The distributor pickup coil’s a key part of the ignition system. It sends out two signals (the crankshaft’s position and engine RPM) that the fuel injection computer uses to activate the igniter and ignition coil.

The pickup coil won’t last forever. When it finally fails, the engine’s gonna crank but won’t start due to a lack of spark.

I’m gonna show you how I check the pickup coil to see if it’s the reason the engine’s not starting. Every test is explained step-by-step.

Contents of this tutorial:

- What Does The Distributor Pickup Coil Do?

- Symptoms Of A Bad Pickup Coil.

- Distributor Connector Circuit Descriptions.

- Where To Buy The Distributor Pickup Coil.

- TEST 1: Checking The Pickup Coil's Resistance With A Multimeter.

- TEST 2: Testing The Pickup Coil's Output With A Multimeter.

- More 1.8L Toyota Corolla Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 1.8L (7A-FE) Toyota Corolla: 1993, 1994.

- 1.8L (7A-FE) Geo Prizm: 1993, 1994.

Ignition System Tests:

- How To Test The Ignition Coil (1993-1994 1.8L Toyota Corolla).

- How To Test The Igniter (1993-1994 1.8L Toyota Corolla).

Ignition System Wiring Diagram:

Engine No-Start Basics:

What Does The Distributor Pickup Coil Do?

Before we jump into the pickup coil tests, here's the stuff you that's gonna help you make sense of them:

- It's actually two sensors in one: The pickup coil inside the distributor isn't just a single sensor. It's got two built into one housing, and each one spits out its own AC voltage signal:

- G1 signal: Acts as the crankshaft position (CKP) signal.

- NE signal: Works as the RPM reference signal.

- They're magnetic sensors: Both G1 and NE are magnetic. They pick up movement from matching reluctor wheels — those are toothed wheels spinning on the distributor shaft.

- How signals are made: When the engine's cranking or running, the reluctor wheels spin too. As their teeth pass by the sensors, two AC voltage signals get created — G1 and NE.

- G1: Lets the computer know where the crankshaft's sitting.

- NE: Feeds engine speed info to the computer.

- It all ties into spark and timing: The computer reads these signals to figure out exactly when to activate the ignition coil through the igniter.

- Once the igniter fires the ignition coil, it sends a high-voltage charge through the distributor cap, rotor, and plug wires —hitting the right spark plug at just the right time

Symptoms Of A Bad Pickup Coil

When the pickup coil fails, it can cause quite the headache. Sometimes it makes starting tough, and other times it just kills the engine outta nowhere. The two most common symptoms you'll notice are:

- Engine won't fire up:

- The igniter doesn't get the IGT signal it needs to turn on.

- Because of that, it won't send power to the ignition coil.

- The computer won't switch on the fuel injectors.

- The fuel pump stays off too — no fuel, no-start.

- Runs rough or suddenly dies:

- You might feel it misfire, shake, or just shut off while you're driving.

- Ignition system trouble codes:

- Code 12: G and NE Signal Problem.

- Code 13: NE Signal Circuit Problem.

Distributor Connector Circuit Descriptions

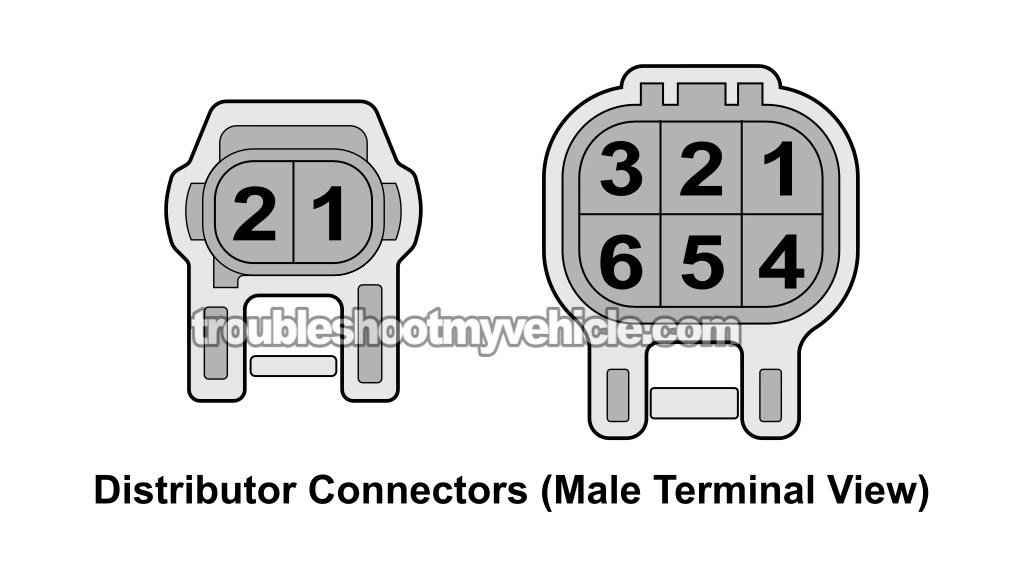

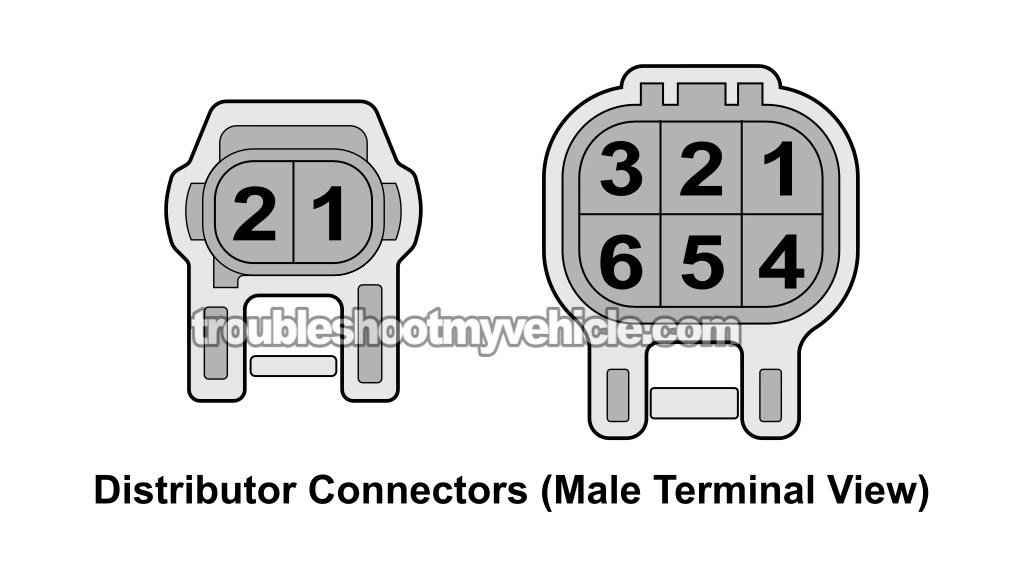

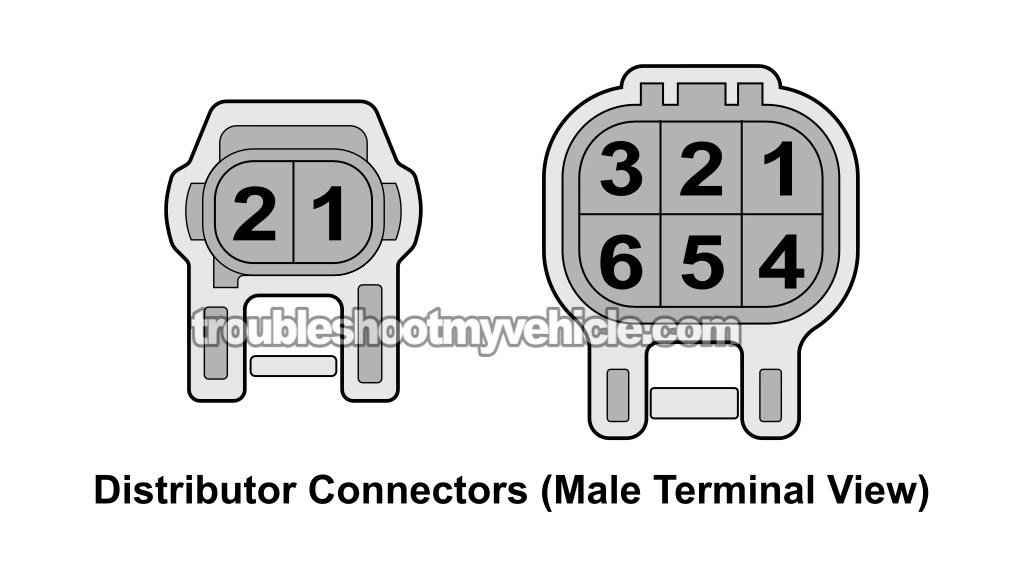

Your 1.8L Toyota Corolla's distributor has two connectors. One is a 2-wire connector, and the other is a 6-wire connector.

NOTE: The wire colors in the tables below match the engine wiring harness connectors, not the ones directly on the distributor.

Here's what each connector's circuits do:

2-Wire Connector:

| Pin | Wire Color | Description |

|---|---|---|

| 1 | Black with orange stripe (BLK/ORG) | B+ → Ignition 12 Volts |

| 2 | Black (BLK) | IG- → Tachometer Signal |

6-Wire Connector:

| Pin | Wire Color | Description |

|---|---|---|

| 1 | Black (BLK) | IGT → Ignition Timing Signal |

| 2 | White (WHT) | NE- → Sensor Ground For NE |

| 3 | Green (GRN) | G- → Sensor Ground For G1 |

| 4 | Black with yellow stripe (BLK/YEL) | IGF → Ignition Feedback Signal |

| 5 | Black (BLK) | NE → Engine Speed Signal |

| 6 | Red (RED) | G1 → Crankshaft Position Signal |

NOTE: The distributor engine wiring harness connector has female terminals. The connector coming out of the distributor itself has male terminals.

Where To Buy The Distributor Pickup Coil

The pickup coil isn't sold separately from the distributor, so if your test results indicate it's bad, you'll need to buy the entire distributor.

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

NOTE: Not sure if the distributor fits your particular Corolla? Don't worry. Once you get to the site, they'll ask you for the specifics of your vehicle. If it doesn't fit, they'll find you the right one.

TEST 1: Checking The Pickup Coil's Resistance With A Multimeter

Most of the time, when the G1 or NE sensor fails, it's because of an internal short or open-circuit problem.

To find out if that's happening inside either sensor, we'll use a multimeter set to Ohms (Ω) mode. That way, we can check the resistance and see if it's in the normal range.

If both NE and G1 are working like they should (no shorts or opens), your multimeter's gonna show readings like this:

- G1 Sensor: Should be between 185–265 Ohms (when the engine's cold).

- NE Sensor: Also should read between 185–265 Ohms (engine cold).

NOTE: Do this test right at the distributor's 6-wire plug — the one with the male spade terminals.

Alright, here's what to do step by step:

- 1

Unplug the distributor's 6-wire connector from the harness coming from the engine.

- 2

Set your multimeter to Ohms (Ω) mode.

- 3

Measure resistance between terminals 2 and 5 of the distributor's 6-wire connector.

Those pins belong to the NE sensor. - 4

You should get a reading between 185 and 265 Ohms.

- 5

Now check between terminals 3 and 6 on the same connector.

Those are for the G1 sensor. - 6

Your meter should again read between 185 and 265 Ohms.

Let's make sense of the results:

CASE 1: Both sensors fall within spec. That means there's no internal short or open —the pickup coil's good.

It's optional, but if you wanna double-check the sensors are making signals too, head over to TEST 2: Testing The Pickup Coil's Output With A Multimeter.

CASE 2: One or both sensors are out of range. That tells us the pickup coil's fried and needs to be swapped out.

Since you can't buy just the pickup coil, you'll have to replace the whole distributor.

And again, if you're the kind that likes to be 100% sure, go ahead and do TEST 2: TEST 2: Testing The Pickup Coil's Output With A Multimeter.

TEST 2: Testing The Pickup Coil's Output With A Multimeter

When the engine's cranking, the G1 and NE sensors inside the pickup coil send out AC voltage. You can check that easily using a multimeter set to Volts AC.

- If the G1 or NE sensor's good: You should see between 0.4 and 1.2 Volts AC on your meter while the engine's cranking.

- If the sensor's bad: The meter's gonna stay at 0 Volts AC while cranking.

NOTE: The voltage you see depends on how fast the engine turns, which depends on how charged up your battery is. So make sure your Corolla's battery's fully charged before you run this test. If it's weak, charge it fully first.

Alright, here's how to do it:

- 1

Unplug the 6-wire distributor connector from the engine wiring harness connector.

- 2

Switch your multimeter to AC Volts mode.

- 3

Use the test leads to check terminals 2 and 5 on the 6-wire connector.

These two belong to the NE sensor.

NOTE: Be sure you're testing the male spade terminals on the connector coming out of the distributor itself, not the female ones on the engine wiring harness connector. - 4

Have someone crank the engine while you watch the meter.

CAUTION: Be careful around a cranking engine. - 5

Your meter should show 0.4 to 1.2 Volts AC coming from the NE sensor.

- 6

Now test terminals 3 and 6 on that same connector.

These are for the G1 sensor.

NOTE: Again, test only the male terminals of the 6-wire connector coming out of the distributor itself. - 7

Have your helper to crank the engine again while you check the meter.

CAUTION: Be careful — engine's cranking again. - 8

The multimeter should read between 0.4 and 1.2 Volts AC for the G1 sensor too.

Let's break down what the results tell us:

CASE 1: Both sensors show the right voltage. That means G1 and NE are doing their job —the pickup coil's working.

CASE 2: One or both show 0 Volts AC. That means the pickup coil's toast —time to replace it.

More 1.8L Toyota Corolla Tutorials

You can find a complete list of 1.8L Toyota Corolla tutorials and wiring diagrams in this index:

Here's a sample of the tutorials you'll find there:

- How To Test The Throttle Position Sensor (1993-1997 1.8L Toyota Corolla).

- How To Diagnose A Broken Timing Belt (1993-1997 1.6L Toyota Corolla).

- How To Test The MAP Sensor (1993-1997 1.8L Toyota Corolla).

- How To Test The Fuel Pump (1993-1997 1.8L Toyota Corolla).

If this info saved the day, buy me a beer!