Diagnosing diagnostic trouble codes P0171 (System Too Lean Bank 1) and/or P0174 (System Too Lean Bank 2) can be tough. Why? Well because these codes do not accuse any specific part as bad.

In this article, I'm gonna' demystify the process of troubleshooting these two codes on the GM 4.3L, 5.0L, and 5.7L and I'm gonna' offer you my own diagnostic strategy (that I've used for a number of years with a lot of success).

Contents of this tutorial:

- Important Suggestions And Tips.

- P0171 And P0174 Essentials.

- Where Are Bank 1 And Bank 2?

- TEST 1: Fuel Trim Check.

- TEST 2: Inducing A Rich Condition.

- Other Important Tests.

- Low Fuel Pressure Causing A Lean Condition.

- Checking For Vacuum Leaks With Carb Spray.

- Most Common Causes Of P0171, P0174 DTCs.

- I've Done All Of The Tests And I Still Have Codes P0171, P0174.

ES ![]() You can find this tutorial in Spanish here: Cómo Probar: Códigos P0171 y P0174 (GM 4.3L, 5.0L, 5.7L) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar: Códigos P0171 y P0174 (GM 4.3L, 5.0L, 5.7L) (at: autotecnico-online.com).

Important Suggestions And Tips

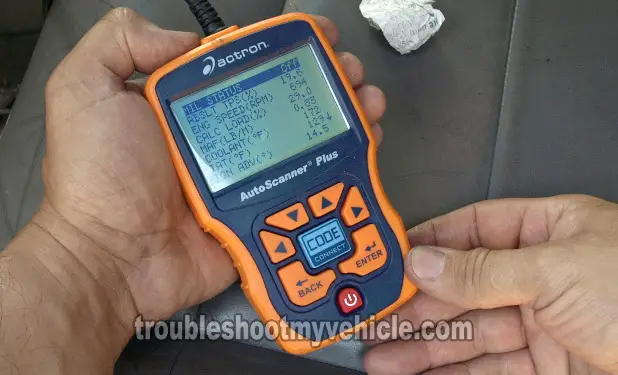

TIP 1: To completely take advantage of the tests and tips in this article, you'll need a scan tool (that has Live Data capability). You don't need to have a professional technician level scan tool, since a generic scan tool that has Live Data capability will do just fine (Don't have a scan tool? Need a scan tool? Check out my recommendation: Actron CP9580 Scan Tool).

TIP 2: Some of my testing suggestions involve tests with the engine running, this means you've got the on your toes and alert. Think safety all of the time.

P0171 And P0174 Essentials

P0171: Fuel Trim System Lean Bank 1 (System Too Lean Bank 1)

- This DTC reports that the PCM has detected an excessive Lean condition.

- In plain English, this means that the PCM has detected a vacuum leak (it may be real or perceived).

- The PCM then reacts by injecting the maximum amount allowed (under its program) of fuel into the cylinders for Bank 1 to compensate for the vacuum leak.

P0174: Fuel Trim System Lean Bank 2 (System Too Lean Bank 2)

- This DTC reports that the PCM has detected an excessive Lean condition.

- In plain English, this means that the PCM has detected a vacuum leak (it may be real or perceived).

- The PCM then reacts by injecting the maximum amount allowed (under its program) of fuel into the cylinders for Bank 2 to compensate for the vacuum leak.

What gives you and me a tremendous head ache, when dealing with these two diagnostic trouble codes, is that they don't accuse a specific sensor or part as being bad. For example, neither of these two codes are saying that the oxygen sensors are bad.

What they are saying is that the computer is having a hard time calculating the amount of fuel it can spray into the engine because there's an unmetered amount of air entering the engine. So no matter how much fuel it dumps (into the engine), it can not compensate for it (usually , but not always, due to a very large vacuum leak).

What specifically 'throws a wrench in the works' is that the engine may not have a vacuum leak at all but the computer thinks it does. It could be an oxygen sensor starting to go bad, but that hasn't died completely yet or even a very dirty MAF sensor.

Well, I'm gonna' show you a good diagnostic strategy that should help you get to the bottom of the issue.

Where Are Bank 1 And Bank 2?

Before I jump into specific testing techniques, to troubleshoot a P0171 or a P0174, let me go into some detail about Bank 1 and Bank 2.

As mentioned before, both codes mean, in layman's terms, that the PCM (Powertrain Control Module= Fuel Injection Computer) has noticed that it needs to dump more fuel than necessary to compensate for a real or perceived vacuum leak that are affecting a specific bank of cylinders.

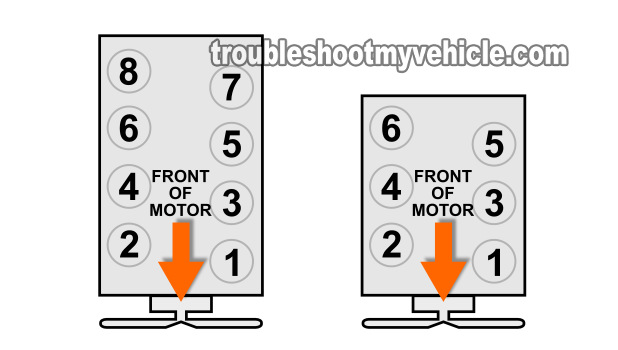

Bank 1: Now, to be a little more specific, P0171 DTC tells you that bank 1 is the one having the issue. Bank 1 is the engine bank that holds the spark plugs for cylinders 1, 3, and 5 (V6 4.3L). Cylinders 1, 3, 5, and 7 (V8 5.0L, 5.7L). This bank is the one on the driver side of the engine.

Bank 2: A P0174 DTC tells you that bank 2 is the one having the issue. Bank 2 is the engine bank that holds the spark plugs for cylinders 2, 4, and 6 (V6 4.3L). Cylinders 2, 4, 6 and 8 (V8 5.0L, 5.7L). This bank is the one on the passenger side of the engine.

The main sensors responsible for telling the PCM that there's a problem with the air fuel mixture are the pre-catalytic converter oxygen sensors.

TEST 1: Fuel Trim Check

The most important thing that has to be done, before anything else, is to verify that the PCM is actually seeing a Lean condition with your scan tool in Live Data mode (Don't have a scan tool? Need a scan tool? Check out my recommendation: Actron CP9580 Scan Tool).

A Lean condition simply means that the PCM is seeing a major vacuum leak (in non-technical terms that is). And you and I can easily check this by checking the Fuel Trim values with a scan tool that has Live Data capability.

This is what you need to do:

- 1

Connect your scan tool to your vehicle and turn the key on.

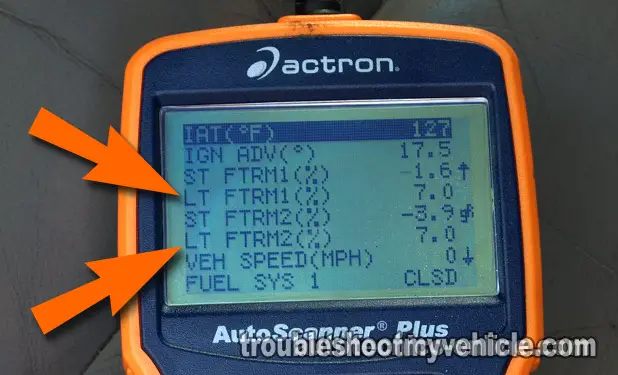

Once the scan tool powers up, go to Live Data mode and scroll down to the PIDs labeled LT FTRM1 and LT FTRM2. - 2

Start the engine and let it run for a few minutes. The engine should warm up to about 190° F (88° C).

Letting the engine warm up to this temperature, before continuing to the next step, will ensure the accuracy of your test results.

How can you find out the engine's temperature? By reading the coolant temperature your scan tool displays in the PID labeled: Coolant. - 3

Note the LT FTRM1 and LTFTRM2 values (once the engine has reached the indicated coolant temperature).

The normal values should be moving between a positive and a negative value. The range should be between 10% and -10% (negative 10%).

If there is a Lean condition present (either because a vacuum leak is present or due to something else), the LT FTRM values will be above 10% and will not come down to a negative value. They will usually hover around 20%.

Let's take a look at what your test results mean:

CASE 1: The LT FTRM1 and LT FTRM2 values moved between 10% and -10%. This tells you that the Lean condition is intermittent.

An intermittent Lean condition can be hard to solve since the problem is not present all of the time. Take a look at the section rest of the article for more testing suggestions.

CASE 2: The LT FTRM1 and LT FTRM2 values were above 10% and/or near 20% and did not come down to a negative value. This result confirms that your vehicle is suffering thru' a bonafide Lean condition and needs further testing. Go to: TEST 2: Inducing a Rich Condition.