In this tutorial, I'm gonna show you how to resistance test the throttle body temperature sensor on the 1989-1991 TBI fuel injected V8 Dodge Ram pickup.

The test is done with a multimeter (no expensive diagnostic tools needed) and with your test results, you'll quickly find out if the TB temp sensor is bad or good.

Contents of this tutorial:

- Symptoms Of A Bad Throttle Body Temperature Sensor.

- What Does The Throttle Body Temperature Sensor Do?

- Important Initial Checks.

- Where To Buy The TB Temp Sensor And Connector.

- TEST 1: Cold Temperature Resistance Check.

- TEST 2: Hot Temperature Resistance Check.

- More 5.2L, 5.9L V8 Dodge Ram Pickup Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- Dodge Ram 150 Pickup 5.2L, 5.9L V8: 1989, 1990, 1991.

- Dodge Ram 250 Pickup 5.2L, 5.9L V8: 1989, 1990, 1991.

- Dodge Ram 350 Pickup 5.9L V8: 1989, 1990, 1991.

Symptoms Of A Bad Throttle Body Temperature Sensor

When the throttle body temp sensor fails, it usually triggers the check engine light and the following code will get registered:

- Code 23: Throttle Body Temp Sensor Voltage Too Low Or Too High.

But it can definitely cause annoying engine performance problems —especially after you've been driving a while and try to restart the engine while it's still hot.

Here are some common symptoms of a bad throttle body temp sensor:

- Hard start: Struggles to fire up after a quick stop —like getting gas or making a short errand.

- Rough idle: Shaky or uneven idle right after restarting a warm engine.

- Engine stall: Shuts off shortly after a hot restart.

- Surging or hesitation: Lags or jerks when you hit the gas after starting warm.

- Extended engine cranking: Takes longer than usual to crank over after a warm shutdown.

You might also notice that your Dodge Ram pickup starts up just fine when it's cold in the morning, but acts weird when it's hot outside —or after it's been running for a while. That's a clue that this sensor isn't telling the computer how hot the fuel system really is.

A bad sensor could also confuse the fuel injection computer (Single Board Engine Controller —SBEC) into thinking the throttle body is cold when it's actually hot —or vice versa. And that means the air/fuel mixture gets out of balance, especially during that tricky "restart window" where vaporized fuel can throw everything off.

What Does The Throttle Body Temperature Sensor Do?

The TB temp sensor is bolted right into the throttle body. Its job is to measure how hot the throttle body gets after the engine has been running. This is especially important when the engine is shut off for a few minutes and come back to start it again.

When you shut off the engine, the heat from the motor rises up and soaks into the throttle body. This makes the fuel that flows thru the throttle body to the fuel injectors hotter and more likely to vaporize, which can cause hard starts, rough idling, or even stalling right after a restart.

To prevent that, the fuel injection computer reads the temperature from this sensor. If it sees that the throttle body is hot, it adjusts the fuel mixture during startup —usually by adding a bit more fuel (a richer mix) to make sure the engine starts smooth and doesn't stumble.

This sensor is especially important because your truck doesn't have an intake air temp (IAT) sensor to read the temperature of the incoming air. Without that, the FI computer needs some way to estimate how hot things are in the intake. So it uses the throttle body sensor as a backup for that job.

Important Initial Checks

Before you start testing the TB temp sensor, take a moment to do these quick visual checks:

- Inspect the sensor's wiring for visible damage, such as frayed or cut wires.

- Look over the connector for any signs of damage. Is the U-shaped metal clip (lock clip) in place?

- Check the sensor itself for any damage, especially since its top part is made of plastic and can break off from its metal base.

Missing metal locking clip: These older Dodge trucks use a type of TB temp sensor connector that needs a small metal clip to lock it in place. It's the same style used on fuel injectors of that era.

If the clip is missing, or if the connector is cracked or broken, it might not make secure and good contact with the sensor —especially when things heat up and start vibrating under the hood.

If the clip is gone or the connector is damaged in any way, replace it with a new pigtail. They're inexpensive and easy to install (WALKER PRODUCTS 270-1034).

Frayed Wires: Fraying occurs when the insulation around the wires falls off, exposing the metal strands inside. This is a very common problem.

Exposed wires can eventually short out, leading to faulty temperature readings and activating the check engine light.

Here's an example that shows what this problem can look like:

- IAT Sensor Wire Insulation Problem And Wires Shorted Together (from: easyautodiagnostics.com).

There are two ways to address this kind of issue:

- If the fraying is extensive or located close to the connector, the best option is to replace the entire connector assembly.

- If the damage is minor and further away from the connector, wrapping the affected area with electrical tape can serve as a temporary fix.

NOTE: Electrical tape should only be considered a short-term solution. For long-lasting reliability, it's best to replace any damaged parts of the connector or wiring.

Where To Buy The TB Temp Sensor And Connector

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

TEST 1: Cold Temperature Resistance Check

To get started, we're gonna remove the TB temp sensor from its place on the throttle body and check its resistance.

If the sensor is faulty, you'll typically get one of the following results when testing it with a multimeter:

- Open-circuit issue: The multimeter will show "OL" (infinite resistance), indicating no continuity.

- Short-circuit issue: The multimeter will display "0 Ohms", showing that the circuit is completely shorted.

IMPORTANT: For this resistance-to-temperature test to be accurate, the sensor must be completely cold (around room temperature). If the engine has been running and the sensor is still warm or hot, wait for it to fully cool down before you begin.

NOTE: Don't have a multimeter or need to upgrade yours? This is the one I use and recommend: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (at: amazon.com).

OK, let's begin:

- 1

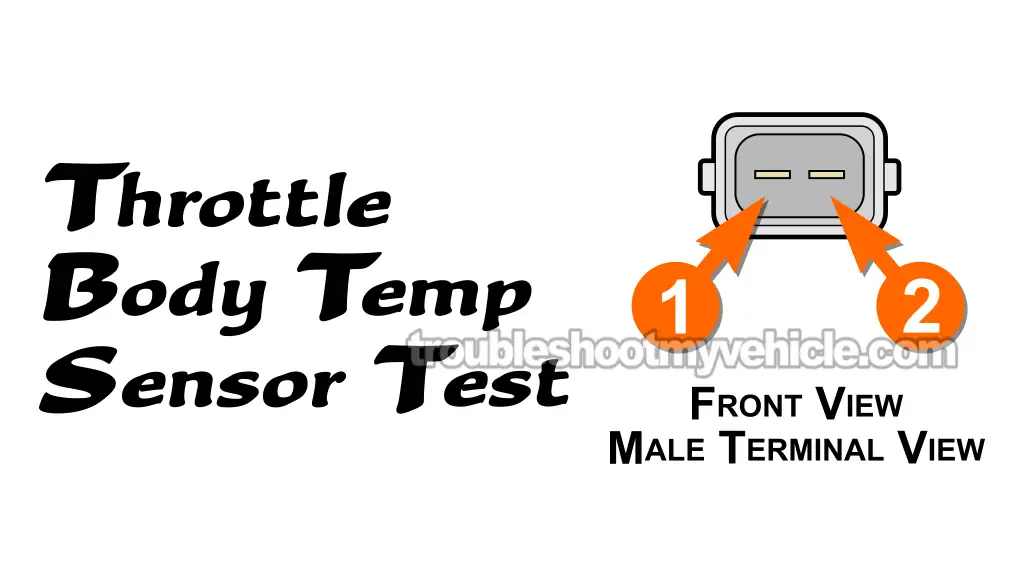

Disconnect the TB temp sensor from its 2-wire connector.

NOTE: Inspect the connector for any damage and confirm that the U-shaped metal clip is not missing. - 2

Remove the TB temp sensor from its place on the throttle body.

NOTE: Be careful not to damage the sensor. Take your time removing it —the plastic portion can crack easily if you don't use the right tools. - 3

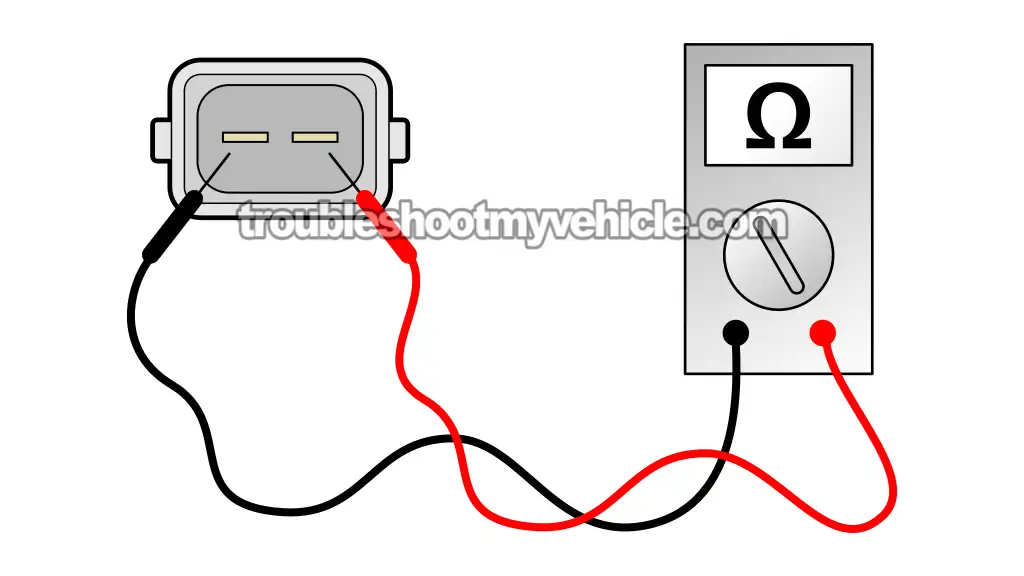

Set your multimeter to its Ohms (Ω) setting.

- 4

Measure the sensor's resistance by placing the multimeter leads on the sensor's male terminals.

At room temperature, you should see a resistance value of: 5.6 to 14.6 K Ohms.

Let's interpret your results:

CASE 1: The resistance is 0 Ohms. This confirms the TB temp sensor is bad and needs to be replaced.

CASE 2: The multimeter displayed infinite Ohms (OL). This confirms the TB temp sensor is bad and needs to be replaced.

CASE 3: The resistance does NOT fall within the indicated range. This is telling you that the TB temp sensor is faulty and should be replaced.

To be absolutely sure, perform the second test: TEST 2: Hot Temperature Resistance Check.

CASE 4: The resistance is within the proper range for the current temperature. In this case, the TB temp sensor is working correctly.

To be absolutely sure that the sensor is good, perform the second test: TEST 2: Hot Temperature Resistance Check.