Testing the fuel pump with a fuel pressure test gauge on the 1992-1993 3.0L V6 Toyota Camry is easier than you might think.

If your Camry isn't starting or is running poorly and you suspect the fuel pump, using a fuel pressure test gauge is the most accurate and reliable way to diagnose the issue.

In this tutorial, I'll show you how to hook up the fuel pressure test gauge, what readings to look for, and a simple trick using starting fluid to confirm if a lack of fuel pressure is causing the engine no-start problem.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 3.0L V6 Toyota Camry: 1992, 1993.

Fuel Pump Circuit Wiring Diagram:

Toyota Fuel Pump Test Tutorials:

- How To Test The Fuel Pump (1994-1996 3.0L V6 Toyota Camry).

- How To Test The Fuel Pump (1997 3.0L V6 Toyota Camry).

- How To Test The Fuel Pump (1998-2001 3.0L V6 Toyota Camry).

Engine No-Start Diagnostics:

Symptoms Of A Bad Fuel Pump

You've probably figured out by now that fuel pumps typically bite the dust in one of two ways:

- They just quit cold turkey.

- They limp along enough to get your Camry started and running, but engine performance suffers (especially under load).

When the fuel pump calls it quits on your 3.0L V6 Toyota Camry, you'll notice:

- When you turn the key, the engine will turn over, but it won't start.

- A spark test confirms that all cylinders are getting spark, which rules out the ignition system as the cause of the engine no-start.

- A Noid light test shows that your Toyota Camry's fuel injection computer is activating the fuel injectors.

- A zero pressure reading on your fuel pressure test gauge confirms the fuel pump's toast.

- If you spray some starting fluid into the throttle body and then crank the engine, it'll fire up - but just for a few seconds.

If your fuel pump is failing and underperforming, you'll notice one or more of the following symptoms.

- Lean air/fuel mixture trouble codes.

- Rough idle.

- Engine starts only after extended cranking.

- Lack of power when accelerating down the road.

- Backfires through the intake manifold when you're accelerating the engine under load.

To diagnose these issues, you can use a fuel pressure gauge to determine if the fuel pump is behind the engine no-start issue or engine performance problem.

Where To Buy A Fuel Pressure Test Gauge

A fuel pressure test gauge is an essential tool for any DIY'er troubleshooting an engine no-start or engine performance issue. You can grab one from most auto parts stores or online retailers.

The following fuel pressure test gauge kits are pretty good deals, and they come with the adapters to test your 3.0L V6 Toyota Camry (and they've got you covered for GM and Ford vehicles with Schrader valves too).

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

NOTE: All of the fuel pump pressure test kits above have the fitting that will connect to your Toyota's fuel system.

TEST 1: Checking Fuel Pressure With A Fuel Pressure Gauge

As I mentioned at the beginning, testing the fuel pressure that your Toyota's fuel pump is producing is the best way to determine if it has failed or is failing.

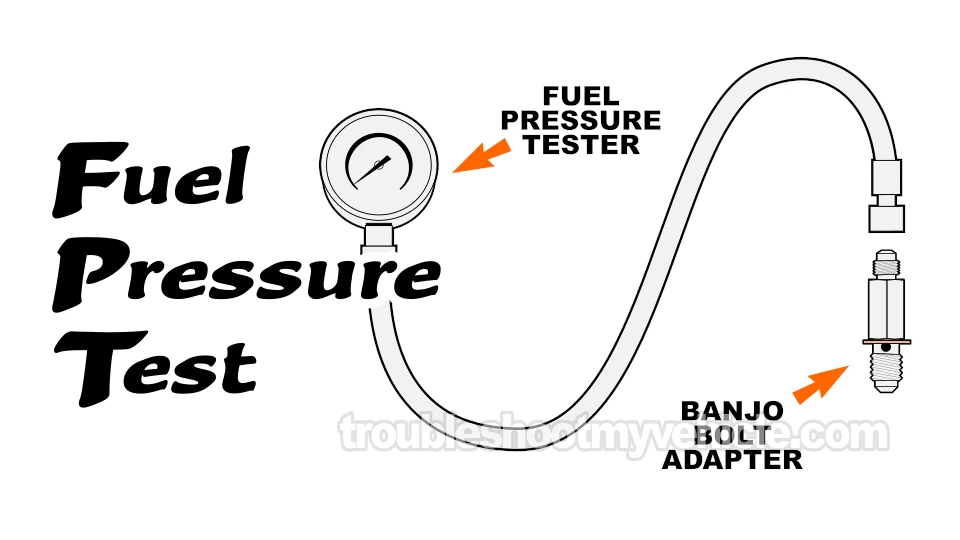

The fuel pressure test gauge is connected to the cold start valve (fuel injector), which is located on the side of the intake manifold plenum (see photo above).

To connect the fuel pressure gauge, you'll need to remove the fuel line union bolt (also known as a banjo bolt) and install the gauge's adapter in its place.

| Engine Off and DLC terminals +B and FP jumpered. |

|---|

| 38-44 PSI |

| Engine running and w/out vacuum hose connected to fuel pressure reg. |

|---|

| 38-44 PSI |

| Engine running and w vacuum hose connected to fuel pressure reg. |

|---|

| 33-37 PSI |

NOTE: If you don't have a fuel pressure gauge, take a look at the section: Where To Buy A Fuel Pressure Test Gauge.

OK, let's get started with this test:

- 1

Remove the top part of the air filter assembly to access the fuel filter.

- 2

Place a shop towel beneath the area of the cold start valve.

This shop towel will absorb and keep any fuel from dripping/leaking/spraying on the engine (if there's any residual fuel pressure in the fuel line) as you loosen the cold start valve's banjo bolt. - 3

Remove the cold-start valve's union bolt. The arrow in image 2 of 2 in the image viewer above points to the cold-start valve's union bolt.

NOTE: Careful the union bolt's 2 copper washers don't fall and get lost in the engine compartment. You'll need to re-install them when you get done with the fuel pressure test. - 4

Install the fuel pressure test kit's adapter in place of the union bolt and tighten it.

- 5

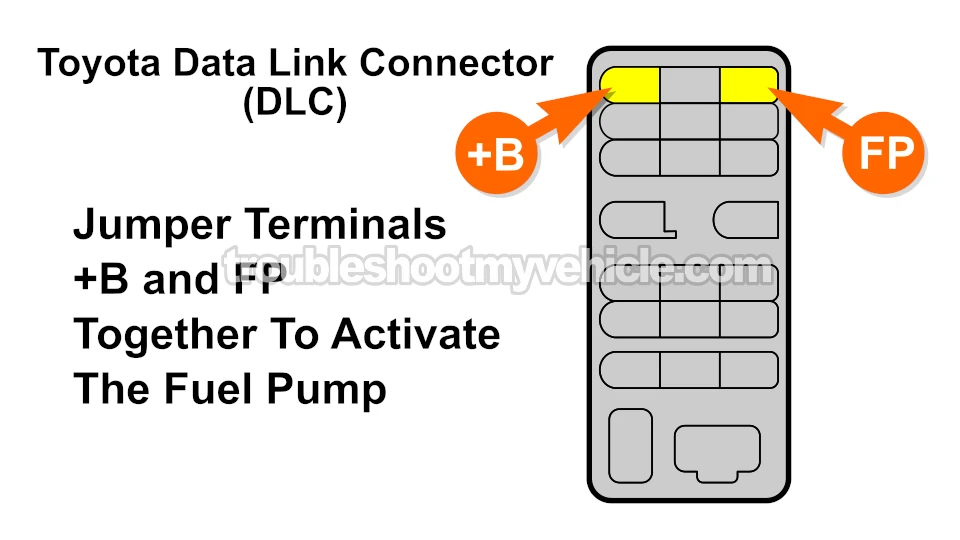

Locate the diagnostic link connector (DLC) and jumper terminals +B and FP together.

Jumpering these two DLC terminals will activate the fuel pump when you turn the key to the ON position and without starting the engine. - 6

Turn the key to the ON position (but don't crank or start the engine).

NOTE: Check the fuel pressure gauge's adapter connection for fuel leaks. If any leaks are present, turn the key OFF and resolve them to get an accurate fuel pressure output result. - 7

Your fuel pressure gauge should register about between 38-44 PSI fuel pressure if the fuel pump is OK.

NOTE: You can also check the fuel pressure with the engine running, just remove the jumper wire from the Data Link Connector (DLC) and start the engine. Check the tables above for the indicated fuel pressure specification.

Let's take a look at what your results mean:

CASE 1: The fuel pressure gauge registered 0 PSI with the indicated DLC terminals jumpered together. This confirms that the cause of your 3.0L V6 Toyota Camry's no-start problem is caused by a lack of fuel.

CASE 2: The fuel pressure gauge registered the specified fuel pressure with the DLC terminals jumpered together. This test result lets you know that the fuel pump is working and delivering enough fuel to the fuel injectors.

If your 3.0L V6 Toyota Camry isn't starting, it's due to another reason. The fuel pump is OK. Check out this tutorial for more diagnostic help:

CASE 3: The fuel pressure gauge registered the specified fuel pressure with the DLC terminals jumpered together, but the fuel pressure drops to 0 with the engine running. This test result usually tells you that the fuel pump itself is OK, but the MAF sensor circuit that enables the fuel pump with the engine running has failed.

On the 1992-1993 3.0L Camry, the MAF sensor plays a huge part in enabling power to the fuel pump once the engine has started. If the fuel pump enable circuit in the MAF sensor has failed, the engine will initially start, but stall.

The following wiring diagram will help you diagnose this particular type of fuel pump issue:

TEST 2: Using Starting Fluid To Confirm Lack Of Fuel

If your 3.0L V6 Toyota Camry is experiencing issues where it "cranks but doesn't start," and you suspect that the fuel pump might be to blame but you don't have a fuel pressure test gauge, I recommend starting with a simple yet effective test: the starting fluid test.

As someone who's used this method to diagnose an engine no-start issue many times, I can attest to its effectiveness in helping reveal whether the problem lies with the fuel pump.

This classic diagnostic engine no-start test involves spraying starting fluid into the intake manifold's throttle body and then cranking the engine to see if it starts.

To get an accurate result from this test, it's crucial that you first confirm all six cylinders are receiving a spark (with a spark tester).

IMPORTANT: When conducting this test, don't forget to reconnect the air intake duct after spraying starting fluid down the throttle bore (even if you tighten the air duct clamp). This ensures that any potential backfires while cranking the engine are contained within the intake manifold plenum.

This is what you have to do:

- 1

Remove the intake air duct from the throttle body.

You don't have to completely remove it, since you'll have to reconnect it in one of the next steps. - 2

Open the throttle plate and spray starting fluid down the bore.

NOTE: As a safety precaution reconnect the air duct after you have sprayed a good squirt of starting fluid (but you don't have to tighten the air duct's hose clamp). - 3

Crank the engine once the air duct is back on and you're clear of the engine compartment.

- 4

You're gonna see one of two things:

1.) The engine will start and run and after a few seconds will die.

2.) The engine won't start at all.

OK, let's find out what your results mean:

CASE 1: The engine started and ran for a few seconds. This test result tells you that the no-start problem is due to a lack of fuel.

Your next step is to check to see what the fuel pressure is with a fuel pressure test gauge. Go to: TEST 1: Checking Fuel Pressure With A Fuel Pressure Gauge.

CASE 2: The engine did not start, not even momentarily. This usually means that a lack of fuel IS NOT the reason your car is not starting.

Now, remember what I said about this test not being very accurate? Well, I suggest you do one more test and this is to check the fuel pressure with a fuel pressure test gauge. Go to: TEST 1: Checking Fuel Pressure With A Fuel Pressure Gauge.

More 3.0L V6 Toyota Camry Tutorials

You can find a complete list of 3.0L V6 Toyota Camry tutorials and wiring diagrams in this index:

Here's a sample of the tutorials you'll find there:

- How To Test Engine Compression (1992-2006 3.0L V6 Toyota Camry).

- How To Test For A Blown Head Gasket (1992-2006 3.0L V6 Toyota Camry).

- How To Test The MAF Sensor (1992-1993 3.0L V6 Toyota Camry).

- How To Test The TPS (1992-1996 3.0L V6 Toyota Camry).

If this info saved the day, buy me a beer!