I'm gonna show you how to test the resistance of the fuel injectors on your 2000-2003 V8 Dodge Ram pickup using a multimeter.

This is the quickest and easiest way to see if any one of them has suffered an internal short-circuit or open-circuit problem causing them to stop injecting fuel into their cylinder.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- Dodge Ram 1500 Pickup 5.2L V8: 2000, 2001.

- Dodge Ram 1500 Pickup 5.9L V8: 2000, 2001, 2002, 2003.

- Dodge Ram 2500 Pickup 5.9L V8: 2000, 2001, 2002.

- Dodge Ram 3500 Pickup 5.9L V8: 2000, 2001, 2002, 2003.

WIRING DIAGRAMS:

- Fuel Injector Circuit Wiring Diagram (1998-2000 5.2L, 5.9L V8 Dodge Ram Pickup).

- Fuel Injector Circuit Wiring Diagram (2001 5.2L, 5.9L V8 Dodge Pickup).

- Fuel Injector Circuit Wiring Diagram (2002 5.9L V8 Dodge Ram Pickup).

- Fuel Injector Circuit Wiring Diagram (2003 5.9L V8 Dodge Ram Pickup).

Symptoms Of A Bad Fuel Injector

Every cylinder in your pickup's V8 needs three key ingredients to fire up and make power:

- Air.

- Fuel.

- Spark.

If a cylinder loses any one of those, it stops pulling its weight. When one of the fuel injectors stops doing injecting fuel for whatever reason, you'll run into one or more of these issues:

- Rough idle: The engine shakes when you're parked or stopped.

- Misfires: You'll feel it stutter or jerk when you accelerate.

- Misfire codes (DTCs): You may see one or more of the following:

- P0300: Random Cylinder Misfire.

- P0301: Cylinder #1 Misfire.

- P0302: Cylinder #2 Misfire.

- P0303: Cylinder #3 Misfire.

- P0304: Cylinder #4 Misfire.

- P0305: Cylinder #5 Misfire.

- P0306: Cylinder #6 Misfire.

- P0307: Cylinder #7 Misfire.

- P0308: Cylinder #8 Misfire.

- Lack of power: It feels like the truck's dragging when you press the gas.

- Bad gas mileage: You'll notice you're stopping to gas up more often than usual.

So, what knocks a fuel injector out of action? Most of the time, it's just wear and tear. But not always. Here are the top three failure types:

- Internal failure: The injector completely fails and stops delivering fuel.

- Partially clogged: The injector sprays some fuel, just not enough to keep the cylinder running smoothly.

- Wiring malfunction: A wiring issue or a glitch inside the fuel injection computer makes an injector stay stuck open and spray fuel constantly.

In this tutorial, I'm gonna focus on the two most common failure types: injectors that have an internal electrical issue and won't spray at all, and clogged ones.

Where To Buy The Fuel Injector And Save

You can buy a new or remanufactured fuel injector for your Dodge Ram pickup at just about any local auto parts store —but generally at a steeper price.

Before you buy, check the prices online. Even if you end up getting it locally, you'll have a solid idea of what a fair price should be for the injector.

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

Not sure if the above fuel injector fits your particular Dodge Ram pickup? Don't worry, once you get to the site, they'll make sure it fits by asking you the particulars of your vehicle. If it doesn't fit, they'll find you the right one.

Fuel Injector Resistance Specifications

| Year | Engine | Resist. |

|---|---|---|

| 2000-2003 | 5.2L/5.9L | 10.8-13.2 Ohms |

NOTE: All resistances at: 68°F/20°C

TEST 1: Fuel Injector Resistance Test

In the steps below, I'm assuming you'll be testing all eight fuel injectors —mostly because they're so easy to probe with the multimeter test leads.

But you don't have to test every single one if you don't want to. If you're only checking one, it's still important to test at least two others. That way, you've got a good baseline to compare your readings against.

NOTE: Don't have a multimeter or need to upgrade yours? This is the one I use and recommend: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (at: amazon.com).

IMPORTANT: You've gotta test the resistance of the fuel injectors when the engine is cold —whatever ambient temp is at your location is fine. If it's been running, give it time to cool all the way down.

Alright, let's get started:

- 1

Disconnect the fuel injector from its electrical connector.

- 2

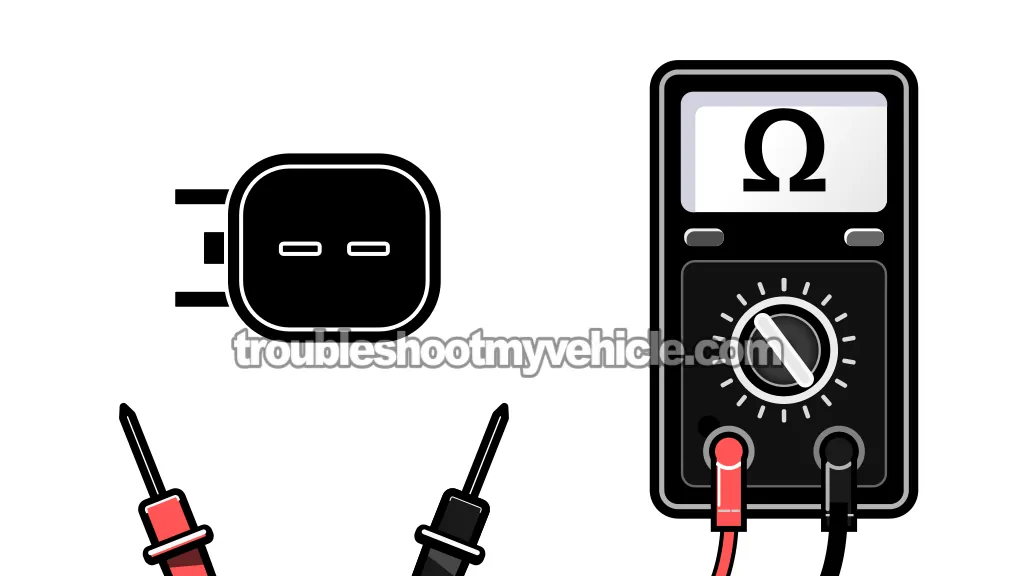

Switch your multimeter to its Ohms (Ω) setting.

- 3

Touch the meter leads to the two terminals on the injector.

You're checking to see if the reading falls within spec: Fuel Injector Resistance Specifications. - 4

Write down the resistance you get.

Be sure to label it by cylinder number using the cylinder ID illustration above. - 5

Repeat the same steps for the other 7 injectors.

Log each reading along with the injector's cylinder.

Let's interpret what your results mean:

CASE 1: All 8 injectors' resistances are within the factory spec. That means none of them are shorted out or open internally —at least electrically.

But just because the resistance is within specification doesn't mean they're not clogged. To dig a little deeper, head over to: Fuel Injector Diagnostic Strategy.

CASE 2: One or more injectors reads way off from the specification. Double-check that one's resistance just to make sure it wasn't a bad test connection.

If the resistance number isn't within the indicated resistance specification, you've got a bad injector on your hands. Replace it.

Fuel Injector Diagnostic Strategy

In this section, I'm gonna show you the fastest way I've found to figure out which fuel injector is giving you trouble.

This step-by-step process will help you track down whether your Dodge Ram pickup's misfire or rough idle is coming from a faulty injector —or something else. The best part? You don't need fancy or expensive tools to pull it off.

Here's what I do:

1.) INSPECT THE INJECTOR SPRAY PATTERN:

One of the advantages of 5.2L/5.9L V8 engine is that the injectors are right out in the open. So when I'm dealing with a misfiring cylinder, I pull that injector and hook it up to a DIY injector cleaner tool (that I bought online). That way, I can see firsthand if it sprays or not.

From there, it's easy to tell if the injector's blocked or malfunctioning. I've put together a detailed, step-by-step tutorial on how to do this yourself —you can check it out here:

2.) USE THE PROCESS OF ELIMINATION:

What I used to do, before I came across the DIY fuel injector cleaner tool I described above, was to methodically work through potential causes of the misfire. This process of elimination hasn't failed me yet —it will also help you find the culprit of the misfire.

- Step 1: Identify the dead cylinder

- This is the most important step. If you've got a generic scan tool or code reader, see if you have any cylinder misfire trouble codes —they'll tell you which cylinder's not firing.

- If no scan tool (or code reader) or no misfire trouble codes, you can do a manual cylinder balance test (my go-to test when I'm chasing down a misfire).

- Step 2: Make sure that cylinder's getting spark

- Use a spark tester on the spark plug wire that connects to the misfiring cylinder, then crank the engine. If you see spark, ignition system's OK. No spark —you've found the source of that cylinder's misfire problem.

- Also, check that the spark plug and boot aren't soaked in oil.

- While you're there, remove the spark plug and look for cracks or carbon tracks on its porcelain insulator.

- Here's a real-world example of carbon tracks causing a cylinder misfire problem: Carbon Tracks Are A Common Cause Of Ignition Misfires (via easyautodiagnostics.com).

- This tutorial will help you test the ignition system:

- Step 3: If spark checks out, test compression

- This test gets overlooked a lot when troubleshooting a cylinder misfire issue —but low compression can definitely cause a dead cylinder. Here's how to do the test:

- Step 4: Use a Noid light to check the injector signal

- If the cylinder has spark and compression, make sure the fuel injector is getting its signal from the PCM.

- This quick guide shows how to use a Noid light:

- How To Use A Noid Light And Where To Buy It (via easyautodiagnostics.com)

- Step 5: Swap injectors if everything else checks out

- If you've confirmed that:

- There's spark

- Compression is solid

- The injector's resistance is good and it's getting pulsed

- NOTE: Don't forget to check this tip: Tech Tip: Always Replace Injector O-Rings.

- If you've confirmed that:

Running through these series of tests will help you rule out spark and mechanical problems before blaming the injector. It's the best way to avoid throwing money at parts that aren't gonna solve the issue.

Speaking from experience —this diagnostic method has saved me more than once from replacing injectors that were actually just fine. Not only that, I found the real issue behind the cylinder misfire.

Tech Tip: Always Replace Injector O-Rings

Any time you're pulling a fuel injector —whether you're swapping it to test or installing a new one— there's one rule you can't skip: Never reuse the old O-rings.

Here's the why of this important rule: Those little O-rings are what seal the injector to the fuel rail and keep fuel from leaking. Once you take the injector out, the O-rings can get damaged, stretched, or slightly deformed —even if they look OK.

Reusing them might seem like a quick fix, but it's not worth the risk. A damaged O-ring can let fuel leak out —and fuel spraying near hot engine parts or sparks? That's a disaster waiting to happen.

Here's what to do instead:

- Install new O-rings that match your injector's particular application exactly.

- Rub a thin layer of clean motor oil on the new O-rings before putting the injector back in. This helps it slide in easily and prevents the O-ring from tearing or pinching.

It only takes a couple of minutes, but it can keep you from dealing with something serious —like a fire resulting in engine damage.

More 5.2L, 5.9L V8 Dodge Ram Pickup Tutorials

You can find a complete list of diagnostic tutorials for the full-size Dodge Ram pickups in this index:

Here's a sample of the tutorials you'll find in the index:

- How To Test The Camshaft Position Sensor (1998-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

- How To Test The Intake Air Temp (IAT) Sensor (1998-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

- How To Test The Fuel Pump (1992-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

- How To Test The MAP Sensor -P0107, P0108 (1997-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

If this info saved the day, buy me a beer!