In this tutorial, we're going to troubleshoot a P0132 diagnostic trouble code (DTC) —which means the upstream oxygen sensor (Bank 1, Sensor 1) is reporting a voltage that's too high.

This is a common issue on 1996-2003 Dodge Ram 5.2L and 5.9L V8 pickups when the O2 sensor's wiring suffers some sort of short to power somewhere in the engine wiring harness.

We'll go step by step, using a multimeter and scan tool with "live data" capability to find out what's really causing the problem.

Whether it's the sensor, the wiring, or the PCM, you'll know exactly how to get to the bottom of it.

Contents of this tutorial:

- What Does a P0132 Mean?

- Symptoms Of A DTC P0132.

- Common Causes Of DTC P0132 (O2 Sensor 1/1 Voltage Too High).

- TEST 1: Checking The Performance Of O2 Sensor 1/1.

- TEST 2: Visually Inspecting The O2 Sensor 1/1 Wiring.

- TEST 3: Check For Voltage On O2 Sensor 1/1 Signal Wire At PCM Connector.

- Is The PCM Bad?

- More 5.2L, 5.9L V8 Dodge Ram Pickup Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- Dodge Ram 1500 Pickup 5.2L V8: 1996, 1997, 1998, 1999, 2000, 2001.

- Dodge Ram 2500 Pickup 5.2L V8: 1996, 1997, 1998.

- Dodge Ram 1500 Pickup 5.9L V8: 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003.

- Dodge Ram 2500 Pickup 5.9L V8: 1996, 1997, 1998, 1999, 2000, 2001, 2002.

- Dodge Ram 3500 Pickup 5.9L V8: 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003.

What Does A P0132 Mean?

A P0132 trouble code means the PCM has detected that the voltage signal from the upstream oxygen sensor (Bank 1, Sensor 1) is stuck too high for too long —specifically, above 1.2 Volts.

On vehicles with two oxygen sensors, O2 sensor 1/1 is located on the inlet pipe of the catalytic converter or directly on the front portion of the catalytic converter.

On vehicles with three or more oxygen sensors, O2 sensor 1/1 is found on the exhaust pipe that connects to the exhaust manifold for cylinders 1, 3, 5, and 7 —also known as Bank 1.

From this position, the sensor measures how much oxygen remains in the exhaust gases exiting either both banks or just Bank 1. This helps the PCM adjust the air-fuel mixture for optimal combustion.

When the sensor's signal wire suffers a short to voltage and the PCM sees this elevated voltage (above 1.2 Volts), it correctly assumes something's wrong —usually with the sensor itself or its signal wire.

Instead of adjusting fuel delivery based on incorrect readings, it triggers a fault code and often switches to a backup mode (open loop) to keep the engine running.

It's important to note: A P0132 is not about the air-fuel mixture being rich —it's about the voltage signal being stuck high, which in no way reflects what's actually happening inside the combustion chambers.

What does "short to voltage" mean? It means that somewhere along the oxygen sensor's signal wire, voltage from another circuit —like a 5-Volt or 12-Volt power wire— is accidentally being fed into the sensor circuit.

That's why we'll focus so heavily on checking for wiring damage and electrical shorts in this tutorial.

Symptoms Of A DTC P0132

When the upstream oxygen sensor (Bank 1, Sensor 1) is shorted to voltage and the PCM logs a P0132, you may or may not notice immediate drivability issues.

That's because the PCM often falls back to a default fuel map. However, depending on the vehicle's condition, several symptoms can appear:

- Check Engine Light (CEL): This is the most reliable and common symptom. The P0132 code will trigger the CEL and store a fault code in the PCM.

- Bad gas mileage: Since the PCM may interpret the high voltage as a rich mixture, it might reduce fuel delivery incorrectly —or, in some cases, ignore the O2 sensor entirely and run in open loop.

- Rough idle or hesitation: If the sensor is affecting the fuel mixture, idle quality or acceleration may suffer.

- Increased emissions: A malfunctioning upstream O2 sensor can cause higher tailpipe emissions due to poor air/fuel mixture control.

- Possible stalling (rare): In extreme cases, poor fuel metering could lead to stalling, especially at idle or when shifting to gear.

Even if the engine seems to run fine, it's important not to ignore this code —a constantly high signal from the upstream O2 sensor can cause long-term damage to the catalytic converter and degrade overall engine performance.

Common Causes Of DTC P0132 (O2 Sensor 1/1 Voltage Too High)

When the PCM sets a P0132 code, it means the voltage from the upstream oxygen sensor (Bank 1, Sensor 1) is stuck above 1.2 Volts for too long —which the PCM sees as an electrical fault, not a fuel mixture issue.

On the 1996–2003 V8 Dodge Ram pickups, there are a few common reasons this happens:

- Engine wiring harness damage (most common): The most frequent cause of a P0132 is a Short to voltage in the O2 sensor signal wire. This can happen when the wire insulation rubs through and contacts a Power source, like a 12V feed or another sensor wire. Look closely near hot exhaust components or areas where the harness is zip-tied to metal brackets.

- Sensor connector damage: A damaged O2 sensor connector, whose terminals are shorting together, can also cause the voltage reading to stay high.

- Faulty oxygen sensor (1/1): Although not as common as wiring issues, a failed upstream O2 sensor can cause the signal voltage to lock high.

- PCM-related issues (rare): In rare cases, a short inside the PCM or a defect in the PCM's internal circuitry can cause the high voltage signal —but this is usually the last thing to suspect, and should only be considered After all wiring and sensor checks pass.

TEST 1: Checking The Performance Of O2 Sensor 1/1

Before diving into wiring checks, it's important to test the actual behavior of O2 Sensor 1/1. The DTC P0132 sets when the PCM detects that the sensor's signal voltage is too high —above 1.2 Volts.

But in most real-world cases, the voltage being reported by O2 sensor 1/1 is actually much higher —often between 5 and 12 Volts DC.

The important thing to know is this: a properly functioning upstream oxygen sensor will never output more than about 1 volt.

In fact, during normal operation, the sensor's voltage should constantly fluctuate between 0.2 and 1.0 Volts as it monitors the changes between lean and rich exhaust conditions.

If the sensor voltage is locked at or above 5 Volts, that's a red flag —either the sensor has an internal short, or the signal wire has been shorted to a power source. In this test, we'll check the live signal voltage to confirm what's actually happening.

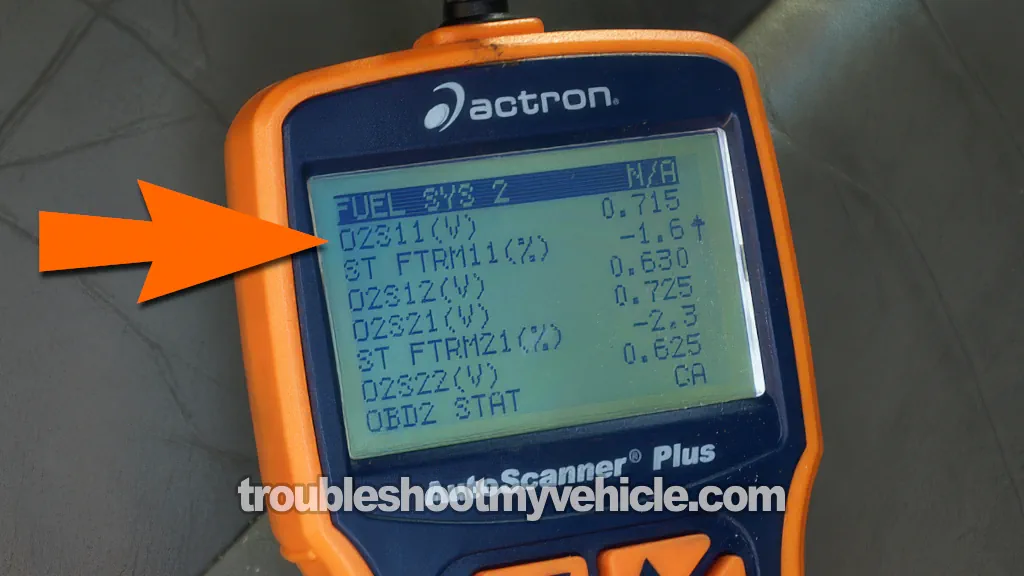

You'll need a scan tool with live data capability or a digital multimeter that can read voltage quickly and accurately.

Don't have a scan tool with Live Data functionality? Check out my recommendation: ZM301 OBD2 Scanner Diagnostic Tool (at: amazon.com).

OK, these are the test steps:

- 1

Start the engine and let it reach operating temperature.

Let the engine idle for at least 2–3 minutes to get the oxygen sensor hot enough to start switching properly. - 2

Access live data on your scan tool and find PID O2S11.

NOTE: Parameter ID (PID) O2S11 is the one that shows the voltage output of O2 Sensor 1/1. - 3

Monitor the voltage signal for at least 30 seconds.

You should see steady fluctuations between 0.2 and 1.0 Volts. Remember, a normal sensor will cycle up and down as the PCM adjusts fuel trims. - 4

Look for an abnormal voltage readings above 1.2 Volts.

If the voltage is stuck high (5V or more), or stuck at a flat 1V with no fluctuation, those are signs of a problem. - 5

Rev the engine briefly to 2,000 RPM.

This should increase the exhaust flow and help verify if the sensor responds.

A good sensor will still fluctuate under light throttle.

Let's interpret your test result:

CASE 1: The sensor voltage is at or above 5 Volts DC. This is not normal. The O2 sensor can't produce this much voltage on its own.

This usually means the signal wire is shorted to a 5V or 12V source —either inside the sensor itself or in the harness.

We now need to check the O2 sensor 1/1's wires for signs of chafing or melted insulation. Go to: TEST 2: Visually Inspecting The O2 Sensor 1/1 Wiring.

CASE 2: The sensor is stuck at 1.0 Volts with no fluctuation (but not above 1.2 Volts). This may indicate a failed sensor that is falsely reporting a rich condition at all times.

Before replacing the O2 sensor, check its performance by inducing a lean and rich conditions. Go to:

If the O2 sensor tests bad, replace it and clear the code. If the new sensor behaves normally, the issue is resolved.

CASE 3: The sensor voltage fluctuates between 0.2 and 1.0 Volts. This is normal behavior —the sensor is responding properly to the exhaust gases.

If you're getting a P0132 code with this kind of signal, the problem is likely intermittent or was present only temporarily. Clear the code and continue to monitor. If the code returns, go to: TEST 2: Visually Inspecting The O2 Sensor 1/1 Wiring.

TEST 2: Visually Inspecting The O2 Sensor 1/1 Wiring

For our 2nd test, we're going to visually inspect the wiring that connects to O2 Sensor 1/1.

This simply involves visually inspecting the wires coming directly out of the sensor, the section where they merge into the engine wiring harness, and tracing them as far as possible toward the PCM connectors.

What we're looking for is any obvious physical damage —such as chafing against a sharp edge, contact with hot exhaust components, melted insulation, or signs of pinched or crushed wires.

A short to voltage often occurs when damaged insulation allows a sensor wire to touch a 12V feed or the sensor signal wire gets bridged to another power wire inside the harness.

This test does not require any tools —just your eyes and a flashlight. Take your time and inspect the entire path of the sensor wiring thoroughly. Remember, we're not gonna tear into the wiring harness.

OK, this is what we need to do:

- 1

Disconnect oxygen sensor 1/1.

- 2

Visually inspect the connector and the 4 wires coming from the O2 sensor.

Look for obvious signs of damage —melted wires, worn insulation, or twisted and stressed wires near the connector. - 3

Visually inspect the O2 sensor connector of the engine wiring harness.

Look for obvious signs of damage. - 4

Trace the wires to the engine harness connection point.

Follow the O2 sensor wires until they join the main engine wiring harness. Inspect this area for pinched wires or chafing against brackets, engine components, or the transmission. - 5

Inspect where the wiring harness where it runs near hot surfaces.

Pay close attention to areas near the exhaust manifold or crossover pipe. Burnt or melted wires are a common failure point in these locations. - 6

Follow the wiring harness as far as possible toward the PCM.

NOTE: You don't need to tear open the harness, but check for any sharp bends, previous repairs, or sections wrapped in tape or loom that may hide damage.

Let's interpret your test result:

CASE 1: You found chafed or melted wires. If the O2 sensor signal wire is exposed or has made contact with another wire or a metal surface, it can short to voltage and trigger a P0132.

Repairing the damaged section (and in the worst case scenario, replacing the wiring harness) should solve the P0132 issue. See:

- Short To Power Repair Tips (1989-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

- How To Repair A Shorted Or Open Wire (Without Tearing Into The Entire Wiring Harness).

CASE 2: The wiring appears intact and undamaged. If everything looks clean and properly routed with no signs of heat damage or chafing, we need to move on to: TEST 3: Check For Voltage On O2 Sensor 1/1 Signal Wire At PCM Connector.