The engine compression test is usually done to find out the internal health of the engine.

But it'll also help you to find out if a misfire is being caused by a cylinder or cylinders with low compression.

In this tutorial I'm gonna' explain how to test the compression of the 5.2L V8 engine in the 1993-1998 Jeep Grand Cherokee. I'm also explaining how to interpret your test results.

Contents of this tutorial:

Symptoms Of Engine Compression Problems

Generally, engine compression problems can be lumped into one of two categories. Either the compression problem causes the engine to not start.

Or the engine compression problem causes a misfire condition. To be a bit more specific, the engine still starts and runs, but runs with a misfire.

If the engine is misfiring, due to a compression problem and your 5.2L Jeep Grand Cherokee is OBD II equipped, you'll see one or more of the following trouble codes:

- P0300: Random Cylinder Misfire.

- P0301: Cylinder #1 Misfire.

- P0302: Cylinder #2 Misfire.

- P0303: Cylinder #3 Misfire.

- P0304: Cylinder #4 Misfire.

- P0305: Cylinder #5 Misfire.

- P0306: Cylinder #6 Misfire.

- P0307: Cylinder #7 Misfire.

- P0308: Cylinder #8 Misfire.

You'll also see:

- Rough idle condition that does not set a misfire trouble code.

- Bad gas mileage.

- Heavy exhaust smell coming out of the tailpipe when the engine is running.

Important Tips And Suggestions

TIP 1: Do not remove the spark plugs from a hot engine.

If your Jeep Grand Cherokee's 5.2L V8 engine has been running for any length of time, you need to let it cool down for at least an hour before attempting to remove the spark plugs.

Attempting to remove the spark plugs from a hot engine can damage the threads in the spark plug holes. This is a nightmare you want to avoid.

TIP 2: Use a spark plug wire puller to disconnect the spark plug wires from the spark plugs.

Using a spark plug wire puller will help you avoid damaging the spark plug wires when disconnecting them from the spark plugs.

To see an example of this tool, check out this article: How To Use A Spark Plug Wire Puller And Where To Buy One (at: easyautodiagnostics.com).

Which Compression Tester Should I Buy?

There are lot of engine compression testers to choose from and many places to buy them. I'm gonna' make these recommendations to you:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

TEST 1: Dry Engine Compression Test

To get the most accurate result from your engine compression test, you need to test all 8 cylinders.

If you don't have an engine compression tester, you can run down to your local auto parts store and buy or rent it there. If you'd like to save a few bucks on its purchase, check out my recommendations here: Which Compression Tester Should I Buy?

Let's get testing:

- 1

Remove the spark plugs.

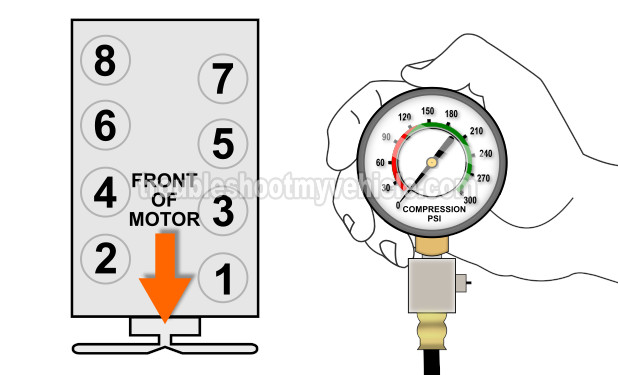

When removing the spark plugs, be careful not to drop any of them on the floor, or you run the risk of having the spark plugs porcelain insulator crack and then you'll have a misfire on your hands. - 2

Thread the engine compression gauge into the spark plug hole for the number 1 engine cylinder.

Hand tighten the compression gauge only! Do not use any type of tool to get it tight. - 3

Have your helper crank the engine till the needle on the compression gauge stops climbing.

- 4

Record the value at which the needle stopped and the number of the engine cylinder on a piece of paper.

- 5

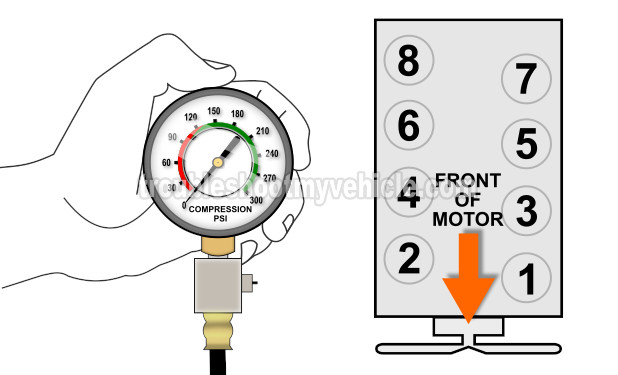

Repeat steps 2-4 on the remaining cylinders.

Let's take a look at what your compression test results mean:

CASE 1: You got 0 PSI in the majority of the cylinders. This tells you that your Jeep Grand Cherokee's engine has serious internal problems. This is usually due to:

- Busted timing chain.

- Engine threw a rod.

Any compression value below 100 PSI (even if it's not 0 PSI) means internal mechanical engine trouble.

CASE 2: All cylinders have compression but their values are not the same. It's normal for each cylinder's compression value to vary slightly from one another. But if they vary too much, you'll have a bonafide misfire or rough idle condition on your hands.

To find out, the next step is to go to: Interpreting The Engine Compression Test Results.

Interpreting The Engine Compression Test Results

It's normal for the cylinder compression values to vary a bit, since the cylinders don't wear out at the exact same rate.

The more wear and tear and engine has, the more these values will vary. What will cause a misfire or rough idle condition is when the lowest cylinder compression value varies by more than 15% of the highest cylinder compression value.

The cool thing is that figuring out if the cylinder is 'dead' due to low compression is not difficult at all.

You can do this one of two ways: You can calculate this 15% difference with pen and paper or you can use my low compression calculator. You can find the low compression calculator here: Online Low Engine Compression Calculator (at: easyautodiagnostics.com).

If you want to manually calculate the 15% difference, here's what you'll need to do:

- STEP 1: Multiply the highest compression value by 0.15 (this is the decimal value of 15%).

- STEP 2: Round the result to the nearest one (for example: 25.6 would become 26).

- STEP 3: Subtract the result (the number that was rounded) from the highest compression value.

- ANSWER: The result of this subtraction is the lowest possible compression value any cylinder can have.

Now, let me give you a more specific example: Let's say that I got the following compression readings:

| Cylinder | Pressure |

|---|---|

| #1 | 165 PSI |

| #2 | 95 PSI |

| #3 | 155 PSI |

| #4 | 175 PSI |

| #5 | 160 PSI |

| #6 | 165 PSI |

| #7 | 160 PSI |

| #8 | 165 PSI |

My next step is to do the following calculation:

- STEP 1: 175 x 0.15 = 26.25.

- STEP 2: 26.25 = 26 (rounded to nearest one).

- STEP 3: 175 - 26 = 149.

- ANSWER: 149 PSI. Any cylinder with this compression (or lower) value will misfire.

Since cylinder #2 is only producing 95 PSI, I can now conclude that it's 'dead' and causing a misfire.

To find out if the lowest compression value you got from your engine compression test is within a good range, you'll need to do the same calculation. Of course, you'll need to use the highest compression value you got and not the one in the example.

Once you've found the 'dead' cylinder, the next step is to find out what's causing the low compression value. For this step, go to: TEST 2: Wet Engine Compression Test.

TEST 2: Wet Engine Compression Test

Generally, two problems cause a cylinder to have low or 0 PSI compression value. These are:

- The cylinder's valves (in the cylinder head) are worn or damaged.

- The cylinder's piston rings are worn.

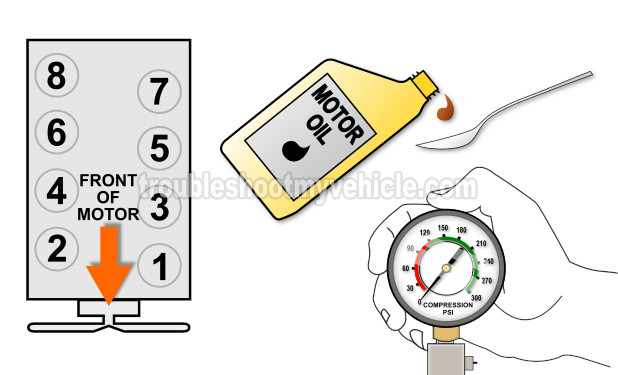

The cool thing is that we can easily find out by doing a 'wet' compression test. This test simply involves adding a small quantity of engine oil to the cylinder with low or 0 PSI compression and retesting its compression.

If the compression value, of that 'dead' cylinder increases, then you can conclude that its piston rings are the cause of the low or 0 PSI compression problem.

If the compression value does not increase, then you can conclude that its cylinder head valves are the ones behind the low or 0 PSI compression problem.

These are the test steps:

- 1

Add a tablespoon (or two) of engine oil in the cylinder you need to retest.

Use a funnel to make sure that the oil reaches the inside of the cylinder. - 2

Install the compression gauge on the cylinder and hand tighten it.

- 3

Have your helper crank the engine till the needle stops climbing on the compression gauge.

- 4

You'll see one of two results:

1.) The needle will climb higher than the previous compression number you recorded for this specific cylinder.

2.) The needle will not move at all or stay at the same number you recorded earlier.

What ever value your compression tester reads, write it down again. - 5

If you have another cylinder to test, repeat steps 1 thru' 4 on it now.

Let's take a look at what test results mean:

CASE 1: The compression value increased. This tells you that the low compression problem is due to worn piston compression rings.

CASE 2: The compression value DID NOT increase (in other words, it stayed the same). This result tells you that the low compression value registered in this cylinder (in the dry test) is due to worn/damaged cylinder head valves.

More 5.2L Jeep Grand Cherokee Tutorials

You can find a complete list of 5.2L Jeep Grand Cherokee tutorials in this index:

Here's a small sample of the tutorials you'll find in the index:

- How To Test The Camshaft Position Sensor (1993-1997 5.2L Grand Cherokee).

- How To Test A Blown Head Gasket (1993-1998 5.2L Grand Cherokee).

- How To Test The MAP Sensor (1993-1996 5.2L Grand Cherokee).

- Ignition System Wiring Diagram (1996-1998 5.2L Jeep Grand Cherokee).

If this info saved the day, buy me a beer!