Sooner or later, the MAP sensor is gonna fail, when it does, you'll definitely see a MAP sensor diagnostic trouble code (DTC) triggering the check engine light and wreaking havoc on engine performance.

Getting a MAP sensor DTC and noticing your van's engine acting up? Odds are the sensor itself is the problem.

But did you know that other engine issues can make the MAP sensor code pop up even when the MAP sensor's working fine.

Here's the good news: checking the MAP sensor on your V8 Dodge Ram van is simple. All you'll need is a basic multimeter and a hand vacuum pump. In this tutorial, I'll show you exactly how to test it.

Contents of this tutorial:

- Symptoms Of A Bad MAP Sensor.

- How The MAP Sensor Works.

- Where To Buy The MAP Sensor And Save.

- TEST 1: Verifying The MAP Signal.

- TEST 2: Making Sure That The MAP Sensor Is Getting Power.

- TEST 3: Verifying The MAP Sensor Ground Circuit.

- MAP Sensor Code Won't Go Away.

- More 5.2L, 5.9L V8 Dodge Ram Van Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 5.2L, 5.9L V8 Dodge Ram B150 Van: 1992, 1993.

- 5.2L, 5.9L V8 Dodge Ram B250 Van: 1992, 1993.

- 5.2L, 5.9L V8 Dodge Ram B1500 Van: 1994, 1995, 1996, 1997.

- 5.2L, 5.9L V8 Dodge Ram B2500 Van: 1994, 1995, 1996, 1997.

OTHER MAP SENSOR TESTS:

- How To Test The MAP Sensor (1989-1990 5.2L, 5.9L V Dodge Ram Van).

- How To Test The MAP Sensor (1991 5.2L, 5.9L V8 Dodge Ram Van).

- How To Test The MAP Sensor (1998-2003 5.2L, 5.9L V8 Dodge Ram Van).

Symptoms Of A Bad MAP Sensor

When the MAP sensor stops working right, your check engine light's gonna pop on — usually along with one of these two DTCs:

- OBD I (1992–1995):

- Code 13: MAP Sensor Signal Problem.

- Code 14: MAP Sensor Voltage High/Low.

- OBD II (1996–1997):

- P0107: MAP Sensor Circuit Low Voltage.

- P0108: MAP Sensor Circuit High Voltage.

Besides those MAP-specific codes, you might notice your van acting up in a few other ways:

- Rough idle: The engine can shake or idle unevenly when you're in Drive —like when you're sitting at a red light.

- Black smoke: You may be seeing black smoke from the exhaust —especially when you hit the gas.

- Sudden engine stalls: The van might shut off without warning —either while coasting or just as you start to accelerate.

- Stalls after startup: The engine may start just fine, then die right away.

- Low power: Acceleration feels weak, and the van struggles to pick up speed.

- Limp-In Mode: The computer switches into "limp mode". You'll feel the engine's power drop and the van's gas mileage suffers.

NOTE: Other engine problems —not tied to the MAP sensor— can fool the computer into setting a MAP-related code. That's why it's smart to test the sensor first before you swap it out.

In this guide, I'll walk you through a quick bench test you can do to figure out if the MAP sensor's actually the problem. If it passes, you'll know it's time to check somewhere else.

How The MAP Sensor Works

Your Dodge Ram van doesn't use a mass airflow (MAF) sensor to track the amount of air entering the engine. Instead, it uses what's called a Speed Density system to get the job done.

This setup lets the fuel injection computer estimate airflow by reading input from three key sensors:

- The manifold absolute pressure (MAP) sensor.

- The intake air temperature (IAT) sensor —to find out how hot or cold the intake air is.

- The crankshaft position (CKP) sensor —to track engine RPM.

With that data, the computer figures out how much air is getting into the engine and how much fuel it needs to inject.

Here's what unfolds when you fire up the engine:

- MAP sensor gets powered up: The computer sends power and Ground to the MAP sensor:

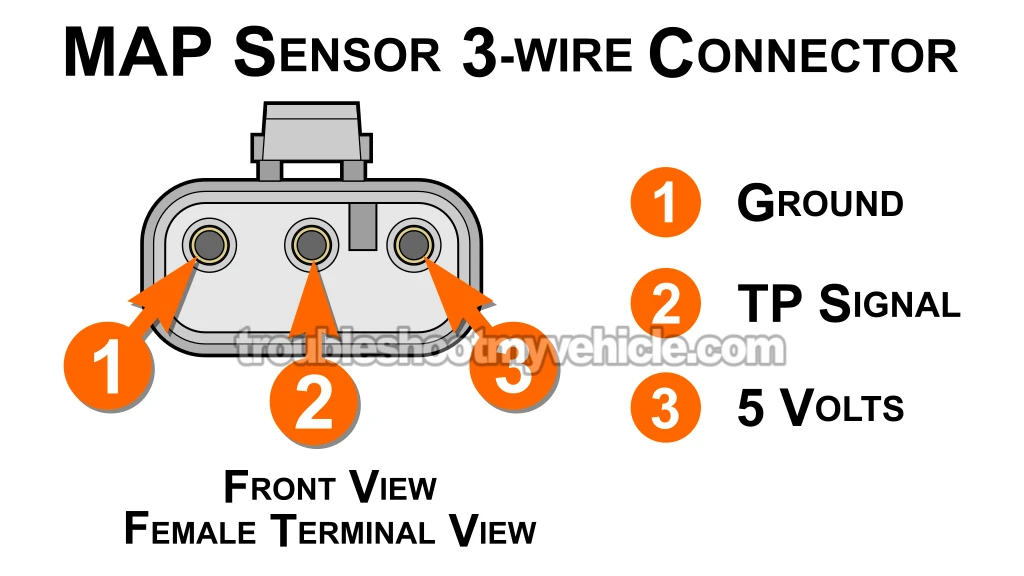

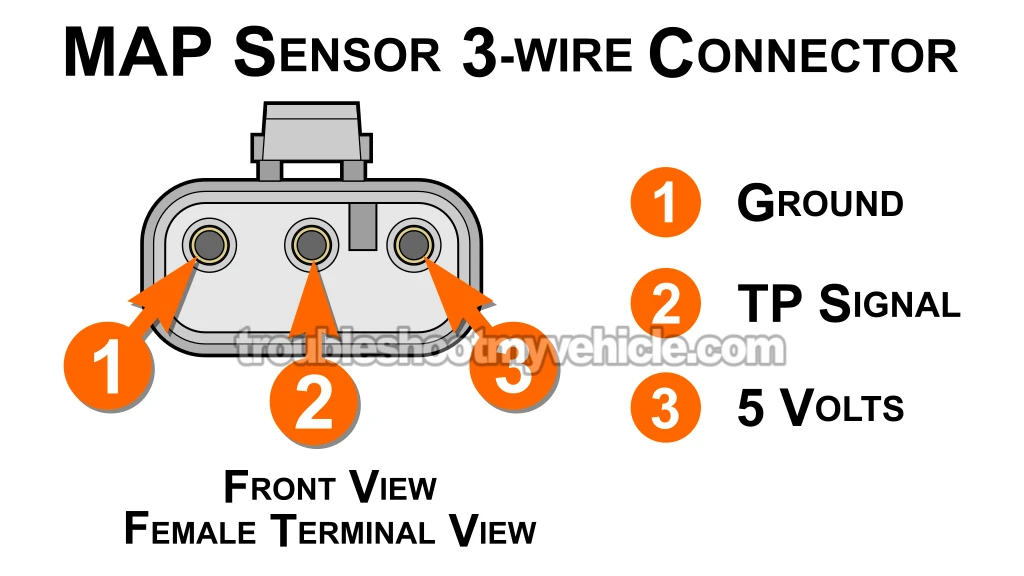

- The violet with white stripe (VIO/WHT) wire sends 5 Volts DC to terminal 3 (check the image above).

- The black with light blue stripe (BLK/LT BLU) wire handles Ground, connecting to terminal 1.

- Vacuum pressure reading begins: The MAP sensor starts monitoring the vacuum pressure inside the intake manifold.

- Idle RPM: When the engine is running at idle speed, there's a strong vacuum in the intake manifold, which lowers the internal air pressure. During this condition, the MAP sensor delivers a low-voltage signal to the vehicle’s computer.

- During Acceleration: As the engine accelerates and throttle opens wider, the intake vacuum drops and the air pressure inside the manifold rises. In response, the MAP sensor generates a higher voltage signal to indicate this shift in pressure.

- Fuel delivery control: The computer uses signals from the MAP, IAT, and CKP sensors to:

- Adjust fuel injector timing —how long each injector stays open.

- Tweak ignition timing to improve performance and efficiency.

Now that you've got a good handle on how the system works, let's move on and test the MAP sensor!

Where To Buy The MAP Sensor And Save

You can find the MAP sensor for your Dodge Ram van at almost any auto parts store –but you're probably gonna pay way more for it.

My advice is to shop around online, or at the very least, compare prices. That way, you'll get a good idea of how much money you could save. Here are my recommendations:

Not sure if the above MAP sensor fits your particular Dodge Ram van? Don't worry, once you get to the site, they'll make sure it fits by asking you the particulars of your vehicle. If it doesn't fit, they'll find you the right one.

TEST 1: Verifying The MAP Signal

Let's get started! First up, we'll check if the MAP sensor gives off a changing voltage signal when you manually apply and release vacuum to it.

We'll do this by connecting a multimeter to the sensor's signal wire. Then, we'll apply and release a vacuum to it with a hand-held vacuum pump —or, if you don't have one, you can do it by mouth.

Depending on the sensor's condition, one of two things will happen:

- Sensor's Working: As you apply and release vacuum, the voltage on the multimeter should drop and rise smoothly.

- Sensor's Bad: If the voltage reading doesn't budge —stays stuck at one value— the sensor's shot.

NOTE: If you need to buy a multimeter (or upgrade yours) or a vacuum pump, these are the ones I have and use:

- Multimeter: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (at: amazon.com).

- Vacuum pump: HTOMT 2 In 1 Vacuum Pump Test Set (at: amazon.com).

Here's how to do it step by step:

- 1

Remove the MAP sensor from its place.

- 2

Connect your vacuum pump to the sensor's vacuum port.

IMPORTANT: Keep the sensor plugged into its 3-wire harness the whole time. - 3

Clip the black multimeter lead to the negative (-) battery terminal.

- 4

Set your multimeter to DC voltage mode.

- 5

Touch the red meter lead to the wire marked 2.

NOTE: You can back probe the connector or use a wire-piercing probe on the wire. For more on this tool, see: Wire Piercing Probe. - 6

Turn the ignition key to ON —don't start the engine.

- 7

With the key ON and no vacuum applied yet, your multimeter should show about 4.5 to 4.7 Volts DC.

- 8

Apply vacuum to the MAP sensor using the pump or your mouth. You should see the voltage drop like this:

1.) 0 in. Hg ...... 4.7 Volts

2.) 5 in. Hg ...... 3.9 Volts

3.) 10 in. Hg .... 3.0 Volts

4.) 20 in. Hg .... 1.1 Volts

NOTE: No matter how you create vacuum, the voltage should drop as vacuum goes up, then climb back up as it's released.

Let's break down what your results tell you.

CASE 1: The voltage changed as you added and released vacuum. That's exactly what should happen —your MAP sensor's working fine!

If the check engine light's still on and that MAP code keeps coming back, check out this section: MAP Sensor Code Won't Go Away.

CASE 2: The voltage stayed stuck at one value. That usually means your MAP sensor's no good.

To be sure the sensor's toast, we need to check it's getting power and Ground. Start here: TEST 2: Making Sure the MAP Sensor is Getting Power.

CASE 3: You got a reading of 0 Volts DC. Either the sensor's dead or it's not receiving power or Ground at all.

Next step: confirm the power and Ground connections are solid. Go to: TEST 2: Making Sure That The MAP Sensor Is Getting Power.

TEST 2: Making Sure That The MAP Sensor Is Getting Power

So far, you've confirmed the MAP sensor isn't putting out a changing voltage —meaning nothing happens when you apply or release vacuum. Now it's time to check if the sensor's getting power.

The MAP sensor gets its power straight from the fuel injection computer. The FI computer sends a steady 5 Volts DC through the violet with white stripe (VIO/WHT) wire in the sensor's 3-wire connector.

This VIO/WHT wire connects to terminal 3 —see the illustration showing the MAP sensor's connector above.

Here's how to test for power:

- 1

Unplug the MAP sensor from its 3-wire connector.

- 2

Place the black lead from your multimeter on the battery's negative (-) post.

- 3

Set your multimeter to DC voltage.

- 4

Turn the key to the ON position —don't start the engine.

- 5

Touch the red lead to terminal 3 —this is the one that connects to the violet with white stripe (VIO/WHT) wire.

- 6

You should see 4.5 to 5 Volts DC if power's reaching the sensor.

Let's break down what the results mean:

CASE 1: You saw 4.5 to 5 Volts on the multimeter. That tells you the sensor is getting power from the computer just like it should.

The next check is just as important —you've got to make sure the sensor has a good Ground too. Head over to: TEST 3: Verifying The MAP Sensor Ground Circuit to continue.

CASE 2: You didn't get the 4.5 to 5 Volt reading. First, double-check your test connections, then test again to rule out a mistake.

If you still don't see that voltage, it explains why the sensor's not working. No power means no output.

In this case, the MAP sensor itself isn't the problem. The issue is the missing 5 Volt supply. Here's where to look:

- The 5 Volt wire could be broken, shorted, or open somewhere between the sensor connector and the computer.

- Much less common, but possible: there's a fault inside the fuel injection computer itself.