Troubleshooting the fuel pump, to see if it's causing your Corolla's engine no-start or engine performance problem isn't difficult.

In this tutorial, I'm gonna show you how to check the fuel pump's performance with a fuel pressure gauge.

I'm also gonna show you a simple test that involves using starting fluid to confirm whether insufficient fuel pressure might be behind your Corolla's engine no-start issue.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 1.8L (7A-FE) Toyota Corolla: 1993, 1994, 1995, 1996, 1997.

- 1.8L Geo Prizm: 1993, 1994, 1995, 1996, 1997.

Fuel Pump Circuit Wiring Diagrams:

- Fuel Pump Circuit Wiring Diagram (1993 1.8L Toyota Corolla).

- Fuel Pump Circuit Wiring Diagram (1994-1995 1.8L Toyota Corolla).

- Fuel Pump Circuit Wiring Diagram (1996-1997 1.8L Toyota Corolla).

Symptoms Of A Bad Fuel Pump

Fuel pumps typically experience two main types of malfunctions:

- Complete failure: This occurs when the pump ceases to function altogether, causing the engine to crank but not start.

- Degraded performance: In this scenario, the fuel pump continues to operate, allowing the engine to start, but it doesn't supply enough fuel to keep the engine running optimally when you shift into drive and step on the accelerator pedal. The drop in engine power and performance under load is very noticeable.

Here's what you'll see when the fuel pump fails and no longer supplies fuel to the engine:

- Engine fails to start: The engine cranks but it won't start.

- Spark test shows spark in all cylinders: A spark test confirms that all cylinders are receiving spark, ruling out any problems with the ignition system.

- Fuel injectors activated: A Noid light test reveals that the fuel injection computer is activating the injectors.

- Zero pressure reading on fuel pressure gauge: Your fuel pressure gauge will read 0 PSI fuel pressure when the pump has stopped functioning.

- Engine starts momentarily with starting fluid: Spraying starting fluid into the throttle body and cranking the engine gets the engine to start for a few seconds (before shutting down again).

When your fuel pump's performance degrades, it may still get the engine to start, but you'll see one of several noticeable issues:

- Air-fuel mixture diagnostic trouble codes (DTCs): A lower fuel pressure and volume delivered to the engine will cause a "lean" air-fuel mixture. The computer, unable to correct it, will illuminate the check engine light (CEL) with a lean air-fuel mixture DTC.

- Engine rough idle: A lean air-fuel mixture will cause the engine to run rough when it's idling as the amount of fuel supplied to the engine is not the optimal amount.

- Engine hard start: Starting the engine becomes a challenge, as you may need to crank the engine for an extended period before it finally starts.

- Lack of power: When you step on the gas pedal, the engine feels weak and sluggish in its response.

- Engine backfires: Under heavy load conditions, such as when driving at high speeds on the highway, your engine might backfire excessively through the intake manifold.

Whether the engine is not starting or has engine performance, a fuel pressure test (using a gauge) is the go-to diagnostic test, you'll need to perform to figure out the issue.

Where To Buy A Fuel Pressure Test Gauge

A fuel pressure test gauge kit is one of those tools that every DIY'er should have in their tool box. You can either purchase one at your local auto parts store or order it online.

The test kits I'm recommending below come equipped with the adapters you'll need for your 1.8L 7A-FE Toyota Corolla. They also include the adapters for GM, Ford and Chrysler vehicles equipped with a Schrader valve on the fuel injector rail.

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

NOTE: All of the fuel pump pressure test kits above have the fitting that will connect to your Toyota's fuel system.

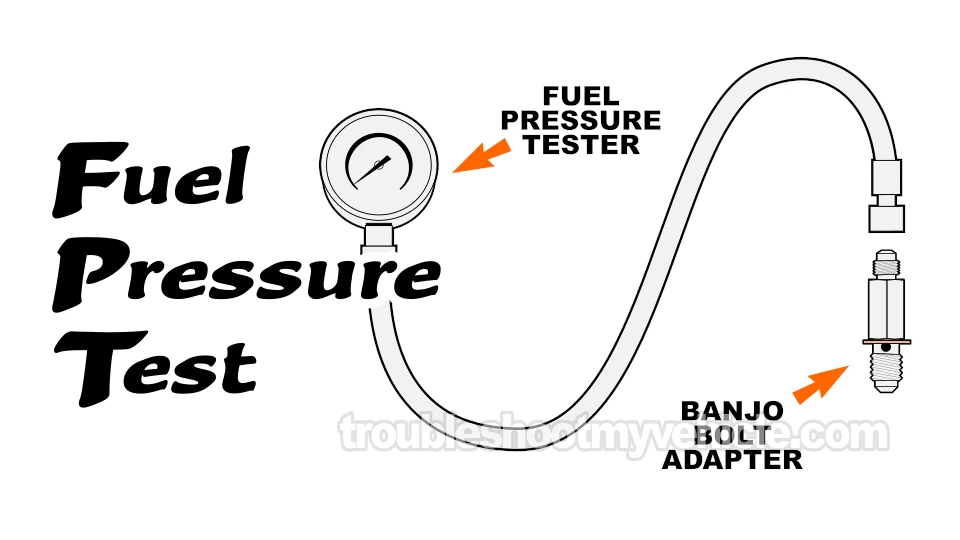

TEST 1: Checking Fuel Pressure With A Fuel Pressure Gauge

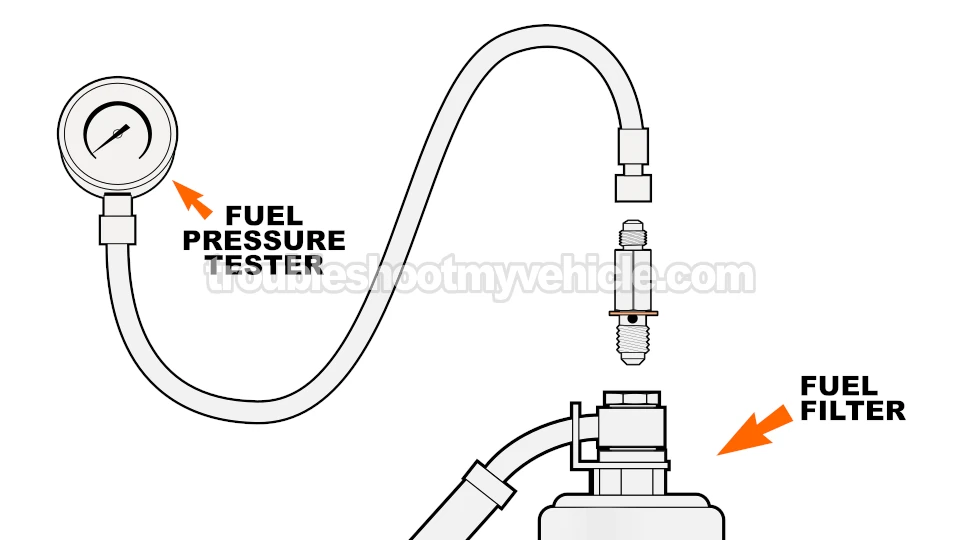

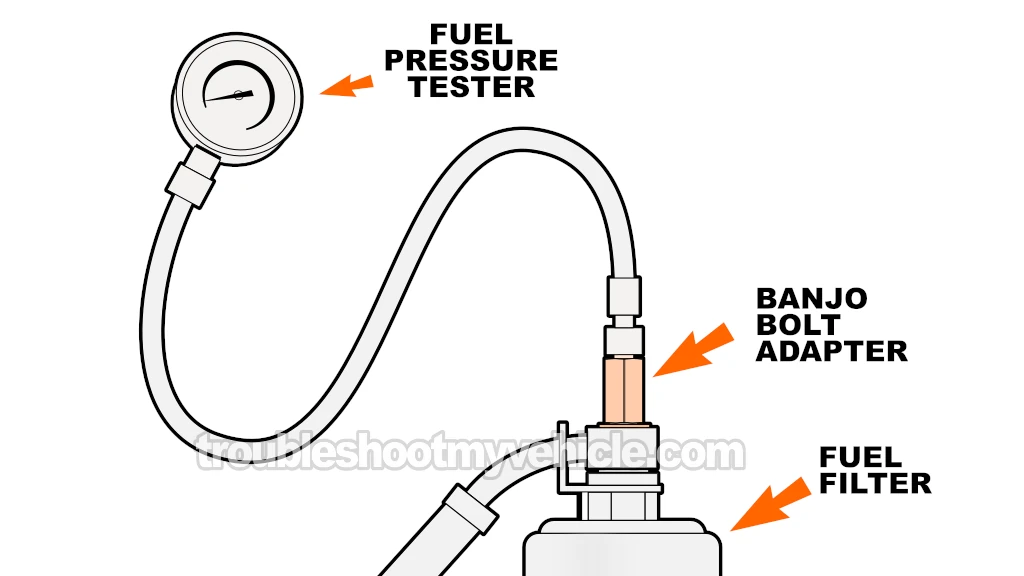

Testing your Corolla's fuel pump's fuel pressure involves connecting a fuel pressure gauge to the output side of the fuel filter.

In the instructions below, I have outlined the steps involved in this procedure. The fuel pressure gauge and adapter will be connected to the fuel filter like what is shown in the illustrations above.

Here are the fuel pressure specifications for the 1993-1996 1.8L Toyota Corolla:

| Engine Off and DLC terminals +B and FP jumpered. |

|---|

| 38-44 PSI |

| Engine running and w/out vacuum hose connected to fuel pressure reg. |

|---|

| 38-44 PSI |

| Engine running and w vacuum hose connected to fuel pressure reg. |

|---|

| 31-37 PSI |

NOTE: If you don't have a fuel pressure gauge, take a look at the section: Where To Buy A Fuel Pressure Test Gauge.

Fuel Filter Location: The fuel filter is located on the left (driver) side of the engine compartment, at the bottom of the strut tower.

Alright, here's how to test it:

- 1

To access the fuel filter, remove the upper section of the air filter assembly as well as the air duct (that connects to the throttle body).

- 2

Wrap a shop towel around the fuel filter.

This will help absorb any leaked or sprayed fuel from spraying all over, especially if there's still pressure within the line. - 3

Loosen and remove the fuel filter's union bolt.

NOTE: Careful you don't lose the two copper washers on the union bolt. These will be needed later when re-installing the union bolt back onto the fuel filter. - 4

Install the adapter from the fuel pressure test kit in place of the removed union bolt, then tighten it securely.

- 5

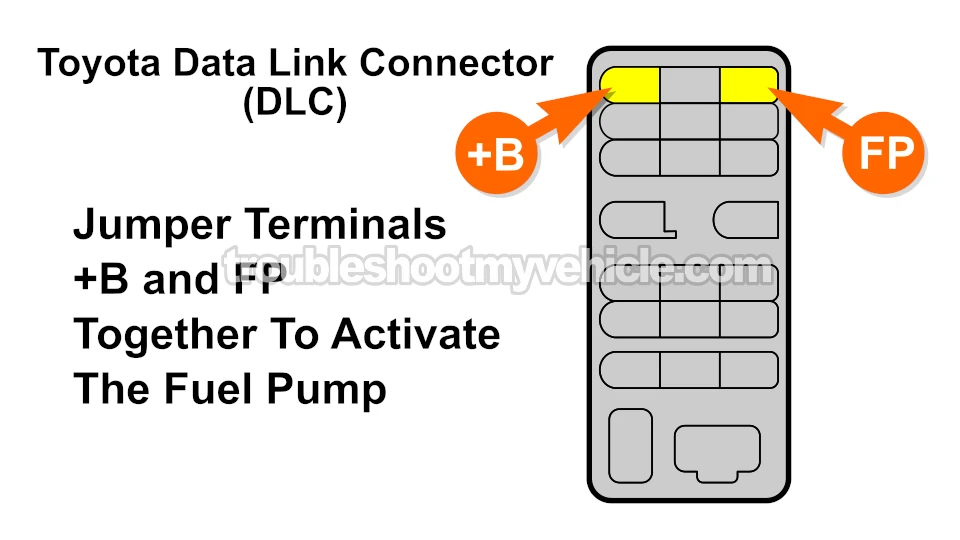

Locate the diagnostic link connector (DLC) and connect terminals +B and FP using a jumper wire.

NOTE: See illustration 4 of 4, in the image viewer, to identify these two terminals. Connecting these two terminals will activate the fuel pump when you turn the key to ON in the next step. - 6

Switch the key to ON position, but do not crank or start the engine.

IMPORTANT: Inspect the adapter connection for any fuel leaks. If leaking fuel, turn off the key and resolve the leak before proceeding —leaks can affect the accuracy of your readings. - 7

Your fuel pressure gauge should display a reading between 38-44 PSI.

NOTE: You can also check the fuel pressure while the engine is running (if the engine starts) by removing the jumper wire from the Data Link Connector, starting the engine and rechecking the gauge. Use the tables provided for the appropriate pressure specifications with the engine running.

Here's what your results mean:

CASE 1: The fuel pressure gauge displays 0 PSI. This indicates that the fuel pump isn't supplying fuel.

This test result tells you that your Corolla's engine no-start issue is due to a lack of fuel. Before you replace the fuel pump, make sure it's getting power from the Circuit Opening Relay.

CASE 2: The fuel pressure gauge reads the specified fuel pressure. This tells you that the fuel pump is functioning correctly and delivering an adequate amount of fuel to the injectors.

If your Corolla's engine is not starting, the issue is not being caused by the fuel pump.

CASE 3: The fuel pressure gauge shows a reading lower than the specified pressure (but not 0 PSI). This confirms that the fuel pump is failing and operating with degraded performance.

Although it's still delivering some fuel to the engine, it's not enough for the engine to run optimally nor efficiently. Replace the fuel pump.

TEST 2: Using Starting Fluid To Confirm Lack Of Fuel

A quick and easy way to determine if a lack of fuel is preventing the engine from starting is the starting fluid test.

This test involves spraying starting fluid into the throttle body bore, then cranking the engine to see if it starts and runs for a few seconds.

If the engine starts after spraying the fluid, then your Corolla's no-start issue is due to a lack of fuel delivery from the fuel pump.

NOTE: I've performed this test many times, and it has been a reliable first step in diagnosing fuel pump issues. I do want to point out that before conducting this test, it's very important to confirm that all four cylinders are receiving spark. So before you start, check each spark plug wire for spark with a spark tester.

IMPORTANT: After spraying starting fluid into the throttle bore, reconnect the air intake duct to the throttle body before cranking the engine. You don't need to tighten the hose clamp —just make sure it's in place. This prevents any potential backfire from spitting flames onto the engine while cranking.

Alright, let's do this:

- 1

Disconnect the intake air duct from the throttle body but leave the end that connects to the air filter box in place.

- 2

Hold open the throttle plate and spray some starting fluid into the bore.

- 3

Reconnect the air duct back onto the throttle body after spraying starting fluid.

Don't worry about tightening the hose clamp. You'll do that once the test is done. - 4

With the air duct in place, crank the engine.

- 5

You'll see one of two outcomes:

A.) The engine starts, runs for a brief period, then shuts off again.

B.) The engine fails to start altogether.

Let's interpret your results mean:

CASE 1: The engine started and ran briefly. This confirms that the no-start issue stems from the fuel pump failing to deliver fuel.

Whenever I perform this test, I still verify the fuel pump pressure with a pressure gauge and I recommend that you do the same: TEST 1: Checking Fuel Pressure With A Fuel Pressure Gauge.

CASE 2: The engine failed to start. This tells you that the engine no-start is not caused by a lack of fuel.

Even if the problem doesn't appear to be fuel-related, at this point I still perform a fuel pressure test using a gauge just to completely rule out the fuel pump. Go to: TEST 1: Checking Fuel Pressure With A Fuel Pressure Gauge.

More 1.8L Toyota Corolla Tutorials

You can find a complete list of 1.8L Toyota Corolla tutorials and wiring diagrams in this index:

Here's a sample of the tutorials you'll find there:

- How To Diagnose A Broken Timing Belt (1993-1997 1.6L Toyota Corolla).

- How To Test The Throttle Position Sensor (1993-1997 1.8L Toyota Corolla).

- How To Do A Cylinder Balance Test (1993-1997 1.8L Toyota Corolla).

- How To Test For A Blown Head Gasket (1993-2008 1.8L Toyota Corolla).

If this info saved the day, buy me a beer!