A stored P0720 trouble code means the PCM isn't receiving a proper signal from the output shaft speed sensor —and that can mess with shifting and torque converter lockup.

In this tutorial, I'll walk you through the same electrical tests a professional tech would use to troubleshoot the sensor and its wiring —no guesswork, just step-by-step verification.

All you'll need is a multimeter and some basic tools to check for opens, shorts, or faulty sensor resistance.

We'll start with simple tests you can do in your driveway and work toward deeper checks if needed.

Contents of this tutorial:

- VSS vs OSS –What's the Difference?

- What Does DTC P0720 Mean?

- Symptoms Of A Bad Output Shaft Speed Sensor.

- Should I Just Replace It And Not Test It?

- Where To Buy The OSS Sensor And Save.

- TEST 1: Checking The Resistance Of The Output Shaft Speed Sensor.

- TEST 2: Checking The Entire Output Shaft Speed Sensor Circuit From PCM Pin To Pin.

- TEST 3: Checking For A Short To Ground In The Output Shaft Speed Sensor Wiring.

- TEST 4: Checking Wire Integrity (Sensor To PCM).

- Is The PCM Bad?

- More 5.2L, 5.9L V8 Dodge Ram Pickup Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- Dodge Ram 1500 Pickup 5.2L V8: 1996, 1997, 1998, 1999, 2000, 2001.

- Dodge Ram 2500 Pickup 5.2L V8: 1996, 1997, 1998.

- Dodge Ram 1500 Pickup 5.9L V8: 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003.

- Dodge Ram 2500 Pickup 5.9L V8: 1996, 1997, 1998, 1999, 2000, 2001, 2002.

- Dodge Ram 3500 Pickup 5.9L V8: 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003.

VSS vs OSS –What's the Difference?

On 1996–2003 Dodge Ram pickups with the 5.2L or 5.9L V8 and 46RE transmission, it's easy to confuse the Output Shaft Speed (OSS) sensor with the Vehicle Speed Sensor (VSS) —but they serve different functions and are located in different areas.

The OSS sensor simply measures the rotational speed of the transmission's output shaft. It's a 2-wire variable reluctor (VR) sensor mounted on the rear of the transmission case, pointing downward toward the Ground.

The signal from the OSS sensor goes directly to the PCM. It plays a critical role in transmission control —helping the PCM manage shift timing, torque converter lock-up, and overall transmission performance.

When the OSS signal is missing, incorrect, or erratic, you'll typically get a P0720 code and experience noticeable shifting problems.

The Vehicle Speed Sensor (VSS) on 1996–1997 Dodge Ram pickups is a 3-wire Hall Effect sensor mounted on the transmission tailshaft housing. It provides vehicle speed information directly to the Powertrain Control Module (PCM) and the speedometer (in the instrument cluster).

- 2WD models: The VSS is located on the extension housing, facing the driver’s side (left side of the truck).

- 4WD models: The VSS is installed on the transfer case.

This sensor plays a key role in reporting actual road speed to the PCM, the speedometer (through the instrument cluster), and the cruise control system. However, it isn't used by the PCM for automatic transmission shift control.

Starting in 1998, Dodge Ram pickups no longer used the tailshaft-mounted VSS to feed speed data to the PCM. Instead, the PCM receives vehicle speed information from the rear wheel speed sensor, which is mounted on the differential housing. This sensor is a 2-wire Variable Reluctance (VR) sensor and serves double duty: it provides vehicle speed data to the PCM and supports the ABS (Anti-lock Brake System).

When either type of vehicle speed sensor (VSS) fails —whether it's the 3-wire Hall Effect type (1996–1997) or the 2-wire VR type (1998–2003)— the PCM will set a P0500: No Vehicle Speed Sensor Signal diagnostic trouble code.

You can find the VSS sensor test here:

What Does DTC P0720 Mean?

On the 1996-2003 Dodge Ram pickups equipped with the 46RE automatic transmission, trouble code P0720 means the PCM (Powertrain Control Module) isn't receiving a valid signal from the output shaft speed (OSS) sensor.

This sensor is mounted on the transmission tail housing and monitors the rotation of the output shaft, which is directly related to vehicle speed.

The PCM uses this signal to determine when to shift gears and when to lock or unlock the torque converter.

If the OSS signal is missing, erratic, or doesn't match what the PCM expects, it sets code P0720 and may trigger Limp Mode, harsh shifting, or other drivability problems.

Symptoms Of A Bad Output Shaft Speed Sensor

When the output shaft speed (OSS) sensor on the 46RE transmission fails or its signal becomes erratic, the PCM can't properly control shifting. This causes a range of automatic transmission drivability problems and can even trigger Limp Mode, where the transmission is locked into into 3rd gear to prevent damage.

Common symptoms on 1996–2003 Dodge Ram pickups with the 5.2L or 5.9L V8 and 46RE transmission include:

- Check Engine Light (CEL) on: Code P0720 is stored due to missing or abnormal output speed signal.

- Harsh or delayed shifting: Transmission may shift roughly, late, or not at all, especially into or out of overdrive.

- Torque converter not locking up: The PCM disables lockup if it can't trust the speed signal.

- Limp Mode activation: The transmission may stay in 3rd gear and refuse to shift as a fail-safe.

If you're seeing these symptoms, the output shaft speed sensor or its wiring may be to blame —and in this guide, I'll show you how to test both.

Should I Just Replace It And Not Test It?

To be honest —most folks (and even many repair shops) just go ahead and replace the Output Shaft Speed (OSS) sensor right off the bat when a P0720 code shows up. And you know what? That's totally fair.

The sensor is inexpensive, easy to access, and takes just a few minutes to swap out. In fact, in about 90% of cases, replacing the sensor fixes the problem —the transmission starts shifting normally again, and the code doesn't return.

But here's the thing: testing the sensor is just as easy as replacing it. All you need is a basic multimeter —no fancy nor expensive diagnostic tools required.

Since you're already removing the sensor (or have already replaced it), it makes sense to test it for good measure. You're checking for the two most common failures: an open circuit or a short circuit inside the sensor. If either one is present, the sensor is bad.

Now, if you've already replaced the OSS sensor and you're still getting code P0720, that's where this tutorial comes in. I'll walk you through how to test the sensor itself —and how to check the wiring between the OSS connector and the PCM— step by step.

Where To Buy The OSS Sensor And Save

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

TEST 1: Checking The Resistance Of The Output Shaft Speed Sensor

The output shaft speed sensor on the 46RE transmission is a simple variable reluctance (VR) sensor. It generates an AC voltage signal based on the rotation of a reluctor wheel inside the transmission tail shaft.

Because it's a passive sensor with a coil of wire inside, we can easily test for internal problems —like an open-circuit (broken coil) or a short-circuit —using a multimeter in Ohms mode.

If you're testing the sensor while it's still in place, you'll need to get under the truck —so always wear eye protection to avoid getting dirt or debris in your eyes.

Also, I use jumper wires with insulated alligator clips to connect my multimeter leads to the sensor's two round male pins, you may have to do the same.

If you choose to remove the sensor to test it, be aware that transmission fluid will leak out, so have a drain pan ready.

NOTE: Don't have a multimeter or need to upgrade yours? This is the one I use and recommend: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (at: amazon.com).

OK, let's begin:

- 1

Set your multimeter to Ohms (Ω) mode.

NOTE: Make sure it's reading correctly by touching the two probes together —you should see 0 Ohms (or near-zero Ohms). - 2

Locate the 2-wire output shaft speed sensor on the driver's side of the transmission tail shaft.

It's a small cylindrical sensor with a two-wire connector in the rear of the transmission. - 3

Disconnect the sensor's harness connector.

CAUTION : If testing in place, wear eye protection. - 4

Connect one multimeter lead to each of the two male pins on the sensor.

If testing with the sensor in place, use jumper wires with alligator clips if needed —make sure you have solid contact and don't short the pins together. - 5

Read the resistance value on your meter.

A good sensor will usually read between 500 (0.5 K) and 1,400 (1.4 K) Ohms.

Let's interpret your test result:

CASE 1: Resistance is between 500 and 1,400 Ohms. The sensor's internal coil is intact and within spec.

OK, now that we've confirmed the OSS sensor itself is OK, we need to check its wiring. Go to: TEST 2: Checking The Entire Output Shaft Speed Sensor Circuit From PCM Pin To Pin.

CASE 2: Resistance is infinite (OL or open-circuit). This indicates the sensor's internal coil is broken —replace the output shaft speed sensor.

CASE 3: Resistance is 0 Ohms. This tells you the sensor is shorted internally and must be replaced.

TEST 2: Checking The Entire Output Shaft Speed Sensor Circuit From PCM Pin To Pin

In this test, we're going to check the integrity of the entire output shaft speed sensor circuit —from the sensor itself, through its two signal wires, all the way back to the PCM.

This test will help us confirm that the PCM is receiving a clean, uninterrupted signal and that there are no hidden problems like internal wire breaks, poor connections, or sensor faults.

We'll also simulate road vibration by wiggling the harness during the test to uncover any intermittent issues that may not show up under static conditions.

If all is well, the reading you get will confirm the circuit is solid and ready to carry an accurate signal.

IMPORTANT: Do not insert your multimeter test leads directly into the PCM terminals —doing so will deform or damage them. For a safe probing method, see: How To Safely Probe The PCM Connector -Without Damaging It.

Alright, let's get going:

- 1

Set your multimeter to Ohms (Ω) mode.

Make sure it's functioning correctly by touching the probes together —you should see near-zero resistance. - 2

Disconnect the battery negative (–) cable.

- 3

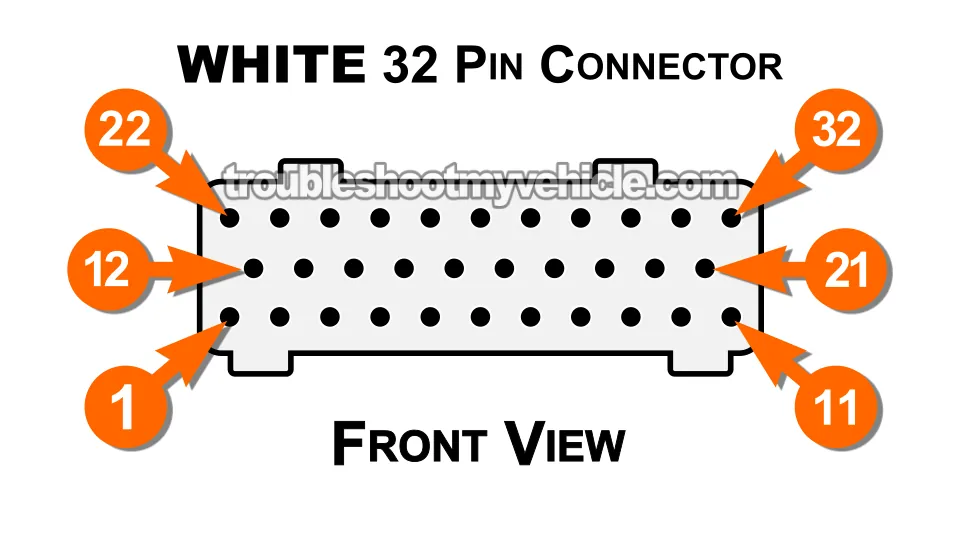

Disconnect all 3 PCM connectors.

NOTE: We'll be working with the WHITE PCM connector. - 4

Leave the output shaft speed sensor connected to its harness.

NOTE: We're measuring through the full circuit, including the sensor. - 5

Insert one multimeter lead into pin 25 of the WHITE PCM connector (DK BLU/BLK wire).

IMPORTANT: Use a thin, non-damaging probe that won't spread the terminal. - 6

Insert the other multimeter lead into pin 28 of the WHITE PCM connector (LT GRN/WHT wire).

- 7

You should see a reading is between 500 and 1,400 Ohms if the sensor and both wires are intact.

- 8

Have a helper gently wiggle the transmission connector and the harness along its accessible length.

- 9

Watch the meter for glitches in the Ohms reading while wiggling the wiring.

Any change in the resistance reading indicates an issue in the engine wiring harness.

Let's interpret your test result:

CASE 1: Resistance is between 500 and 1,400 Ohms and remains stable during the wiggle test. So far so good. The entire circuit seems to be intact —both wires and the sensor look to be in good working order.

For our next test, let's head over to: TEST 3: Checking For A Short To Ground In The Output Shaft Speed Sensor Wiring.

CASE 2: Multimeter shows open-circuit ("OL") or infinite resistance. This indicates a broken (open) wire or bad terminal in the sensor's connector.

Begin by inspecting the sensor's connector. If it looks OK, you now need to test each wire from the PCM to the sensor. Go to: TEST 4: Checking Wire Integrity (Sensor To PCM).

CASE 3: Resistance is out of range (too high or too low) or flickers during the wiggle test. This points to a poor connection or intermittent open —usually caused by a damaged wire in the wiring harness or a bad OSS sensor connector.

Closely inspect the wiring harness —from the OSS sensor connector all the way to the PCM connector— for signs of chafing or movement-related wear.

I like to use a small flashlight to carefully examine one section at a time, especially in areas where the harness runs over sharp edges on the transmission, engine, or brackets, or passes near the exhaust pipe.

Repair or replace any damaged sections as needed, then repeat the test. This tutorial offers some helpful repair tips: