TEST 3: Manually Inducing A Lean Air/Fuel Mixture

In this test, we'll introduce a controlled vacuum leak by slightly cracking open the vacuum hose connected to the power brake booster.

This will lean out the air/fuel mixture and help us determine if the rear O2 sensor is responding properly.

This is a safe and simple way to simulate a lean condition without using any special tools —but you'll need a scan tool "live data" capability to monitor the rear O2 sensor voltage in real time.

IMPORTANT: Loosen the brake boosters vacuum supply hose before you start so it can be easily cracked open during the test. The brake booster vacuum hose can be stuck on tight, and you don't want to be wrestling with it while the engine is running.

OK, these are the test steps:

- 1

Locate the vacuum hose going to the power brake booster.

It's a large-diameter rubber hose connected to the booster canister mounted on the firewall behind the master cylinder. - 2

With the engine OFF, gently loosen and disconnect the rubber hose from the vacuum port on the branke booster.

This will break the seal so the vacuum hose can be easily cracked opened later. Once done, re-seat it onto the its vacuum port on the brake booster. - 3

Start the engine and let it warm up fully.

We need to make sure the PCM is in closed loop and the scan tool is showing live rear O2 sensor voltage data. - 4

Carefully crack open the vacuum hose just enough to let in unmetered air.

NOTE: Do not remove the hose completely or the engine may stall. You just want to introduce a small vacuum leak.

If the engine does stall, reconnect the vacuum hose, restart the engine, and repeat the test using a smaller opening. - 5

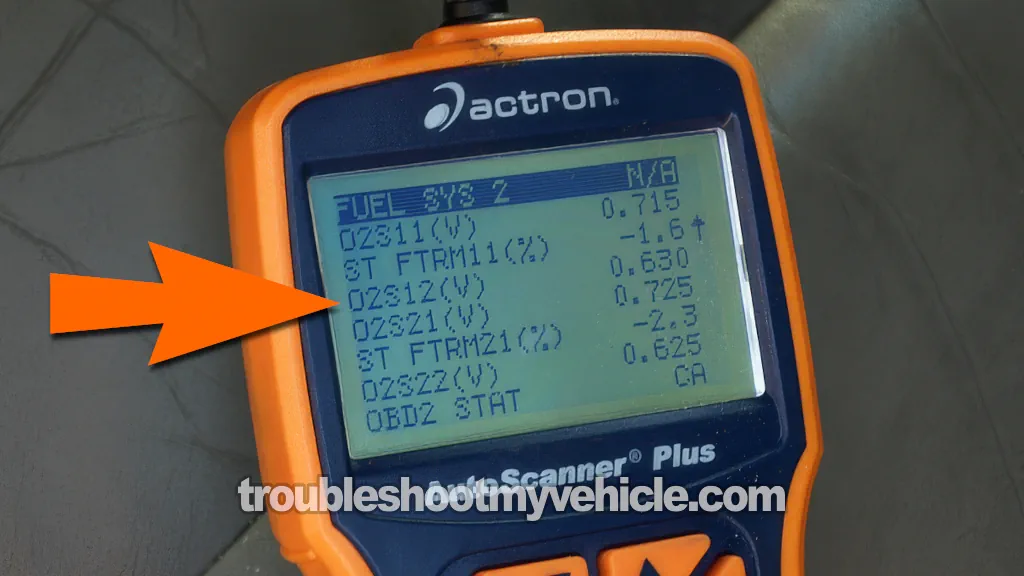

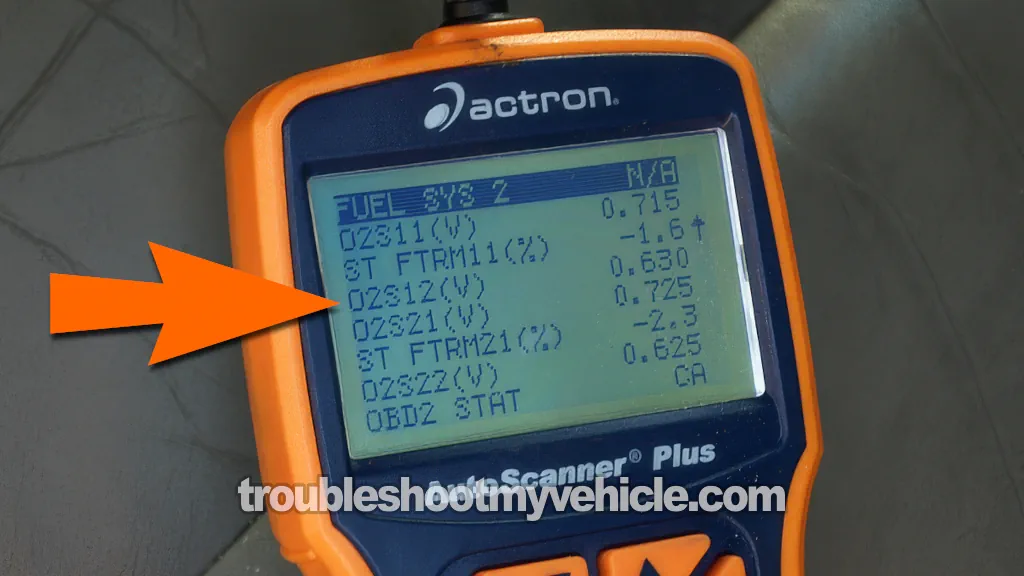

Observe the rear O2 sensor (O2S12) voltage on your scan tool.

A functioning sensor should detect the lean condition (as long as you're allowing air into the vacuum hose) and drop below 0.5 Volts. - 6

Once done, reconnect the vacuum hose securely and turn OFF the engine.

Let's interpret your test result:

CASE 1: The rear O2 sensor voltage drops below 0.5 Volts. This confirms the sensor is working and capable of detecting lean conditions.

Our next step is to induce a "rich" condition and see if the rear O2 sensor reacts to it. Go to: TEST 4: Manually Inducing A Rich Air/Fuel Mixture.

CASE 2: The rear O2 sensor voltage does not respond (stays above 0.5 Volts). This indicates the sensor is not picking up the lean condition.

Either the sensor is faulty or the catalytic converter is so compromised that it's masking the lean mixture. In this case, I recommend replacing the O2 sensor and repeating the test before condemning the converter.

TEST 4: Manually Inducing A Rich Air/Fuel Mixture

In this final test, we'll manually introduce a richer-than-normal air/fuel mixture by spraying a small amount of carburetor cleaner into the intake.

This test helps confirm that the rear O2 sensor is still functional and capable of detecting a rich exhaust condition when one occurs.

As with the previous test, you'll need a scan tool in live data mode to monitor the rear O2 sensor voltage.

IMPORTANT: Only perform this test in a well-ventilated area. Make sure the engine is fully warmed up and idling in closed loop mode. Have a fire extinguisher nearby and avoid spraying near hot surfaces or electrical connectors.

OK, let's begin:

- 1

Remove the air cleaner duct from the throttle body.

- 2

Start the engine and allow it to reach full operating temperature.

Confirm the PCM is in closed loop and your scan tool is displaying live rear O2 sensor voltage. - 3

Give a quick, controlled spray of carb cleaner over the throttle body.

NOTE: A short burst (½–1 second) is enough —do not unload the spray can into the throttle body. The goal is to momentarily enrich the mixture, not flood the engine. - 4

Observe the rear O2 sensor voltage on the scan tool.

A working downstream O2 sensor should spike above 0.5 Volts in response to the richer exhaust mixture. - 5

Let the engine stabilize after the spray.

Wait a few seconds before performing another spray so that you can confirm repeatability. - 6

Once finished, let the engine idle for about 1 to 2 minutes and then shut off the engine.

Let's interpret your test result:

CASE 1: The rear O2 sensor voltage spikes above 0.5 Volts. This confirms the sensor is working and capable of detecting a rich condition.

If TEST 3 also showed a lean response, your rear O2 sensor is functioning correctly. Code P0420 is telling you that it's time to replace the catalytic converter.

CASE 2: The rear O2 sensor voltage does not change. This suggests the rear O2 sensor is unresponsive, possibly degraded or faulty.

In this case, I recommend replacing the O2 sensor and repeating the test before condemning the converter.

What "Rich" And "Lean" Mean On An Oxygen Sensor

To understand how to read oxygen sensor voltage output on your scan tool in "live data" mode, it helps to know what the terms "rich" and "lean" actually mean.

These readings tell you how much oxygen is left in the exhaust gases after combustion —and that gives you insight into how the engine is running.

- Rich: This means there's Too much fuel and Not enough oxygen in the air/fuel mix. The O2 sensor shows a high voltage —usually around 0.8 to 0.9 volts.

- Lean: This means there's Too much oxygen and Not enough fuel. The sensor reports a low voltage —typically around 0.1 to 0.2 Volts.

When everything's working right, the front O2 sensor (before the catalytic converter) should constantly switch between rich and lean —that's how the PCM fine-tunes the air/fuel mixture in real time.

The rear O2 sensor (after the catalytic converter) should not switch as rapidly. If the cat is working properly, it scrubs the exhaust gases and smooths out the sensor signal —so you'll usually see a slow, gentle fluctuation between lean and rich voltage outputs.

But if the rear sensor voltage stays stuck above 0.5 Volts and doesn't fluctuate, that tells you something important: the cat is no longer removing the unburned fuel (hydrocarbons) from the exhaust.

There are no hard-coded numbers to "look for" here —what matters is the behavior. A steady, constant rich signal from the rear sensor and a trouble code P0420 point to a failed catalytic converter.

What "Closed Loop" Means —And Why It Matters

When your engine first starts up —especially when it's cold— the PCM (Powertrain Control Module) runs in what's called open loop mode.

That means it's using pre-programmed fuel settings, not sensor feedback, to run the engine. The system is basically running blind until the engine warms up.

Once the engine reaches full operating temperature, the PCM switches to closed loop mode.

In closed loop is when it starts using live data from the oxygen sensors (and other sensors) to adjust the air/fuel mixture in real time. This is the mode you want for running accurate tests on your catalytic converter or O2 sensors.

Most scan tools will tell you whether the PCM is in open or closed loop. Look for a line in the live data that says something like "Fuel System Status: Closed Loop" —that's your confirmation the engine is warm and the sensors are actively being used.

If you try to test the rear O2 sensor while the engine is still in open loop, your results won't be reliable. Always make sure the engine is fully warmed up and the system is in closed loop before reading O2 sensor voltages.

More 5.2L, 5.9L V8 Dodge Ram Pickup Tutorials

I've written several more tutorials for the V8 Dodge Ram pickups that may be of interest to you that you can find in this index:

Here's a sample of the tutorials you'll find in the index:

- How To Test The Fuel Pump (1992-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

- How To Test The MAP Sensor -P0107, P0108 (1997-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

- How To Test Engine Compression (1989-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

- Troubleshooting A Blown Head Gasket (1989-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

If this info saved the day, buy me a beer!