This step-by-step tutorial will show you how to test the spark plug wires, distributor cap/rotor, and the ignition coil using simple tools like a spark tester and a multimeter.

So, if your 3.0L V6 Honda Accord isn't starting —or it's running rough with a misfire— and you suspect the ignition system is to blame, I'll help you figure it out.

You don't need a scan tool or fancy equipment to get solid answers. Each test is laid out in plain English, so you can follow along and zero in on the root cause.

Let's get started and find out what's keeping your Honda from running right.

Contents of this tutorial:

- Symptoms Of Ignition System Component Failure.

- TEST 1: Checking For Spark On All Plug Wires.

- TEST 2: Checking For Spark At The Distributor Cap.

- TEST 3: Checking The Ignition Coil's High Tension Wire For Spark.

- TEST 4: Checking For Spark Directly On The Ignition Coil.

- TEST 5: Confirming The Ignition Coil Is Getting 12 Volts.

- TEST 6: Confirming The Ignition Coil Is Getting An Activation Signal.

- More 3.0L V6 Honda Accord Diagnostic Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 3.0L V6 Honda Accord: 1998, 1999.

- 3.0L V6 Acura CL: 1997, 1998, 1999.

IGNITION SYSTEM WIRING DIAGRAM: The following wiring diagram complements the info in this tutorial.

IGNITION SYSTEM DIAGNOSTIC TESTS:

- How To Test The Ignition Control Module (1998-1999 3.0L V6 Honda Accord).

- How To Test The CMP Sensors (1998-2002 3.0L V6 Honda Accord).

Symptoms Of Ignition System Component Failure

The ignition system on the 1998–1999 3.0L V6 Honda Accord is a mechanical distributor setup. That means spark is generated and routed by several key components —like the ignition coil, ignition control module, rotor, distributor cap, and spark plug wires. When any of these parts fail, the engine will either refuse to start, or it'll run rough due to a misfire.

There are two main types of problems you'll see when an ignition component stops working:

- Engine no-start: This happens when the coil or ignition control module completely fails and stops spark from reaching the cylinders.

- Cylinder misfire: A single component (like a spark plug wire, rotor, or cap) may fail intermittently or only affect one cylinder, causing the engine to run rough but still start.

Here's a list of common symptoms to watch for when diagnosing ignition issues:

- OBD II misfire trouble codes like P0300, P0301, P0302, etc.

- Rough or unstable idle.

- Engine hesitation or stumbling under load.

- Poor gas mileage.

- Lack of power when accelerating.

- Strong fuel smell from the tailpipe.

- No-start condition with no spark during cranking.

- Occasional or random misfires that come and go.

If your Honda is suffering from a misfire problem, I've got a full tutorial that dives deeper into the most common causes, how to test them and resolve them:

TEST 1: Checking For Spark On All Plug Wires

To get to the bottom of a no-start or misfire problem, the first thing you need to know is whether or not spark is reaching all six spark plugs.

This is a very simple test but it has to be done with a dedicated spark tester to get an accurate test result. You can use any spark tester you own. If you don't have one and need to buy one, this is the one I use and recommend:

- OTC 6589 Electronic Ignition Spark Tester (Amazon affiliate link).

Once you've check all six spark plug wires for spark, the results will point you to the next test.

NOTE: As you're disconnecting the spark plug wire and taking it out of it the spark plug well (tube), check it to see if it's soaked in oil or if it has any visible damage. If they're swimming in engine oil, you've found an issue that causes cylinder misfires and you'll need to replace valve cover gaskets (especially the spark plug tube seals), the wires and spark plugs.

Let's get started:

- 1

Disconnect one of the spark plug wires from its spark plug.

- 2

Connect your HEI spark tester (or similar tool) to the end of that wire.

- 3

Use a battery jumper cable to Ground the spark tester to the negative (-) battery post.

- 4

Now have someone crank the engine while you watch the tester for spark.

- 5

You're going to see one of two things: A visible spark —or nothing at all.

- 6

Repeat this check on the remaining five spark plug wires one by one.

Let's interpret that test result:

CASE 1: You got spark on all of the spark plug wires. That's a good sign —the ignition coil, distributor, CMP and CKP sensors and ignition control module (ICM) are working correctly.

If the engine still isn't starting, your next step is to check for fuel delivery and verify engine mechanical condition (like timing belt integrity and compression). See:

CASE 2: None of the six spark plug wires sparked. This confirms that a lack of spark is behind the engine's no-start problem.

It could be a failed ignition coil, a bad ignition control module, or even a worn-out distributor cap and rotor.

To find out, your next step is to see if the high tension wire, that delivers the spark from the ignition coil to the distributor cap, is actually delivering spark. Go to: TEST 3: Checking The Ignition Coil's High Tension Wire For Spark.

CASE 3: You got spark on some but not all of the spark plug wires. That usually points to one of the following:

- A bad spark plug wire.

- A problem with the distributor cap (the contacts inside are burned or corroded).

Your next step is to now check for spark directly on the towers, on the distributor cap, where those non-sparking spark plug wires connect to. Go to: TEST 2: Checking For Spark At The Distributor Cap.

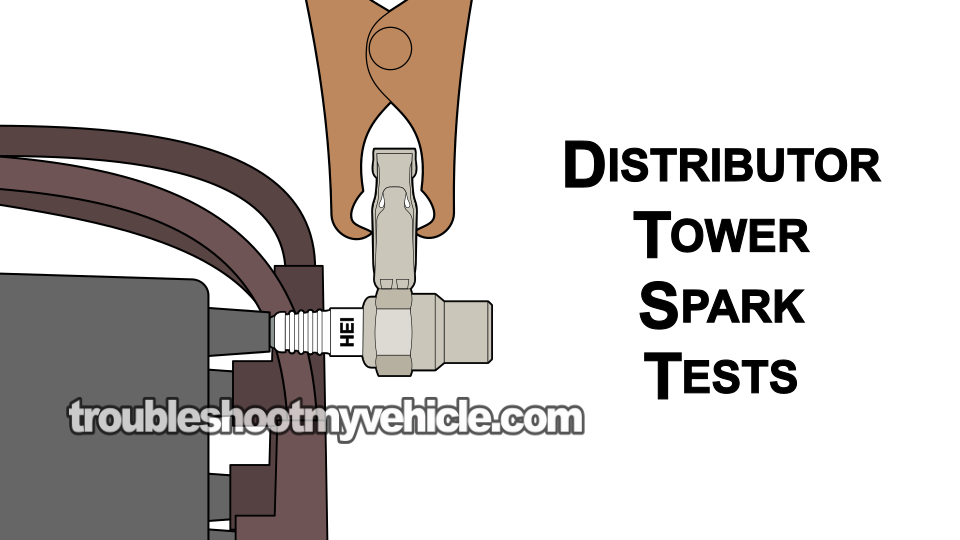

TEST 2: Checking For Spark At The Distributor Cap

If one or more plug wires failed the spark check in TEST 1, then it's time to take a closer look at the distributor cap itself.

As the distributor cap wears out over time, the metal terminals inside each tower can start to corrode. Every time the rotor swings past a terminal, the spark has to jump a small air gap —and that constant arcing slowly eats away at the metal.

Eventually, one or more towers can become so corroded or pitted that the spark either weakens or stops altogether. When that happens, the spark never makes it through to the plug wire. And if there's no spark, that cylinder's going to misfire every time.

In this test, you'll use a spark tester to find out whether that distributor tower is actually delivering spark or not.

Time to get to work:

- 1

Disconnect the plug wire (the one that didn't spark) from its distributor cap tower.

- 2

Insert your spark tester directly into the distributor tower.

- 3

Use a jumper cable to Ground the spark tester to the battery's negative (-) terminal.

- 4

Have someone crank the engine while you watch for spark at the tester.

- 5

One of two things will happen: either you'll see spark —or you won't.

Alright, let's find out what it all means:

CASE 1: You got spark. That means the distributor cap tower (of the non-sparking spark plug wire) is doing its job.

In this case, the spark plug wire you removed (and that did not spark in TEST 1) is bad —it needs to be replaced.

It's also a good idea to replace all of the spark plug wires as a set, since the others may not be far behind. And even though this test confirms the distributor cap tower is working, if the cap and rotor are as old —or older— than the wires, they should be replaced too as part of a proper tune-up.

CASE 2: You got NO spark. That tells you the distributor cap is bad.

To get spark flowing to that misfiring cylinder again, you'll need to replace both the distributor cap and rotor.

And now that you've tracked down the source of the no-spark issue, it's a good idea to replace all of the spark plug wires too —especially if they're as old as the cap and rotor— as part of a proper tune-up.

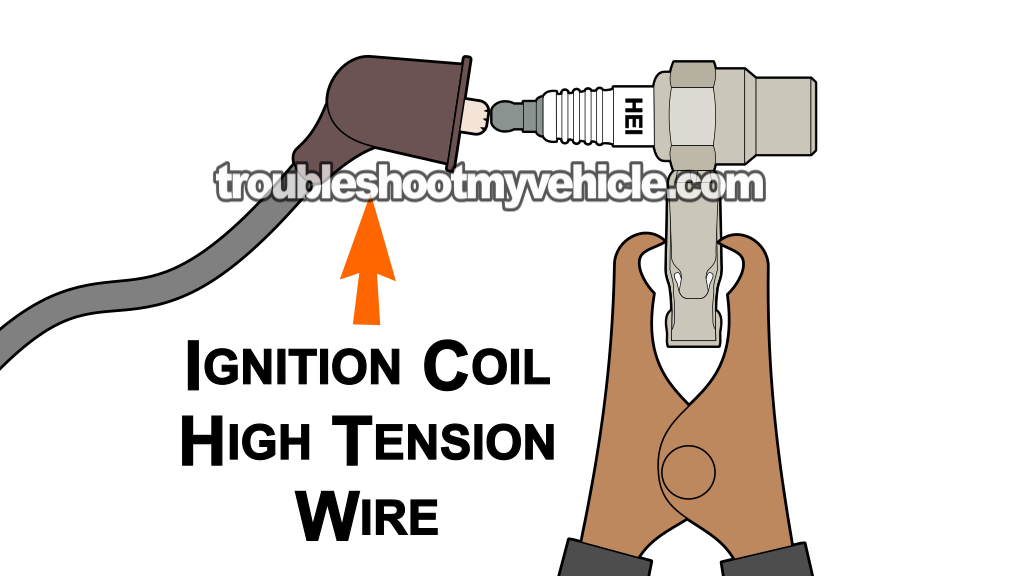

TEST 3: Checking The Ignition Coil's High Tension Wire For Spark

If none of the spark plug wires fired in TEST 1, the next thing to check is whether the ignition coil is actually sending spark to the distributor.

The first part of this ignition coil check is to test the high tension wire —the thick wire that runs from the coil to the center of the distributor cap— for spark.

If that high tension wire isn't delivering spark, then none of the plug wires will fire, even if the ignition coil is good.

Depending on your spark test result, you'll know if the issue lies with the wire itself or if we need to continue digging deeper.

Here's the game plan:

- 1

Unplug the ignition coil's high tension wire from the distributor cap (leave the other end connected to the coil).

- 2

Remove the distributor cap from the distributor.

This will help you see if the distributor rotor turns. - 3

Attach your spark tester to the loose end of the wire —the one that normally connects to the center of the distributor cap.

NOTE: You'll need to use a strip of black electrical tape to secure the spark tester to the metal terminal of the wire (see image 2 of 2). - 4

Have your assistant crank the engine while you do two things: (1) watch the spark tester for spark, and (2) confirm the rotor inside the distributor is spinning.

- 5

One of two results will show up: either you'll get spark —or you won't.

Let's break down what your results mean:

CASE 1: You got spark and the distributor rotor turns. That tells you the ignition coil is firing correctly, the high tension wire is good, and the timing belt is OK (since the distributor rotor is turning).

Since the high tension wire is sparking, the problem is with the distributor rotor and cap not transmitting spark to all six spark plug wires.

You'll need to replace the distributor cap and rotor to get spark going to the spark plugs. Now, if the spark plug wires are as old as the distributor cap and rotor, it's a good idea to replace them too.

CASE 2: You got NO spark and the distributor rotor DOES NOT turn. This means the distributor isn't spinning because the timing belt is broken.

Without the belt turning the camshaft, the CMP sensors don't generate their signals and the PCM doesn't activate the ignition control module —which means no spark from the ignition coil.

Your next step is to inspect the timing belt and confirm it's snapped. If so, you've found the root cause of your Accord's engine no-start.

CASE 3: You got NO spark and the distributor rotor DOES turn. The rotor is moving, so the timing belt is intact.

We now need to go one step further and test for spark right at the ignition coil's tower. Go to: TEST 4: Checking For Spark Directly On The Ignition Coil.

TEST 4: Checking For Spark Directly On The Ignition Coil

So far, you've checked:

- None of the plug wires are sparking (TEST 1).

- The ignition coil's high tension wire is not sparking (TEST 3).

Now it's time to test the ignition coil itself —the heart of the spark system because if it's not firing, the engine won't start.

This quick test will tell you if the coil is doing its job or if we need to continue digging a little deeper.

Let's get this pot of water boiling:

- 1

Unplug the high tension wire from the ignition coil's tower.

- 2

Insert the HEI spark tester directly into the coil's tower.

NOTE: To keep the spark tester securely in place, use a battery jumper cable as shown in the photo above. - 3

Have your assistant crank the engine while you hold the tester and watch for spark.

- 4

You're either going to see spark —or you won't.

Let's break down what those results are telling you:

CASE 1: You got spark. That confirms the ignition coil is doing its job —the problem is the high tension wire itself. It's not carrying the spark to the distributor, which means it's worn out or damaged.

Replace it, and while you're at it, swap out the entire set of spark plug wires. A bad coil wire usually means the others aren't far behind.

CASE 2: You got NO spark. If the coil isn't firing at all, then we need to dig deeper.

It could be a power supply issue, a failed ignition control module, or the coil itself may be bad. Your next step is to make sure the ignition coil is actually getting power. Go to: TEST 5: Confirming The Ignition Coil Is Getting 12 Volts.

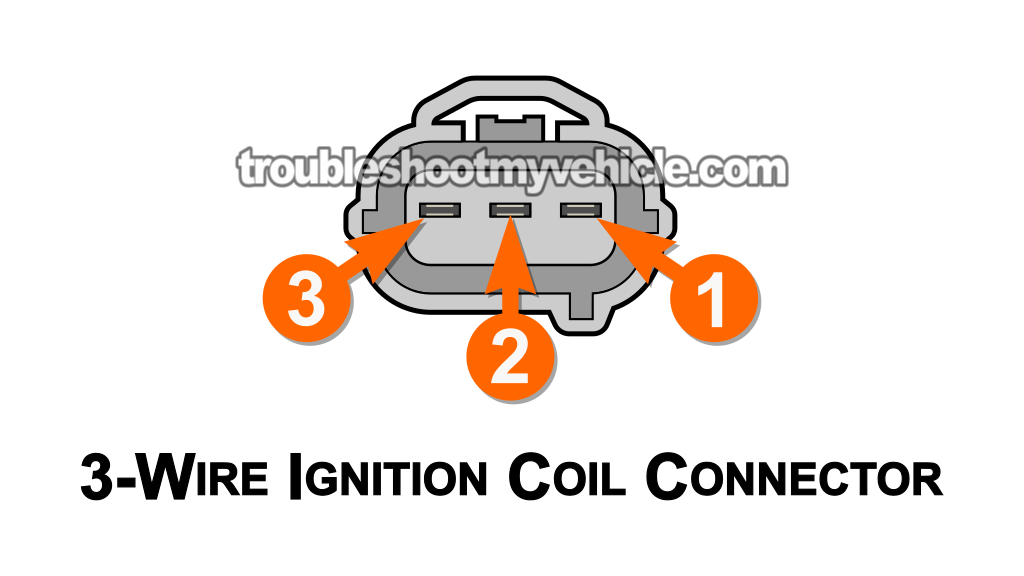

TEST 5: Confirming The Ignition Coil Is Getting 12 Volts

Before concluding the ignition coil is toast, we need to make sure it's actually getting power, since without it, it won't fire spark.

The coil has three wires coming out of its connector —and one of them delivers battery voltage whenever the key is in the ON or START position.

This test will tell you if the middle black with yellow stripe (BLK/YEL) wire (that connects to female terminal 2) is bringing 10 to 12 Volts from Fuse #6 in the under-dash fuse/relay box.

Let's get going:

- 1

Turn the key to the ON position, but don't crank the engine.

- 2

Disconnect the ignition coil connector so you can access the terminals inside.

- 3

Set your multimeter set to DC Volts.

- 4

Connect the black multimeter test lead to the battery negative (-) post.

- 5

Gently probe the middle BLK/YEL wire's female terminal at the front of the connector.

NOTE: Only the middle BLK/YEL wire of the connector delivers 12 Volts. - 6

You should see 10 to 12 Volts with the key in the ON position.

Let's see what your results mean:

CASE 1: You got 10 to 12 Volts. That means the ignition coil is getting power.

The next step is to check if the coil is receiving the activation signal from the ignition control module. Go to: TEST 6: Confirming The Ignition Coil Is Getting An Activation Signal.

CASE 2: You did NOT get 10 to 12 Volts. That means the coil has no power —and it won't spark without it.

Check Fuse #6 (15 Amp) in the under-dash fuse/relay box. If the fuse is blown replace it and repeat this test section.

If the fuse isn't blown, then the BLK/YEL wire probably has an open-circuit problem between the connector and the fuse box. Your next step is to troubleshoot the issue and restore power to the circuit.

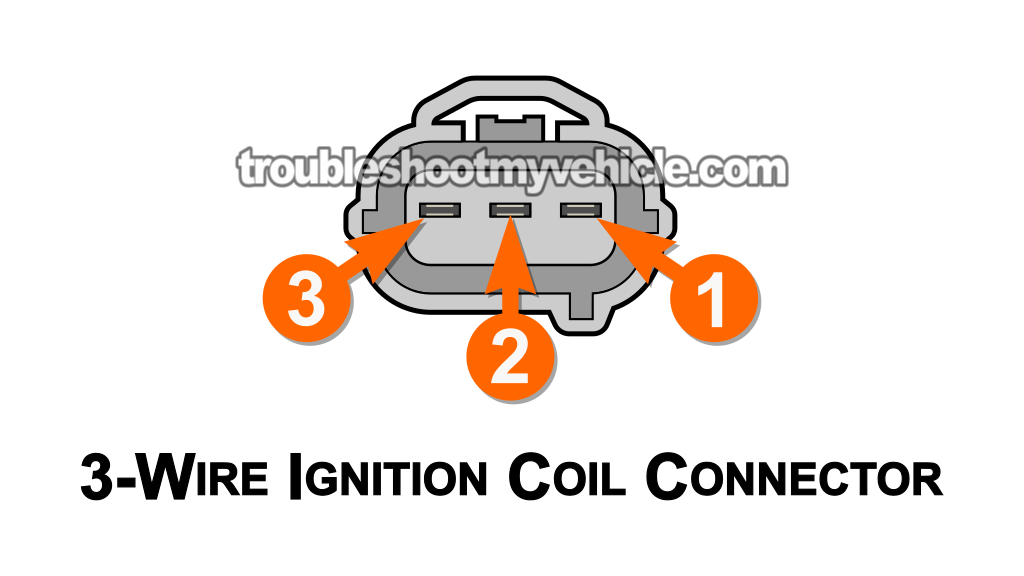

TEST 6: Confirming The Ignition Coil Is Getting An Activation Signal

Now that you've confirmed the ignition coil is getting power from the middle BLK/YEL wire, the next piece of the puzzle is to check for the activation signal.

This signal is delivered by the ignition control module (ICM), which lives inside the distributor. Without this signal, the coil won't fire spark.

In this test, you'll use a test light to check if the ignition control module is pulsing the BLU wire during cranking.

If you don't have a 12V automotive test light, this is the one I use and recommend:

- Lisle 28400 Heavy Duty 12 Volt Test Light (Amazon affiliate link)

IMPORTANT: Both the ignition coil and the distributor must remain connected to their 3-wire connectors to be able to check the ignition coil's activation signal.

Let's find out if the coil is being told to spark:

- 1

Turn the ignition key to the OFF position.

- 2

Connect the test light's clip to the battery positive (+) terminal.

- 3

Probe the BLU wire terminal with the tip of the test light.

You'll need to pierce the BLU wire with the test light's metal probe. - 4

Have your helper crank the engine while you watch the test light.

- 5

The 12V test light should pulse (flash) ON/OFF as long as the engine is being cranked.

- 6

Once done, wrap the BLU wire, where it was punctured, with black electrical tape.

Here's what those results mean:

CASE 1: The test light flashed ON and OFF while cranking. That's exactly what you want —the ignition control module is doing its job and activating the coil correctly.

This tells you the ignition coil itself is the fried and is causing the engine no-spark no-start problem. Replace it.

- Standard Motor Products UF179 Ignition Coil (Amazon affiliate link).

CASE 2: The test light did NOT flash at all. That means the ignition coil isn't getting an activation signal from the ignition control module (ICM).

The ICM (located inside the distributor) is probably bad. We can very easily confirm this and I'll show you how in this step-by-step tutorial:

More 3.0L V6 Honda Accord Diagnostic Tutorials

In the following index, you can find a complete list of real-world how-to guides written with both DIYers and experienced techs in mind.

Here's a quick peek at some of the step-by-step tutorials you'll find there:

- How To Troubleshoot A No Start (1998-2007 3.0L V6 Honda Accord).

- How To Test For A Broken Timing Belt (1998-2007 3.0L V6 Honda Accord).

- How To Test a Misfire Condition and Misfire Codes (3.0L V6 Honda Accord).

- How To Test Engine Compression (1998-2007 3.0L V6 Honda Accord).

If this info saved the day, buy me a beer!