plenum gaskets.

CAUSE 3: Fuel pump that's going bad, but hasn't completely fried yet.

CAUSE 4: A dirty (contaminated) MAF sensor.

CAUSE 5: An exhaust leak right before the pre-catalytic converter oxygen sensors. This is usually caused by bad Exhaust Flange gaskets.

CAUSE 6: Bad pre-catalytic converter oxygen sensor.

I've Done All Of The Tests And I Still Have Codes P0171, P0174

So, you have done all of the tests, you have researched the codes to death (online and in repair manuals) and nothing you have done or replaced has solved the problem!

Trying to solve P0171 and P0174 DTCs can convert your GM pickup (van or SUV) into a money pit. To avoid this you need to remember one very important thing:

Be Patient: Whatever part, whether it's an intake manifold gasket or an O2 sensor, is causing the codes hasn't completely fried yet. This happens.

Parts don't always fail in an immediate fashion. So, the gaskets or vacuum hoses or the sensor could seal/work/function/ correctly most of the time, and every now and then they stop doing their jobs. This happens a lot! What can you do about it? Not much but wait till the problem is present all of the time.

Patience is a virtue. If you have checked for vacuum leaks and you have none and you have verified that the Fuel Trims are OK (which means the O2 sensors are OK too), then the best thing to do is to wait a few days and retest again. Whatever is failing will continue to fail until eventually the problem will be present to verify it with the tests described in this article.

The important thing to remember, is that you can use your scan tool to check the Fuel Trim values with your scan tool to verify the Lean condition (that is setting the P0171 and/or P0174 codes) is actually present.

If this info saved the day, buy me a beer!