Testing the camshaft position (CMP) sensors on your 1998–2002 3.0L V6 Honda Accord isn't as hard as it seems.

In fact, with just a basic multimeter and a few minutes of your time, you can find out if the CMP sensor assembly is good or bad.

This tutorial will walk you through two simple tests: a resistance check and a live signal test while cranking the engine.

Let's get started.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 3.0L V6 Honda Accord: 1998, 1999, 2000, 2001, 2002.

IGNITION SYSTEM WIRING DIAGRAM: The following wiring diagram complements the info in this tutorial.

IGNITION SYSTEM TESTS:

- How To Test The CKP Sensor (1998-2002 3.0L V6 Honda Accord).

- How To Test The Coil-On-Plug Ignition Coil (2000-2003 3.0L V6 Honda Accord).

Symptoms Of A Bad CMP Sensor

The camshaft position (CMP) sensors on your 3.0L V6 Honda Accord play a key role in helping the fuel injection and ignition systems stay in sync with the rotation of the engine. If one or both of these sensors fail, you're going to notice problems —some mild, some that'll stop the engine from running altogether.

Here's what you might see if one or both CMP sensors go bad:

- Extended cranking or a no-start condition —the engine may crank for longer than usual or not start at all, especially if the PCM isn't receiving a reliable cam signal during startup.

- Rough idle or stalling —a faulty signal can throw off ignition timing just enough to make the engine stumble at idle or stall while slowing down or idling at a stoplight.

- Poor acceleration or loss of power —you might notice hesitation when pressing the gas, or that the engine struggles to rev smoothly, particularly above 4,000 RPM.

- Check Engine Light (CEL) is on —you may see trouble codes:

- P1361:: TDC 1 Sensor Intermittent Interruption.

- P1362:: TDC 1 Sensor No Signal.

- P1366:: TDC 2 Sensor Intermittent Interruption.

- P1367:: TDC 2 Sensor No Signal.

- Intermittent misfire —if the signal from one sensor cuts out intermittently, it can confuse the PCM and lead to occasional misfires without setting a specific cylinder code.

- Failing emissions test —a weak or erratic cam signal can cause timing issues that increase emissions, even if the car still runs relatively well.

In many cases, these symptoms come and go —especially if the failure is heat-related or wiring-related. That's why we'll walk through a few solid tests to confirm if your CMP sensors are actually to blame before throwing parts at the problem.

If your Honda is suffering from an engine no-start problem, I've got a full tutorial that dives deeper into the most common causes, how to test them and resolve them:

CMP Dual Sensor Connector Location

The camshaft position (CMP) sensor assembly on the 1998–2002 3.0L V6 Honda Accord is located right behind the camshaft gear of bank 2 —that's the cylinder head on the radiator side of the engine compartment (cylinders 4, 5, and 6).

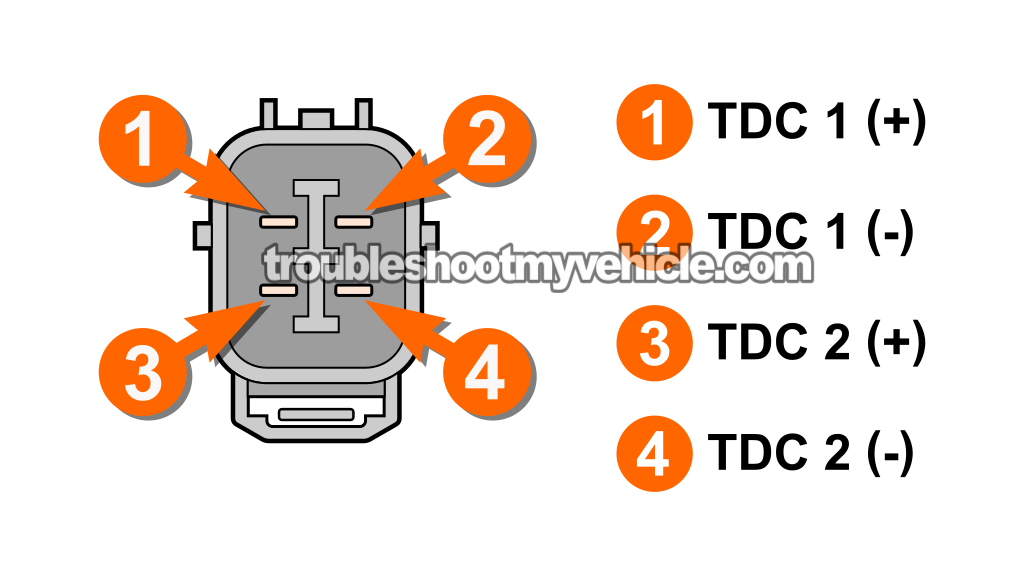

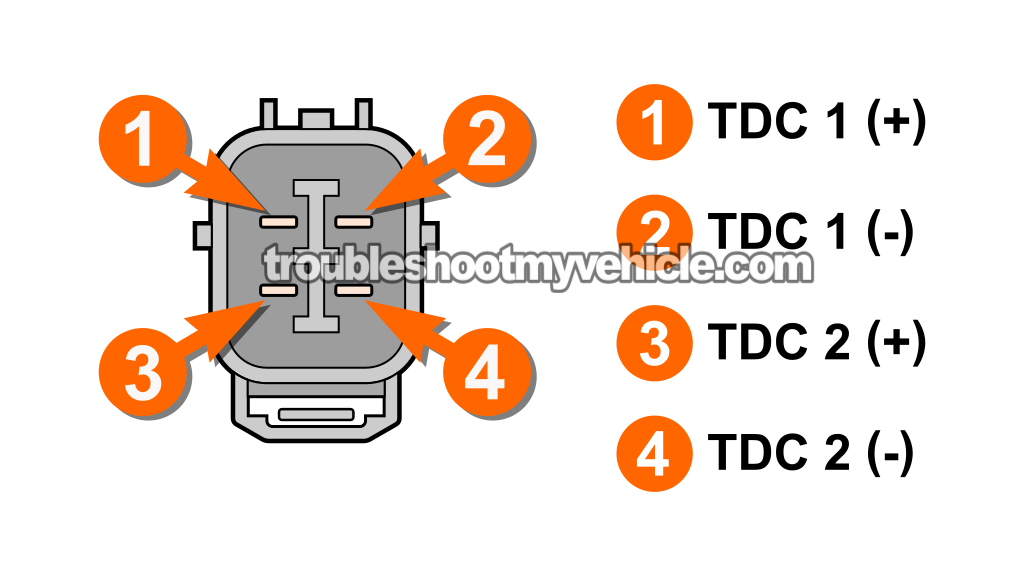

This sensor assembly contains two individual sensors (DTC 1 and DTC 2) and connects to a single 4-wire connector.

This 4-wire connector is located between the power steering pump and the top timing belt cover for the Bank 2 cylinder head. In the image above, the arrow points to its exact location.

Here's the good news: to test the CMP sensors, you do not need to remove the timing belt or the plastic timing belt cover. Just disconnect the sensor connector, and you'll be able to check resistance and signal while everything is still bolted up.

Now the bad news: if either sensor is confirmed bad and you need to replace the CMP assembly, you'll have to remove the timing belt and the camshaft gear to get it change it out.

So before replacing anything, we'll run a couple of quick tests that'll help us confirm if the sensor is fried.

TEST 1: Checking The Resistance Of CMP Sensors

In this first test, we're going to check the internal resistance of the two CMP sensors that make up the dual sensor assembly.

The goal is to find out whether each sensor —TDC 1 and TDC 2— falls within the factory spec of 1,850 to 2,450 Ohms (Ω).

We can tell the sensors apart by their connector terminals and wire colors:

- TDC 1: Connector terminals 1 and 2 —wire colors green (GRN) and red (RED).

- TDC 2: Connector terminals 3 and 4 —wire colors yellow (YEL) and black (BLK).

Now, if your multimeter shows a 0 Ohms reading (which means the sensor is shorted internally), or an infinite Ohms reading (which means the circuit is open), or anything outside the specified range, that's a clear sign the CMP sensor assembly is bad and needs to be replaced.

If you don't have a multimeter on hand —this is the exact one I use and recommend. It's affordable, reliable, and perfect for this kind of diagnostic work:

- Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (Amazon affiliate link).

NOTE: This test —and TEST 2— are performed on the 4-wire CMP sensor connector that has the male spade terminals. This is the connector that's part of the CMP dual sensor assembly itself. The other connector, which has the female terminals, belongs to the engine wiring harness and its wires lead to the PCM.

Let's kick things off:

- 1

Disconnect the CMP sensor's 4-wire connector.

- 2

Set your multimeter to Ohms (Ω).

- 3

Measure TDC Sensor 1: Probe male terminals 1 and 2.

You should see a resistance reading between approximately 1,850 to 2,450 Ohms. - 4

Now measure TDC Sensor 2: Probe the other pair of male terminals (3 and 4).

This second sensor should show similar resistance —again between 1,850 to 2,450 Ohms.

Let's interpret your test result:

CASE 1: Both sensors show resistance within spec. That's good news. The sensors aren't internally damaged.

Next, we need to check the signals they produce while the engine is cranking. Go to: TEST 2: Checking The CMP Sensor Signals With The Engine Cranking.

CASE 2: One or both sensors show resistance out of spec. That's a clear sign the sensor assembly is bad. Replace the CMP dual sensor assembly.

TEST 2: Checking The CMP Sensor Signals With The Engine Cranking

Each sensor —TDC 1 and TDC 2— generates an AC voltage signal when the engine is cranking or running, which we can easily detect with a multimeter set to Volts AC mode.

So in this test, we'll connect our multimeter to the appropriate terminals and check if both camshaft position (CMP) sensors are actually producing a signal (while the engine is cranking).

Since the sensors rely on the rotation of the camshaft to generate a signal, the faster the engine cranks, the stronger the AC voltage output —and the easier it'll be to catch that signal on your multimeter.

That's why it's important to make sure your battery is fully charged before testing the CMP sensor signals. If your battery is weak or low, take a moment to recharge it so you can get an accurate result.

Also, I recommend using jumper wires with insulated alligator clips to connect your multimeter test leads to the male spade terminals of the CMP sensor's 4-wire connector. Since the engine will be cranking during the test, holding the test leads steady by hand is gonna be a challenge. If you don't have any jumper wires, here's a link to the ones I use and recommend:

- Jumper Wires With Insulated Alligator Clips (Amazon affiliate link).

CAUTION: Be careful when working near the engine while it's cranking. Keep hands, tools, and clothing away from moving parts like the serpentine belt and power steering pump pulley to avoid injury.

This is what you need to do:

- 1

Fully charge the battery if it's low or weak.

A weak battery will cause the engine to crank slowly, which can prevent the CMP sensors from generating a strong AC signal. - 2

Set your multimeter to Volts AC.

- 3

Connect your multimeter test leads to TDC 1 sensor male terminals 1 and 2.

I recommend using jumper wires with insulated alligator clips to connect your multimeter test leads to the male spade terminals of the CMP sensor's 4-wire connector. - 4

Have a helper crank the engine while you watch the multimeter.

- 5

You should see an AC voltage reading between 0.7 and 1.2 Volts AC.

- 6

Repeat the test for the TDC 2 sensor.

Probe the other two male spade terminals (3 and 4) in the connector and crank the engine again.

You should see a similar AC voltage output.

Let's interpret your test results:

CASE 1: TDC 1 sensor output is 0 Volts AC. That confirms TDC 1 sensor is not generating a signal. The CMP sensor assembly is bad and needs to be replaced.

CASE 2: TDC 2 sensor output is 0 Volts AC. This tells you TDC 2 sensor is not generating a signal. The CMP assembly is bad and must be replaced.

CASE 3: Both TDC 1 and TDC 2 sensor outputs are within the expected range. That's the correct and expected test result and it means the sensor assembly is doing its job.

But if you're still getting a CMP sensor trouble code (P1361, P1362, P1366, or P1367), there's a good chance that:

- The sensor is failing intermittently.

- The sensor signal isn't reaching the PCM due to a problem in the wiring between the CMP sensor connector and the PCM.

Since both tests have ruled out a bad CMP sensor, your next step is to check for continuity between the CMP sensor connector and the PCM.

More 3.0L V6 Honda Accord Diagnostic Tutorials

I've written quite a few how-to guides for the 3.0L V6 Honda Accord, written with both DIYers and experienced techs in mind. You can find them all in this index:

Here's a quick peek at some of the step-by-step tutorials you'll find there:

- How To Troubleshoot A No Start (1998-2007 3.0L V6 Honda Accord).

- How To Test For A Broken Timing Belt (1998-2007 3.0L V6 Honda Accord).

- How To Test a Misfire Condition and Misfire Codes (3.0L V6 Honda Accord).

- How To Test Engine Compression (1998-2007 3.0L V6 Honda Accord).

If this info saved the day, buy me a beer!