If you suspect the fuel pump is behind your minivan's no-start or performance issues, this tutorial will help you confirm it.

I'll walk you through how to test fuel pressure using a gauge, step by step. You'll also learn how to run a simple Starting Fluid Test to quickly tell if the engine's getting fuel or not.

Whether your minivan won't start at all or just runs poorly, these tests will help you find out if the fuel pump is the problem.

Contents of this tutorial:

- Symptoms Of A Bad Fuel Pump.

- Where To Buy A Fuel Pressure Test Gauge.

- Fuel Pressure Specifications.

- TEST 1: Checking Fuel Pressure With A Fuel Pressure Gauge.

- TEST 2: Using Starting Fluid To Diagnose A No-Start Condition.

- Inspecting the Fuel Pump Fuse.

- More 3.3L V6 Chrysler, Dodge, And Plymouth Minivan Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 3.3L V6 Chrysler Town & Country: 2000.

- 3.3L V6 Chrysler Voyager: 2000.

- 3.3L V6 Dodge Caravan: 2000.

- 3.3L V6 Dodge Grand Caravan: 2000.

- 3.3L V6 Plymouth Voyager: 2000.

- 3.3L V6 Plymouth Grand Voyager: 2000.

FUEL PUMP TEST TUTORIALS:

- How To Test The Fuel Pump (1992-1993 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

- How To Test The Fuel Pump (1994-1995 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

- How To Test The Fuel Pump (1996-1999 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

- How To Test The Fuel Pump (2001-2007 3.3L V6 Chrysler And Dodge Minivan).

Symptoms Of A Bad Fuel Pump

The fuel pump plays a critical role —it draws fuel from the tank and sends it to the engine at the pressure it needs to run properly. When it starts to fail, it can either stop working completely or begin to fall short under stress.

There are two common ways these pumps go bad:

- Total failure: The engine won't get any fuel at all —you'll turn the key, and it'll crank but never fire.

- Partial failure: This one is sneakier. The pump still works, but not well enough. The engine might start and run for a bit, but then stall or act up when you put a load on it.

What do I mean by "load"? That's any time the engine is being asked to work harder —like when you're pulling away from a stop, climbing a hill, driving with a full load, or even just switching on the A/C. In those moments, a weak pump can't keep up, and performance takes a hit.

Here are a few other signs that the fuel pump isn't doing its job:

- Rough idle: The engine may sound uneven or feel shaky while it's sitting still.

- Hard starts: You're cranking longer than usual before the engine catches —or it may not start at all.

- Loss of power during acceleration: You step on the gas and the van feels like it's struggling to move.

- Backfiring through the intake: A lean fuel condition during throttle input can cause a backfire through the intake manifold.

- Check engine light with code P0171: This code means the engine is running too lean —and that's often because the fuel pump isn't delivering enough fuel.

If you're seeing one or more of these symptoms, it's time to test fuel pressure and confirm whether the pump is the real issue. That's exactly what I'll walk you through in this tutorial.

Where To Buy A Fuel Pressure Test Gauge

All of the fuel pump pressure test kits below have the fitting that will connect to your Dodge's Schrader valve:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

Fuel Pressure Specifications

| 2000 3.3L V6 Fuel Pressure Spec | ||

|---|---|---|

| Year | KOEO | KOER |

| 2000 | 43-53 PSI | Not Given |

- KOEO = Key On Engine Off.

- KOER = Key On Engine Running.

TEST 1: Checking Fuel Pressure With A Fuel Pressure Gauge

The factory manual says to use a scan tool to activate the fuel pump and check fuel pressure. If you've got one of those "bidirectional control" scan tools, great —go ahead and use it to power the pump during the test.

But if you don't, no big deal. I'm going to show you how to activate the pump by bypassing the fuel pump relay with a simple jumper wire.

It's easy to do, totally safe when done right, and gets the job done just as well.

IMPORTANT: Use an appropriately sized jumper wire (no thicker than the relay pins) to prevent damage to your fuse box terminals.

Let's get this show on the road:

- 1

Start by placing a shop towel beneath the Schrader valve on the fuel rail.

This will catch any fuel that might spill out when you connect the gauge. - 2

Thread your fuel pressure gauge onto the Schrader valve.

- 3

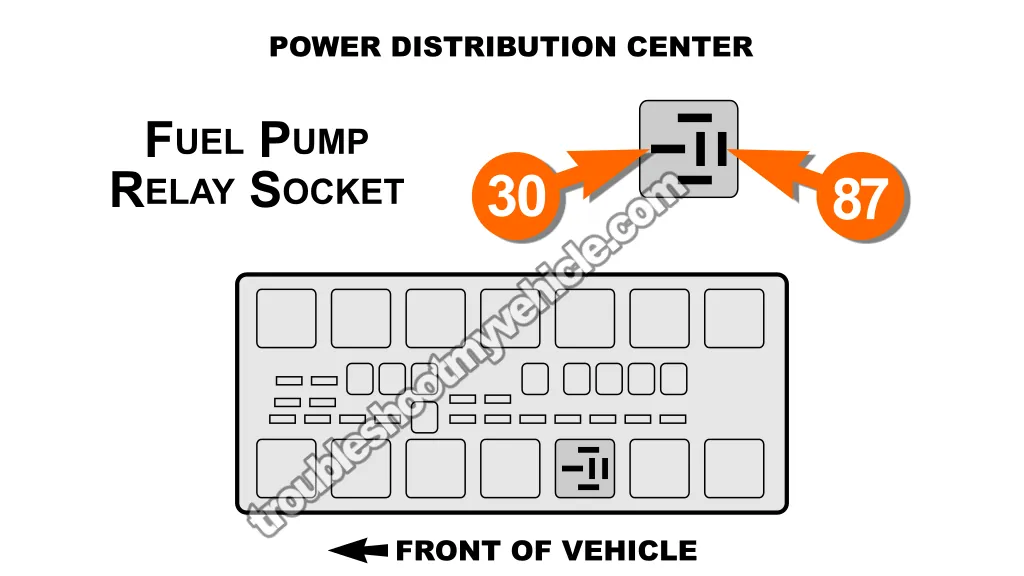

Pop open the underhood fuse and relay box and locate the fuel pump relay.

If you're unsure which one it is, check the diagram on the fuse box cover to confirm or the illustration above. - 4

Using a jumper wire, bridge terminals 30 and 87 inside the relay socket.

This sends power directly to the fuel pump, bypassing the relay entirely.

NOTE: Only connect those two terminals —nothing else. - 5

As soon as the jumper is in place, the pump should kick on.

Keep an eye on your gauge connection. If you see fuel leaking around the Schrader valve, tighten the gauge just a bit more by hand to stop it. - 6

Your gauge should register a pressure between 43-53 PSI.

Here's what your test result is telling you:

CASE 1: Fuel pressure is lower than 43 PSI. If the gauge shows a reading that's under spec, the pump is weak and struggling to build proper pressure.

It might still run the engine, but not well —and under load, things will get worse. Time to replace the fuel pump.

CASE 2: Fuel pressure is 0 PSI. No pressure at all means the pump didn't run.

Check and confirm power (12 Volts) at terminal 30 of the relay socket. If that checks out, the pump is toast.

If terminal 30 has no voltage, jump to: Checking The Fuel Pump Fuse.

CASE 3: Fuel pressure is right at 43-53 PSI. That's what you want to see. The fuel pump is doing its job and delivering the correct pressure.

If the engine doesn't start or doesn't run right, the issue lies somewhere else —ignition, timing, sensors, or possibly fuel injector control. But the pump? It's doing what it should.

TEST 2: Using Starting Fluid To Diagnose A No-Start Condition

This is one of the fastest ways to figure out if your engine's not starting because of a fuel delivery issue. It's simple and doesn't require any tools other than a can of starting fluid or carb cleaner.

If the engine fires up for a second when you give it that temporary fuel source, you'll know it's missing fuel —not spark or compression. But this test only works if all six spark plug wires are actually firing spark, so double-check that first.

Once you've confirmed you've got spark, this test can point your engine no-start diagnostic in the right direction. I'll walk you through exactly how to do it.

IMPORTANT: The accuracy of this test depends on all six spark plug wires firing spark. So before you reach for the carb cleaner or starting fluid, confirm that all six cylinders are getting spark.

Let's get testing:

- 1

Loosen the clamp on the intake hose and lift it off the throttle body.

No need to remove the whole duct —just move it aside enough to give yourself clear access to the throttle opening. You'll put it right back on after the spray. - 2

Spray a short burst of starting fluid or carb cleaner into the throttle body.

- 3

Slip the intake hose back onto the throttle body immediately.

You don't need to clamp it down —just make sure it's seated well. - 4

Have your helper crank the engine right away.

- 5

The engine will do one of two things:

1.) Catch and run for a few seconds.

2.) Engine will just crank and not start.

Here's how to read what the engine just told you:

CASE 1: Engine starts briefly, then stalls. That tells you the engine has spark and compression —it fired up when it got a shot of fuel.

The problem? It's not getting fuel on its own. That's a solid sign the issue is in the fuel delivery system, most likely a weak or dead fuel pump.

Time to check fuel pressure: TEST 1: Checking Fuel Pressure With A Fuel Pressure Gauge.

CASE 2: Engine cranks but never catches. If it just spins and shows no signs of starting, then fuel isn't the issue.

You're likely dealing with a mechanical issue such as low compression, etc. Either way, the fuel pump isn't your culprit here.

Inspecting the Fuel Pump Fuse

If your fuel pressure gauge stayed at zero during the test, don't assume the pump itself is toast just yet. First, you need to confirm whether it's even getting electrical power.

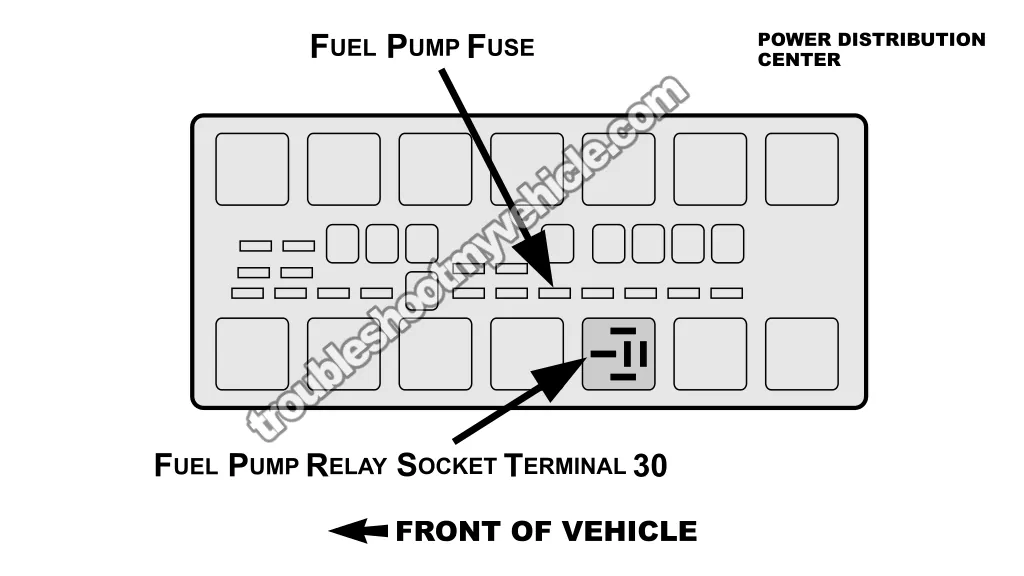

The voltage feeding the fuel pump comes from terminal 30 in the fuel pump relay socket. This terminal is always live —it gets a steady 12 Volts, regardless of the key position. That constant power is supplied by fuse #5 (20 amp) in the underhood fuse and relay box (Power Distribution Center).

Here's what you need to do: use a multimeter or test light to probe terminal 30 for voltage. If you're not getting 12V, go ahead and pull fuse #5 and inspect it. If the fuse is blown, replace it and then re-run the fuel pressure test to see if the pump kicks on.

Tech tip: In a lot of cases, when fuse #5 is blown, it's not just a fluke —it's a warning. A pump that's starting to fail can still run, but the internal resistance starts climbing. That causes it to draw more amps than the fuse is rated for, which is why it pops. Basic Ohm's Law —higher resistance = higher current draw.

If you swap in a new fuse and it blows again, even if the engine runs for a bit, you're looking at a fuel pump that's reached the end of the line. Go ahead and replace it.

Now, if terminal 30 has voltage, the fuse isn't blown, and your gauge reads zero, there's only one conclusion left —the pump is shot. Power's getting there, but fuel isn't. The pump's dead and needs to be replaced.

More 3.3L V6 Chrysler, Dodge, And Plymouth Minivan Tutorials

You can find a complete list of 3.3L V6 Chrysler, Dodge, and Plymouth minivan tutorials in this index:

Here's a small sample of the tutorials you'll find in the index:

- P0171 Diagnostics (1996-2010 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

- P0420 Diagnostics -Catalytic Converter Tests (1996-2010 3.3L V6 Chrysler, Dodge And Plymouth Minivan).

- How To Check For Vacuum Leaks: Carb Cleaner Spray (1991-2010 3.9L V6 Chrysler, Dodge, And Plymouth Minivan).

- How To Test For A Blown Head Gasket (1991-2010 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

If this info saved the day, buy me a beer!