In this tutorial, we're going to troubleshoot the vehicle speed sensor (VSS) and P0500 trouble code, which means the PCM isn't seeing a vehicle speed signal from the VSS sensor.

This is a common issue on many Dodge Ram pickups causing a dead speedometer and poor engine performance.

In this tutorial, I'll walk through a step-by-step process to test the sensor itself using a multimeter and a generic scan tool with "live data" functionality.

Contents of this tutorial:

- What Does The Vehicle Speed Sensor Do?

- Symptoms Of A Bad VSS Sensor.

- Common Causes Of A P0500 DTC.

- Should I Just Replace The VSS Sensor Without Testing It?

- Where To Buy The VSS Sensor And Save.

- TEST 1: Checking The Vehicle Speed Signal Using A Scan Tool.

- TEST 2: Checking For The VSS Signal At The Sensor Connector.

- TEST 3: Making Sure The VSS Sensor Is Getting Power.

- TEST 4: Making Sure The VSS Sensor Is Getting Ground.

- TEST 5: Inspecting The Plastic Speedometer Pinion Gear.

- A More Controlled Way To Spin The Wheels For The VSS Signal Test.

- VSS Signal Reaches The PCM —But The Speedometer Doesn't Work.

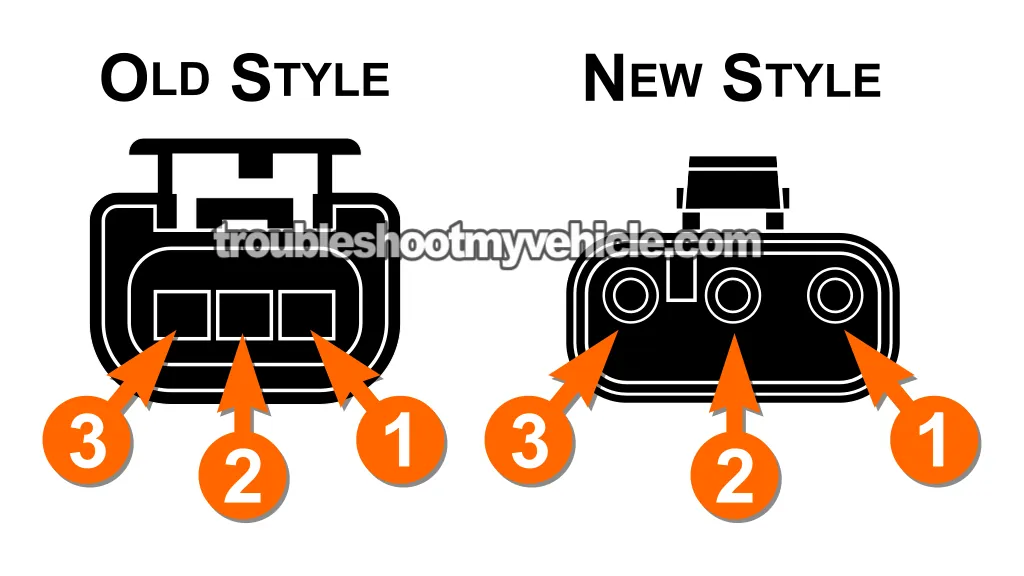

- Updated VSS Sensor Connector And Why Soldering Is Critical.

- More 5.2L, 5.9L V8 Dodge Ram Pickup Tutorials.

APPLIES TO: This tutorial applies to the following vehicles with a 3-wire VSS sensor on the transmission tail housing:

- Dodge Ram 1500 Pickup 5.2L V8: 1996, 1997.

- Dodge Ram 2500 Pickup 5.2L V8: 1996, 1997.

- Dodge Ram 1500 Pickup 5.9L V8: 1996, 1997.

- Dodge Ram 2500 Pickup 5.9L V8: 1996, 1997.

- Dodge Ram 3500 Pickup 5.9L V8: 1996, 1997.

VSS SENSOR DIAGNOSTIC TUTORIALS:

- How To Index The VSS And Speedometer Gear Housing (1993-1997 5.2L, 5.9L V8 Dodge Ram Pickup).

- VSS Sensor Tests -OBD I Code 15 (1993-1995 5.2L, 5.9L V8 Dodge Ram Pickup).

What Does The Vehicle Speed Sensor Do?

In a nutshell, the vehicle speed sensor (VSS) is responsible for telling the PCM how fast the vehicle is moving.

It's a Hall-effect type sensor that requires 5 Volts and Ground from the PCM to generate its signal.

In case you're curious, here's a quick breakdown of how the VSS sensor works:

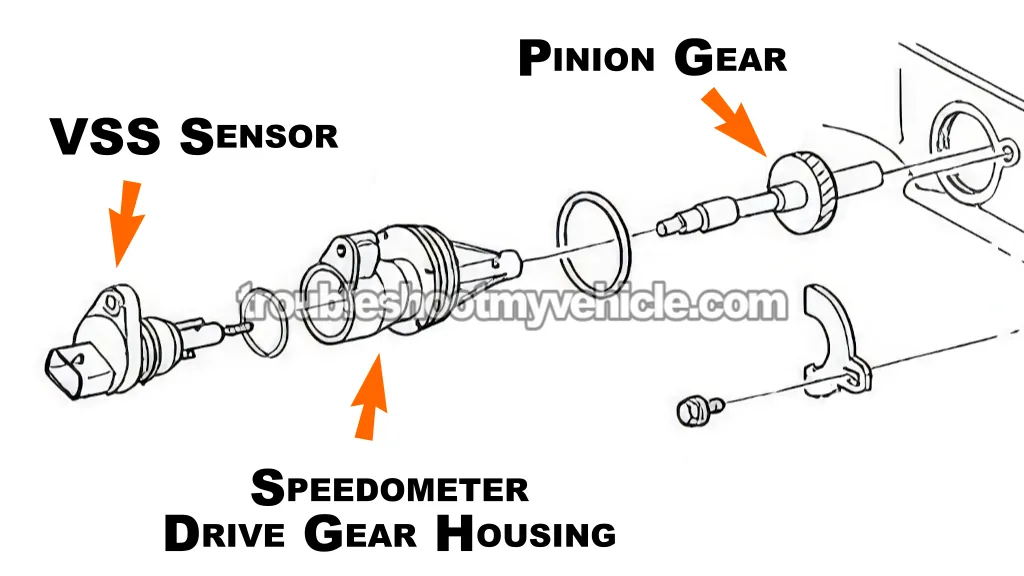

- As the rear wheels turn, that rotation is transferred through the driveshaft and into the transmission, where it spins a small plastic speedometer gear connected to the VSS sensor.

- The VSS responds by generating a digital signal —it toggles a 5-volt reference signal ON and OFF rapidly, creating a square-wave (or pulse) signal that the PCM can read as vehicle speed.

In simpler terms: it's like the sensor is flipping a light switch really fast —5 Volts ON, 0 Volts OFF— and the faster the wheels spin, the faster the pulses.

This ON/OFF signal allows the PCM to calculate vehicle speed —which is used to control idle speed, cruise control, and even fuel injection strategy.

If the PCM doesn't receive this signal, it logs a P0500: No Vehicle Speed Sensor Signal diagnostic trouble code (DTC).

Symptoms Of A Bad VSS Sensor

If the vehicle speed sensor (VSS) isn't working properly, or its signal can't reach the PCM and speedometer, you'll likely notice one of these symptoms:

- Check Engine Light (CEL): The PCM will log a P0500 and trigger the CEL if it doesn't see a proper speed signal.

- Speedometer not working or erratic: The needle may bounce, stick, or drop to zero unexpectedly.

Common Causes Of A P0500 DTC

When the PCM logs a P0500 code, it means it's not receiving a valid vehicle speed signal from the VSS sensor.

This could be due to an issue with the sensor itself, the wiring, or even the PCM. Here's a breakdown of the most common causes:

- VSS sensor not seated or misaligned: If the sensor isn't installed (indexed) correctly, it's pinion gear won't rotate properly.

- Damaged or open VSS signal wire: The white with orange stripe (WHT/ORG) wire may be cut, shorted, or corroded.

- It connects to pin 27 of the white PCM connector and to the instrument cluster (speedometer).

- Open or shorted 5V supply circuit: The orange (ORG) wire provides 5V power from pin 31 of the white PCM connector.

- Sensor Ground circuit open: The Ground wire is black with a light blue stripe (BLK/LT BLU) and connects to pin 4 of the black PCM connector. An open here will prevent the sensor from working.

- Damaged speedometer pinion gear: If the plastic speedometer pinion gear (that fits into the transmission) is stripped or broken, the sensor won't detect movement.

- Failed vehicle speed sensor: Like any component, the VSS can fail electrically or mechanically and stop sending an usable signal.

- Faulty PCM (rare): If all wiring and the sensor check out, the PCM may have failed internally and is no longer processing or receiving the signal correctly.

Should I Just Replace The VSS Sensor Without Testing It?

It's pretty common to see a P0500 trouble code and jump straight to replacing the vehicle speed sensor —after all, the code says there's a problem with it, right?

And to be honest with you, this approach works more often than not. Swapping out the sensor usually clears the code and gets the speedometer working again.

So if you're thinking about going ahead and replacing it, no problem —nobody's gonna judge you (LOL).

Take a look at this tutorial to learn how to index the VSS to the transmission:

But if you've already replaced the sensor and the code came back, or your speedometer still isn't working —or maybe you just want to be 100% sure before spending money on a new one— then this tutorial will walk you through exactly how to test the sensor step by step.

Where To Buy The VSS Sensor And Save

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

TEST 1: Checking The Vehicle Speed Signal Using A Scan Tool

In this first test, we're going to use a scan tool with live data capability to check whether the PCM is receiving a vehicle speed signal from the VSS sensor.

We'll do this by navigating to the live data section of the scan tool, locating the VEHICLE SPEED PID (Parameter ID), and then road testing the vehicle.

If the sensor is working, the scan tool should show the speed of the vehicle in real time.

If no speed is displayed, we've confirmed the PCM is not receiving the signal —and we'll move on to test the sensor output directly at the connector in TEST 2.

NOTE: It's a good idea to have a helper in the passenger seat monitor the scan tool while you focus on driving.

Don't have a scan tool with Live Data functionality? Check out my recommendation: ZM301 OBD2 Scanner Diagnostic Tool (at: amazon.com).

This is what we need to do:

- 1

Connect your scan tool and turn the key to the ON position.

- 2

Navigate to the live data or datastream section.

- 3

Scroll through the available data and locate the VEHICLE SPEED (MPH or km/h) PID.

- 4

Start the engine and begin a short road test.

- 5

Have a helper watch the scan tool as you drive.

- 6

The VEHICLE SPEED PID should show the MPH in real time as the vehicle moves.

Let's figure out what your test result is telling us:

CASE 1: The scan tool did not show any vehicle speed while driving. This confirms the PCM is not receiving a signal from the vehicle speed sensor. The P0500 DTC is valid.

Our next step is to check for the VSS signal output directly at the VSS sensor connector. Go to: TEST 2: Checking For The VSS Signal At The Sensor Connector.

CASE 2: The scan tool displayed vehicle speed normally. This means the vehicle speed sensor is currently functioning and sending data to the PCM.

The P0500 code may be intermittent. Clear the code, continue driving, and retest if the code returns.

TEST 2: Checking For The VSS Signal At The Sensor Connector

The vehicle speed sensor (VSS) generates a 5-Volt ON/OFF signal as the rear wheels turn. More specifically:

- ON: The signal wire carries 5 Volts.

- OFF: The signal drops to 0 Volts.

In this test, we're going to check for that ON/OFF signal directly from the sensor by measuring voltage pulses on the white with orange stripe (WHT/ORG) wire —that's the VSS output signal.

To do it safely and accurately, you'll need to lift the rear of the vehicle, place it securely on jack stands, and let the engine run in Drive. This will rotate the driveshaft and rear wheels at low speed.

IMPORTANT: If the wheels spin too fast, you won't catch the ON/OFF pulsing —you'll just see a constant 5 Volts. That's why your helper will need to gently ride the brake to keep things slow and steady. See:

Also, the sensor must stay connected to its 3-wire connector —so you'll use a wire-piercing probe to tap into the signal wire without unplugging anything. You can find out more about this tool (and buy it here too): Wire Piercing Probe Tool.

SAFETY WARNING: This test requires working under the vehicle while the drivetrain is rotating. Stay alert and take all necessary safety precautions:

- Wear safety glasses —there's a good chance dirt and debris will fall into your eyes while working under the vehicle.

- Use heavy-duty jack stands on a level, solid surface —never rely on a jack alone.

- Chock the front wheels securely to prevent forward movement.

- Keep hands, clothing, and tools away from the driveshaft, wheels, and rotating parts.

- Do not exceed idle speed —no revving up the engine.

- Have a helper remain in the driver's seat with foot over the brake at all times.

If you don't have a multimeter or need to upgrade yours? This is the one I use and recommend: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (at: amazon.com).

Let's begin:

- 1

Safely raise the rear of the vehicle. Use a floor jack to lift the rear axle, then place both sides on heavy-duty jack stands.

- 2

Chock the front wheels and keep a helper in the driver's seat.

Your helper is there, ready to apply the brakes immediately if needed. - 3

Identify the WHT/ORG signal wire at the VSS connector.

- 4

Place your multimeter in it Volts DC setting.

- 5

Connect the red multimeter test lead to the WHT/ORG wire using the either a wire piercing probe or a back probe on the connector.

- 6

Ground the black multimeter test lead to a clean metal surface on the chassis or engine block.

NOTE: The metal surface should be paint and rust free. - 7

Start the engine and shift into Drive but have your helper pressing the brake pedal to keep the rear wheels from turning.

- 8

Have your helper let off the brake pedal so the rear wheels can turn at idle speed while you monitor the multimeter.

NOTE: Do not rev-up the engine by stepping on the gas pedal.

Your helper may need to slightly ride the brake to keep the wheel speed down, otherwise you won't be able to see the ON/OFF voltage pulses. - 8

Watch for ON/OFF voltage pulses. A good VSS will produce a pulsing DC voltage that toggles between near 0V and up to 5V rapidly.

Here's what to read into that result:

CASE 1: No ON/OFF pulses detected from the signal wire. This means the vehicle speed sensor isn't producing a signal.

Our next step is to make sure the VSS sensor is getting power. Go to: TEST 3: Making Sure The VSS Sensor Is Getting Power.

CASE 2: ON/OFF signal pulses are present. This confirms that the vehicle speed sensor is working and generating the correct signal.

But here's the conundrum: if the VSS is producing its signal, why didn't the scan tool register any speed during the road test?

The answer lies in how the circuit works. The PCM sends 5 Volts to the VSS on the signal wire. As the sensor activates, it briefly pulls that voltage down to 0 Volts —this is the ON/OFF signal we're reading with the multimeter. So if we're seeing that pulse, it means the PCM is supplying the 5 Volts and the sensor is responding correctly.

However, if the scan tool still shows zero MPH and the P0500 code keeps coming back, there's a good chance the PCM's internal circuit isn't interpreting or processing that signal correctly —even though it's sending out voltage just fine.

This kind of PCM failure is rare, but it does happen.