TEST 2: Checking The Output Of The Rear Oxygen Sensor

With the help of a scan tool, you and I can confirm that the catalytic converter has failed. How?

By checking the voltage output of the rear oxygen sensor (with a scan tool with Live Data mode). Specifically, seeing if the rear O2 sensor is reporting a continuous Rich condition.

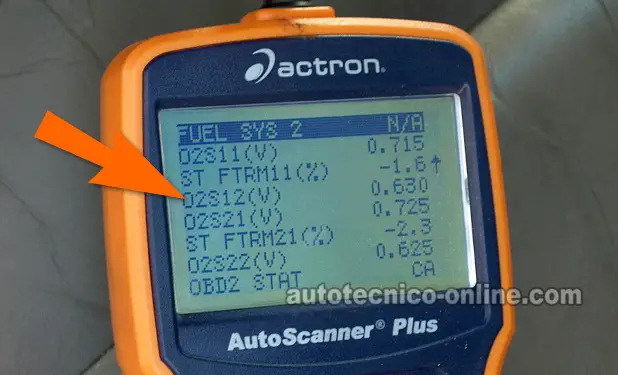

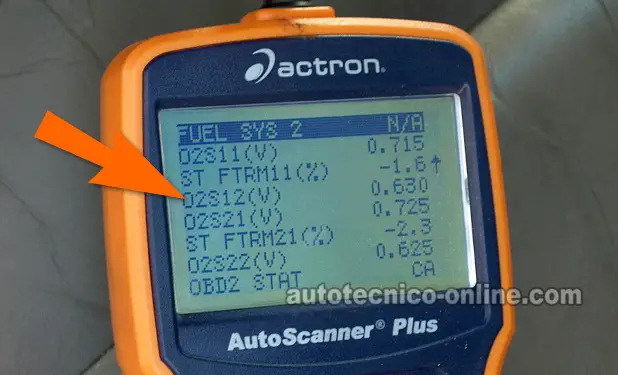

In the photo above, the arrow points to the rear oxygen sensor's PID (Parameter Identification). This is the PID that will show us the rear oxygen sensor's output voltage. (Don't have a scan tool? Need a scan tool? check out my recommendation: Actron CP9580 Scan Tool Review).

Alright, let's get started:

- 1

Connect your scan tool to your car or mini-van and start the engine (Don't have a scan tool? Need a scan tool? check out my recommendation: Actron CP9580 Scan Tool Review).

Since the catalytic converter needs to a few minutes to activate and start the oxidation process, let the engine warm up for about 15 minutes.

- 2

Scroll down to the PID that's labeled O2S12 on your scan tool. This PID is the one that will show you what the downstream oxygen sensor is reporting in Volts DC.

- 3

Now, take a look at the voltage readings for O2S12.

When the catalytic converter fails, the downstream O2 sensor will report a continuous fixed voltage above 0.5 Volts DC and this is what your looking for (in a normally operating catalytic converter, the rear O2 sensor should report a steady voltage between 0.100 Volts and 0.500 Volts).

NOTE: Unlike the front O2 sensor (O2S11), whose voltage varies constantly/rapidly between 0.1 to 0.9 Volts, the rear O2 sensor's voltage should fluctuate less and stay around 0.5 Volts or less.

What is the oxygen sensor reporting on your scan tool?

CASE 1: The downstream O2 sensor's voltage is fixed above 0.5 Volts. This let's you know that there is a problem and that the catalytic converter is not cleaning the exhaust like it should.

This continuous Rich condition, you've just confirmed, usually indicates that the catalytic converter has failed but there's a good chance that the rear oxygen sensor has failed.

That's right, the downstream O2 sensor may be bad and is stuck reporting a fixed high voltage to the PCM. So the next step is to induce a Lean condition and see if the rear oxygen sensor reacts and reports the change. For this test, go to: TEST 3: Manually Inducing A Lean Condition.

CASE 2: The downstream O2 sensor's voltage IS NOT fixed above 0.5 Volts. This test result tells you that at this moment, the catalytic converter is working like it should. It may also indicate that the catalytic converter is failing intermittently (this type of condition is very common and I've seen it quite a bit)

There's one more test, you and I need to do, and it's to check the performance of the rear oxygen sensor. We need to make sure it's not bad (since this could fool the PCM into thinking the catalytic converter is bad when it isn't).

The good thing is that you can test the performance of the rear O2 sensor to see if good or bad. For this test, go to: TEST 4: Manually Inducing a Rich Condition.

TEST 3: Manually Inducing A Lean Condition

The rear oxygen sensor is the one tasked with monitoring the hydrocarbon content of the catalytic converter.

This O2 sensor can fail and fool the fuel injection computer into thinking that the catalytic converter has stopped working.

So, in this test step, we'll check the performance of the downstream O2 sensor by checking to see if it can react correctly to a manually induced Lean condition.

I'll show you how. This is what you'll need to do:

- 1

With your scan tool still in Live Data mode (and the engine running), scroll down to the PID that's labeled O2S12.

NOTE: If you turned off the engine after the previous test, restart it and let it warm up for about 15 minutes again. This will let both the catalytic converter and rear oxygen sensor reach their optimal operating conditions. - 2

With the engine running, have a helper slightly disconnect a big vacuum hose while you observe your scan tool's O2S12 voltage values.

NOTE: The idea here is to NOT completely disconnect this vacuum hose while engine is running or the engine may stall. The idea is let a sufficient amount of air to Lean out the air/fuel mixture. - 3

As ambient air starts to get sucked into the vacuum hose's port, you should see the voltage numbers of O2S12 immediately go down to about 0.100 Volts.

- 4

Reconnecting the vacuum hose and see if the rear O2 sensor's reading goes back to it previous activity.

Let's take a look at what your test results mean:

CASE 1: The downstream O2 sensor's voltage decreased to 0.1 Volt. This confirms that the downstream oxygen sensor is OK and is able to fully respond to the changes in the air/fuel mixture.

This also means that the high voltage the downstream O2 sensor is reporting is being caused by a genuine Rich condition and the catalytic converter has failed.

Before you replace the catalytic converter, you need to make sure that your car or mini-van doesn't have any other fuel or ignition system malfunction that may be causing unburned fuel to pass into the exhaust. Here are some suggestions:

- Check for leaking fuel injectors.

- EVAP canister vacuum hose leaking fuel into the intake manifold.

- Make sure all tune up parts (spark plugs, spark plug wires, distributor cap, etc.) don't have excessive wear and tear.

- Check for low engine compression.

CASE 2: The downstream O2 sensor's voltage DID NOT decrease to 0.1 Volt. This tells you that the downstream oxygen sensor is bad and needs to be replaced.

If the oxygen sensor was operating normally, it would have reacted to the removal of the PCV valve (from the valve cover) immediately by producing a voltage around 0.1 Volts (100 millivolts) since it did not, you can deduce correctly that it's fried and needs to be replaced.

CASE 3: The downstream O2 sensor's wiring is melted to the exhaust pipe. Replace the downstream oxygen sensor.