One of the fuel injector tests that's been a total game-changer for me —especially when diagnosing a clogged injector causing a cylinder misfire— is being able to visually see the fuel spray pattern.

In this tutorial, I'm going to show you a DIY fuel injector spray test that's simple, effective, and easy to do with a basic cleaning kit you can buy online (and I'll show you where to get one).

Contents of this tutorial:

- Fuel Injector Spray Test Basics.

- Checking If The Fuel Injector Sprays Fuel.

- TECH TIP 1:Important Precautions When Removing The Upper Intake Manifold Plenum.

- TECH TIP 2: Always Replace Injector O-Rings.

- TECH TIP 3: Install The Intake Manifold Plenum Gasket Dry.

- More 3.3L V6 Chrysler, Dodge, And Plymouth Minivan Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 3.3L V6 Chrysler Town & Country: 1991, 1992, 1993, 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003, 2004, 2005, 2006, 2007, 2008, 2009, 2010.

- 3.3L V6 Chrysler Voyager: 2000, 2001, 2002, 2003.

- 3.3L V6 Dodge Caravan: 1991, 1992, 1993, 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003, 2004, 2005, 2006, 2007.

- 3.3L V6 Dodge Grand Caravan: 1991, 1992, 1993, 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003, 2004, 2005, 2006, 2007, 2008, 2009, 2010.

- 3.3L V6 Plymouth Voyager: 1991, 1992, 1993, 1994, 1995, 1996, 1997, 1998, 1999, 2000.

- 3.3L V6 Plymouth Grand Voyager: 1991, 1992, 1993, 1994, 1995, 1996, 1997, 1998, 1999, 2000.

FUEL INJECTOR RESISTANCE TESTS:

- Fuel Injector Resistance Tests (1996-2000 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

- Fuel Injector Resistance Tests (2001-2005 3.3L V6 Chrysler And Dodge Minivan).

Fuel Injector Spray Test Basics

Just because a fuel injector passes a resistance test with a multimeter doesn't mean it's actually doing its job. A clogged injector can still show the correct resistance —but if it's blocked or only spraying a weak stream, the cylinder it feeds will misfire.

On the 3.3L V6 engines, checking the spray pattern isn't as simple as popping off a fuel rail. The intake manifold plenum has to come off first —which makes this test a bit more involved compared to other vehicles.

To actually see whether an injector is spraying fuel properly, you'll need a special injector cleaning and testing tool. The good news is, these tools are inexpensive and easy to use once the injector is removed.

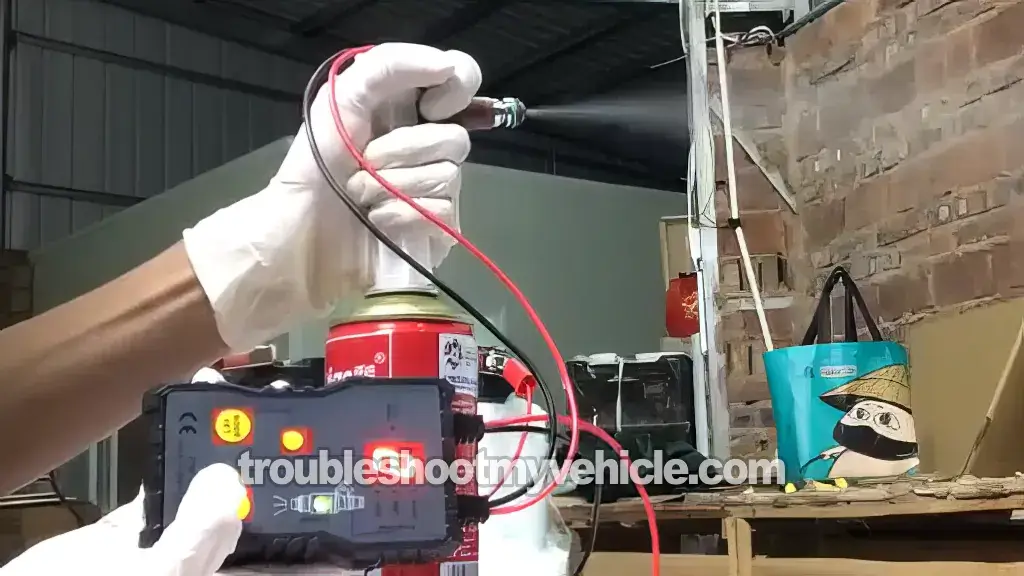

The tool has two key parts:

- Fuel injector power module: Lets you connect the injector to your minivan's battery and simulate the pulsing action that happens during normal operation.

- Plastic adapter: Connects the fuel injector to a can of brake cleaner so you can check the spray pattern once it's removed from the engine.

To use it, you just hook up the adapter to a brake cleaner can and connect the injector to the power module. As you pulse the injector, the brake cleaner is forced through and out of the nozzle —just like it would be in the engine with fuel.

If the injector sprays a fine, even mist, then you know it's working right. But if the spray looks more like a squirt gun —or nothing comes out at all —the injector is likely clogged and needs cleaning or replacement.

I've used this tool myself, and let me tell you —it's SUPER effective. I honestly wish something like this had existed 30 years ago when I first started my automotive repair career.

Where to buy it:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

Checking If The Fuel Injector Sprays Fuel

Alright, let's confirm whether or not the injector is physically delivering fuel in the correct way —and it needs to be done safely. Before you begin:

- Read the tool's user manual carefully to understand how it operates.

- Always perform this test in a well-ventilated area —away from open flames, sparks, or any heat sources —since brake cleaner is extremely flammable.

- Wear safety glasses to protect your eyes.

- Wear gloves to avoid skin contact with the cleaner.

NOTE: You'll need to remove the intake manifold plenum to safely remove a fuel injector —even if it's not one of the three located under the plenum (on 1991–2000 models). This avoids damaging the fuel rail or stressing the other injectors' O-rings. On 2001–2010 models, all six injectors are under the plenum, so removal is required either way. Before you start, make sure to read: TECH TIP 1: Important Precautions When Removing The Upper Intake Manifold Plenum.

Let's get testing:

- 1

Remove the intake manifold plenum.

- 2

Remove the fuel injector from the engine.

- 3

Remove the spray nozzle from your can of brake cleaner spray.

- 4

Connect the injector to the plastic adapter. This adapter will allow the spray can and injector to link up securely.

- 5

Attach the adapter to a can of brake cleaner. Make sure the connection is snug so nothing leaks when you apply pressure.

- 6

Use the power module to pulse the injector. This will simulate the fuel injector's operation and allow the cleaner to flow through it —just like fuel would.

Here's what that test result is telling you:

CASE 1: The fuel injector produced a fine, even spray mist when pulsed with the tool. This is the result you're looking for. It confirms that the injector is not clogged and is capable of atomizing fuel correctly.

If the cylinder is still misfiring, the cause lies elsewhere —most likely in the ignition system, compression, or wiring. See:

CASE 2: The fuel injector did not spray at all. This usually means the injector is completely clogged and not delivering any fuel.

In this case, you'll need to replace the injector —cleaning won't help a completely blocked one.

CASE 3: The injector produced a solid stream (like a squirt gun) instead of a fine mist. This means the injector is partially clogged and not atomizing fuel correctly.

You can try running brake cleaner through it a few more times. If the spray pattern improves and turns into a mist —awesome, you've cleared it. But if it doesn't improve, it's time to replace the injector.

TECH TIP 1: Important Precautions When Removing The Upper Intake Manifold Plenum

If you're a seasoned tech, pulling the upper plenum on a 3.3L V6 is no big deal —you've probably done it a dozen times. But if you're a DIYer turning wrenches in the driveway, it's a bit more hands-on and takes a little extra care.

That said, this job is totally doable, even if it’s your first time. I'm not gonna break down the removal here, but I'll share a few key tips to help you avoid the kind of mistake that turns a simple job into a major one.

If you've never removed an intake before, do your homework first. Look up your minivan's exact procedure, crack open a Chilton or Haynes manual, or check out a few YouTube walkthroughs to get familiar before diving in.

When you're ready to start:

- Keep all bolts, nuts, and brackets far away from the engine bay as you remove them. Don't leave anything sitting on the cowl, valve cover, or plenum. All it takes is one small slip for something to fall into an open port.

- As soon as the plenum's off, cover all six intake runners with clean rags or towels. Do this right away. Even a tiny washer or speck of debris can ruin your day if it drops inside.

- Skip the RTV or sealant when reinstalling the upper intake manifold gaskets. They're made to go on dry. Using sealant here can cause vacuum leaks or sealing issues that'll force you to tear it all back down (see: TECH TIP 3: Install The Intake Manifold Plenum Gasket Dry).

Heads-up: If anything falls into one of the intake ports, getting it out is a nightmare. You'll be pulling the cylinder head. And if you miss it and fire up the engine? That rogue bolt or washer can wreck valves, scar cylinder walls, and shatter pistons in seconds.

Again, this job is totally doable —just remember to take your time, keep the engine bay clean (watch those bolts and parts), and cover up those intake ports the moment the plenum comes off. Do that, and you'll avoid turning a simple injector test into a full-blown engine rebuild.

TECH TIP 2: Always Replace Injector O-Rings

This step isn't optional —it's critical. When reinstalling a fuel injector into the fuel rail, you must replace the O-rings with brand-new ones. Reusing old O-rings, even if they "look fine", is a serious safety risk.

These small rubber O-rings are what keep fuel from leaking where the injector meets the fuel rail. But once removed, they can get nicked, stretched, or develop invisible warping that compromises the seal.

If a damaged or worn O-ring leaks, fuel can spray or drip onto hot engine parts —turning a simple repair into a dangerous fire hazard.

Here's how to do it right:

- Buy O-rings that are the exact match for your injector and engine.

- Before installing, lightly coat the new O-rings with clean engine oil to help them slide in smoothly without tearing or folding.

- Take your time and double-check that each O-ring is seated properly.

O-rings are cheap —but skipping them could cost you your engine, or worse. This is one of those small details that makes a big difference in keeping your engine safe and leak-free.

TECH TIP 3: Install The Intake Manifold Plenum Gasket Dry

When it comes time to reinstall the upper intake manifold plenum, do not apply any sealer or gasket maker to the gasket —not even a light coat of RTV silicone.

This applies whether you're working with a rubber-style gasket or a traditional paper one. Both are designed to seal properly when installed dry. Adding sealant might seem like a good idea, but it can actually cause sealing issues by affecting how the gasket seats against the mating surfaces.

Using RTV or other sealants here can lead to vacuum leaks, poor engine performance, and the frustration of having to pull the plenum back off to do the job again.

So remember: clean the surfaces, install the gasket dry, torque everything to spec, and you're good to go.

More 3.3L V6 Chrysler, Dodge, And Plymouth Minivan Tutorials

You can find a complete list of diagnostic tutorials for the full-size Dodge Ram pickups in this index:

Here's a sample of the tutorials you'll find in the index:

- How To Test The MAP Sensor (2001-2004 3.3L V6 Caravan, Grand Caravan, Voyager, Grand Voyager, Town & Country).

- How To Test Engine Compression (1991-2010 3.3L V6 Chrysler, Dodge, Plymouth Minivan).

- How To Test For A Blown Head Gasket (1991-2010 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

- P0420 Diagnostics -Catalytic Converter Tests (1996-2010 3.3L V6 Chrysler, Dodge And Plymouth Minivan).

If this info saved the day, buy me a beer!