Testing the engine compression on the FWD Ford Taurus and Mercury Sable equipped with the 3.8L V6 engine isn't difficult.

In this tutorial, I'm going to explain how to perform the test —and just as importantly— how to interpret your results.

With your compression test results, you'll be able to quickly and easily determine if a compression issue is causing a rough idle, a cylinder misfire, or even an engine no-start problem.

Contents of this tutorial:

ES ![]() You can find this tutorial in Spanish here: Cómo Probar La Compresión Del Motor (1991-2003 3.8L Ford FWD) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar La Compresión Del Motor (1991-2003 3.8L Ford FWD) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles:

- 3.8L V6 Ford Taurus: 1990, 1991, 1992, 1993, 1994, 1995.

- 3.8L V6 Mercury Sable: 1990, 1991, 1992, 1993, 1994, 1995.

3.0L/3.8L V6 TAURUS/SABLE, WINDSTAR AND RANGER: The compression test for the 3.0L V6 Taurus, Sable, and Ranger -and- the 3.8L V6 Windstar can be found here:

- How To Do And Interpret An Engine Compression Test (1990-2007 3.0L V6 Ford Taurus, Mercury Sable).

- How To Do And Interpret An Engine Compression Test (1995-2003 3.8L V6 Ford Windstar).

- How To Test The Engine Compression (1991-2008 3.0L V6 Ford Ranger) (at: easyautodiagnostics.com).

Symptoms Of Low Or No Compression

When an engine experiences compression issues, it can manifest in two main ways:

- Low compression in some but not all cylinders: This means that the pressure within certain cylinders is lower than it should be, which can lead to various performance problems.

- Zero PSI compression in some or all cylinders: This is a severe issue where there is no compression at all in certain cylinders, indicating potential damage or failure.

Regardless of whether the compression is low or zero, you'll notice several symptoms that indicate there's an issue with the engine's compression:

- Hard starting or no start: Difficulty starting the engine, or it may not start at all.

- Poor engine performance: The engine may run rough, feel sluggish, or lack power.

- Misfiring: This is when one or more cylinders fail to ignite their air/fuel mixture properly, causing jerking or shaking.

- Reduced power and performance: The vehicle may struggle to accelerate or maintain speed.

- Excessive Oil Consumption: Compression issues can lead to oil leaking into the cylinders, causing increased oil consumption.

- Audible engine noise: You may hear unusual noises like knocking or tapping, indicating internal engine mechanical problems.

Important Tips And Suggestions

TIP 1: Don't remove the spark plugs if your Taurus or Sable's engine is hot.

You run the risk of stripping the threads, of the spark plug hole, if you remove the spark plugs with a hot engine. This is a nightmare I wouldn't wish on my worst enemy.

TIP 2: Be careful and take all necessary safety precautions as you perform the engine compression test (since the engine has to be cranked).

TIP 3: Before you remove or disconnect the spark plug wires, label them so you can reconnect them in the correct firing order later on.

TIP 4: This is probably the most important tip I can give you —use a pair of spark plug wire pullers to disconnect the wires from the spark plugs. It's a common issue with high-tension wires that the metal terminal inside the boot stays stuck to the spark plug when pulled off by hand. That's a hassle you can easily avoid with the right tool.

If you don't have a set, this is the one I recommend: Performance Tool W80519 Adjustable Spark Plug Boot And Wire Remover (Amazon affiliate link)

Which Compression Tester Should I Buy?

There are lot of engine compression testers to choose from and many places to buy them. I'm gonna' make some recommendations to you:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

TEST 1: Dry Compression Test

In this section, we're gonna' check the compression of all 6 cylinders. Checking them all will help us to find out which cylinder or cylinders are dead (due to low engine compression).

Let me tell you that depending on the age and mileage of your Taurus or Sable's engine, the compression of each cylinder probably will not be similar.

Up to a certain point, this is normal. Now if the values vary too much between themselves, then this could lead to an engine cylinder misfire or rough idle condition.

Don't worry, I'll explain how to interpret your test results to find out if those dissimilar values are within a normal range or not.

NOTE: Remember to label the spark plug wires with their corresponding cylinder numbers before disconnecting them, and use a pair of spark plug wire pullers to safely remove the wires from the spark plugs: Performance Tool W80519 Adjustable Spark Plug Boot And Wire Remover (Amazon affiliate link).

Alright, these are the test steps:

- 1

Disable the ignition system by disconnecting the ignition coil from its electrical connector. This will prevent the ignition coil from sparking during the test.

- 2

Disconnect the spark plug wires from the spark plugs.

NOTE: Before you remove them, label them with the cylinder number they belong to, this will help you when reconnecting them back to their correct spark plug.

Also, use a spark plug wire puller tool to disconnect them (to avoid having the wire's terminal stay stuck on the spark plug. - 3

Remove the spark plugs.

NOTE: When removing the spark plugs, be careful not to drop any of them on the floor, or you run the risk of having the spark plugs porcelain insulator crack and then you'll have a misfire on your hands. - 4

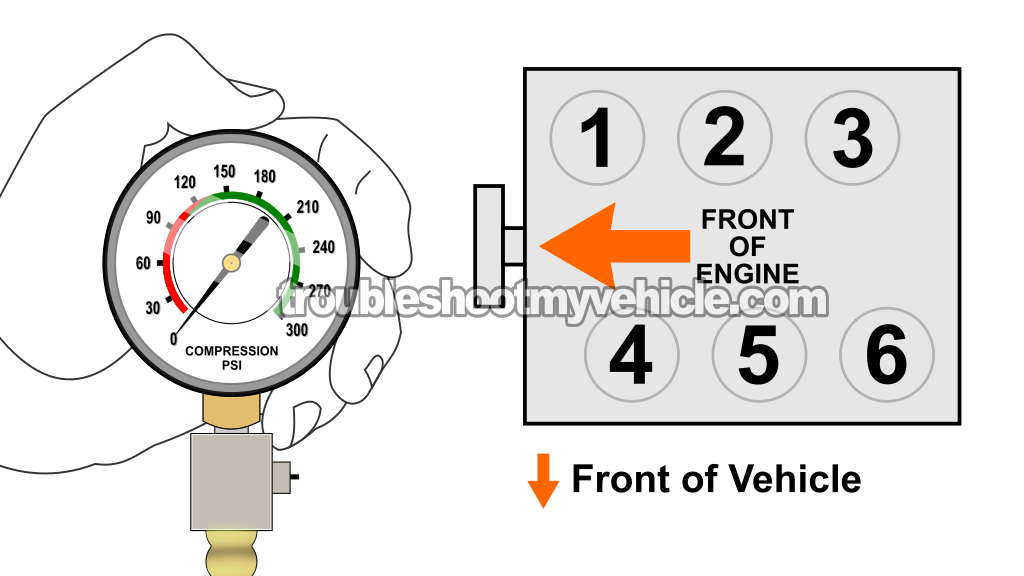

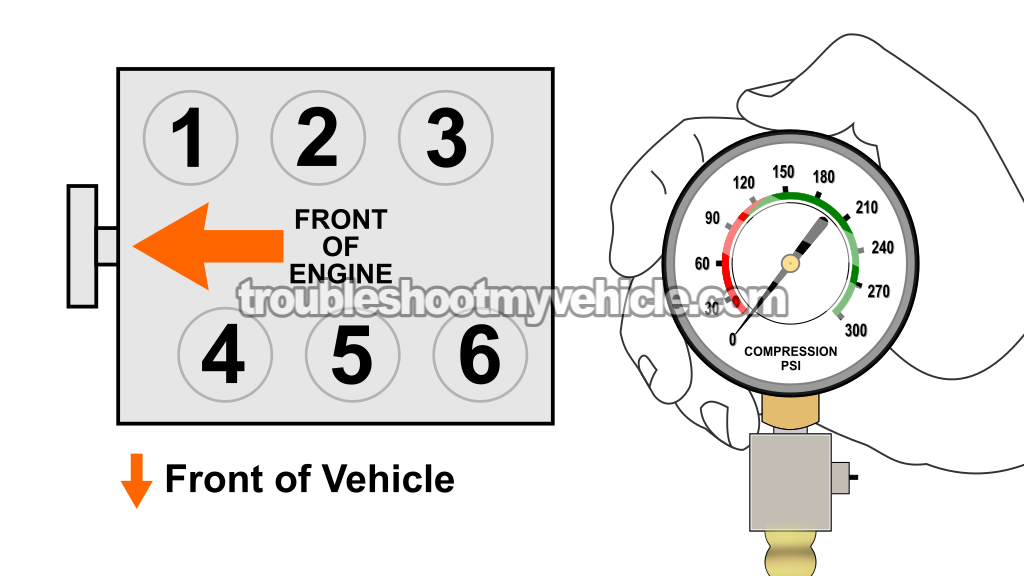

Thread the engine compression gauge into the spark plug hole for the number 1 engine cylinder.

Hand tighten the compression gauge only! Do not use any type of tool to get it tight. - 5

Have your helper crank the engine till the needle on the compression gauge stops climbing.

- 6

Record the value at which the needle stopped and the number of the engine cylinder on a piece of paper.

- 7

Check the compression of the remaining cylinders.

Let's take a look at what your compression test results mean:

CASE 1: You got 0 PSI in the majority of the cylinders. This tells you that your Taurus or Sable's engine has serious internal problems. You should check for a:

- Blown head gasket.

- Blown engine (thrown rod).

Any compression value below 100 PSI (even if it does not 0 PSI) means internal mechanical engine trouble.

CASE 2: All cylinders have compression but their values are not the same. It's normal for each cylinder's compression value to vary slightly from one another. But if they vary too much, you'll have a bonafide misfire or rough idle condition on your hands.

To find out, the next step is to go to: Interpreting The Compression Test Results.

Interpreting The Compression Test Results

On engines with a lot of miles, it's normal to see some differences in compression numbers from cylinder to cylinder. Small variations usually don't affect how the engine runs.

The trouble starts when one or more cylinders drop too far below the rest. That's when you'll run into a rough idle, a misfire, and a check engine light shining nice and bright on the instrument panel.

The good news is figuring out whether those low readings are a problem isn't complicated. In this part, I'll walk you through the process step by step.

The general guideline is that the weakest cylinder should not be more than 15% lower than the strongest one (the highest PSI you wrote down in TEST 1). If it is, that cylinder will misfire and your Fiesta's engine will idle unevenly.

You can run the numbers with my Online Low Engine Compression Calculator (at: easyautodiagnostics.com), or you can do the math by hand.

To show you how to work it out manually, let's look at these sample results:

- Cylinder #1: 175 PSI

- Cylinder #2: 165 PSI

- Cylinder #3: 160 PSI

- Cylinder #4: 120 PSI

- Cylinder #5: 165 PSI

- Cylinder #6: 160 PSI

Here's the math:

- Take 15% of the highest value: 175 × 0.15 = 26.25 (rounded to 26).

- Subtract that from the highest value: 175 − 26 = 149.

- That means the lowest acceptable compression is 149 PSI.

Looking at the results, cylinder #4 only has 120 PSI, which is well below 149. That makes it the problem cylinder and the cause of the misfire.

Once you've identified the weak cylinder, the next step is to track down why it's low. For that, go to: TEST 2: Wet Compression Test.

TEST 2: Wet Compression Test

In this test section, we're gonna' add a little bit of oil (two tablespoons) to the cylinder that gave you a low compression value test result in TEST 1. This will help us to find out what's causing the low compression value.

To be a bit more specific, what generally provokes a low engine compression (or a 0 PSI) value is worn piston rings or worn cylinder head valves.

Now, if the low compression is due to worn piston rings, then adding oil cause them to seal better and the compression value will shoot up.

If the low compression is due to severely worn or damaged cylinder head valves, then the oil will have no effect on the compression value. In other words, adding oil to the cylinder will not cause a change in the compression value you recorded in TEST 1.

Alright, let's get started:

- 1

Add a tablespoon (or two) of engine oil in the cylinder you need to retest. Use a funnel to make sure that the oil reaches the inside of the cylinder.

- 2

Once you've added the oil, install the compression gauge, and hand tighten it.

- 3

Have your helper crank the engine till the needle stops climbing on the compression gauge.

- 4

You'll see one of two results:

1.) The needle will climb higher than the previous compression number you recorded for this specific cylinder, or...

2.) The needle will not move at all or stay at the same number you recorded earlier.

What ever value your compression tester reads, write it down again. - 5

If you have another cylinder test, repeat steps 1 thru' 4 on it now.

Let's take a look at what test results mean:

CASE 1: The compression value went up after adding motor oil and retesting. This tells you that the low compression problem is due to worn piston compression rings.

Here's why: The motor oil you just added helped the piston rings to create a tighter seal. With the piston rings now sealing the compression inside the cylinder, the compression value on your compression tester went up. This type of test result only happens when the problem is due to worn piston rings.

CASE 2: The compression value DID NOT go up after adding oil and retesting (in other words, it stayed the same). This result tells you that the low compression value registered in this cylinder (in the dry test) is due to worn/damaged cylinder head valves.

More 3.8L V6 Ford Taurus Diagnostic Tutorials

You can find a complete list of diagnostic tutorials for the 3.8L V6 Ford Taurus and Mercury Sable in this index:

Here's a sample of the tutorials you'll find for the 3.8L Ford Taurus (Mercury Sable):

- How To Test The TPS With A Multimeter (1990-1995 3.8L V6 Taurus, Mercury Sable).

- How To Test The MAF Sensor (1991-1995 3.8L V6 Ford Taurus, Mercury Sable).

- How To Test The Fuel Pump (1990-1995 3.8L V6 Ford Taurus, Mercury Sable).

- How To Test For A Blown Head Gasket (1990-1995 3.8L V6 Ford Taurus, Mercury Sable).

If this info saved the day, buy me a beer!