In this tutorial, I'll explain how to test the engine compression on the Ford Escape (Mazda Tribute) with a 3.0L 6-cylinder engine. More importantly, I'll explain how to interpret the test results so that you can know whether you have a bad cylinder or not.

As you're probably already aware, it can be quite a challenge to do a compression test on the Escape's V6 engine since the intake manifold plenum has to be removed. Having removed it a few times before myself, I have a few suggestions to make the job a little less complicated.

Contents of this tutorial:

- Important Tips And Suggestions.

- Symptoms Of Low Or No Cylinder Compression.

- Which Compression Tester Should I Buy?

- TEST 1: Dry Compression Test.

- Interpreting Your Compression Test Results.

- TEST 2: Wet Compression Test.

- The Intake Manifold Plenum Has To Be Removed.

- More 3.0L V6 Ford Escape Diagnostic Tutorials.

ES ![]() You can find this tutorial in Spanish here: Cómo Verificar La Compresión Del Motor (3.0L Ford Escape) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Verificar La Compresión Del Motor (3.0L Ford Escape) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles:

- 3.0L V6 Ford Escape: 2001, 2002, 2003, 2004, 2005, 2006, 2007, 2008, 2009, 2010, 2011, 2012.

- 3.0L V6 Mercury Mariner: 2005, 2006, 2007, 2008, 2009, 2010, 2011.

- 3.0L V6 Mazda Tribute: 2001, 2002, 2003, 2004, 2005, 2006.

Important Tips And Suggestions

TIP 1: You'll need to remove the intake manifold's plastic plenum to access the spark plugs in bank 1 of the engine. Bank 1 is the cylinder head that houses spark plugs for cylinders #1, #2, and #3. Although I don't include any remove and replace instructions, I recommend that you take a look at the following section: The Intake Manifold Plenum Has To Be Removed.

TIP 2: You'll be working around a cranking engine, when doing a compression test. This means you have to be alert and take all necessary safety precautions. Use common sense and think safety all of the time.

TIP 3: Your Ford Escape (Mazda Tribute) comes equipped with cylinder heads that are made of aluminum. This means that you need to wait till the engine is completely cooled down before you remove the spark plugs. Removing the spark plugs from a hot engine can/will damage the spark plug hole threads in the aluminum cylinder heads.

Symptoms Of Low Or No Cylinder Compression

Generally, compression problems can be divided into two categories:

- Low engine compression in one or several cylinders causing a misfire condition and misfire trouble code.

- Zero compression on all cylinders causing your Ford Escape's engine to crank but not start.

Let's go into a more detailed look at these two types of problems:

Low compression on one or two cylinders in your engine 3.0L Ford Escape will cause the engine to misfire at idle. This misfire usually goes away when you accelerate the engine.

If your Ford is OBD II diagnostic system equipped, you'll also see one or more of the following misfire trouble codes:

- P0300: Random Cylinder Misfire.

- P0301: Cylinder #1 Misfire.

- P0302: Cylinder #2 Misfire.

- P0303: Cylinder #3 Misfire.

- P0304: Cylinder #4 Misfire.

- P0305: Cylinder #5 Misfire.

- P0306: Cylinder #6 Misfire.

Unfortunately, even if your Ford is equipped with OBD II, the computer doesn't always register a misfire fault code even when the engine is truly experiencing a cylinder failure.

Zero compression in two or more cylinders will cause your 3.0L Ford Escape to 'crank but not start'. Generally, this usually happens when the head gasket is blown or there's a timing belt/chain issue.

You'll also see one or more of the following symptoms:

- When you crank the engine to start it, it cranks very fast and this fast cranking speed is so noticeable that you know without a doubt that something's wrong.

- Each cylinder is getting spark. This let's you know that the engine's 'cranks but does not start' problem is not due to a fault in the ignition system.

- The fuel injectors are injecting fuel.

- You can confirm this by checking the injector pulse with a Noid light.

- You can confirm this by removing the spark plugs and verifying that they're soaked in gasoline.

- The most common causes of zero compression in all cylinders are:

- Blown head gasket.

- Broken timing chain.

- Engine threw a rod.

Let's get testing.

Which Compression Tester Should I Buy?

There are lot of engine compression testers to choose from and many places to buy them. I'm gonna' make some recommendations to you:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

TEST 1: Dry Compression Test

As mentioned earlier, the intake manifold's plastic plenum has to be removed to test the compression on cylinders 1, 2, and 3. If you haven't already, take a look at the suggestions here: The Intake Manifold Plenum Has To Be Removed.

Alright, these are the test steps:

- 1

Remove the intake manifold's plastic plenum and remove all 6 ignition coils.

- 2

Remove the spark plugs.

When removing the spark plugs, be careful not to drop any of them on the floor, or you run the risk of having the spark plugs porcelain insulator crack and then you'll have a misfire on your hands. - 3

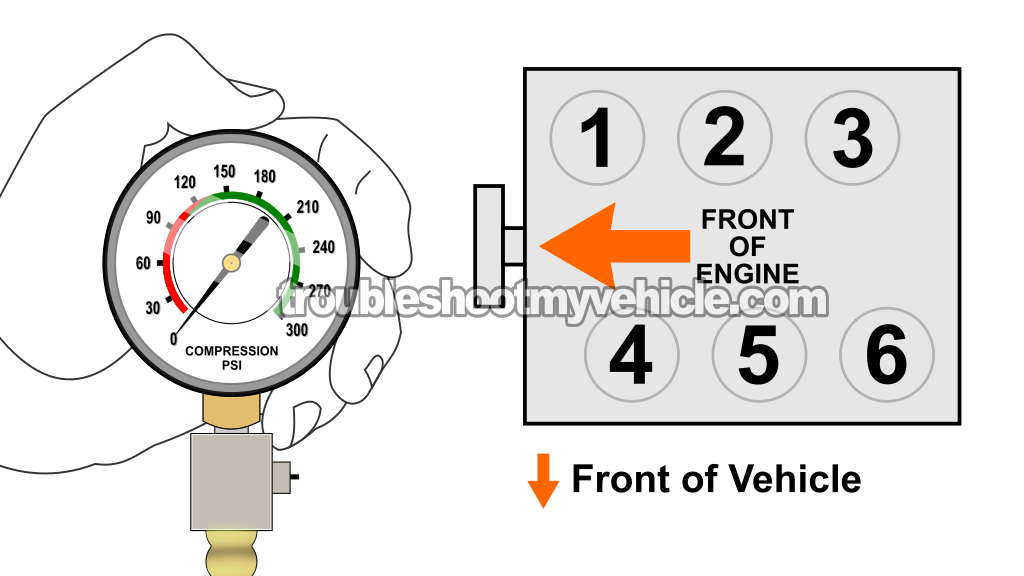

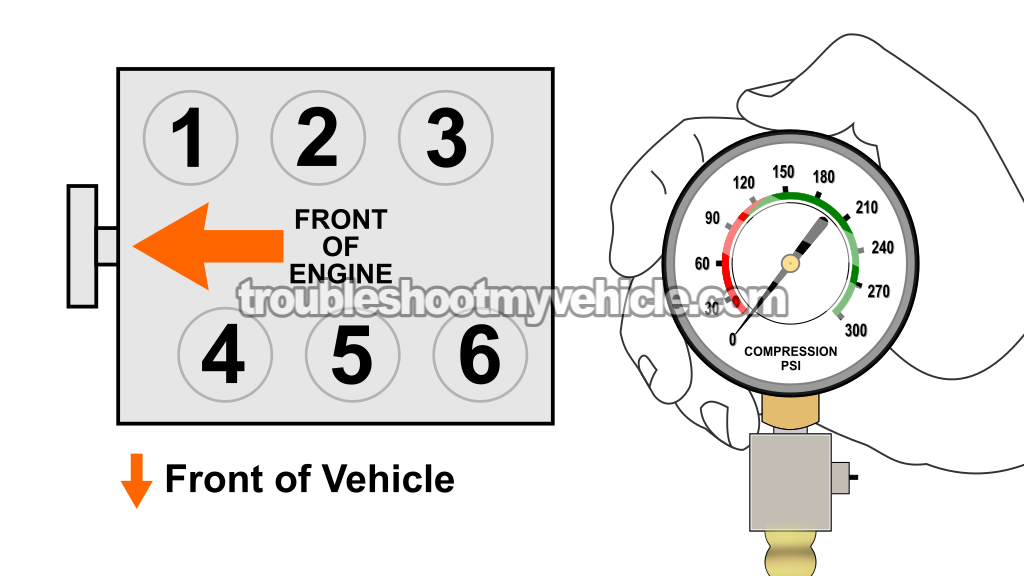

Thread the engine compression gauge into the spark plug hole for the number 1 engine cylinder.

Hand tighten the compression gauge only! Do not use any type of tool to get it tight. - 4

Have your helper crank the engine till the needle on the compression gauge stops climbing.

- 5

Record on paper the value at which the needle stopped and the number of the engine cylinder on a piece of paper. Release the pressure on the gauge and repeat this step one more time.

- 6

Repeat this test step on the remaining cylinders.

Let's take a look at what your test results mean:

CASE 1: 0 PSI on all cylinders. This means that the engine has a serious internal mechanical problem caused by one of the following:

- Timing chain problem.

- Blown head gasket.

- Blown engine.

Any compression value below 100 PSI (even if it does not 0 PSI) means internal mechanical engine trouble.

CASE 2: Low compression in one or more cylinders. Up to a certain point this variation in the compression values could be normal.

What is NOT normal is if the values vary too much. The cool thing is that we can find out if the variations in the values, you wrote down, indicate a problem (with that cylinder) or not. To find out go to: Interpreting Your Compression Test Results.

Interpreting Your Compression Test Results

If your Escape's engine compression test indicates you've got one or more cylinders producing a low compression value, then the next step is to figure out if they are causing a problem (or not).

As I mentioned before, up to certain point, it's not unusual to see the compression values vary between a bit (especially in high mileage engines).

But when the difference is too big, you'll have a rough idle or a misfire condition on your hands.

To find out if the lower compression value is causing a problem, you need to find out if it's lower than 15% of the highest compression value you got.

You can do this (figuring out the 15%) in one of two ways: You can calculate this 15% difference with pen and paper or you can use my low compression calculator. You can find the low compression calculator here: Online Low Engine Compression Calculator (at: easyautodiagnostics.com).

If you want to manually calculate the 15% difference, here's what you'll need to do:

- STEP 1: Multiply the highest compression value by 0.15 (this is the decimal value of 15%).

- STEP 2: Round the result to the nearest one (for example: 25.6 would become 26).

- STEP 3: Subtract the result (the number that was rounded) from the highest compression value.

- ANSWER: The result of this subtraction is the lowest possible compression value any cylinder can have.

Now, let me give you a more specific example: Let's say that I got the following compression readings:

| Cylinder | Pressure |

|---|---|

| #1 | 165 PSI |

| #2 | 95 PSI |

| #3 | 155 PSI |

| #4 | 175 PSI |

| #5 | 160 PSI |

| #6 | 165 PSI |

My next step is to do the following calculation:

- STEP 1: 175 x 0.15 = 26.25.

- STEP 2: 26.25 = 26 (rounded to nearest one).

- STEP 3: 175 - 26 = 149.

- ANSWER: 149 PSI. Any cylinder with this compression (or lower) value will misfire.

Since cylinder #2 is only producing 95 PSI, I can now conclude that it's 'dead' and causing a misfire.

To find out if the lowest compression value you got from your engine compression test is within a good range, you'll need to do the same calculation. Of course, you'll need to use the highest compression value you got and not the one in the example.

Once you've found the 'dead' cylinder, the next step is to find out what's causing the low compression value. For this step, go to: TEST 2: Wet Compression Test.

TEST 2: Wet Compression Test

If your test results (from TEST 1) indicate one or several cylinders with low compression, the next step is finding out what is causing it.

What's usually causes a cylinder to have low compression is one of two conditions: either its piston compression rings are severely worn or the its intake or exhaust valve are severely worn.

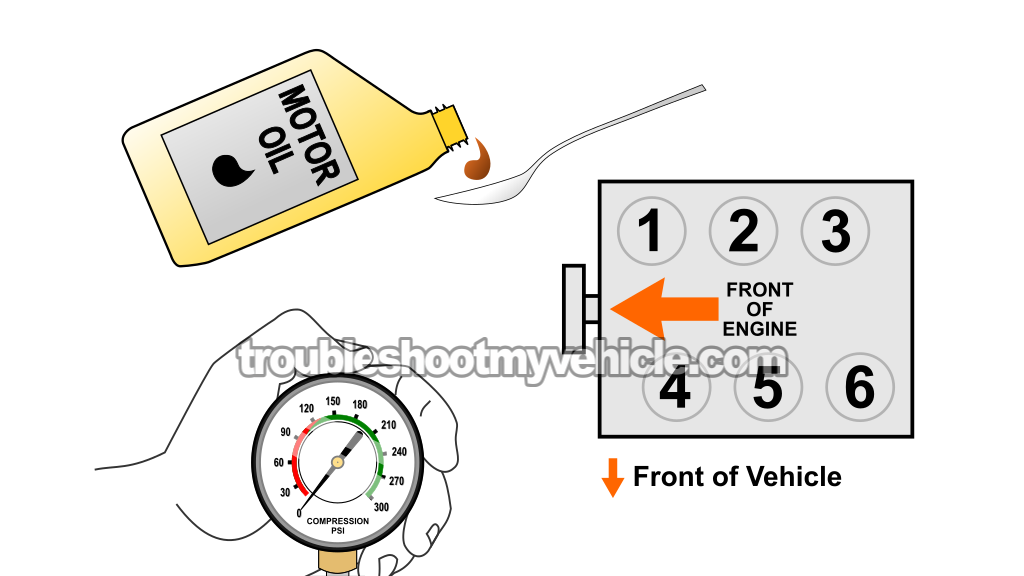

Thankfully, you and I can find out by adding a little oil to the affected cylinder and testing its compression again. This is known as a 'wet' compression test.

If the low compression is due to worn rings, the compression value of the affected cylinder will go up. If the problem is caused by worn cylinder head valves, the compression value will stay the same.

These are the test steps:

- 1

Add a tablespoon (or two) of engine oil to the cylinder you need to retest.

I suggest using a small and long funnel so that the oil will reach the inside of the cylinder. - 2

Install the compression gauge, and as before just hand tighten it.

- 3

Have your helper crank the engine till the needle stops climbing on the compression gauge.

- 4

You'll see one of two results:

1.) The needle will climb higher than the previous compression number you recorded for this specific cylinder.

2.) The needle will not move at all or stay at the same number you recorded earlier.

Whatever value your compression tester reads, write it down again. - 5

Repeat steps 1 thru' 4 on any other cylinder with a low compression value.

Let's take a look at what test results mean:

CASE 1: The compression value went up after adding motor oil and retesting. This tells you that the low compression problem is due to worn piston compression rings.

Here's why: The motor oil you just added helped the piston rings to create a tighter seal. With the piston rings now sealing the compression inside the cylinder, the compression value on your compression tester went up. This type of test result only happens when the problem is due to worn piston rings.

CASE 2: The compression value DID NOT go up after adding oil and retesting (in other words, it stayed the same). This result tells you that the low compression value registered in this cylinder (in the dry test) is due to worn/damaged cylinder head valves.

The Intake Manifold Plenum Has To Be Removed

The thing that complicates doing a compression test on your 3.0L Ford Escape (3.0L Mazda Tribute) is the fact that the upper intake manifold plenum must be removed to access cylinders 1, 2, and 3 of bank 1.

I don't include any instructions on this procedure, so you may want to buy a repair manual for this procedure.

For the DIY'er that doesn't have a lot of wrenching experience, this might be a job that's best left to an experienced automotive mechanic/technician. Since paying for his expertise may end up saving you from a tremendous headache.

If you do tackle the compression test job, here are some pointers:

- As you're removing bolts, nuts, etc., place them in a container and away from the engine. This is important since you'll want to avoid having anything fall into the open intake manifold runners (that will be exposed when the plenum is removed).

- You WILL NOT be able to place rags in the open intake runners while doing the compression test. Why? Because if you do place rags in the open intake runners (to avoid stuff falling into them), then these rags will get sucked into the cylinder as the engine cranks.

- Use new gaskets. Do not re-use the old intake manifold plenum gasket. Also, when installing the new one, do not coat it in any type of sealer (like RTV Silicon). This is not necessary and could back fire on you since the sealer can cause a vacuum leak.

Yes, testing engine compression on the 3.0L Ford Escape (3.0L Mazda Tribute) isn't for the 'faint of heart'. So take all necessary safety precautions and avoid having anything fall into the open intake manifold runners. Or consider letting a professional mechanic do it.

More 3.0L V6 Ford Escape Diagnostic Tutorials

You can find a complete list of 3.0L V6 Ford Escape, Mercury Mariner and Mazda Tribute diagnostic tutorials in this index:

Here's a sample of the diagnostic tutorials you'll find in the index:

- How To Test The Fuel Injectors (2001-2004 3.0L Ford Escape).

- How To Test The MAF Sensor (2001-2007 Ford 3.0L V6 Ford Escape, Mercury Mariner).

- How To Test For A Blown Head Gasket (2001-2012 3.0L V6 Ford Escape, Mercury Mariner).

- How To Test The Fuel Pump (2001-2004 3.0L Ford Escape).

If this info saved the day, buy me a beer!