Testing the engine compression on your 4.3L or 5.0L or 5.7L GM equipped vehicle is not hard. In this article, I'll guide you every step of the way and I'll also show you how to interpret the results of the compression test.

Why do an engine compression test? Well, if you're wanting to know the mechanical condition and/or sealing effectiveness of the piston rings or cylinder head valves, an engine compression test is the only way to ascertain this info.

Not only that, but your 4.3L (or 5.0L, 5.7) car, pickup, mini-van, van or SUV may be suffering a hard to diagnose misfire code that has you pulling your hair out (and maybe even spending money on parts your vehicle doesn't need) and lighting up the check engine light (MIL) with the following misfire diagnostics trouble codes: P0300, P0301, P0302, P0303, P0304, P0305, P0306, P0307, P0308. If this is happening to you, then an engine compression test is in order for your vehicle.

Contents of this tutorial:

ES ![]() You can find this tutorial in Spanish here: Prueba: Compresión Del Motor (GM 4.3L, 5.0L, 5.7L) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Prueba: Compresión Del Motor (GM 4.3L, 5.0L, 5.7L) (at: autotecnico-online.com).

Tools You'll Need:

- Compression Gauge Tester.

- A Helper

- Pen and Paper

Symptoms Of An Engine Compression Problem

When an engine experiences compression issues, it usually falls into one of two categories:

- Low Compression in Some but Not All Cylinders: This means that the compression pressure in one or more cylinders is lower than it should be, but not all cylinders are affected. This can be caused by issues such as worn piston rings, leaking valves, or a blown head gasket.

- Zero PSI Compression in Some or All Cylinders: This indicates a more severe problem where there is no compression pressure at all in one or more cylinders. This could be due to a catastrophic failure such as a cracked engine block, severe valve damage, or a broken piston.

Regardless of whether the engine has low or zero compression, you'll notice various symptoms that can impact its performance, reliability, and drivability:

- Hard Starting or No Start: Compression is essential for the engine to start. If compression is low or non-existent, the engine may struggle to start or fail to start altogether.

- Poor Engine Performance: Reduced compression means less power is generated during the combustion process, leading to sluggish acceleration, rough idling, and overall poor performance.

- Misfiring: Inadequate compression can cause cylinders to misfire, resulting in a noticeable shaking or vibration while driving, especially under load.

- Reduced Power and Performance: With compromised compression, the engine won't be able to generate as much power as it should, leading to decreased performance and responsiveness.

- Excessive Oil Consumption: Compression issues can cause oil to leak into the combustion chamber, leading to increased oil consumption and potentially blue smoke from the exhaust.

- Audible Engine Noise: Severe compression problems can result in abnormal engine noises such as knocking, rattling, or tapping as components struggle to operate under suboptimal conditions.

Which Compression Tester Should I Buy?

There are lot of engine compression testers to choose from and many places to buy them. I'm gonna' make three recommendations to you:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

TEST 1: The 'Dry' Engine Compression Test

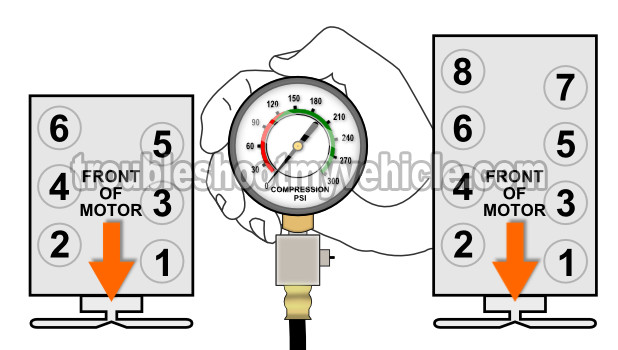

The illustration above has two images that will help you to identify the individual engine cylinders. This will come in super handy in the following test steps.

Before you start, take a look at the whole article and familiarize yourself with all of the steps. Please remember to always think safety first, since you'll be working around a cranking engine.

OK, to get this show on the road, I'll first explain the test steps. At the end of the test steps, you'll find two possible test results that will help you to interpret your specific test results.

NOTE: If possible, the engine in your vehicle must not be HOT and yet not completely cold. So, if your car or pickup (or mini-van, van, SUV) has bee running for an extended amount of time, let it cool down for about an hour. Now, if your car doesn't start and you're testing a no-start condition, don't worry about having a warm engine for the compression test.

Let's get started:

- 1

Disable the fuel system. You can easily do this by simply disconnecting the fuel injector 'Spider' assembly. This step is important, so don't skip it.

- 2

Disable the ignition system. You can accomplish this by disconnecting the ignition coil or the ignition module. This step is also very important.

- 3

Now, remove all six (or eight spark plugs) spark plugs.

As you're taking them out, be careful and don't drop any of them on the floor, or you could cause the spark plug's ceramic insulator to break, and this will cause a misfire! - 4

Thread the engine compression gauge into the spark plug hole for the number 1 engine cylinder. Hand tighten the compression gauge only! Do not use any type of tool to get it tight.

- 5

Have a helper crank engine as you observe the needle on the compression tester's gauge.

- 6

Once the needle on the gauge stops climbing, have him or her stop cranking the engine.

- 7

Write down this compression reading on a piece of paper. Include the number of the cylinder this reading belongs to.

- 8

Now repeat steps 4 thru' 7 on the other cylinders.

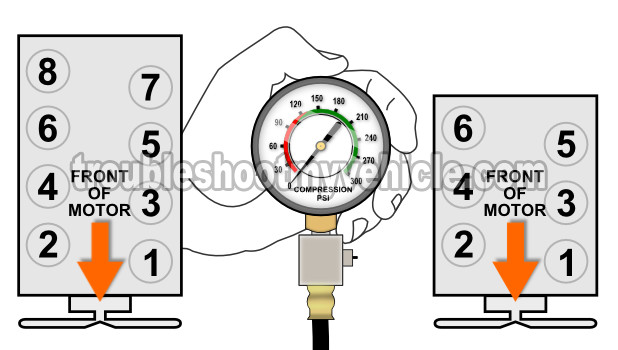

Let's examine your test results:

CASE 1: All eight cylinders had 0 PSI. This test result tells you that the engine has an internal mechanical problem.

The most common cause of this condition is a broken timing chain or a blown head gasket.

Your next step should be to check the condition of the timing chain and perform a blown head gasket test.

CASE 2: One or more cylinders had a low compression value compared to the others. This could be normal or it could be causing a problem.

To find out if the compression values are normal or not, go to: How To Interpret The Engine Compression Test Results.

CASE 3: All eight compression values were similar and above 120 PSI. This lets you know that a compression problem is not behind the no-start or misfire problem you're trying to troubleshoot.

Interpreting The Results Of The Engine Compression Test

The idea behind the engine compression test (in the case of a misfire condition or rough idle condition) is to find out if any one engine cylinder is not contributing 100% of its power to the overall engine output.

If one or more cylinders have compression value lower than 15% of the highest compression value, your GM 4.3L (or 5.0L, 5.7L) equipped vehicle will run rough or cause a misfire code to set and turn on the check engine light.

Figuring this 15% difference isn't hard, you can easily figure out in one of two ways: You can calculate this 15% difference with pen and paper or you can use my low compression calculator.

You can find the low compression calculator here: Online Low Engine Compression Calculator (at: easyautodiagnostics.com).

If you want to manually calculate the 15% difference, here's what you'll need to do:

- STEP 1: Multiply the highest compression value by 0.15 (this is the decimal value of 15%).

- STEP 2: Round the result to the nearest one (for example: 25.6 would become 26).

- STEP 3: Subtract the result (the number that was rounded) from the highest compression value.

- ANSWER: The result of this subtraction is the lowest possible compression value any cylinder can have.

Now, so that this calculation can make more sense to you, let's say that my 4.3L C1500 Pick Up (or Astro or Blazer, etc.) gave me the following compression readings:

| Cylinder | Pressure |

|---|---|

| #1 | 165 PSI |

| #2 | 95 PSI |

| #3 | 165 PSI |

| #4 | 175 PSI |

| #5 | 160 PSI |

| #6 | 165 PSI |

My next step is to do the following calculation:

- STEP 1: 175 x 0.15 = 26.25.

- STEP 2: 26.25 = 26 (rounded to nearest one).

- STEP 3: 175 - 26 = 149.

- ANSWER: 149 PSI. Any cylinder with this compression (or lower) value will misfire.

Since cylinder #2 is only producing 95 PSI, I can now conclude that it's 'dead' and causing a misfire.

To find out if the lowest compression value you got from your engine compression test is within a good range, you'll need to do the same calculation. Of course, you'll need to use the highest compression value you got and not the one in the example.

Once you've found the 'dead' cylinder, the next step is to find out what's causing the low compression value. For this step, go to: TEST 2: 'Wet' Engine Compression Test.

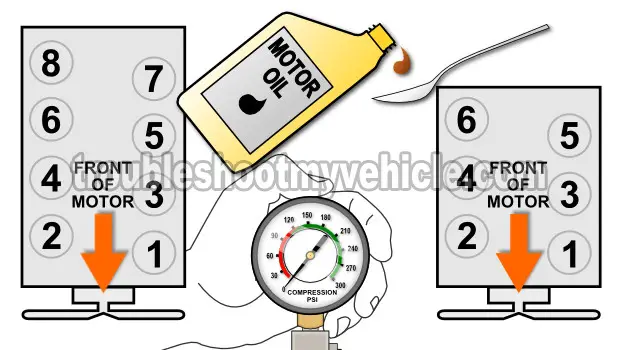

TEST 2: 'Wet' Engine Compression Test

So, you've found the 'dead' cylinder or cylinders, what next? The next step is to do a 'Wet' compression test and find out if the low compression value (or 0 compression value you got) is due to bad cylinder head valves or bad piston compression rings.

This involves adding a few drops (2 tablespoons) of engine oil to the cylinders with the low engine compression result and repeating the compression test.

The results you obtain from this second 'Wet' compression test will help you determine if the low compression you recorded in the 'Dry' compression test are caused by worn piston rings or worn cylinder head valves.

OK, this is what you need to do:

- 1

Add a small amount of engine oil to the cylinder that reported low compression or no compression in the 'Dry' compression test.

The amount should be about 1 to 2 tablespoons of oil. - 2

Install the compression tester onto the cylinder. Do not use any type of tool to tightened the compression tester. Hand tight is fine.

- 3

When all is set up, have your helper crank the engine.

- 4

You'll get one of two results:

1) The compression value will go up (from the one you recorded before).

2) The compression value will stay the same.

Let's interpret your test results:

CASE 1: The compression value shot up. This tells you that the piston compression rings are worn out and thus the problem is in the bottom end (block) of the engine in your GM 4.3L, 5.0L, or 5.7L equipped vehicle.

Here's why: The engine oil helped the piston rings seal better, thus bringing up the compression value almost back to normal. If the problem were in the cylinder head valves, then the engine oil you just added wouldn't make a difference at all (on the compression value).

CASE 2: The compression value stayed the same. This confirms that the problem is in the cylinder head valves.

Here's why: If the cylinder head valves and their seats are worn out (or maybe even bent from a broken timing belt), no amount of engine oil is gonna help seal the compression in, in the cylinder. So, if the compression value, for the specific cylinder you're testing did not go up (after you added oil to it), then this is a dead giveaway that you've got cylinder head valve damage.

Why An Engine Compression Test?

This is one of the most overlooked tests to find the root cause of a misfire code, rough idle or an engine miss or a blown head gasket.

Over the years, I have solved many unsolvable misfire codes, rough idle, lack of power issues by doing a simple engine compression test and if you're faced with something similar, I highly recommend doing an engine compression test.

Related Test Articles

To see the 4.3L, 5.0L, and 5.7L specific articles here at troubleshootmyvehicle. Com, go to: GM 4.3L, 5.0L, 5.7L Index Of Articles.

Here's a sample of the tutorials you'll find in the index:

- How To Test The 'Spider' Fuel Injector Assembly (4.3L, 5.0L, 5.7L).

- Troubleshooting The Fuel Pump (GM 4.3L, 5.0L, 5.7L).

- Coolant Leaking From Intake Gaskets (GM 4.3L, 5.0L, 5.7L).

- How To Diagnose Misfire Codes (GM 4.3L, 5.0L, 5.7L).

- MAP Sensor Test (P0106, P0107, P0108) (GM 4.3L, 5.0L, 5.7L).

If you need and/or want to test the distributor ignition system to see if it's the source of the misfire condition (or misfire code: P0300, P0301, P0302, P03030, P0304, P0305, P0306, P0307, P0308), you can go to this link (found at easyautodiagnostics. Com):

- How To Test A Misfire / No Spark-No Start Condition GM 4.3L, 5.0L, 5.7L Distributor Ignition System (1996-2004) (at: easyautodiagnostics.com).

If this info saved the day, buy me a beer!