Tracking down a cylinder misfire on your 2.4L Chrysler, Dodge, or Plymouth minivan can get frustrating fast —especially when it keeps popping up or doesn't point to a specific code like P0301 through P0304.

But if you take a structured, step-by-step approach, you'll be able to figure out what's going on without throwing parts at the problem or wasting time chasing your tail.

In this tutorial, I'll show you the exact diagnostic path I use to figure out whether the misfire —whether it's a random P0300 or tied to a specific cylinder— is being caused by ignition issues, a fuel delivery problem, or something mechanical. Whether you're doing this at home or in a shop, this process flat-out works.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 2.4L Chrysler Voyager: 2000, 2001, 2002, 2003.

- 2.4L Dodge Caravan: 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003, 2004, 2005, 2006, 2007.

- 2.4L Dodge Grand Caravan: 1996, 1997.

- 2.4L Plymouth Voyager: 1996, 1997, 1998, 1999, 2000.

- 2.4L Plymouth Grand Voyager: 1996, 1997.

What Is A Cylinder Misfire?

Every cylinder needs three things to do its job: spark, fuel, and compression. If even one of those is weak or missing, the cylinder will misfire.

In other words, that cylinder ends up doing nothing —just along for the ride instead of making power.

When this happens, you'll usually notice some clear drivability issues and a check engine light to go with it.

- Rough or uneven idle.

- Stumbling or hesitation under acceleration.

- Loss of power when climbing hills or under load.

- Check engine light flashing or staying on steady.

- Stored trouble codes like P0300 (random misfire) or P0301 through P0304 —depending on which cylinder is misfiring.

Misfires may seem minor at first, but if you let them go too long, they can damage the catalytic converter —or even the engine itself.

That's why it's important to pinpoint the cause early —whether it's ignition, fuel, or a mechanical issue— and take care of it before it snowballs into a costly chain of repairs.

How To Troubleshoot A Cylinder Misfire

If you're dealing with a misfire —whether it's a random one (like P0300) or tied to a specific cylinder (like P0301 through P0304)— the goal is to figure out what the cylinder isn't getting: spark, fuel, or compression.

That's what I'll walk you through here —the same diagnostic process I use to nail down the root cause without throwing parts at the problem.

Every cylinder needs three basic things to fire: spark, the right amount of fuel, and good compression. If even one of those is missing, that cylinder stops pulling its weight —and your engine performance suffers.

Here's how I troubleshoot it step by step:

- Identify the misfiring cylinder:

- Once you've found which one isn't firing, you're already halfway to solving the problem.

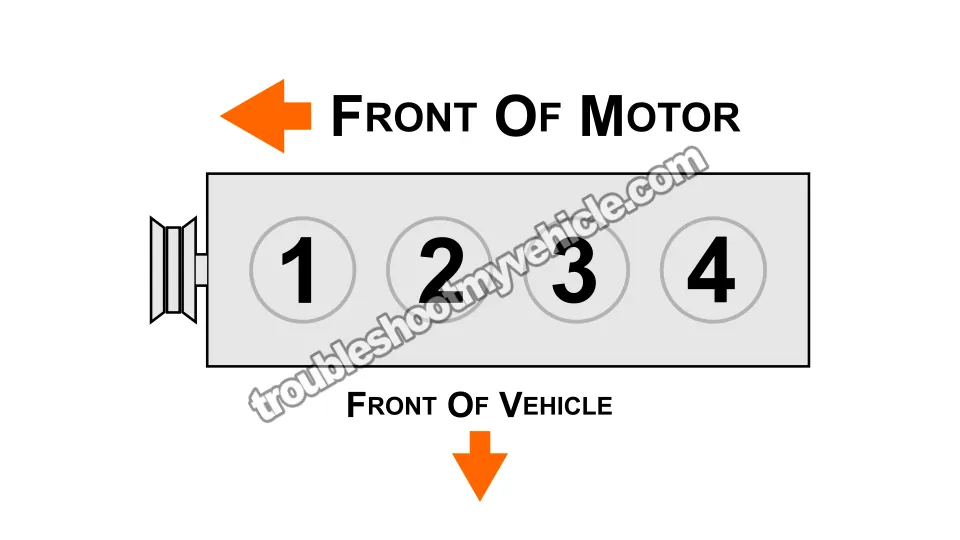

- Scan for misfire codes. You'll usually see a code like P0301 for cylinder #1, P0302 for cylinder #2, and so on.

- If you're not getting any codes, but the engine is running rough or misfiring, you can still narrow it down with a manual cylinder balance test.

- Verify spark delivery to that cylinder:

- Now that you know which cylinder's misfiring, check if its spark plug is getting spark from its spark plug wire.

- Check the spark plug wire for spark first —it has to be delivering spark when the engine's cranking or running.

- If there's no spark, you're dealing with an ignition system issue. The next step is to track down which part isn't doing its job —ignition coil pack or high tension wire.

- Need help testing ignition components? Check out the specific guides linked below that break it all down:

- Inspect the spark plug from the misfiring cylinder:

- Pull the spark plug from the cylinder that's setting the misfire code —whether it's P0301, P0302, P0303, or P0304.

- Check the porcelain insulator for cracks or carbon tracking. Either one can cause the spark to short out before it ever fires the mixture.

- Look closely at the electrodes —if they're fouled with carbon, soaked in oil, or badly worn, that plug might be the reason the cylinder's not firing.

- Need help spotting a bad plug? These spark plug diagnostic guides can walk you through it step by step:

- Confirm the misfiring cylinder has good compression:

- If spark delivery is fine, it's time to make sure the cylinder itself is mechanically healthy.

- This step gets skipped a lot when chasing down a rough idle or trouble codes like P0301 through P0304 —but it's absolutely essential.

- Grab a compression gauge and compare readings across all cylinders. If the misfiring one is more than 15% lower than the highest reading, you've likely found the problem.

- Low compression will prevent proper combustion —and that'll keep triggering the misfire, no matter what parts you swap.

- Use this step-by-step guide to run a compression test on your 2.4L engine:

- And here's a real-world case study of a cylinder misfire caused by low compression:

- Check the fuel injector's resistance:

- If the cylinder has spark and solid compression but still misfires (like a P0301, P0302, P0303, or P0304 code), then it's time to check that the fuel injector is working right.

- With the injector wiring harness connector unplugged (not the individual injector connector), use a multimeter to measure resistance across the terminals.

- Compare the reading to factory specs. If it's way off —depending on the value— that injector might be open or shorted, and the reason you're seeing that persistent misfire code:

- Perform a Noid light test at the injector connector:

- Even without removing the intake manifold plenum, you can usually squeeze a Noid light into the injector connector —it's a tight fit, but doable.

- This test confirms the PCM is supplying both power and a pulse signal to the injector on the misfiring cylinder (P0301, P0302, P0303, or P0304).

- This quick guide shows how to use a Noid light:

- How To Use A Noid Light And Where To Buy It (at: easyautodiagnostics.com).

- Remove the upper intake plenum for an injector spray pattern check:

- This step requires pulling the injector from the misfiring cylinder —only after confirming spark, good compression, and proper injector resistance.

- Once removed, hook the injector up to a fuel injector cleaner/tester (I'll link you to a solid one), and observe the spray.

- You're looking for a fine, even mist —not a dribble or off-center stream. A poor spray pattern (that's not a fine mist and conical) can cause a dead cylinder and trigger P0300–P0304 codes.

- Although the tutorial below is for the 3.3L V6, the injector spray test procedure is the same on the 2.4L engine —you're just working with a different intake layout:

When you're tracking down a cylinder misfire —whether it's a P0301, P0302, P0303, P0304, or even a P0300 random misfire— the secret to getting it fixed is simple: methodically rule things out one step at a time.

Your first goal is to find out which cylinder isn't firing —the one that's "dead". Once you've nailed that down, it's time to confirm three critical things: is it getting spark, does it have good compression, and is the fuel injector working?

Working through the tests I outlined above —in that exact order— helps you pinpoint the weak link in the chain. And the best part? You'll avoid replacing good parts and save yourself a ton of time and guesswork.

Vacuum Leaks Causing A Misfire Or Rough Idle

If your 2.4L Dodge, Chrysler, or Plymouth minivan is running rough at idle —especially during a cold start— a vacuum leak might be the cause. And while the upper plenum gasket is one common suspect, it's not the only place unmetered air can sneak in.

Some 2.4L engines came with a steel metal shim-style intake plenum gasket instead of the paper type. Over time, that metal gasket can warp or lose its seal, causing a leak right at the plenum-to-intake connection. This can lead to cold-start misfires, stumbling idle, and trouble codes like P0300 through P0304.

Unfortunately, the fun doesn't stop there. Vacuum leaks can also come from:

- Dry-rotted vacuum hoses that have cracked or hardened with age.

- Brittle plastic vacuum fittings that snap or split where hoses connect.

- Leaking PCV hoses that have collapsed or cracked, especially near the intake port.

- Brake booster vacuum hose leaks —which can affect both idle quality and braking performance.

- Throttle body gasket leaks if it's been removed and reused without a new gasket.

- Intake manifold gasket failure —less common, but still worth checking.

If you're trying to track down a possible vacuum leak, here's a quick step-by-step guide using carb spray to help you confirm it (it's for the 3.3L V6 engine, but the process is the same for the 2.4L):

More 2.4L Chrysler, Dodge, And Plymouth Minivan Tutorials

I've written several more tutorials for the 2.4L Chrysler, Dodge, and Plymouth minivans that you might find helpful. You can browse them all in this index:

Here's a sample of the tutorials you'll find in the index:

- How To Test The TPS (1998-2000 2.4L Dodge, Plymouth Mini-Van).

- Testing The Crankshaft Position Sensor -P0320 (1996-2002 2.4L Caravan, Grand Caravan, Voyager, Grand Voyager).

- How To Test The Fuel Pump (2001-2005- 2.4L Chrysler Voyager And Dodge Caravan).

- How To Find Out If The Catalytic Converter Is Bad (1996-2007 2.4L Caravan, Grand Caravan, Voyager, Grand Voyager).

If this info saved the day, buy me a beer!