If you're dealing with an engine no-start condition and code P0340: No Cam Signal At PCM, you've probably already replaced the CMP sensor —but the engine still won't start.

This tutorial will help you go beyond the sensor and walk you through testing the circuits between the CMP sensor and the PCM, step by step.

We'll also check for mechanical issues inside the distributor that can prevent the cam signal from ever reaching the PCM.

By the end, you'll know exactly what's causing the problem —and how to fix it without guessing or replacing parts you don't need.

Contents of this tutorial:

- What Does A P0340 Mean?

- Symptoms Of A P0340 DTC.

- Already Replaced The CMP Sensor? Read This First.

- TEST 1: Checking If The Distributor Shaft Turns And Is Free of Play.

- TEST 2: Checking The CMP Sensor Wires For An Open-Circuit (CMP To PCM).

- TEST 3: Checking The CMP Sensor Wires For A Short To Ground.

- TEST 4: Check If CMP Sensor Wires Are Shorted To Each Other.

- Watch Out For Shared Sensor Power And Ground Circuits.

- Is The PCM Bad?

- More 5.2L, 5.9L V8 Dodge Ram Pickup Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- Dodge Ram 1500 Pickup 5.2L V8: 1996, 1997, 1998, 1999, 2000, 2001.

- Dodge Ram 2500 Pickup 5.2L V8: 1996, 1997, 1998.

- Dodge Ram 1500 Pickup 5.9L V8: 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003.

- Dodge Ram 2500 Pickup 5.9L V8: 1996, 1997, 1998, 1999, 2000, 2001, 2002.

- Dodge Ram 3500 Pickup 5.9L V8: 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003.

What Does A P0340 Mean?

A P0340: No Cam Signal at PCM diagnostic trouble code means that the Powertrain Control Module (PCM) isn't receiving a signal from the Camshaft Position (CMP) sensor while the engine is being cranked.

The PCM continuously monitors engine position using both the CMP and Crankshaft Position (CKP) sensors. If it detects that the crankshaft is turning —typically after 96 crank pulses— but sees No corresponding signal from the camshaft, it sets code P0340.

This code doesn't just point to a bad sensor. It can also be caused by:

- The CMP sensor's 5-volt reference or sensor Ground circuit is open.

- Wiring damage between the CMP sensor and the PCM (open or shorted circuits).

- Defective CMP sensor connector.

- Distributor problem (mechanical issue).

- Internal PCM driver circuit failure (rare).

In short, a P0340 means the PCM can see the engine is cranking (via the CKP sensor), but without a cam signal, it can't properly control ignition or fuel —and the engine won't start. This tutorial will help you test the CMP circuit wiring step-by-step to track down the real cause.

Symptoms Of A P0340 DTC

When trouble code P0340: No Cam Signal At PCM appears on your 1996–2003 Dodge Ram with a 5.2L or 5.9L V8, you're likely dealing with an engine cranks-but-does-not-start condition.

As I mentioned in the section above, this code is set when the PCM detects crankshaft position sensor (CKP) signals but doesn't receive any camshaft position sensor (CMP) signals.

In other words, the PCM knows the engine is turning over —but it's missing the cam signal needed to trigger injector and ignition timing.

Here's what you'll typically notice:

- Engine cranks but won't start: The engine turns over but doesn't fire up.

- No spark or injector pulse: Without a cam signal, the PCM won't enable fuel or ignition.

- P0340 stored in memory: A scan tool will show this DTC even if the Check Engine Light isn't on yet.

Since the CKP sensor is providing input and the PCM is counting crankshaft rotations, the problem lies somewhere in the cam signal circuit —and that's exactly what this tutorial will help you diagnose.

Already Replaced The CMP Sensor? Read This First

This tutorial doesn't cover how to test the CMP sensor itself —that's already handled in detail in the following step-by-step guides:

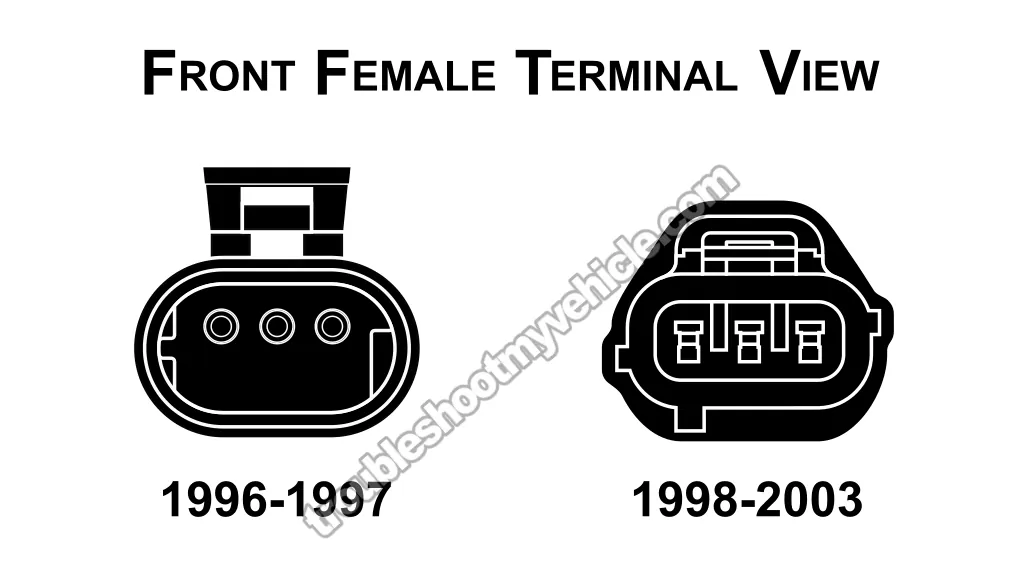

- How To Test The Camshaft Position Sensor (1996-1997 5.2L, 5.9L V8 Dodge Ram Pickup).

- How To Test The Camshaft Position Sensor (1998-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

In about 95% of cases, replacing the CMP sensor takes care of a P0340 code and gets the engine running again. But in the remaining 5% of cases, the problem usually lies elsewhere —either a mechanical issue inside the distributor, or an electrical fault in the wiring between the CMP sensor and the PCM.

This tutorial is designed for that scenario —where the CMP sensor has already been replaced, but the engine still won't start and P0340 keeps showing up in the PCM's memory.

I'll show you how to test the CMP sensor wiring circuits from end to end —including how to confirm continuity and check for shorts between the sensor and the PCM. We'll also cover how to test the distributor's pulse ring (without removing the distributor) to rule out mechanical damage.

TEST 1: Checking If The Distributor Shaft Turns And Is Free of Play

Before diving into wiring tests, let's make sure the distributor itself hasn't failed mechanically. These older-style distributors don't last forever. Over time, the bushings inside can wear out, eventually causing the shaft to bind, twist, or even snap completely.

If that happens, the CMP sensor will never create a proper signal —and the PCM will never receive one either. That means you'll be stuck with an engine no-start condition and a P0340 code, no matter how many sensors you replace.

So, in this test, we'll confirm that the distributor shaft (and its pulse ring) isn't seized and that it rotates smoothly while the engine is being cranked. We'll also check for any side-to-side play in the shaft, which would indicate internal wear.

NOTE: This is an on-car test, don't remove the distributor from the vehicle.

SAFETY WARNING: Since this test involves working near a cranking engine, stay alert and keep your hands, clothing, and tools away from moving parts. Only perform this test if you can do so safely.

Let's get started:

- 1

Disconnect the battery negative (-) cable from the battery.

- 2

Remove the distributor cap and set it aside.

- 3

Remove the distributor rotor —it should pull straight off the shaft with a firm tug.

- 4

Disconnect the CMP sensor and remove it from the distributor housing.

- 5

Try wiggling the shaft that the rotor attaches to.

It should feel solid —no side-to-side movement. If it wiggles, the distributor bushings are worn out and you've found a serious problem. - 6

Reconnect the battery and have an assistant crank the engine for a few seconds.

- 7

Watch the distributor shaft as the engine cranks.

It should rotate smoothly without hesitation or wobble.

Let's interpret your test results:

CASE 1: The distributor shaft rotates smoothly and shows no side-to-side play. Perfect —the distributor is mechanically sound, and you can move on to testing the CMP sensor wiring.

Head over to: TEST 2: Checking The CMP Sensor Wires For An Open-Circuit (CMP To PCM).

CASE 2: The distributor shaft does not rotate when cranking the engine. This indicates a serious mechanical failure —the distributor may be seized, broken, or disconnected internally. This is why the PCM isn't receiving a cam signal.

Your next step is to remove the distributor and replace it.

CASE 3: The shaft rotates but wobbles or has noticeable side-to-side play. Worn distributor bushings can cause signal distortion or complete signal loss from the CMP sensor. The distributor needs to be rebuilt or replaced.

TEST 2: Checking The CMP Sensor Wires For An Open-Circuit (CMP To PCM)

In this test, we're going to start a series of circuit checks between the CMP sensor and the PCM.

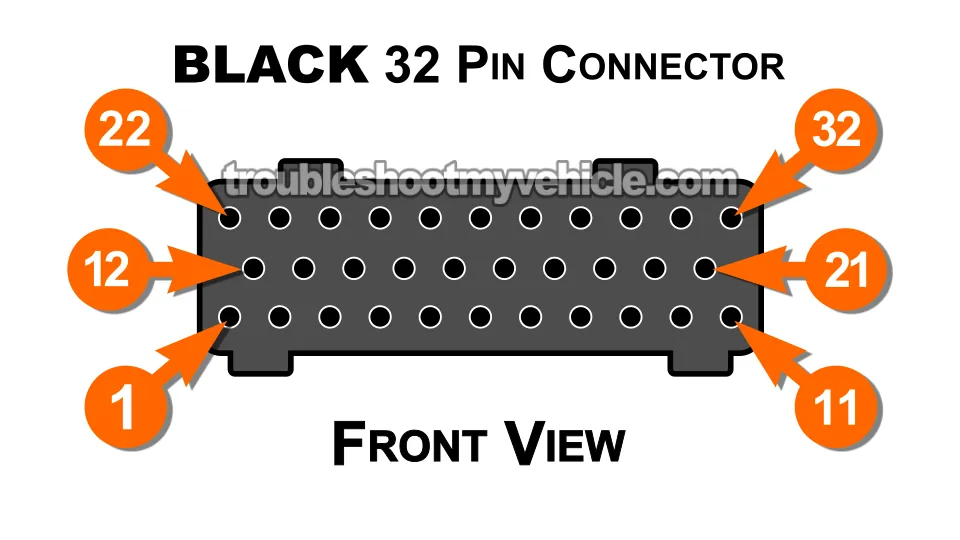

The goal here is simple: verify that each of the three CMP sensor wires has a complete, unbroken connection between the sensor's connector and the PCM's BLACK connector.

As you're already aware, the CMP sensor has three wires:

- TAN/YEL: CMP signal wire —connects to pin 18 of the BLACK PCM connector.

- BLK/LT BLU: Sensor Ground wire —connects to pin 4 of the BLACK PCM connector. This Ground is shared with many other sensors in the engine and transmission.

- VIO/WHT: 5 Volt reference wire —connects to pin 17 of the BLACK PCM connector. This 5V supply is also shared with a few other sensors.

We'll check for continuity on each wire using a multimeter. If any wire shows open-circuit (infinite resistance), that wire is broken somewhere in the harness and will need to be repaired.

IMPORTANT: Do not insert your multimeter test leads directly into the PCM connector terminals —doing so will permanently deform or damage them. For a safe probing method, see: How To Safely Probe The PCM Connector -Without Damaging It.

Let's get started:

- 1

Disconnect the battery negative (-) cable from the battery post.

- 2

Disconnect all three PCM connectors from the PCM.

NOTE: We'll be working with the BLACK connector in this test. - 3

Disconnect the CMP sensor connector from the sensor.

- 4

Set your multimeter to the Ohms (Ω) setting.

NOTE: Don't use the Continuity setting, instead set it to Ohms to get the most accurate reading of the circuits health. - 5

Test the TAN/YEL wire: Place one lead on the CMP connector's TAN/YEL terminal and the other on pin 18 of the BLACK PCM connector.

- 6

Test the BLK/LT BLU wire: Place one lead on the CMP connector's BLK/LT BLU terminal and the other on pin 4 of the BLACK PCM connector.

- 7

Test the VIO/WHT wire: Place one lead on the CMP connector's VIO/WHT terminal and the other on pin 17 of the BLACK PCM connector.

- 8

Each wire should show less than 1 Ohm of resistance (you'll usually see 0.5 Ohms).

Infinite resistance (OL) means there's an open-circuit in that wire.

Let's interpret your test results:

CASE 1: One or more wires show open-circuit (infinite resistance). This confirms a break in the wiring between the CMP sensor and the PCM.

You'll need to locate and repair the damaged wire(s). See:

CASE 2: All three wires show continuity (under 1 Ohm of resistance). Good news —the CMP signal, Ground, and 5 Volt reference wires are all intact.

You can now move on to: TEST 3: Checking The CMP Sensor Wires For A Short To Ground.